Concrete

Pipe & Precast

Installation

Pocket Guide

ONTARIO CONCRETE PIPE ASSOCIATION

January 2019

Contents

ONTARIO PRODUCER MEMBERS ............................ 1

INTRODUCTION ...................................................... 2

ONTARIO PROVINCIAL STANDARDS ....................... 3

PRECAST CONCRETE PLANT CERTIFICATION ........... 4

PRE-CONSTRUCTION .............................................. 6

SITE PREPARATION ................................................. 6

ORDERING PRECAST CONCRETE PRODUCTS ........... 7

HANDLING .............................................................. 8

Load-Carrying Capacity of Lift Anchors ................. 9

Handling Pipe ...................................................... 10

900 mm Diameter and Smaller ........................ 10

975 mm Diameter and Larger .......................... 10

Handling MH Sections ......................................... 11

Handling Box Units .............................................. 13

JOB SITE PRODUCT RECEIVING ............................. 15

Inspection of Product Shipment .......................... 15

Unloading ............................................................ 16

Stockpiling ........................................................... 16

Storage ................................................................ 17

EXCAVATIONS ...................................................... 19

Excavated Material .............................................. 20

Dewatering .......................................................... 21

Support Systems .................................................. 21

Trench Boxes .................................................... 22

CONCRETE PIPE INSTALLATION ............................. 24

Pipe Details .......................................................... 24

Wall Thickness ..................................................... 26

Excavation Limits ................................................. 26

Line and Grade .................................................... 28

Foundation Preparation ...................................... 32

Pipe Bedding ........................................................ 33

Bedding Materials ............................................ 35

Class B Bedding ................................................ 36

Class C Bedding ................................................ 36

Cover ................................................................... 36

Backfill ................................................................. 37

Jointing ................................................................ 39

Jointing Materials ................................................ 39

Rubber Gaskets ................................................ 40

Mastic .............................................................. 41

Mortar .............................................................. 42

External Bands ..................................................... 42

Jointing Procedures ............................................. 44

Jointing Procedures for Pre-lubricated Gasket

with Single Offset Joints ................................... 47

Jointing Procedures for O-Ring Gasket ............ 50

How to Use Lift Anchors for Setting Pipe ......... 54

Service Connections ............................................ 56

Changes in Alignment .......................................... 56

MH INSTALLATION ............................................... 58

Prebenched MH Monobases ............................... 59

MH Connections .................................................. 59

Precast Concrete Adjustment Units .................... 61

Frames with Grates or Covers ............................. 61

BOX UNIT INSTALLATION ...................................... 62

Foundations ......................................................... 62

Bedding ............................................................... 63

Levelling ............................................................... 63

Backfill and Cover ................................................ 63

Distribution Slab .................................................. 64

FIELD TESTING ...................................................... 64

Soil Density .......................................................... 65

Visual/Video Inspection....................................... 66

Infiltration Testing ............................................... 67

Exfiltration Testing .............................................. 68

Testing With Water .......................................... 68

Low Pressure Air Testing .................................. 70

Leakage Test Acceptance .................................... 70

APPENDIX ............................................................. 71

APPENDIX A – Concrete Jacking Pipe .................. 72

APPENDIX B – Damage Assessment .................... 76

Repair Types .................................................... 76

Joint Integrity ................................................... 77

Cracks ............................................................... 79

Basis of Acceptance ......................................... 84

Autogenous Healing ............................................ 85

Rehabilitation Techniques ................................... 86

Chemical Grout ................................................ 87

Trenchless Technologies .................................. 88

REFERENCES ......................................................... 90

Concrete Pipe & Precast Installation

1

ONTARIO PRODUCER MEMBERS

Coldstream Concrete

402 Quaker Lane, RR#2

Ilderton, ON N0M 2A0

(519) 666-0604

coldstreamconcrete.com

Con Cast Pipe

299 Brock Road South

Puslinch, ON N0B 2J0

1-800-668-7473

concastpipe.com

DECAST Ltd

8807 County Road 56

Utopia, ON L0M 1T0

1-800-461-5632

decastltd.com

Forterra Pipe & Precast

2099 Roseville Road

Cambridge, ON N1R 5S3

1-888-888-3222

forterrabp.com

M CON Pipe & Products

2691 Greenfield Road

Ayr, ON N0B 1E0

1-866-537-3338

mconproducts.com

M CON Products

2150 Richardson Side Road

Carp, ON K0A 1L0

1-800-267-5515

mconproducts.com

Miller Precast

58 Cooper Road

Rosslyn, ON P7K 0E3

(807) 939-2655

millerprecast.ca

Rainbow Concrete Industries

2477 Maley Drive

Sudbury, ON P3A 4R7

1-800-461-6281

rcil.ca

Concrete Pipe & Precast Installation

2

INTRODUCTION

Proper installation is a critical step in a process that also

includes surface and sub-surface investigations, detailed

design, specification preparation, quality manufacturing,

and field testing.

The design of a concrete pipeline assumes that certain

minimum conditions of installation will be met in the field.

Acceptance criteria should be established by the owner to

ensure that the quality of workmanship and materials

provided during construction has met the design

requirements.

Standard specifications for the installation of precast

concrete drainage products can also be found in the

following references:

Product

OPSS

ASTM

Concrete Pipe

410

C1479

MH and CB

407

C1821

Box

422

C1675

General installation procedures are presented in this

guide, together with some of the problems that might be

encountered. This is only a guide and is not intended to

supersede the project specifications.

