General:

Enclosures and fittings shall be prepared for

finishing, utilizing a five stage process and the

coating shall be electrostatically applied powder

in accordance with the following specifications.

Factory Painted Finish:

The paint coating shall be dry powder,

electrostatically applied to produce a finish of 3

to 5 mils thickness. The coated metal shall then be

baked. The coating shall be commercially smooth,

substantially free of flow lines, paint washout,

streaks, blisters and other defects that would

impair serviceability or detract from general

appearance.

Tests and Certification:

Salt Spray Resistance: the undercutting of the

film of the coating shall not exceed 1/8” average,

from lines scored diagonally and deep enough to

expose the base metal, after 2500 hours exposure

in a salt spray cabinet in accordance with ASTM

Designation: B 117.

Adherence:

There shall be no coating loss when tested by

California Test 645. Compliance of the coating

system to the above requirements may be

determined by the application of the coating, to 4”

X 8” X 0.024” test specimens of the same material

as the cabinets, in the same manner as applied

to the cabinet. Testing shall include cross-hatch

(tape pull), M.E.K. rub, and manual bend testing in

compliance with California Test Method 645.

A Fade & Chalk Test:

Shall result in a maximum of 10% deviation from

an original finish measurement when checked by

weatherometer and fadeometer.

Note:

Standard enclosures are fabricated from hot-

dipped galvanized sheet steel, cleaned and painted

in accordance with the preceding specifications.

Optional enclosure materials include aluminum,

uncoated aluminum, clear anodized or painted

in accordance with these specifications. Stainless

steel enclosures are available either painted

in accordance with these specifications or left

uncoated with a natural finish.

Standard Colors

ANSI 61 Gray, ANSI 49 Gray, White, Autumn White,

Camel Tan, Dark Olive Green, Gloss Black,

Mint Green, Ranch Green

Corporate Headquarters

8440 Florin Road

Sacramento, CA 95828

(916) 395-8800

www.TescoControls.com

Regional Oces

Southern CA

42015 Remington Ave.

Suite 102

T

emecula, CA 92590

(951) 308-6450

Central CA

1315-B Dayton St.

Salinas, CA 93901

(831) 754-6838

Nevada

213 Sage St.

Carson City, NV 89706

(800) 94-TESCO

Southeastern US

10699 Airline Hwy. Suite B

Baton Rouge, LA 70816

(800) 94-TESCO

Tesco Controls Paint Line

100% Employee-Owned

PAINT PROCESS SPECIFICATION

Enclosures Metal Preparation and Painting

PAINT PROCESS SPECIFICATION

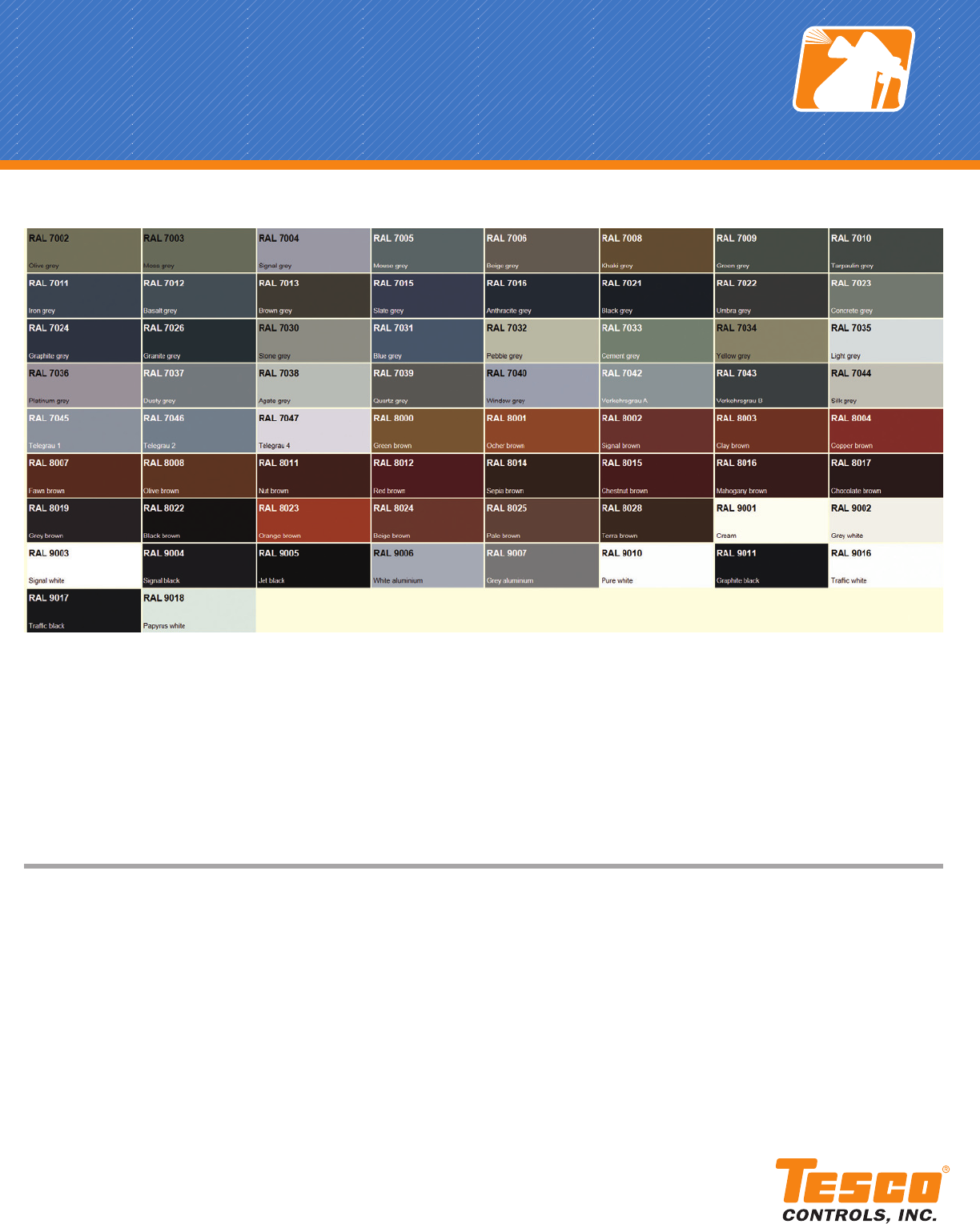

Available RAL Colors

*Actual color may vary slightly. Please refer to our website for more accurate color

*Paint chips are available upon request

PAINT PROCESS SPECIFICATION

Available RAL Colors

*Actual color may vary slightly. Please refer to our website for more accurate color

*Paint chips are available upon request

**Ask about our clear coatings - available in all chemistries

Anti-Graffiti Coating:

Grati is a continuing problem. Removal is both costly and labor intensive. In our continued eort to provide

our customers real solutions, Tesco oers an optional anti-grati coating. The purpose of anti-grati coating

is to allow removal of grati without damage to the coating.

*Ask about additional custom applications

PAINT PROCESS

SPECIFICATIO N

ANSI 49 Gray

Dark Olive

Green

ANSI 61 Gray

Gloss Black

Autumn White

Mint Green

Camel Tan

Ranch Green

Corporate Headquarters

8440 Florin Road

Sacramento, CA 95828

(916) 395-8800

www.TescoControls.com

White

100% Employee-Owned

Examples of Popular Finishes

Standard Cabinet Colors

© 2015 Tesco Controls, Inc. TESCO® is a trademark of Tesco Controls, Inc.

Control #A030315