Revised March 2024 (Apply/Pay)

FIRE DEPARTMENT ● CITY OF NEW YORK

STUDY MATERIAL FOR

THE CERTIFICATE OF LICENSE EXAMINATION

W-16

CERTIFICATES OF LICENSE FOR THE INSTALLATION, ALTERATION,

TESTING AND REPAIR OF LIQUID MOTOR FUEL STORAGE TANK AND

DISPENSING SYSTEMS. (Citywide)

All applicants are required to apply and pay for an exam online

before arriving at the FDNY. It can take about 30 minutes to

complete.

Simplified instructions for online application and payment can be found

here:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/fdny-

business-cof-individuals-short.pdf

Create an Account and Log in to:

http://fires.fdnycloud.org/CitizenAccess

This book is provided to the public for free by the FDNY.

*Note: W-16 C of L is NOT authorized to supervise the installation, alteration,

testing and repair of non-motor fuel storage tank and dispensing systems. The

installation, alteration, testing and repair of non-motor fuel storage tank and

dispensing systems must be under the supervision of a W-94 C of F holder.

© 10 /2011 New York City Fire Department - All rights reserved ®

This study material is provided to the public for free by the FDNY.

A

CONTENT

EXAM SPECIFIC INFORMATION FOR W-16 CERTIFICATE OF license

............................................................................................................................................ 1

NOTICE OF EXAMINATION ..................................................................................... 1

The W-16 Certificate of License cannot be obtained by the alternative

issuance procedure. --W-16 SAMPLE RECOMMENDATION LETTER-- ............. 3

FIRE STATISTICS AND FACTS ............................................................................ 10

PART 1. DOCUMENTS, PERMIT, AND CERTIFICATE OF LICENSE .... 11

1.1 Design and Installation Documents ................................................. 11

1.2 Permit ............................................................................................................ 11

1.3 Action and Time Periods on Application ....................................... 12

1.4 Certificate of License and Certificate of Fitness ....................... 12

1.4.1 W-16 Certificate of License .............................................................. 12

1.4.2 P-15 Certificate of Fitness ................................................................ 12

1.5 Approval and Inspections ...................................................................... 13

1.6 Related Regulations ................................................................................. 15

PART 2. DEFINITIONS ............................................................................................ 16

PART 3. GENERAL REQUIREMENTS ................................................................ 19

3.1 Piping, Valves, Fittings and Ancillary Equipment ..................... 19

3.1.1 Materials and testing ......................................................................... 19

3.1.2 Protections ............................................................................................. 19

3.1.3 Overfill and backflow prevention ................................................... 20

3.1.4 Connections, joints and bends ....................................................... 22

3.1.5 Tank vents and opening ................................................................... 24

3.1.6 Filling pipes ........................................................................................... 26

3.2 Labeling and Signage ............................................................................... 26

3.2.1 Color coding and symbols of fill ports .......................................... 26

3.2.2 Warning signs....................................................................................... 27

PART 4. UNDERGROUND LIQUID MOTOR FUEL STORAGE TANK ..... 30

4.1 Tank Contents and Capacity Limitations ...................................... 30

4.2 Design and Constructions of the Tanks ......................................... 30

4.2.1 General requirements ........................................................................ 30

4.2.2 Cathodically protected steel tanks ................................................ 30

4.2.3 Coatings ................................................................................................. 32

4.3 Location ........................................................................................................ 33

4.4 Leak Detection ........................................................................................... 34

4.5 Installation of Underground Tank and Piping Systems ........... 37

4.5.1 Safety requirements during excavation operations ................. 37

4.5.2 Pouring concrete and backfilling ................................................... 39

4.5.3 Preparation for installation .............................................................. 40

4.5.4 Installation of underground tank and piping systems ........... 40

4.6 Monitoring, Inspection and Testing ................................................. 43

4.6.1 Monitoring at new underground storage tanks ........................ 43

4.6.2 Periodic Maintenance Requirements. ........................................... 44

This study material is provided to the public for free by the FDNY.

B

4.6.3 Initial tank test .................................................................................... 45

4.6.4 Initial piping test ................................................................................. 45

4.6.5 Leak detection functionality test .................................................... 45

4.6.6 Fire extinguishing system test ........................................................ 48

4.6.7 Emergency tank and piping system test ..................................... 48

4.6.8 Periodic tank and piping test .......................................................... 48

PART 5. ABOVEGROUND LIQUID MOTOR FUEL STORAGE TANK ...... 49

5.1 Contents and Tank Capacities Limitation .................................... 49

5.2 Design and Constructions of Motor Fuel Tank Installations 49

5.3 Location Requirements .......................................................................... 50

5.3.1 Locations ................................................................................................ 50

5.3.2 Protection ............................................................................................... 50

5.4 Drainage Control, Diking and Secondary Containment .......... 51

5.4.1 Diked areas ........................................................................................... 52

5.4.2 Secondary containment system for aboveground tanks ........ 52

PART 6. FUEL-DISPENSING SYSTEM AND AREA ....................................... 54

6.1 Location of Dispensing Devices ......................................................... 54

6.1.1 Outdoor dispensing devices ............................................................. 54

6.1.2 Indoor dispensing devices ................................................................ 54

6.2 Fuel-Dispensing Systems ...................................................................... 54

6.2.1 Fixed pumps required ....................................................................... 54

6.2.2 Mounting of dispensers ..................................................................... 54

6.2.3 Dispenser emergency valve .............................................................. 55

6.2.4 Dispenser hose ..................................................................................... 55

6.2.5 Fuel delivery nozzles .......................................................................... 56

6.2.6 Vapor-balance systems ..................................................................... 57

6.2.7 Emergency disconnect switches..................................................... 57

6.3 Supervision of the Dispensing of Liquid Motor Fuel ................ 58

6.3.1 Self-service motor fuel-dispensing facilities ............................... 58

6.3.2 Full service motor fuel-dispensing facilities ............................... 59

PART 7. RECORD, MAINTENANCE AND REPORT ...................................... 60

7.1 Inventory Control for Underground Tanks .................................... 60

Example of the maintenance log book ......................................................... 61

7.2 Inspections and Tests Records ........................................................... 63

7.3 Equipment Maintenance ....................................................................... 63

7.4 Reporting of Spills and Discharges ................................................... 63

PART 8. RECONDITIONING, REPAIR AND OUT OF SERVICE TANKS 65

8.1 Reconditioning an Underground Steel Tank ................................ 65

8.1.1 Manufacturer's guarantee ................................................................ 65

8.1.2 Structural requirements ................................................................... 65

8.1.3 Preparation of tank interior ............................................................. 65

8.1.4 Coating (lining) specifications ......................................................... 66

8.1.5 Application of coating ........................................................................ 66

8.1.6 Tank closings ........................................................................................ 66

This study material is provided to the public for free by the FDNY.

C

8.1.7 Tank tightness testing ....................................................................... 66

8.2 Repair or Alteration of Tanks and Piping ...................................... 67

8.2.1 Cleaning of tank prior to repair ...................................................... 67

8.2.2 Coating (lining) specifications ......................................................... 67

8.2.3 Inspection of coating .......................................................................... 67

8.3 Out of Service Tanks ............................................................................... 68

8.3.1 Underground out of service tanks ................................................. 68

8.3.2 Aboveground out of service tanks ................................................. 68

8.4 Removal of Tanks ..................................................................................... 69

PART 9. EMERGENCY PLAN AND FIRE CONTROL .................................... 70

9.1 Control of Ignition, Brush and Debris ............................................. 70

9.2 Fire Extinguishers .................................................................................... 70

9.2.1 Different Types Of Fire Extinguishers .......................................... 71

9.2.2 Portable Fire Extinguisher Tags ..................................................... 73

9.2.3 Fire Extinguisher Inspections ......................................................... 74

9.3 Fire Extinguishing System ................................................................... 74

10. LITHIUM-ION BATTERY SAFETY ....................................................... 76

APPENDIX A. STAGE II VAPOR COLLECTION DECOMMISIONING ..... 79

APPENDIX B. FIRE CODE CHAPTER 9 ............................................................ 81

FC 901 General ........................................................................................................ 81

FC 904 Fire Extinguishing Systems ................................................................. 91

FC 906 Portable Fire Extinguishers ............................................................... 112

APPENDIX C. CHAPTER 23 MOTOR FUEL-DISPENSING FACILITIES

AND REPAIR GARAGES .......................................................................................... 119

SECTION FC [2201] 2301 GENERAL .................................................................... 119

SECTION FC [2202] 2302 DEFINITIONS .............................................................. 120

SECTION FC [2203] 2303 LOCATION OF LIQUID MOTOR FUEL DISPENSING

DEVICES .............................................................................................................. 122