Concrete Pipe & Precast Installation

3

ONTARIO PROVINCIAL STANDARDS

The Ontario Provincial Standards (OPS) for Roads and

Public Works were published for the first time in January

1984, with the intent of improving the administration and

cost-effectiveness of road building and other municipal

services, such as sewers and watermains. OPS drawings

and specifications correspond to those used by many

municipalities and the Ontario Ministry of Transportation.

The Ontario Provincial Standards currently contain the

following manuals:

Ontario Provincial Standards Specifications (OPSS)

Ontario Provincial Standards Drawings (OPSD)

An online version of these standards can be found at:

www.ops.on.ca

Relevant OPS documents are listed in some sections of this

guide for easy reference.

Concrete Pipe & Precast Installation

4

PRECAST CONCRETE PLANT CERTIFICATION

As of January 1, 2018, the Canadian Precast/Prestressed

Concrete Institute (CPCI) and the Canadian Concrete Pipe

and Precast Association (CCPPA) established an

independent third-party administered and audited

certification program for both prestressed and non-

prestressed precast concrete manufacturing facilities

across Canada.

Both the CPCI and CCPPA recognize the mutual benefit for

owners, contractors, and the precast concrete industry by

combining the strengths of two well-established national

plant certification programs, CPCI Certification Program for

Structural, Architectural and Specialty Products and

Production Processes (CPCI Certification) and the Plant

Prequalification Program for Precast Concrete Drainage

Products (PPP), into the new Canadian Precast Concrete

Quality Assurance (CPCQA) Certification Program.

Concrete Pipe & Precast Installation

5

In Ontario, manufacturers of precast concrete drainage

products must possess a current Prequalification

Certificate in accordance with the Ontario Provincial

Standard Specifications listed below:

OPSS 1351

Precast Reinforced Concrete Components for MH,

Catch Basins, Ditch Inlets, and Valve Chambers

OPSS 1820 Circular and Elliptical Concrete Pipe

OPSS 1821

Precast Reinforced Concrete Box Culverts and Box

Sewers

Plants that are prequalified must identify all precast

concrete drainage products covered by their certification,

with this marking:

For a list of prequalified plants or more information about

the precast concrete certification program visit:

www.precastcertification.ca

.

Concrete Pipe & Precast Installation

6

PRE-CONSTRUCTION

Pre-construction planning is essential for a successful

project. All engineering plans, project specifications, soils

reports, standard drawings, and special provisions must be

reviewed prior to construction. A review of the design at

the project site is helpful in identifying potential problems.

Addressing these potential problems can eliminate

unnecessary and costly delays.

All personnel associated with the project should become

familiar with the federal, provincial and local occupational

health and safety codes related to construction projects.

SITE PREPARATION

Site preparation can significantly influence progress of the

project. The amount and type of work involved in site

preparation varies with the location of the project,

topography, surface conditions, and existing utilities.

References in Ontario Provincial Standards:

OPSS 490

Site Preparation for Pipelines, Utilities, and

Associated Structures

OPSS 491

Preservation, Protection, and Reconstruction of

Existing Facilities

OPSS 510

Removal

Concrete Pipe & Precast Installation

7

ORDERING PRECAST CONCRETE PRODUCTS

The ordering of materials is the contractor’s responsibility,

however design engineer and supplier familiarity with the

contractor’s proposed schedule will enable better

coordination to avoid delays in product deliveries and

avoid unnecessary product handling.

Precast concrete manufacturers stock a wide range of

standard components, however longer delivery lead times

may be required when large quantities and/or custom

precast concrete products are required. Information

required to initiate an order should include:

Name and location of project

Design and manufacturing standards

Product size, type, strength class, and quantities

Joint materials or performance requirements

List of special fittings

Product or material test requirements

Delivery date

Invoicing instructions

The contractor must provide access roads to allow delivery

trucks to reach the unloading area under their own power.

References in Ontario Provincial Standards:

OPSS 1351

Precast Reinforced Concrete Components for MH,

Catch Basins, Ditch Inlets, and Valve Chambers

OPSS 1820

Circular and Elliptical Concrete Pipe

OPSS 1821

Precast Reinforced Concrete Box Culverts and Box

Sewers

Concrete Pipe & Precast Installation

8

HANDLING

IMPORTANT

Work procedures for material handling, worker safety,

the modification of excavators for use as cranes, and all

components of any lifting assembly for precast concrete

products must comply with the Occupational Health and

Safety Act requirements for Construction Projects

(Ontario Regulation 213/91). A competent person

designated by the contractor should inspect all lifting

assemblies and attachment hardware prior to each use.

Any damage or defective lifting equipment must be

immediately removed from service. All other safety

procedures and recommended operating practices by the

manufacturer of commercial lifting equipment must be

followed. Failure to observe the above warnings may

lead to property damage, personnel injury and death.

All precast concrete products must be handled with

reasonable care. The Contractor must take all necessary

precautions to ensure the method used in lifting or placing

the product uniformly distributes the weight and does not

induce point loading on the product.

Proprietary lifting systems are typically used for precast

concrete products, including pipe, box units, and

maintenance hole components. It is imperative that all

lifting system components and rigging hardware be used

as they are intended.

Concrete Pipe & Precast Installation

9

Load-Carrying Capacity of Lift Anchors

IMPORTANT

Lift anchors are sized and located specifically for each

precast concrete product to be lifted individually.

Contractors must not attempt to lift more than one

precast concrete section at a time, and must ensure that

the load is applied to all lift anchors simultaneously in

order to safely lift the product.

The MAXIMUM safe working load is clearly visible on the

head of the lift anchor for easy recognition of the

appropriate hardware and accessories to be used.

However the safe working load of any lift anchor may be

significantly reduced due to several factors, such as:

Length of anchor, or embedment depth

Distance to edges, corners or openings

Concrete compressive strength

Number of lifting points and type of rigging used

Direction of pull (cable or sling angle)

Impact or dynamic loads

Concrete Pipe & Precast Installation

10

Handling Pipe

900 mm Diameter and Smaller

Lifting devices such as slings, chains or cables should be

placed around the pipe, or arranged so that the pipe is

lifted in a horizontal position at all times. If the lifting

device could chip or damage the pipe, padding should be

provided between the pipe and lifting device. These types

of lifting devices should not be passed through the pipe.

A common device used for unloading small to

intermediate diameter pipe (900 mm and smaller), is a lift

fork. Lift forks are easily attached to a heavy equipment

machine, such as a front end loader. Lift forks make

unloading more efficient, and enable the contractor to

easily move pipe around the site.

975 mm Diameter and Larger

Concrete pipe 975 mm and larger are typically provided

with two embedded lift anchors placed laterally along the

top of the pipe. Special pipe fittings may require more

than two lift anchors in various other locations on the

Concrete Pipe & Precast Installation

11

product. Because the pipe is lifted by two or more points,

stability during lifting is established.

When pipe is provided with lift holes, the lifting device

should pass through the wall and distribute the weight

along the inside barrel of pipe. Concrete pipe with lift

holes, require a specially designed lifting device consisting

of a steel thread eye bar with a wing type nut and bearing

plate. Lift holes should be filled in after the pipe is

installed.

Handling MH Sections

In maintenance hole products, lift anchors are typically

placed on the sides of the product. MH components have

Concrete Pipe & Precast Installation

12

one or more lift anchors on either side of the product for

stability during installation and stacking.

For MH sections provided with lift holes, properly

designed and sized lifting pins should be used.

Concrete Pipe & Precast Installation

13

Using short lifting cables or chains that result in a sling

angle greater than 60 degrees can greatly increase the

possibility of damaging the top shoulders of the MH riser

and potentially cause the MH riser to fail structurally.

When MH risers have multiple hole openings, extra care

must be taken to reduce the inward force from the rigging

by means such as a spreader beam or longer cables.

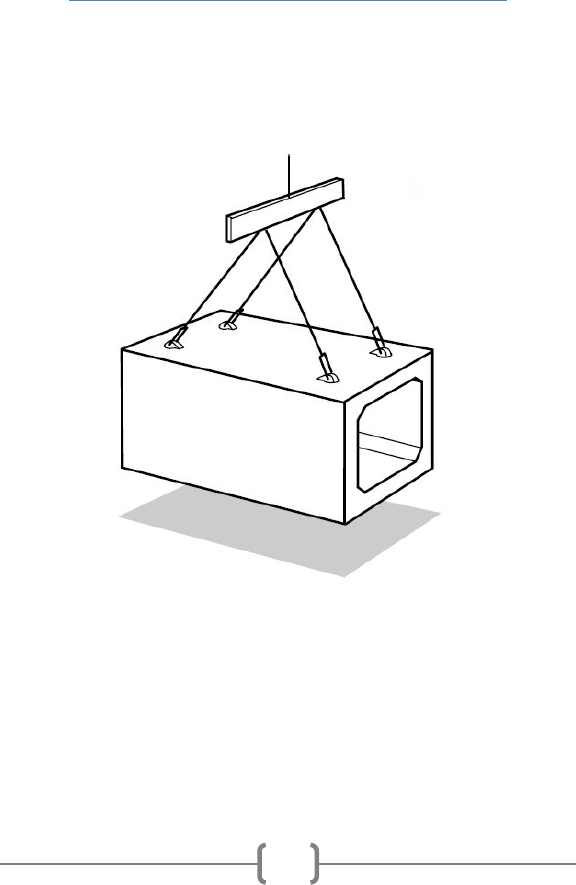

Handling Box Units

Concrete box units are typically provided with four

embedded lift anchors placed on the top slab. Additional

lift anchors may be provided for unloading, or rotating the

product from its shipping position to its installed position.

Concrete Pipe & Precast Installation

14

Special box fittings may require lift anchors in various

other locations on the product. Because the box is lifted

by two or more points, stability during lifting is

established.

Source: Guidelines for Handling Concrete Pipe and Utility

Products by Dayton Superior.

Concrete Pipe & Precast Installation

15

JOB SITE PRODUCT RECEIVING

Inspection of Product Shipment

Each shipment of precast concrete product is blocked and

tied down at the plant to avoid damage during transit. The

product should be inspected on the truck when it first

arrives at the jobsite before it is unloaded to ensure that

damage has not occurred during transit. Damaged or

missing items must be reported at this time.

It is important to check that the product is the correct size,

type, and strength class, and is supplied with the proper

joint material. Typically markings on the product include:

Manufacturing standard

Strength designation, such as pipe class or design

earth cover

Date of manufacture

Name or trademark of the manufacturer

Quality assurance program certification, if applicable

Appropriate markings to indicate the correct

orientation when installed, if applicable

Other markings as specified by the owner

Concrete Pipe & Precast Installation

16

Unloading

Unloading of precast concrete product should be done on

a level site and be controlled to avoid colliding with other

products. Care should be taken to avoid damage,

especially to the bells and spigots. Caution should be

exercised to ensure personnel are out of the path of the

product as it is moved.

If the product is damaged during delivery or unloading, the

product should be set aside. Minor chips or cracks which

do not pass through the wall can usually be repaired. The

manufacturer can provide advice on proper repair

methods.

If the product has to be moved after unloading, the

sections should be lifted, and should never be dragged.

Transporting product over rough ground should be done in

a manner that prevents excessive impact or dynamic loads

on the lifting hardware. Pipe sections should not be rolled

over rough ground.