SECTION FC [2204] 2304 DISPENSING OF LIQUID MOTOR FUEL ................ 123

SECTION FC [2205] 2305 OPERATION AND MAINTENANCE OF LIQUID

MOTOR FUEL-DISPENSING FACILITIES ...................................................... 127

SECTION FC [2206] 2306 DESIGN AND INSTALLATION REQUIREMENTS

FOR LIQUID MOTOR FUEL-DISPENSING FACILITIES .............................. 129

SECTION FC [2207 RESERVED] 2307 DESIGN AND INSTALLATION

REQUIREMENTS FOR BIODIESEL MOTOR FUEL ..................................... 143

SECTION FC [2208] 2308 COMPRESSED NATURAL GAS MOTOR FUEL-

DISPENSING FACILITIES ................................................................................. 143

SECTION FC [2209] 2309 HYDROGEN MOTOR FUEL-DISPENSING AND

GENERATING FACILITIES .............................................................................. 153

SECTION FC [2210] 2310 MARINE LIQUID MOTOR FUEL-DISPENSING

FACILITIES ......................................................................................................... 157

SECTION FC [2211] 2311 REPAIR GARAGES ..................................................... 160

APPENDIX D. FIRE CODE CHAPTER 57 ....................................................... 167

SECTION FC [3401] 5701 GENERAL .................................................................... 167

SECTION FC [3402] 5702 DEFINITIONS .............................................................. 169

This study material is provided to the public for free by the FDNY.

D

SECTION FC [3403] 5703 GENERAL REQUIREMENTS .................................... 171

SECTION FC [3404] 5704 STORAGE..................................................................... 177

SECTION FC [3405] 5705 HANDLING AND USE ................................................ 211

SECTION FC [3406] 5706 SPECIAL OPERATIONS ............................................. 222

SECTION 5707 FLEET FUELING OPERATIONS ................................................. 247

APPENDIX E. FIRE RULE CHAPTER 22 ........................................................ 250

Rule Section § 2204-01 ....................................................................................... 250

Rule Section § 2205-01 ....................................................................................... 251

Rule Section § 2206-01 ....................................................................................... 251

Rule Section § 2206-02 ....................................................................................... 253

Rule Section § 2211-01 ....................................................................................... 255

APPENDIX F. FIRE RULE CHAPTER 34 ........................................................ 256

Rule Section § 3404-01 ....................................................................................... 256

Rule Section § 3404-02 ....................................................................................... 257

Rule Section § 3404-03 ....................................................................................... 259

APPENDIX G. FIRE RULE CHAPTER 48 ........................................................ 262

Rule Section § 4802-01 ....................................................................................... 262

Former Fire Department Rule 3 RCNY §21-14 ....................................... 263

Former Administrative Code §27-4066 ...................................................... 270

Former Administrative Code §27-4227 ...................................................... 270

Former Administrative Code §27-4055 ...................................................... 271

Former Administrative Code §27-4053 ...................................................... 272

Former Fire Department Rule 3 RCNY §21-06 ....................................... 274

Former Fire Department Rule 3 RCNY §21-17 ....................................... 274

This study material is provided to the public for free by the FDNY.

1

EXAM SPECIFIC INFORMATION FOR

W-16 CERTIFICATE OF license

NOTICE OF EXAMINATION

Save time and submit application online!

All applicants are required to apply and pay for an exam online before

arriving at the FDNY. It can take about 30 minutes to complete.

Simplified instructions for online application and payment can be found here:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/fdny-business-cof-

individuals-short.pdf

Create an Account and Log in to:

http://fires.fdnycloud.org/CitizenAccess

REQUIREMENTS FOR CERTIFICATE OF FITNESS APPLICATION

General requirements:

Review the General Notice of Exam:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/general-notice-of-exam-cof.pdf

Special requirements for the: W-16 Certificate of License

(1) The applicants must demonstrate all the following qualifications:

a. High school diploma or its equivalent;

b. A minimum of three (3) years work experience in the installation, alteration,

testing or repair of automotive or marine liquid motor fuel storage and

dispensing systems in the five (5) year period prior to the date of filing of the W-

16 C of L application. Such experience shall have been obtained working under

the general supervision of a W-16 C of L holder.

c. Liability insurance of not less than $500,000, naming the City of New York and

the Fire Department as additional insured’s and rated by AM best A or A-;

d. Qualified staff and sufficient equipment and facilities to competently and safely

perform the business or activity requiring the certificate of license;

(2) The applicant must apply for qualification review and obtain pre-approval before

taking the computer based exam:

Applicants may not take the computer based test until obtaining the approval.

Applicants must submit the required application documents by mail or in person

to: New York City Fire Department, Attention: C of F Unit, Bureau of Fire

Prevention, 9 MetroTech Center - 1st Floor, Brooklyn, New York, 11201-3857,

Attn: COL Review. If there are any questions, please contact (718) 999-1988.

This study material is provided to the public for free by the FDNY.

2

Applicants will be notified whether they qualify or if additional documents are

required.

The required documents for pre-approval:

a. Valid high school diploma or GED.

b. Completed and signed W-16 application form

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/certificate-of-license-application.pdf

c. Any documentation that can verify the certification or experience indicated in

the W-16 application form above. The W-2 forms (wage and tax statement) and

a resume and a letter of recommendation may be a supporting document for

work experience.

d. Recommendation letter(s) signed by the previous/current employer(s) who

possesses a W-16 Certificate of License. All the recommendation letters must

include:

(i) Length of time employed

(ii) Job duties in the previous/current company

(iii) W-16 Certificate of License name and license number

Valid W-16 C of L holder list could be found on the FDNY website:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/approved-companies-motor-fueled-installer.pdf

e. A copy of ACORD summary of an insurance policy not less than $500,000. The

FDNY must be co-named on the insurance policy. The issuance policy must be

issued by an approved insurance company that is licensed to do business in

New York State and has an A. M. Best rating of A- or better.

APPLICATION FEE:

Pay the $145 application fee in person by one of the following methods:

• Cash

• Credit card (American Express, Discover, MasterCard, or Visa)

• Debit card (MasterCard or Visa)

• Personal or company check or money order (made payable to the New York

City Fire Department)

A convenience fee of 2.00% will be applied to all credit card payments.

For fee waivers submit: (Only government employees who will use their C of F for

their work- related responsibilities are eligible for fee waivers.)

• A letter requesting fee waiver on the Agency’s official letterhead stating

applicant full name, exam type and address of premises; AND

• Copy of identification card issued by the agency

REQUIREMENTS FOR ALTERNATIVE ISSUANCE PROCEDURE (AIP)

This study material is provided to the public for free by the FDNY.

3

The W-16 Certificate of License cannot be obtained by the alternative issuance

procedure.

This study material is provided to the public for free by the FDNY.

4

--W-16 SAMPLE RECOMMENDATION LETTER--

COMPANY NAME

BUSINESS ADDRESS

Date: __________________

Fire Department

Bureau of Fire Prevention

9 Metro Tech Center

Brooklyn, NY 11201-3857

To whom it may concern:

I am pleased to recommend (Applicant’s name) to apply for the W-16

Certificate of License for INSTALLATION, ALTERATION, TESTING AND REPAIR

OF LIQUID MOTOR FUEL STORAGE TANK AND DISPENSING SYSTEMS.

The applicant has been worked under the supervision of (name of a W-16 C of L

holder) with the license number: (W-16 holder’s license number) and have

performed the duties related to installation, alteration, testing or repair of

automotive or marine liquid motor fuel storage and dispensing systems for

(months, years)

After the applicant receives the W-16 C of L, the applicant will be employed in the

company: (Company title and company address).

Applicant is of GOOD CHARACTER and is PHYSICALLY ABLE to perform the

functions required by the holder of the Certificate of License.

__________________________ ______________________ _________________________

(Printed name of W-16 C of L holder) (W-16 C of L’s title) (Signature of W-16 C of F holder)

NOTE: The recommendation letter should be on employer’s letterhead. If not

on employer’s letterhead, signature must be notarized.

This study material is provided to the public for free by the FDNY.

5

EXAM INFORMATION

The computer based test will consist of 100 multiple-choice questions, administered on a

“touch screen” computer monitor. It is a time-limited exam. Based on the amount of the

questions, applicants will have 153 minutes to complete the test. The test will appraise

the applicant's familiarity with the law, rules and regulations established for the

installation, alteration, testing and repairing of various kinds of gasoline, diesel fuel oil

(for motor vehicles) and other volatile flammable oil equipment including above-ground

tanks for diesel motor fuel storage; the various methods and problems of installation; the

principles and parts of all related equipment; and the care and safety that should be

exercised by both the installer and the occupant when the latter assumes operation.