Stockpiling

If the excavation is open, the pipe should be placed on the

side opposite the excavated material. The pipe sections

should be placed so that they are protected from traffic

and construction equipment, but close enough to the

trench edge to minimize handling.

If the excavation is not yet open, the pipe should be strung

out on the opposite side from where the excavated

material will be placed. To avoid disruption to existing

Concrete Pipe & Precast Installation

17

natural drainage and enable construction to proceed as

quickly as possible, pipe installation should follow

immediately after preparation of the bedding foundation.

For culverts to be installed on shallow bedding at

approximately the same elevation as original ground, the

pipe should be strung out immediately after clearing and

rough grading.

Storage

Storage of pipe should be as close as is safely possible to

where the pipe will be installed. Pipe sections generally

should not be stored at the job site in a greater number of

layers that would result in a total height of 2 m.

Pipe should be layered in the same manner as they were

loaded on the truck. Pipe should be placed on timbers to

prevent them from becoming frozen to the ground in the

winter, and to permit ease of handling in summer. For

small diameter pipe sizes that have protruding bells, the

pipe barrel should carry the weight of the pipe keeping the

bell ends free of load concentrations.

The bottom layer should be placed on a level base, on

timbers supporting the barrel at either end. Each layer of

bell and spigot pipe should be arranged so that bells are at

the same end. The bells in the next layer should be at the

opposite end, and projecting beyond the spigot of the

section in the lower layer. Where only one layer is being

stockpiled, the bell and spigot ends should alternate

between adjacent pipe sections.

Concrete Pipe & Precast Installation

18

All flexible gasket materials, including joint lubricating

compounds where applicable should be stored in a cool

dry place in the summer, and prevented from freezing in

the winter. Rubber gaskets and preformed mastics should

be kept clean, away from oil, grease, excessive heat, and

out of direct sunlight.

Concrete Pipe & Precast Installation

19

EXCAVATIONS

For sewer and culvert construction, the scope of

operations involved in general includes excavating, soil

stabilization, backfilling, and control of groundwater and

surface drainage.

Adequate knowledge of subsurface conditions is essential

for any type of excavation. This is accomplished through

soil surveys and subsequent soil classification. Soil borings

are usually obtained for design purposes, and the

information included on the plans, or made available to

the contractor in a geotechnical report. This soil boring

information is useful in evaluating unsuitable subsoil

conditions requiring special construction. If the subsoil

information on the plans is not sufficiently extensive, it is

normally the responsibility of the contractor to obtain

additional test borings.

It is the contractor’s responsibility to adhere to all

Occupational Health and Safety Act requirements for

excavations. The sloping requirements for Soil Type 1, 2, 3

or 4 are described in OHSA Ontario Regulation 213/91 for

Construction Projects and is detailed in the OPSD 802.03X

and 802.05X series drawings for concrete pipe installation.

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

OPSS 403

Rock Excavation for Pipelines, Utilities, and

Associated Structures in Open Cut

OPSS 539

Temporary Protection Systems

OPSS 902

Excavating and Backfilling – Structures

Concrete Pipe & Precast Installation

20

Excavated Material

In open cut installations, suitable excavated material is

usually used for backfill, and should be placed in a manner

that reduces re-handling during backfilling operations.

Stockpiling excavated material adjacent to the trench

causes a surcharge load which may cave in trench walls.

The ability of the trench walls to stand vertically under this

additional load depends on the cohesion characteristics of

the particular type of material being excavated. This

surcharge load should be considered when evaluating the

need to provide trench support. As a general rule, for

unsupported trenches, the minimum distance from the

trench to the toe of the spoil bank should not be less than

one half the trench depth. For supported trenches, a

minimum of 1.0 m is normally sufficient.

For deep or wide excavations, it may be necessary to haul

away a portion of the excavated soil or spread the

stockpile with a bulldozer or other equipment.

If the excavated soil differs significantly from the backfilled

material set forth in the plans, it may be necessary to haul

the unsuitable soil away and import backfill material. All

material to be used as backfill should be visually inspected

for frozen lumps, cinders, ashes, refuse, vegetable or

organic matter, rocks and boulders over 150 mm in any

dimension, and other deleterious material.

Concrete Pipe & Precast Installation

21

Dewatering

A continuous dewatering operation should be provided in

order to keep the excavation stable and free of water.

Dewatering efforts must be monitored for impacts to

items such as ground settlement and ground water usage.

Water from dewatering operations must be disposed of in

accordance with local regulations. Pumped water requires

that it be filtered through a sediment control measure and

disposed of such that it does not cause erosion or other

damage to adjacent lands.

When dewatering efforts are no longer required they must

be discontinued in a manner so that disturbance of any

structure or pipeline is avoided.

References in Ontario Provincial Standards:

OPSS 517

Dewatering of Pipeline, Utility, and Associated

Structure Excavation

OPSS 518

Control of Water from Dewatering Operations

Support Systems

Soil stabilization may require the opinion of a professional

engineer to ensure that the walls of an excavation are

sufficiently stable before any workers enter the

excavation. The support system requirements for

excavations in Soil Type 1, 2, 3 or 4 are described in OHSA

Ontario Regulation 213/91 for Construction Projects.

Concrete Pipe & Precast Installation

22

The structural requirements of a support systems depend

on numerous factors such as:

depth and width of excavation

characteristics of the soil

water content of the soil

weather conditions

proximity to other structures

vibration from construction equipment or traffic

soil placement or other surcharge loads

code requirements

As the excavation is backfilled, the support system should

be removed, unless it is specified to be left in place.

Improper removal of a support system can affect the

backfill load on the pipe or structure, so it should be

withdrawn gradually as backfilling progresses. Additional

compaction of the backfill material may be necessary to fill

the voids behind the support system, as it is removed. The

procedure for extracting the support system and placing

backfill shall ensure the backfill load is applied gradually

and disturbance of the pipeline or structure is avoided.

Trench Boxes

Trench boxes, or shields, are prefabricated support

systems composed of heavily braced steel sidewalls, and

are capable of being moved as a unit to protect workers as

pipe installation progresses. Trench boxes are commonly

used for pipe or box installations and must be designed by

Concrete Pipe & Precast Installation

23

a professional engineer in accordance with OHSA Ontario

Regulation 213/91 for Construction Projects.

When a trench box is used, care should be taken when the

shield is moved ahead, so as not to disturb the bedding or

pull the pipe or box joints apart.

Specially designed manhole shields are also available for

the installation of maintenance holes, or other vertical

structures.

References in Ontario Provincial Standards:

OPSS 404

Support Systems

OPSS 539

Temporary Protection Systems

Concrete Pipe & Precast Installation

24

CONCRETE PIPE INSTALLATION

This section covers the requirements for the installation of

concrete pipe in open cut. Pipe installation using

trenchless methods are discussed in Appendix A.

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

OPSS 403

Rock Excavation for Pipelines, Utilities, and

Associated Structures in Open Cut

OPSS 410

Pipe Sewer Installation in Open Cut

OPSS 421

Pipe Culvert Installation in Open Cut

Pipe Details

Cross-section

Concrete Pipe & Precast Installation

25

Expanded Bell End - 975mm Dia & Smaller

Flush Bell End - 1050mm Dia & Larger

Concrete Pipe & Precast Installation

26

Wall Thickness

Concrete pipe is typically supplied with industry standard

wall thicknesses, but may vary by manufacturer. Wall

thickness can be determined with the following equations:

: t =

ID

12

: t =

ID

12

+ 1

: t =

ID

12

+ 1.75

Where: t = wall thickness (inches)

ID = inside pipe diameter (inches)

Excavation Limits

The most important excavation limitations are trench

width and depth. As excavation progresses, trench grades

should be periodically checked against the elevations

established on the sewer profile.

Improper trench depths can result in high or low spots in

the line, which may adversely affect the hydraulic capacity

of the sewer, and require correction or additional

maintenance after the line is completed. If the trench

depth is excavated beyond the limits of the required

excavation, granular material should be placed and

compacted in the trench to reinstate the required trench

limits prior to backfilling the trench.

Concrete Pipe & Precast Installation

27

The backfill load transmitted to the pipe is directly

dependent on the trench width at the crown of the pipe.

To determine the backfill load the designer assumes a

certain trench width, and then selects a pipe strength

capable of withstanding this load. If the constructed

trench width exceeds the maximum trench width specified

in the design, the pipe may be overloaded and may require

the use of a stronger pipe or a higher class of bedding, or

both. Where maximum trench widths are not indicated in

any of the construction contract documents, trench widths

should be as narrow as possible, with side clearance

adequate enough to ensure proper compaction of backfill

material at the sides of the pipe.

When unstable soil conditions are encountered, sheathing

or shoring can be used, or the banks of the trench can be

sloped to the natural angle of repose of the native soil. If

the trench sides are allowed to slope back, the pipe should

be installed in a shallow subtrench excavated at the

bottom of the wider trench. The depth of the subtrench

should be at least equal to the vertical height of the pipe.

For a confined trench installation, OPSD 802.03X specifies

the following trench widths at the top of the pipe:

SIDE CLEARANCE TABLE

Pipe Inside Diameter

(mm)

Side Clearance

(mm)

900 or less

300

Over 900

500

Concrete Pipe & Precast Installation

28

For culverts installed under embankments, it may be

possible to simulate a narrow subtrench by installing the

pipe in the existing stream bed.

When culverts are installed in a negative projecting

condition of construction, the same excavation limitations

should be followed as for trench excavation.

OPSS 401 requires that no more than 15 m of trench be

open in advance of the completed pipe system.

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

Line and Grade

For sewer construction, where the pipe is installed in a

trench, line and grade are usually established by one, or a

combination of the following methods:

Control points consisting of stakes and spikes set at

the ground surface, and offset a certain distance from

the proposed sewer centerline

Control points established at the trench bottom, after

the trench is excavated

Trench bottom and pipe invert elevations established

while excavation and pipe installation progresses

Global Positioning System (GPS)

Concrete Pipe & Precast Installation

29

IMPORTANT

Line and grade should be checked as the pipe is installed,

and any discrepancies between the design and actual

alignment and pipe invert elevations should be corrected

prior to placing the backfill or fill over the pipe.

Where control points are established at the surface and

offset, lasers, transits, batter boards, tape and level, or

specially designed transfer instruments, are used to

transfer line and grade to the trench bottom. Regardless

of the specific type of transfer apparatus used, the basic

steps are:

Stakes and spikes, as control points, are driven flush

with the ground surface at 7.5 to 15m intervals for

straight alignment, with shorter intervals for curved

alignment.

Offset the control points 3m, or another convenient

distance, on the opposite side of the trench from

which excavated material will be placed.

Determine control point elevations by means of a

level, transit or other leveling device. Drive a guard

stake to the control point, and mark the depth of the

control point from the control point to the trench

bottom or pipe invert.

After the surface control points are set, a grade sheet

is prepared listing reference points, stationing, offset

distance and vertical distance from the control points

to the trench bottom or pipe invert.