Applicant must attain a score of at least 70% on the computer based test in order to

receive the W 16 Certificate of Qualification for the COL.

If all the requirements are met and pass the computer based test a W-16 Certificate of

License will be issued the same day.

If fail, to retake the W-16 C of L exam, applicants will need to:

• Schedule an appointment

• submit a new A-20 form

• Pay $145 fee*

*The application fee may be waived once if the applicant obtains a failure mark between

65% and 69%. This opportunity is available only ninety (90) days after the initial failure.

Applicants must surrender the Failure Notice at the time of the second test. It is the

applicants responsibility to safeguard the Failure Notice. No second opportunity test will

be given without the Failure Notice.

Call (718) 999-2473 for additional information and forms.

Please always check for the latest revised booklet at FDNY website before you take the

exam.

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/cof-w16-noe-study-materials.pdf

EXAM SITE: FDNY Headquarters, 9 MetroTech Center, Brooklyn, NY. Enter

through the Flatbush Avenue entrance (between Myrtle Avenue

and Tech Place).

This study material is provided to the public for free by the FDNY.

6

RENEWAL REQUIREMENTS

General renewal requirements:

Review the General Notice of Exam:

https://www1.nyc.gov/assets/fdny/downloads/pdf/business/general-notice-of-exam-cof.pdf

Special renewal requirements for the W-16 Certificate of License:

This Certificate of License must be renewed every TWO YEARS. The renewal fee is $30.

FDNY also reserves the right to require the applicants to take a re-examination upon

submission of renewal applications.

You will receive a courtesy notice of renewal 90 days via email before the expiration date.

However, it is your responsibility to renew your Certificate. It is very important to renew

your Certificate of License before it expires. Renewals submitted 90 days (up to one year)

after the expiration date will incur a $25 penalty in addition to the renewal fee.

Certificates expired over one year past expiration date will not be renewed. New exams

will be required.

This study material is provided to the public for free by the FDNY.

7

Read the Quick Renewal Guide for FLSD, Expeditors or Fee Exempt Applicants to learn

the procedure:

http://www1.nyc.gov/assets/fdny/downloads/pdf/business/cof-renewal-short.pdf

QUESTIONS?

FDNY Business Support Team: For questions, call 311 and ask for the FDNY

Customer Service Center or send an email to FDNY.Bu[email protected]

STUDY MATERIAL AND TEST DESCRIPTION

About the Study Material

This study material will help you prepare for the examination for the Certificate of

License for motor fuel storage and dispensing system. This study material consists of 9

parts. The exam covers the entire booklet and any tables. It will not be provided to you

during the test. It is critical that you read and understand this booklet to help

increase your chance of passing this exam. The study material does not contain all of

the information you need to know for motor fuel storage and dispensing system. It is

your responsibility to become familiar with all applicable rules and regulations of the City

of New York, even if they are not covered in this study material. You need to be familiar

with the National Fire Protection Association (NFPA) 30, 30A and 2022 Fire Code Chapter

23, Chapter 27, and Fire Rule Chapter 22, Fire Rule Section §4834-01, and the New York

City Building Code §26-229 and the regulations of the New York State Department of

Environmental Conservation, as set forth in 6 NYCRR Parts 612, 613 and 614 which

regulate the motor fuel storage and dispensing system in order to adequately prepare for

the exam.

2022 FIRE CODE ENACTED

The amended New York City Fire Code, to be known as the 2022 Fire Code, takes effect

on April 15, 2022. It may not have been updated in this study material and the

exam will be mainly based on this booklet, not the 2022 Fire Code. However, as the

Certificate of Fitness holder, it is your responsibility to become familiar with the

applicable sections of the new 2022 Fire Code.

Design and installation provisions.

The design and installation provisions of the 2022 Fire Code shall apply to:

• Facilities established and conditions arising on or after 04/15/2022.

• Facilities and conditions not lawfully existing prior to 04/15/2022.

The facilities and conditions lawfully existing prior to the 04/15/2022 can be continued

in compliance with the requirements of the former Fire Code/Fire Rule except as

otherwise provided in the New Fire Code 102.5.

Operational and maintenance provisions.

The operational and maintenance provisions of the 2022 Fire Code, including permit and

certification requirements, shall apply to all facilities, operations, conditions, uses and

occupancies, regardless of when they were established or arose.

This study material is provided to the public for free by the FDNY.

8

Whenever this code is amended or a rule is promulgated to require a permit or certificate

for a facility, operation, condition, use or occupancy, and no permit or certificate was

previously required therefor pursuant to this code or the rules, such facility, operation,

condition, use or occupancy may be continued without such permit or certificate until

04/15/2023, except as may otherwise be provided by such amendment or rule.

The 2022 Fire Code can be obtained via the following website:

http://www1.nyc.gov/site/fdny/codes/fire-code/fire-code.page

The 2014/2022 New York City Fire Code Cross-Reference Table can be referred to the

following website:

http://www1.nyc.gov/assets/fdny/downloads/pdf/codes/fire-code-cross-reference.pdf

About the Test

All questions on the Certificate of License examination are of the multiple choice type

with four alternative answers to each question. Only one answer is most correct for each

question. If you do not answer a question, or if you mark more than one alternative your

answer will be scored as incorrect. A score of 70% is required on the examination in

order to qualify for the Certificate of License. Read each question carefully before

marking your answer. There is no penalty for guessing.

SAMPLE QUESTIONS

The following questions represent the “format” of the exam questions,

not the content of the real exam.

1. Which of the following are allowed to be used while taking a Certificate of

License examination at 9 Metro Tech Center?

I. cellular phone

II. study material booklet

III. reference material provided by the FDNY

IV. mp3 player

A. III only

B. I, II, and III

C. II and IV

D. I only

Only reference material provided by the FDNY is allowed to be used during Certificate of

License examinations. Therefore, the correct answer would be A. You would touch “A”

on the computer terminal screen.

2. If the screen on your computer terminal freezes during your examination, who

should you ask for help?

This study material is provided to the public for free by the FDNY.

9

A. the person next to you

B. the firefighters in the testing room

C. the examiner in the testing room

D. the computer help desk

If you have a computer related question, you should ask the examiner in the testing

room. Therefore, the correct answer would be C. You would touch “C” on the computer

terminal screen.

3. If you do not know the answer to a question while taking an examination, who

should you ask for help?

A. the person next to you

B. the firefighters in the testing room

C. the examiner in the testing room

D. you should not ask about test questions since FDNY staff can not assist applicants

You should not ask about examination questions or answers since FDNY staff cannot

assist applicants with their tests. Therefore, the correct answer would be D. You would

touch "D" on the computer terminal screen.

This study material is provided to the public for free by the FDNY.

10

FIRE STATISTICS AND FACTS

According to the Fires at U.S. Service Stations report published by the Fire Analysis and

Research Division of the National Fire Protection Association (NFPA) in April, 2011, an

estimated 5,020 fires and explosions occurred at public service stations per year from

2004-2008. That means that, on average, one in every 13 service stations experienced a

fire. These fires caused an annual average of two civilian deaths, 48 civilian injuries and

$20 million in property damage.

Fires in these occupancies represent a variety of incidents, including structure fires,

vehicle fires, outdoor fires and other fires. The majority of incidents are vehicle fires

(61%), but the majority of the property damage (59%), results from structure fires. In

structure fires, heating equipment was the leading cause, followed by electrical

distribution and lighting equipment. The top three leading items first ignited in

structure fires at service stations are flammable or combustible liquids, gases, and

associated piping or filter (22%); rubbish, trash, or waste (18%) and electrical cable or

insulation (13%).

The leading factors contributing to the ignition of different fires:

Structure Fires:

(1) Electrical failures or malfunctions

(2) Abandoned materials

Vehicle Fires:

(1) Mechanical failures or malfunctions

(2) Electrical failure or malfunction

(3) A flammable liquid or gas being spilled

Outdoor and unclassified fires:

(1) Abandoned or discarded materials or products

(2) electrical failures or malfunctions

This study material is provided to the public for free by the FDNY.

11

PART 1. DOCUMENTS, PERMIT, AND CERTIFICATE OF LICENSE

1.1 Design and Installation Documents

(FC 105.3.9)

Design and installation documents shall be submitted to the department for review and

approval prior to the installation, alteration, repair or construction of automotive liquid

motor fuel-dispensing facilities. As-built drawings are required to depict modified

installations after the station is built or reconstructed

The installation or alteration of a liquid motor fuel storage and dispensing system shall

not be approved by the department unless the design and installation documents

demonstrate that the proposed work complies with the regulations of the United States

Environmental Protection Agency, as set forth in 40 CFR Part 280, and the regulations of

the New York State Department of Environmental Conservation, as set forth in 6 NYCRR

Parts 612, 613 and 614.