Concrete Pipe & Precast Installation

30

Transferring the line and grade along the trench bottom is

achieved by using a laser system, or a batter board system.

The laser system, the most commonly used system, uses a

transit or level to set the starting point on the trench

bottom. As with any surveying instrument, the initial

setting is most important. Once the starting point is

established, the laser can be set for direction and grade.

Temperature can affect the trueness of the laser beam;

therefore, it is helpful to keep the line well ventilated. The

laser instrument can be mounted in a maintenance hole,

set on a tripod or placed on a solid surface to project the

light beam either inside, or outside the pipe.

There are two types of batter board systems. One type is

incorporated for narrow trenches, the other for wide

trenches.

For narrow trenches, a horizontal batter board is spanned

across the trench, and adequately supported at each end.

The batter board is set level at the same elevation as the

stringline, and a nail driven in the upper edge, at the

centerline of the pipe. In many cases the batter board is

used only as a spanning member, with a short vertical

board nailed to it at the pipe centerline. A stringline is

pulled tight across a minimum of three batter boards, and

the line transferred to the bottom by a plumb bob cord

held against the stringline. Grade is transferred to the

trench bottom by means of a grade rod, or other suitable

vertical measuring device.

Concrete Pipe & Precast Installation

31

Example Batter Board Set-up for Narrow Trench

Where wide trenches are necessary, due to large pipe sizes

or sloped trench walls, the batter board may not be able

to span the width of excavation. In such cases, the same

transfer principle is used, except that the vertical grade

rod is attached to one end of the batter board, and the

other end set level against the offset stringline. The length

of horizontal batter board is the same as the offset

distance. The length of the vertical grade rod is the same

as the distance between the pipe invert and the stringline.

Concrete Pipe & Precast Installation

32

Foundation Preparation

A stable and uniform foundation is necessary for

satisfactory performance of any pipe. The foundation

must have sufficient load bearing capacity to maintain the

pipe in proper alignment and support the loads of the

backfill material placed over the pipe. The foundation

should be checked for hard or soft spots, due to rocks or

low load-bearing soils. Where undesirable foundation

materials exist, it should be stabilized by ballasting, or soil

modification.

Ballasting requires removal of the undesirable foundation

material and replacing it with select materials such as

sand, gravel, crushed rock, slag, or suitable earth backfill.

The depth, gradation, and size of the ballast depend on

the specific material used and the amount of stabilization

required, but usually the ballast should be well graded.

Soil modification involves the addition of select material to

the native soil. Crushed rock, gravel, sand, slag, or other

durable inert materials with a maximum size of 75 mm, is

worked into the subsoil to the extent necessary to

accomplish the required stabilization.

In rock or hard, unyielding soils, the excavation should be

continued below grade, and the over-excavation replaced

with select material to provide a cushion for the pipe.

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

Concrete Pipe & Precast Installation

33

Pipe Bedding

Once a stable and uniform foundation is provided, it is

necessary to prepare a bedding in accordance with the

requirements set forth in the plans, specifications or

standard drawings.

An important function of the bedding is to level out any

irregularities in the foundation, and assure uniform

support along the barrel of each pipe section. The bedding

is also constructed to distribute the load bearing reaction,

due to the mass of the backfill or fill material, around the

lower periphery of the pipe. The structural capacity of the

pipe is directly related to this load distribution, and several

Concrete Pipe & Precast Installation

34

types of bedding have been established to enable the

specification of pipe strengths during the design phase.

This guide describes the Class B and Class C Beddings since

these are commonly used in the Ontario Provincial

Standards for rigid pipe. Other bedding types, such as

Standard Installations Types 1 to 4, are described in the

OCPA Concrete Pipe Design Manual and the Canadian

Highway Bridge Design Code (CSA S6).

The following general requirements should be understood:

Bedding material placed in the haunches must be

compacted prior to continued placement of cover

material. To ensure support in the haunches, the

bedding under the middle third of the pipe should be

loosely placed and uncompacted.

Bedding material should be placed in layers not

exceeding 200 mm in thickness, loose measurement,

and compacted to contract specifications before a

subsequent layer is placed.

Bedding on each side of the pipe should be

completed simultaneously. At no time should the

levels on each side differ by more than the 200 mm

uncompacted layer.

Bell holes should be excavated to accommodate

projecting joints, and to provide support along the

barrel of the pipe.

Concrete Pipe & Precast Installation

35

Uniform Support for Pipe with Expanded Bells

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

OPSS 501

Compacting

OPSD

802.030 to

802.034

Rigid Pipe Bedding, Cover, and Backfill Drawings

OPSD

802.050 to

802.054

Horizontal Elliptical Rigid Pipe Bedding, Cover, and

Backfill Drawings

Bedding Materials

Materials for bedding should be selected on the basis that

uniform contact can be obtained between the bedding and

the pipe. Since most granular material will shift to attain

this uniform contact as the pipe settles, an ideal load

distribution can be realized.

OPSS 401 specifies that bedding material be:

Granular A

Granular B, Type I, II, or III, 26.5 mm or less in

size, or

Unshrinkable fill in accordance with OPSS 1359.

Concrete Pipe & Precast Installation

36

Class B Bedding

The bedding depth below the pipe has a specified

thickness of 0.15 times the outside pipe diameter,

with a minimum of 150mm and maximum of 300mm.

Class B Bedding should extend at least half way up at

the sides of the pipe (to springline).

The bedding material is shaped to receive the bottom

of the pipe. The width should be sufficient to allow

0.6 times the outside pipe diameter for circular pipe,

and 0.7 times the outside span for elliptical pipe.

Class C Bedding

The bedding depth below the pipe has a specified

thickness of 0.15 times the outside pipe diameter,

with a minimum of 150mm and maximum of 300mm.

Class C Bedding should extend up the sides of the

pipe for a height of at least 0.15 times the outside

pipe diameter (forming a 90 degree bedding angle).

The bedding material is shaped to receive the bottom

of the pipe. The width should be sufficient to allow

0.5 times the outside pipe diameter for circular pipe,

and 0.5 times the outside span for elliptical pipe.

Cover

Cover material should be placed so that damage to or

movement of the pipe is avoided.

OPSS 401 specifies that cover material be:

Granular A, or

Concrete Pipe & Precast Installation

37

Granular B, Type I, II, or III, 26.5 mm or less in

size

The following general requirements should be understood:

Compacted cover material should be placed on top of

the bedding to a depth of at least 300 mm above the

top of the pipe.

Cover material should be placed in layers not

exceeding 200 mm in thickness, loose measurement,

and compacted to contract specifications before a

subsequent layer is placed.

Cover on each side of the pipe should be completed

simultaneously. At no time should the levels on each

side differ by more than the 200 mm uncompacted

layer.

Heavy equipment should not be used for compacting until

there is a minimum depth of 900mm above the crown of

the pipe.

Backfill

OPSS 401 specifies that backfill material be:

Granular A

Granular B, Type I, II, or III

Unshrinkable fill in accordance with OPSS 1359

Approved native material

The following general requirements should be understood:

Concrete Pipe & Precast Installation

38

Backfill material should be placed in uniform layers

not exceeding 300 mm in thickness for the full width

of the trench and each layer should be compacted to

95% of the maximum dry density before a subsequent

layer is placed.

Backfill should be placed to a minimum depth of

900mm above the crown of the pipe before power

operated tractors or rolling equipment should be

used for compacting. Uniform layers of backfill

material exceeding 300mm in thickness may be

placed with the approval of the Contract

Administrator.

If the contract specifies native backfill material,

acceptable earth backfill material may be substituted

with the approval of the Contract Administrator. In

areas within the roadway, for a depth equal to the

frost treatment, the earth backfill material should

have frost susceptible characteristics similar to the

adjacent material.

References in Ontario Provincial Standards:

OPSS 401

Trenching, Backfilling, and Compacting

OPSS 492

Site Restoration Following Installation of Pipelines,

Utilities, and Associated Structures

OPSS 501

Compacting

Concrete Pipe & Precast Installation

39

Jointing

Pipe should be lowered into the trench, or set in place for

embankment installations, with the same care as when the

pipe was unloaded from the delivery trucks.

In laying the pipe, it is general practice to face the bell end

of the pipe in the upstream direction. This placing helps

prevent bedding material from being forced into the bell

during jointing, and enables easier coupling of pipe

sections.

Jointing Materials

Several types of joints and sealant materials are utilized

for concrete pipe, to satisfy a wide range of performance

requirements. All of the joints are designed for ease of

installation. The manufacturer’s recommendations

regarding jointing procedures should be closely followed

to assure resistance to infiltration of groundwater and/or

backfill material, and exfiltration of sewage or storm

water.

Concrete Pipe & Precast Installation

40

The most common joint sealants and joint fillers used for

sewers and culverts are:

Rubber gasket

Mastic sealants

Mortar

Regardless of the specific joint sealant used, each joint

should be checked to be sure all pipe sections are in a

homed position. For joints sealed with rubber gaskets, it is

important to follow the manufacturer’s installation

recommendations to ensure that the gasket is properly

positioned, and is under compression.

Rubber Gaskets

Rubber gaskets are of three basic types:

Pre-lubricated gasket for single offset joints. This is

the gasket type most commonly used for standard

concrete gravity pipe in Ontario.

Profile gasket for single offset joints.

O-ring gasket, which is placed in a groove on the

spigot and confined by the bell after the joint is

completed.

In some cases, a smooth round object, such as a

screwdriver shaft, should be inserted under the gasket and

run around the circumference two or three times, to

equalize the stretch in the gasket, before jointing.

For all gasket types, dirt, dust, and foreign matter must be

cleaned from the joint surfaces. Except for pre-lubricated

Concrete Pipe & Precast Installation

41

type, the gasket and bell should be coated with a lubricant

recommended by the manufacturer. The lubricant must

be clean and be applied with a brush, cloth pad, sponge or

glove.

Rubber gaskets are required to be stored in a sheltered,

cool dry place. They need to be protected from prolonged

exposure to sunlight, extreme heat in the summer, and

extreme cold in the winter. Proper care of the gaskets

prior to the installation will ensure maximum ease of

installation and maximum sealing properties.

Gaskets are generally formulated for maximum sealing

performance in a standard sewer installation carrying

primarily storm water or sanitary sewage. Custom rubber

formulations are available for special situations, where

specific elements are being carried in the effluent. Some

common examples of where a custom formulation would

be required are where resistance is needed against

hydrocarbons, acids, UV rays, ozone, and extreme heat.

Mastic

Mastic sealants consist of bitumen or butyl rubber and is

usually cold applied. The joint surfaces must be

thoroughly cleaned, dried and prepared in accordance

with the manufacturer’s recommendations.

Typically supplied in pre-formed coils, the flexible rope

style sealant should be properly sized based on the

dimensions of the annular joint space being sealed.

Concrete Pipe & Precast Installation

42

During cold weather, better workability of the mastic

sealant can be obtained if the mastic and joint surfaces are

warmed.

Mortar

Mortar for joints is composed of one part normal Portland

cement and two parts mortar sand, wetted with only

sufficient water to make the mixture plastic.