The commissioner may require that the applicant for a permit or renewal thereof

demonstrate, by submission of a certificate of occupancy or other authorization or

approval issued by the Department of Buildings, that the building, structure or premises

or portion thereof used for the manufacture, storage, handling or use of flammable or

combustible liquids, are designed, constructed and occupied in accordance with the

certificate of occupancy, the construction codes and the Electrical Code. No permit shall

be issued when work requires the approval of the Commissioner of Buildings in

connection with a material, operation or facility unless proof is submitted to the

department that such work has been approved by the Commissioner of Buildings.

1.2 Permit

A permit is required:

1. To store, handle or use amounts of gasoline and other petroleum-based Class I

liquids other than paints, varnishes and lacquers, in excess of 2½ gallons, except

that a permit is not required for the storage or use of gasoline or other petroleum-

based Class I liquids in the fuel tank of a motor vehicle, aircraft, or watercraft.

2. To store, handle or use amounts of Class II or Class III liquids with a flash point of

300°F or less, other than paints, varnishes and lacquers, in excess of 10 gallons,

except that a permit is not required for the storage or use of Class II or Class III

liquids with a flash point of 300°F or less in the fuel tank of a motor vehicle,

aircraft, or watercraft.

FDNY Site-specific permit authorizes the permit holder to store or handle motor fuels at a

specific premises or location. A site-specific permit is valid for 12 months only. Every

permit or renewal shall require an inspection and shall expire after twelve months.

FDNY permits are not transferable, and any change in occupancy, operation, tenancy or

ownership requires that a new permit be issued. The Certificate of License holder is

responsible for making sure that all fire safety regulations and procedures are obeyed on

This study material is provided to the public for free by the FDNY.

12

the premises. Permits shall be readily available on the premise for inspection by

Fire Department representatives.

1.3 Action and Time Periods on Application

(FC105.2.4)

Normally, the completed permit/documentation applications should be notified (either

approved or denial) by the commissioner no latter than 40 calendar days from the

submission. Except that on or before the fortieth day, the commissioner may, for good

cause, extend such time for an additional 40 calendar days.

When a permit application has been denied or preliminarily denied and is thereafter

revised and resubmitted to meet the stated grounds for denial, the revised completed

application shall be approved or denied or preliminarily denied in accordance with the

foregoing procedures and time periods.

New regulations for stage II vapor recovery.

The New York State Department of Environmental Conservation (NYSDEC) has repealed

the requirements for the stage II vapor collection systems. Existing installations with

such systems which choose to decommission a stage II vapor collection system must

have a W-16 Certificate of License holder to do the work and provide the FDNY with

proper documentation when completed. The sample documentation is provided in the

Appendix A. Contact Bulk Fuel Safety Unit (Tel: 718-999-2460) for additional information

and forms.

1.4 Certificate of License and Certificate of Fitness

(FC2201.7; FC2201.8)

A certificate holder shall be responsible for:

1. The safe manufacturing, storage, handling, use, operation, maintenance, inspection,

testing, repair and/or supervision of the material, operation or facility for which the

certificate is required, in accordance with this code, the rules, and any other

applicable laws, rules and regulations.

2. Notifying the department of any explosion, fire, reportable leak or other release of

hazardous material, or other emergency related to the duties of his or her certificate.

3. Keeping such certificate upon his or her person or otherwise readily available for

inspection by any representative of the department, at all times while conducting or

supervising the material, operation or facility for which the certificate is required.

1.4.1 W-16 Certificate of License

Persons who install, alter, test or repair any automotive or marine liquid motor fuel

storage and dispensing systems shall hold a certificate of license or shall be employed by

and perform such duties under the general supervision of a person holding such

certificate.

1.4.2 P-15 Certificate of Fitness

This study material is provided to the public for free by the FDNY.

13

The dispensing of liquid motor fuel at motor fuel dispensing facilities shall be conducted

by or under the supervision of a P15 C of F holder, who shall be responsible to ensure

that dispensing operations are conducted and the facility is maintained in accordance

with this chapter, as follows:

1. Dispensing operations shall be conducted by or under the personal supervision of a

P15 C of F holder at self service automotive liquid motor fuel-dispensing facilities.

2. Dispensing operations shall be conducted by or under the personal supervision of a

P15 C of F holder at fleet automotive liquid motor fuel-dispensing facilities.

3. Dispensing operations shall be conducted by or under the personal supervision of a

P15 C of F holder at full service automotive liquid motor fuel-dispensing facilities.

1.5 Approval and Inspections

The application, installation and tests of underground storage tanks in the motor fuel

station that need to be involved with Fire Department:

Application

Step 1. Plan Approval (New York City Building Department)

Submit to the New York City Building Department plans for a work permit.

Step 2. Plan Approval (New York City Fire Department)

The above plans once approved by the DOB are submitted to the Fire Department,

Technology Management for review and approval.

Appointments

Once the plans are approved by the FDNY, certain appointments should be scheduled

with the Bulk Fuel Unit of the Bureau of Fire Prevention.

The following 6 inspectional appointments need to be scheduled with the Bulk Fuel Unit

of the Bureau of Fire Department and a representative of the Fire Department:

1. Base slab placement,

2. Backfill bed placement,

3. Hydrostatical test for the tanks and piping,

4. Top slap placement,

5. After paving test (only required for the discharging system)

6. Fire suppression system test, emergency shut down test, and leak detection

system functionality test.

If there is no outstanding violation, the first FDNY site-specific permit will be issued

after the approval of final inspection and an A111 letter of approval will be issued. A site-

specific permit is valid for 12 months only. Every permit or renewal shall require an

inspection and shall expire after twelve months.

Periodic Tests

Leak detection functionality test, fire extinguishing system test, and precision test must

be performed periodically at the owner's risk, before a representative of the Fire

This study material is provided to the public for free by the FDNY.

14

Department: at least once every 2 years for a leak detection functionality test and at least

once every 5 years for a fire extinguishing system test and precision test.

Emergency Situation

All emergency repairs or tests, contractors must notify the Bulk Fuel Safety Unit of Fire

Department.

This study material is provided to the public for free by the FDNY.

15

1.6 Related Regulations

The installation, maintenance, and removal of motor fuel storage and dispensing system

are required to comply with the following regulations:

• Motor Fuel-Dispensing Facilities and Repair Garages [2022 FC Chapter 23 and

Fire Rule Chapter 22]

• Flammable and Combustible Liquids [2022 FC Chapter 57]

• Installation of Storage Tanks and Piping for Liquids Having Flashpoints of 100

Degrees Fahrenheit or Higher [Fire Rule Section 4834-01(l)(2)]

• Flammable and Combustible Liquids Code [NFPA 30, 2003 edition]

• Code for Motor Fuel Dispensing Facilities and Repair Garages [NFPA 30A, 2003

edition]

• Petroleum Bulk Storage Regulations [6 NYCRR Parts 612, 613 and 614]

• Safety Requirements During Excavation Operations [NYC DOB §26-229]

• Safety and Health Regulations for Construction [OSHA 29 CFR 1926.650 to 29

CFR 1926.652]

This study material is provided to the public for free by the FDNY.

16

PART 2. DEFINITIONS

AUTOMOTIVE LIQUID MOTOR FUEL-DISPENSING FACILITY. Any building, structure

or premises upon which or wherein, liquid motor fuel is stored and dispensed from a

liquid motor fuel storage and dispensing system into the fuel tanks of motor vehicles or

motorcycles.

BULK PLANT OR TERMINAL. Any premises upon which flammable or combustible

liquids are received from marine vessel, pipeline, tank car or cargo tank and are stored or

blended in bulk for the purpose of distributing such liquids by marine vessel, pipeline,

tank car, cargo tank or container.

BULK TRANSFER. The loading or unloading of flammable or combustible liquids from or

between marine vessels, pipelines, tank cars, cargo tanks or storage tanks.

P15 C OF F HOLDER. A person holding a certificate of fitness for the supervision of an

automotive liquid motor fuel-dispensing facility, marine liquid motor fuel-dispensing

facility or automotive CNG motor fuel-dispensing facility.

COMBUSTIBLE LIQUID. For purposes of transportation, a combustible liquid, as defined

in the regulations of the United States Department of Transportation, as set forth in 49

CFR Section 173.120. For all other purposes, a liquid, other than a compressed gas or

cryogenic fluid, having a closed cup flash point at or above 100°F (38°C), classified as

follows: (e.g. diesel)

Class II. Liquids having a closed cup flash point at or above 100°F (38°C) and below

140°F (60°C).

Class IIIA. Liquids having a closed cup flash point at or above 140°F (60°C) and

below 200°F (93°C).

Class IIIB. Liquids having closed cup flash points at or above 200°F (93°C).

DISPENSING DEVICE, OVERHEAD TYPE. A dispensing device mounted above a

dispensing area, typically within a canopy structure, and characterized by the use of an

overhead hose reel.

FLAMMABLE AND COMBUSTIBLE LIQUID STORAGE SYSTEM. A flammable or

combustible liquid storage tank and all devices, equipment and systems associated with

such tank, including the tank, piping, valves, fill connection, vent lines, pumps and any

other ancillary equipment, except liquid motor fuel storage and dispensing systems and

flammable and combustible liquid storage systems at a bulk plant or terminal used for

bulk transfer operations.

FLAMMABLE LIQUID. For purposes of transportation, a flammable liquid defined in the

regulations of the United States Department of Transportation, as set forth in 49 CFR

Section 173.120. For all other purposes, a liquid, other than a compressed gas or

cryogenic fluid, having a closed cup flash point below 100°F (38°C), classified as follows:

Class IA. Liquids having a flash point below 73°F (23°C) and having a boiling point

below 100°F (38°C). Examples: Ethyl, Ether, Propylene.

This study material is provided to the public for free by the FDNY.

17

Class IB. Liquids having a flash point below 73°F (23°C) and having a boiling point at

or above 100°F (38°C). Examples: Acetone, Benzene, Gasoline, Methanol, Toluene, Jet

fuel.

Class IC. Liquids having a flash point at or above 73°F (23°C) and below 100°F (38°C).

Examples: Propyl, Alcohol, Turpentine.

FLAMMABLE LIQUID MOTOR FUEL. Gasoline or other flammable liquids used as fuel

in the operation of motor vehicles, motorcycles, watercraft and aircraft.

FLASH POINT. The minimum temperature in degrees Fahrenheit at which a liquid will

give off sufficient vapors to form an ignitable mixture with air near the surface or in the

container, but will not sustain combustion. The flash point of a liquid shall be

determined by appropriate test procedure and apparatus as specified in ASTM D 56,

ASTM D 93 or ASTM D 3278.

FLEET AUTOMOTIVE LIQUID MOTOR FUEL-DISPENSING FACILITY. An automotive

liquid motor fuel-dispensing facility wherein liquid motor fuel is stored and/or dispensed

into the fuel tank of motor vehicles or motorcycles owned or operated by or on behalf of

the owner of the facility, and where dispensing operations are conducted by persons

employed by or otherwise working for the owner of the facility.

FULL SERVICE AUTOMOTIVE LIQUID MOTOR FUEL-DISPENSING FACILITY. An

automotive liquid motor fuel-dispensing facility wherein liquid motor fuel is dispensed

into the fuel tank of motor vehicles or motorcycles by a P15 C of F holder or, when under

the personal supervision of a P15 C of F holder, by persons employed by or otherwise

working for the owner of the facility.

GENERAL SUPERVISION. Supervision by the holder of any department certificate who

is responsible for performing the duties of the certificate holder but need not be

personally present on the premises at all times.

LIQUID MOTOR FUEL. Gasoline, diesel fuel or other flammable or combustible liquids

used as fuel in the operation of motor vehicles, motorcycles, watercraft and aircraft.

LIQUID MOTOR FUEL STORAGE AND DISPENSING SYSTEM. A liquid motor fuel

storage tank and all motor fuel storage and dispensing equipment associated with such

tank, including the tank, piping, valves, fill connection catchment basins, vent lines,

pumps, dispensing devices and any other ancillary equipment.

MOTOR VEHICLE. A vehicle or other conveyance having more than 2 running wheels

and using liquid motor fuel or flammable gas as fuel for generating motive power, except

such vehicles as have a storage tank with a maximum capacity for less than 2 gallons

(7.6 L) of liquid motor fuel or flammable gas that generates energy that is equivalent to

the energy generated by 2 gallons (7.6 L) of gasoline.

PERSONAL SUPERVISION. Supervision by the holder of any department certificate who

is required to be personally present on the premises, or other proximate location

acceptable to the department, while performing the duties for which the certificate is

required.

PROCESS TRANSFER. The transfer of flammable or combustible liquids between cargo

tanks or tank cars and containers, tanks piping and other equipment that is to be used

in process operations.

This study material is provided to the public for free by the FDNY.

18

PROCESSING VESSEL. A tank or other container used in manufacturing or other

process operation that involves the use of a flammable or combustible liquid supplied

from other than a cargo tank, tank car or pipeline.

SELF-SERVICE AUTOMOTIVE LIQUID MOTOR FUEL-DISPENSING FACILITY. An

automotive liquid motor fuel-dispensing facility where liquid motor fuel is dispensed from

a liquid motor fuel storage and dispensing system into the fuel tank of motor vehicles or

motorcycles by customers of the facility.

STAGE I VAPOR RECOVERY. Stage I Vapor Recovery refers to the control of vapors

during the transfer of gasoline from the cargo tank to the gasoline dispensing facility.

Stage I Vapor Recovery systems control emissions during delivery and storage of gasoline

at the gasoline dispensing facility. During gasoline delivery, emissions are controlled by

diverting the displaced gasoline vapor from the storage tank into the tanker compartment

of the vehicle unloading gasoline. The captured vapor is then transported back to the

terminal for processing by condensation, adsorption or incineration.

STAGE II VAPOR RECOVERY. The New York State Department of Environmental

Conservation (NYSDEC) has repealed the requirements for the stage II vapor collection

systems. Existing installations with such systems which choose to decommission a stage

II vapor collection system must have a W-16 Certificate of License holder to do the work

and provide the FDNY with proper documentation when completed. The sample

documentation is provided in the Appendix A. Contact Bulk Fuel Safety Unit for

additional information and forms.

SUBSTANTIALLY MODIFIED FACILITY. Any existing facility which has been modified in

one or more of the following ways:

(a) one or more new stationary tanks has been added;

(b) an existing stationary tank has been replaced, reconditioned or permanently

closed; or

(c) a leaking storage tank has been replaced, repaired or permanently closed.

TANK, PROTECTED ABOVEGROUND. An atmospheric aboveground tank listed in

accordance with UL 2085 or equivalent standard that is provided with integral secondary

containment, protection from physical damage, and an insulation system intended to

reduce the heat transferred to the primary tank when the tank is exposed to a high

intensity liquid pool fire.

This study material is provided to the public for free by the FDNY.

19

PART 3. GENERAL REQUIREMENTS

3.1 Piping, Valves, Fittings and Ancillary Equipment

3.1.1 Materials and testing

(FC2206.6.2.7; FC2206.6.2.8; FC2206.6.3.1; FC2206.6.3.3; FC3403.6.2.1; FC3403.6.3;

FC3403.6.12; Rule 2206-01(c)) )

Piping system components shall be designed and manufactured in accordance with NFPA

30, Chapter 3. Low-melting-point materials, such as aluminum, copper or brass, that

soften on fire exposure, such as nonmetallic materials, and nonductile material, such as

cast iron, shall be acceptable for use underground only in accordance with ANSI B31.9.

Piping system components must be constructed of Schedule 40 steel or a higher

Schedule steel. Approved nonmetallic piping, such as fiberglass-reinforced plastic or

other equivalent corrosion-resistant material, may be installed underground.

Underground tank piping must be installed underground, except for the vertical riser of

the vent.

Unless tested in accordance with the applicable section of ANSI B31.9, piping, before

being covered, enclosed or placed in use, shall be hydrostatically tested to 150% of the

maximum anticipated operating pressure of the system, but not less than 15 psig at the

highest point of the system or precision tested. This test shall be maintained for a

sufficient time period to complete visual inspection of joints and connections. For a

minimum of 60 minutes, there shall be no leakage or permanent distortion. Piping

system tests shall be conducted at the owner’s risk by his or her representative before a

representative of the department. Care shall be exercised to ensure that these pressures

are not applied to vented storage tanks. Such storage tanks shall be tested independently

from the piping.

Existing piping shall be tested in accordance with the requirements, upon a

determination by the commissioner that such piping may be leaking. Piping that could

contain flammable or combustible liquid vapors shall not be tested pneumatically, except

that vapor-recovery piping may be tested pneumatically using an inert gas. Such tests

shall be conducted at the owner’s risk by his or her representative.

Upon completion of the installation of a motor fuel dispenser or motor fuel-dispensing

pump, such dispenser and pump shall be tested for proper operation by a certificate of

license holder. All readily accessible piping shall be inspected for any evidence of leaks.

An affidavit executed by such installer attesting to compliance with this requirement

shall be submitted to the Bulk Fuel Safety Unit of the Bureau of Fire Prevention.

Piping, fittings, components and joint compounds shall be mutually compatible, and

compatible with diesel fuel and other commonly-used combustible liquid motor fuels,

including the additives commonly used in such combustible motor fuels. Joint

compounds shall be listed and approved.

3.1.2 Protections

(FC2206.6.1; FC3403.6.4)

This study material is provided to the public for free by the FDNY.

20

Posts or other approved means shall be provided to protect piping, valves, fittings or

ancillary equipment subject to vehicular damage. Where subject to external corrosion,

piping, related fluid-handling components and supports for both underground and

aboveground applications shall be fabricated from noncorrosive materials, coated or

otherwise provided with corrosion protection. Dissimilar metallic parts that promote

galvanic action shall not be joined. Piping shall be located such that it is protected from

physical damage and designed to accommodate settlement, vibration, expansion or

contraction.

Piping systems shall be substantially supported and protected from physical damage and

designed to accommodate settlement, vibration, expansion, contraction or exposure to

fire. The supports shall be constructed of steel, concrete or other approved

noncombustible material.

3.1.3 Overfill and backflow prevention

(FC2306.6.2.3; FC2306.6.2.4; FC2306.6.2.6; FC5704.2.9.4; FC5704.2.9.6.6;

FC5704.2.9.6.8; FC5704.2.11.4; FC 5703.6.6; DEC613.3(c)(4); DEC613.3(c)(6) )

The size of the spill containment boxes should be based on the amount of fluid stored in

the hose volume and not less than 15-gallon capacity and an approved overfill prevention

system to automatically prevent overflow.

Overfill protection shall be provided for storage tanks. Tanks shall not be filled in excess

of 95% of their capacity. An approved overfill prevention system shall be provided for

each tank. During tank-filling operations, the system shall automatically shut off the

flow of liquid to the tank when the quantity of liquid in the tank reaches 95% of tank

capacity. For rigid hose liquid-delivery systems, an approved means shall be provided to

empty the fill hose into the tank after the automatic shutoff device is activated. A durable

sign shall be conspicuously posted on or immediately adjacent to the fill point for the

tank, setting forth the filling procedure and the tank calibration chart. For aboveground

tanks, the filling procedure shall require the person filling the tank to determine the

gallonage required to fill it to 90 %of capacity before commencing the fill operation.

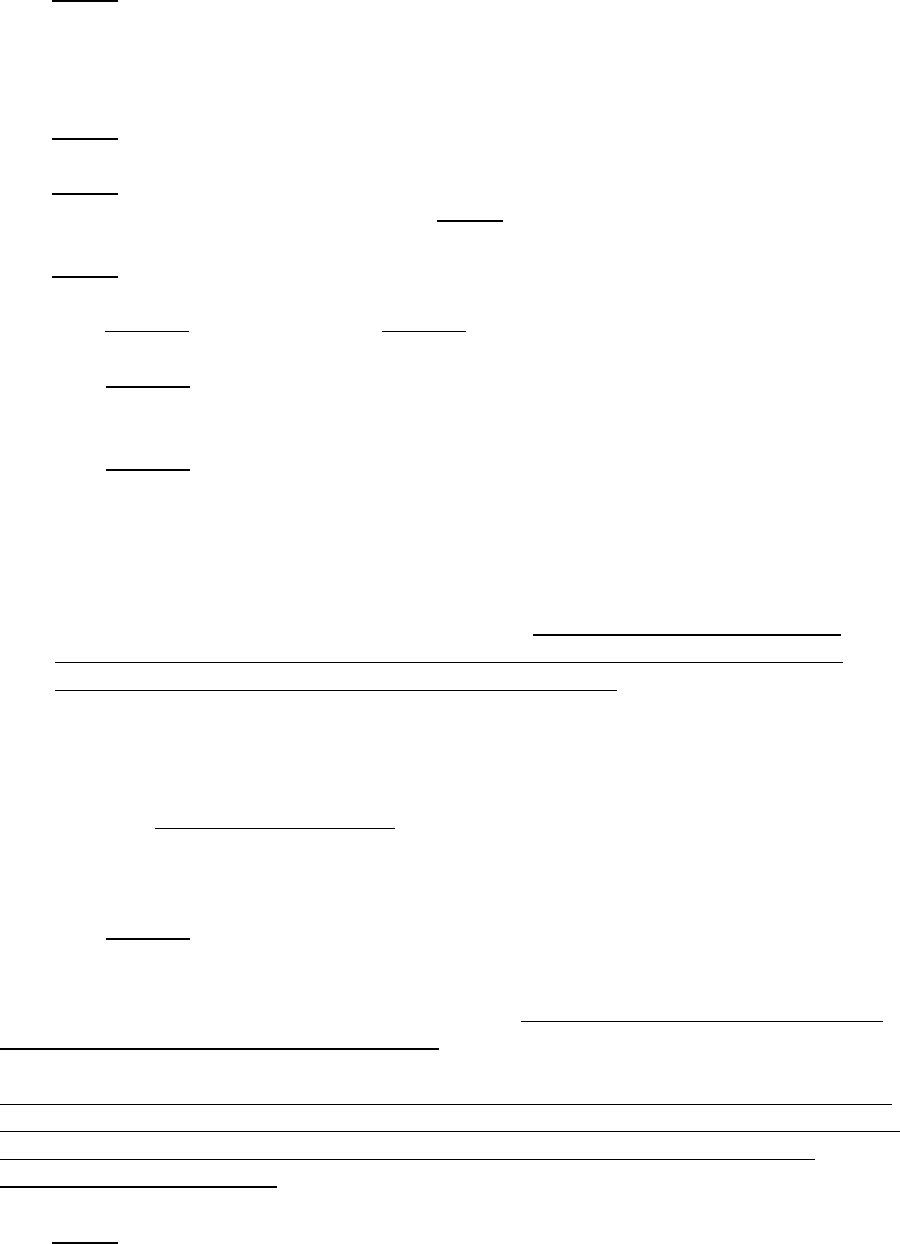

Three types of overfill prevention devices are commonly used: vent restriction devices, low

shut-off devices, and alarms as shown below.

1. vent

restriction

2. flow shut-off

devices

3. alarm and

sensor

Vapor recovery Fill pipe Tank

gauging

This study material is provided to the public for free by the FDNY.

21

Vent restriction devices are installed at the base of the vapor recovery riser pipe and

extend into the top of the tank. As the liquid level approaches the top of the tank, a float

rises and obstructs the vapor recovery vent. This creates a vacuum in the cargo tank

compartment, dramatically slowing product flow. This alerts the driver to shut-off the

flow from the tanker. This type of device is called a negative pressure overfill prevention.

The flow shut-off devices:

It will automatically shut off the flow of liquid to the tank when the liquid level reaches

95% of the tank capacity

The sensor and alarm:

This study material is provided to the public for free by the FDNY.

22

(1) Valves and backflow protection

Piping systems shall contain a sufficient number of manual control valves and check

valves to operate the system properly and to protect the facility under both normal and

emergency conditions. Piping systems in connection with pumps shall contain a

sufficient number of such valves to control properly the flow of liquids in normal

operation and in the event of physical damage or fire exposure.

Connections to pipelines or piping by which tank cars, cargo tanks, or marine vessels or

other equipment discharge liquids into storage tanks shall be provided with check valves

or block valves for automatic protection against backflow where the piping arrangement

is such that backflow from the system is possible. All fill pipes leading to a pump-filled

petroleum tank must be equipped with a properly functioning check valve or equivalent

device which provides automatic protection against backflow. A check valve is required

only when the piping arrangement of the fill pipe in such that backflow from the receiving

tank is possible. Where loading and unloading is done through a common pipe system, a

check valve is not required. However, a block valve shall be provided which is located so

as to be readily accessible or remotely operable.

Manual drainage-control valves shall be located at approved locations remote from the

tanks, diked area, drainage system and impounding basin to ensure their operation in a

fire condition.

(2) Siphon prevention

Approved antisiphon devices shall be installed in each external pipe connected to the

protected aboveground tank when the pipe extends below the level of the top of the tank.

3.1.4 Connections, joints and bends

The sensor of

the liquid level.

It triggers the

alarm.

Overfill alarm warms the

truckman to stop

transferring the motor

fuel.

This study material is provided to the public for free by the FDNY.

23

(FC2206.6.2.2; FC3403.6.7; FC3403.6.9.1; FC3403.6.10; FC3404.2.7.5.1; FC3404.2.7.5.6

FC3404.2.9.6.7)

Connections for tank openings below the liquid level shall be liquid tight. Joints shall be

liquid tight and shall be welded, flanged or threaded except that listed flexible connectors

are allowed. Threaded or flanged joints shall fit tightly by using approved methods and

materials for the type of joint. Joints in piping systems used for Class I liquids (e.g.

gasoline) shall be welded when located in concealed spaces within buildings or

structures. Nonmetallic joints shall be subject to the approval of the commissioner and

shall be installed in accordance with the manufacturer’s instructions. Pipe joints that are

dependent on the friction characteristics or resiliency of combustible materials for liquid

tightness of piping shall not be used in buildings or structures. Piping shall be secured to

prevent disengagement at the fitting.

(1) Connections for aboveground tanks.

Aboveground tanks with connections located below normal liquid level shall be provided

with internal or external isolation valves located as close as practical to the shell of the

tank. Except for liquids whose chemical characteristics are incompatible with steel, such

valves, when external, and their connections to the tank shall be of steel.

The fill-pipe for aboveground tanks shall be provided with a means for making a direct

connection to the cargo tank’s fuel-delivery hose so that liquid motor fuel is not exposed

to the open air during the filling operation. Operator safety equipment for the filling

operation shall be provided in accordance with OSHA regulations. Where any portion of

the fill-pipe exterior to the tank extends below the level of the top of the tank, a check

valve, a dry break coupling and a quick closing valve shall be installed at the fill

connection. The check valve must be installed in the fill pipe not more than 12 inches

from the fill hose connection. Tank fill connections from a remote location are prohibited.

(2) Joints for underground tanks.

A flexible connectors on an underground storage tank’s suction, vent, and fill lines can

protect the tank system from loads applied during settling. Flexible joints shall be listed

and approved and shall be installed on underground liquid, vapor and vent piping at all

of the following locations:

1. Where piping connects to underground tanks.

2. Where piping ends at pump islands and vent risers.

3. At points where differential movement in the piping can occur.

Fiberglass-reinforced plastic piping is not required to be provided with flexible joints in

locations where both of the following conditions are present:

1. Piping does not exceed 4 inches in diameter.

2. Piping has a straight run of not less than 4 feet on one side of the connection

when such connections result in a change of direction. In lieu of the minimum 4-

foot straight run length, approved and listed flexible joints are allowed to be used

under dispensers and suction pumps, at submerged pumps and tanks, and

where vents extend aboveground.

(3) Bends.

This study material is provided to the public for free by the FDNY.

24

The bending of pipe and tubing shall be performed in accordance with ANSI B31.9.

3.1.5 Tank vents and opening

(FC2206.6.2.1; FC2206.6.2.9;FC2206.6.2.10; FC2206.6.2.11; FC3404.2.7.3;

FC3404.2.7.3.2; FC3404.2.7.4; FC3404.2.7.5.4; FC3404.2.7.5.7; FC3404.2.9.6.2;

FC3404.2.9.6.3)

(1)Vent pipes

Vent pipes shall be installed such that they will drain toward the tank without sags or

traps in which liquid can collect. Each tank shall be provided with a separate

unobstructed vent line, without any trap or device that causes excessive back pressure,

and shall be maintained unobstructed at all times. Vent lines from tanks shall not be

used for purposes other than venting unless approved.

The lower end of the vent pipe shall not extend more than 1 inch through the top of the

storage tank. Cross-connection between a vent pipe and fill pipe is prohibited.

Where a battery of storage tanks designed to hold identical material is installed, vent

pipes may be run into a main header. Vent shall be at least 1 1/4 inch in diameter for

storage tanks not exceeding 1,100 gallon capacity and at least 2 inches in diameter for

storage tanks of 1,100 gallons or more. Vent pipes shall be provided with an approved

weatherproof hood having a free area of at least the pipe size area. Vent pipes shall

terminate outside the building in a non-hazardous location, at least 2 feet from any

building opening and not less than 2 feet nor more than 12 feet above the fill pipe

terminal unless otherwise permitted by the Commissioner.

If the vent pipe terminal is not visible from the fill pipe terminal location, a one inch tell-

tale line shall be connected to the tank and shall parallel the fill pipe and terminate at

the fill terminal with an unthreaded end. Such telltale lines shall be provided with a

check valve set to prevent flow of surface water to the storage tank.

This study material is provided to the public for free by the FDNY.

25

Vent pipe outlets shall be located such that

the vapors are released at a safe point

outdoors and not less than 15 feet above the

adjacent ground level. Vapors shall be

discharged upward or horizontally away from

adjacent walls to assist in vapor dispersion.

Vent outlets shall be located such that

flammable or combustible vapors will not be

trapped by eaves or other obstructions and

shall be at least 10 feet from building

openings or lot lines. Tank openings for

aboveground tanks shall be through the top

only. There shall be no openings except those

necessary to inspect, fill, empty and vent the

tank.

Tank vent piping shall not be manifolded unless required for special purposes such as

vapor recovery, vapor conservation or air pollution control.

(a)Aboveground tanks. For aboveground tanks, manifolded vent pipes shall be

adequately sized to prevent system pressure limits from being exceeded when

manifolded tanks are subject to the same fire exposure.

(b) Underground tanks. F

or underground tanks, manifolded vent pipes shall be sized

to prevent system pressure limits from being exceeded when manifolded tanks are

filled simultaneously.

(2) Tank openings for vapor recovery

Tank openings provided for purposes of vapor recovery shall be protected against vapor

release by means of a spring-loaded check valve or dry-break connections, or other

approved device, unless the opening is a pipe connected to a vapor processing system.

Openings designed for combined fill and vapor recovery shall also be protected against

Posts that protect piping, valves, fittings

or ancillary equipment subject to

vehicular damage.

This study material is provided to the public for free by the FDNY.

26

vapor release unless connection of the liquid delivery line to the fill pipe simultaneously

connects the vapor recovery line. Connections shall be vapor tight.

Filling, emptying and vapor recovery connections to tanks shall be located outdoors at a

location free from sources of ignition and not less than 10 feet away from building

openings or lot lines. Such openings shall be provided with a liquid-tight cap which shall

be closed when not in use and properly identified.

(3) Special devices

(a) Pressure relief devices.

Where liquid motor fuel may become trapped between shutoff valves and/or check

valves, affected piping sections shall be provided with pressure-relief devices that will

discharge the pressure generated by thermal expansion back into the tank.

(b) Manual gauging.

Openings for manual gauging, if independent of the fill pipe, shall be provided with a

liquid-tight cap or cover. Covers shall be kept closed when not gauging. Openings for

manual gauging shall not be permitted for tanks installed indoors.

3.1.6 Filling pipes

(Rule 4834(d)(1)f)

The filling pipe shall be at least 2 inches and not larger than 4 inches nominal inside

diameter, and shall be laid at a descending grade to the tank, terminating within 6

inches of the bottom of the tank. The intake of a filling pipe shall be located outside of

any building and not less than 10 feet from any door, subway grating or basement

opening, and in a heavy metal box, which shall be sunk flush with the sidewalk at the

curb level, or at some other location offering equal facilities for the filling of the tank and

fitted with a heavy metal cover, which shall be liquid tight and kept closed when not in

use. The filling pipe shall be closed at the intake by a cock or valve fitted with a coupling

for attaching to the tank truck, and with a liquid tight cap or plug to close the opening

when not in use. The filling pipe shall be provided with a screen made of one thickness of

20-mesh brass wire gauze, placed immediately below the filling cock or valve. Where a

storage system for flammable liquids and a storage system for diesel motor fuel oil

and/or fuel oil are to be used on the same premises, the terminal of the diesel motor fuel

oil and/or fuel oil fill pipe shall be provided with a left handed thread and the fill pipe

fitting shall be of a different size than that required for the fill pipe to tanks containing

flammable liquids.

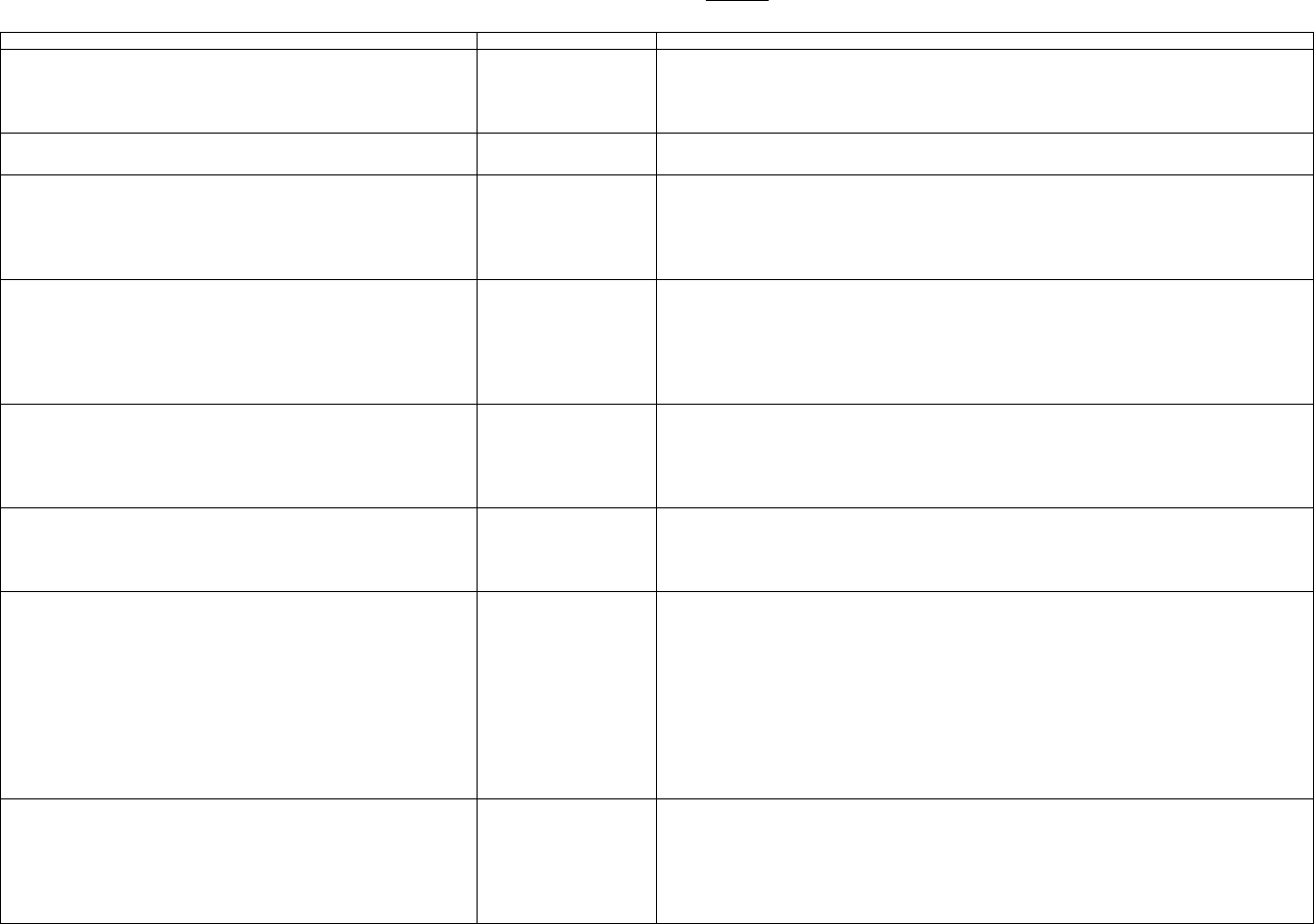

3.2 Labeling and Signage

3.2.1 Color coding and symbols of fill ports

(DEC613.3(b)(2), DEC613.3(b)(3))

The owner or operator must permanently mark all fill ports to identify the product inside

the tank. These markings must be consistent with the color and symbol code of the

American Petroleum Institute which follows. The colors to be used are:

This study material is provided to the public for free by the FDNY.

27

(i)

High gasoline

Red

(ii)

Middle gasoline

Blue

(iii)

Lower gasoline

White

(iv)

High unleaded gasoline

Red w/white cross

(v)

Middle unleaded gasoline

Blue w/white cross

(vi)

Lower unleaded gasoline

White w/black cross

(vii)

Vapor recovery

Orange

(viii)

Diesel

Yellow

(ix)

#1 fuel oil

Purple w/yellow bar

(x)

#2 fuel oil

Green

(xi)

Kerosene

Brown

The symbols to be used are:

(i) a circle for gasoline products and

vapor recovery lines;

(ii) hexagon for other distillates; and

(iii) a border must be painted around

fuel products containing extenders

such as alcohol. The border will be

black around a white symbol and

white around all other colors.

3.2.2 Warning signs

(FC2204.2.3; FC2204.2.6)

(1) Control area sign.

A durable metal sign that reads as follows shall be posted in plain view within the control

area:

Emergency Procedures:

Shut off product pumps.

Direct vehicle occupants to exit vehicles and leave area

immediately.

Keep all persons away from the area.

Manually activate fire extinguishing system.

Notify the Fire Department (Call 911).

This study material is provided to the public for free by the FDNY.

28

(2) Dispensing area signs and instructions.

Durable warning signs shall be conspicuously posted on or immediately adjacent to each

dispenser in the fuel-dispensing area and shall state the following:

1. It is illegal and dangerous to fill unapproved containers with fuel.

2. Smoking is prohibited.

3. The engine shall be shut off during the refueling process.

4. Portable containers shall not be filled while located inside the trunk, passenger

compartment, or truck bed of a vehicle.

5. It is unlawful for customers to fill portable containers. See attendant for

assistance.

Dispenser operating instructions shall be conspicuously posted in approved locations on

every dispenser and shall indicate the location of the emergency controls.

The view of the sign should not be obstructed.

This study material is provided to the public for free by the FDNY.

29

This study material is provided to the public for free by the FDNY.

30

PART 4. UNDERGROUND LIQUID MOTOR FUEL STORAGE TANK

4.1 Tank Contents and Capacity Limitations

(FC2206.2.1.3#4; FC2206.2.3.2; FC3404.1.2.2)

Individual underground storage tanks shall not exceed a capacity of 12,000 gallons. The

aggregate capacity at a facility in both aboveground and underground tanks shall not

exceed 40,000 gallons. Underground tanks shall not store petroleum products containing

mixtures of a nonpetroleum nature, such as ethanol or methanol blends, without

evidence of compatibility such as a manufacturer’s letter stating the compatibility.

4.2 Design and Constructions of the Tanks

4.2.1 General requirements

(FC2206.2.1.3)

The manufacture of the tanks and all related equipments must be UL certificated and

tanks must be designed and constructed in accordance with the following:

1. Tanks shall be completely double-walled and constructed of steel, fiberglass-

reinforced plastic or a combination of both materials. The secondary tank shall be

capable of containing any leakage from the primary tank.

2. Tanks shall be designed and constructed to withstand 1.5 times the maximum

operating loads and stresses, regardless of the amount of liquid motor fuel

contained in the tank. Such capabilities shall be established by buoyancy

calculations and load and stress analyses.

3. Tanks shall be designed and constructed to withstand a pressure of 15 psig or 1½

times the maximum anticipated static head pressure, whichever is greater, for the

primary tank and 5 psig for the secondary tank.

4.2.2 Cathodically protected steel tanks

(DEC614.3(e) Rule 2206-01(c))

Cathodically protected steel tanks used for underground storage of petroleum must meet

or exceed the design regulated by the New York State Department of Environmental

Conservation 614.3(e) and manufacturing standards. Such steel tanks must be

cathodically protected with sacrificial anodes or an impressed current cathodic protection

system designed in accordance with the applicable National Association of Corrosion

Engineers (NACE) standard or other approved standard(e.g. API RP 1632; ULC-S603.1M;

STI-P3; NACE RP-0169; NACE RP-0285; UL 1746 or STI RP 892). The cathodic protection

system must be designed to provide a minimum of 30 years of protection. Cathodic

protection systems shall be designed by a trained person knowledgeable of the

requirements of the United States Environmental Protection Agency for such systems.

Such person shall first inspect the site and test the site for soil resistivity and the

presence of stray currents. A qualified engineer or corrosion specialist must personally

supervise the installation of the cathodic protection system where this is necessary to

assure that the system has been installed as designed. Each cathodic protection system

must have a monitor which enables the owner or operator to check on the adequacy of

cathodic protection. Tanks which are protected by sacrificial anodes must be electrically

insulated from the piping system with di-electric fittings, bushings, washers, sleeves or

This study material is provided to the public for free by the FDNY.

31

gaskets which are chemically stable when exposed to petroleum, petroleum additives, or

corrosive soils.

Cathodic protection systems shall be inspected and tested in the presence of a

representative of the Fire Department at the time of installation in compliance with the

applicable National Association of Corrosion Engineers standard and the following

procedures:

(A) All piping shall be subjected to a holiday test and tanks and associated piping shall