The joint surface is thoroughly cleaned and soaked

with water immediately before the joint is made

A layer of mortar is placed in the lower portion of the

bell end of the installed pipe and on the upper

portion of the spigot end of the pipe section to be

installed.

The spigot is then inserted into the bell of the

installed pipe until the sealant material is squeezed

out.

The annular space within the pipe joint is filled with

mortar, and the excess mortar on the inside of the

pipe is wiped and finished to a smooth surface.

External Bands

External bands may be used in addition to any jointing

material to serve two functions:

prevent fine materials from entering the joint

prevent infiltration of groundwater

If the prevention of bedding material from entering the

conveyance system is the primary objective, filter fabric,

Concrete Pipe & Precast Installation

43

while allowing the groundwater to infiltrate, will stop the

bedding backfill material from entering.

To prevent the infiltration of water, external extruded

rubber gaskets are utilized. The gasket must be of

sufficient width to cover the joint, and must be installed

with some tension applied, according to the

manufacturer’s recommendations. As the joint is

backfilled, pressure is applied to the gasket as it is pressed

against the structure, providing a seal at the joint.

Concrete Pipe & Precast Installation

44

Jointing Procedures

Joints for pipe sizes up to 600 mm in diameter can usually

be assembled by means of a bar and wood block. The axis

of the pipe section to be installed should be aligned as

closely as possible to the axis of the previously installed

pipe section, and the spigot end inserted slightly into the

bell, or groove. A bar is then driven into the bedding and

wedged against the bottom bell end of the pipe section

being installed. A wood block is placed horizontally across

the end of the pipe to act as a fulcrum point, and to

protect the joint end during assembly. By pushing the top

of the vertical bar forward, lever action pushes the pipe

into a home position.

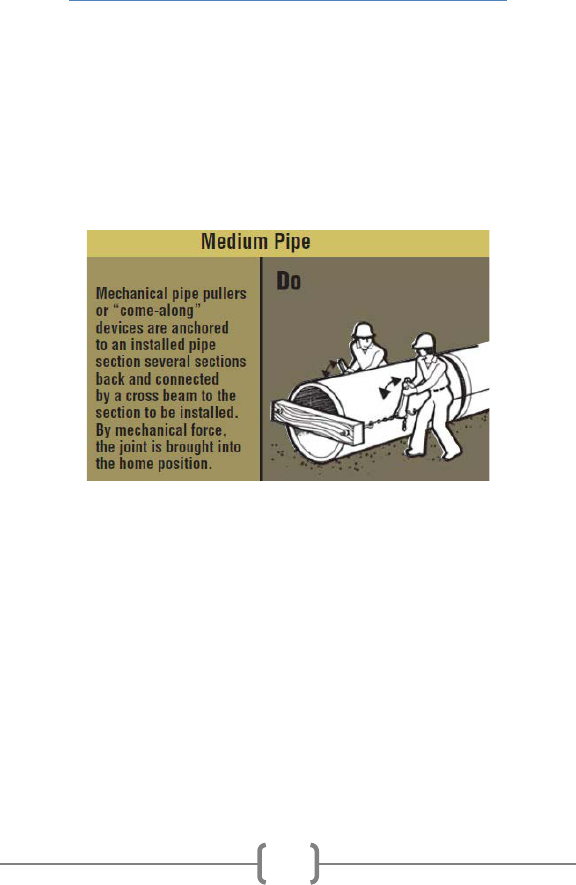

When jointing medium diameter pipe, a chain or cable is

wrapped around the barrel of the pipe behind the spigot

and fastened with a grab hook, or other suitable

connecting device. A lever assembly is anchored to the

installed pipe, several sections back from the previously

Concrete Pipe & Precast Installation

45

installed section, and connected by means of a chain, or

cable, to the grab hook on the pipe to be installed. By

pulling the lever back, the spigot of the pipe being jointed

is pulled into the bell of the previously installed pipe

section. To maintain close control over the alignment of

the pipe, a laying sling can be used to lift the pipe section

slightly off the bedding foundation.

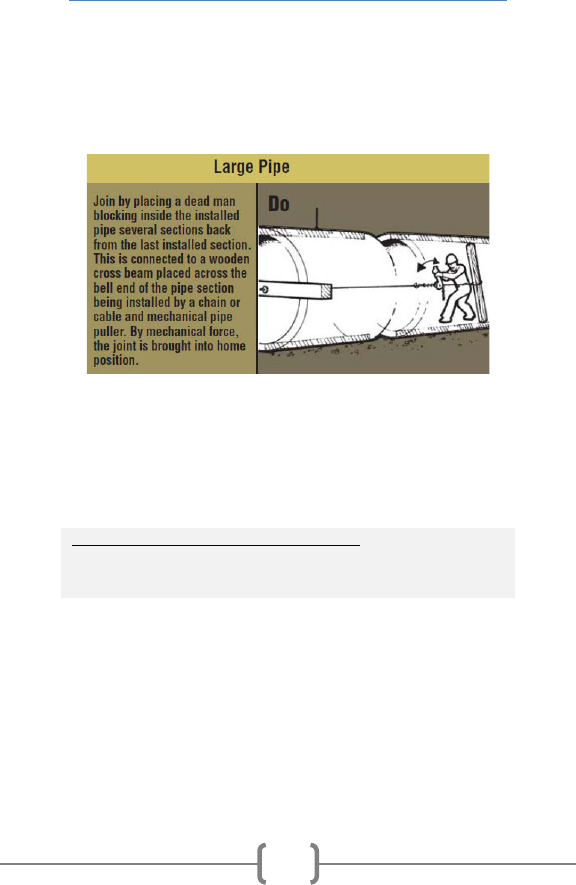

When jointing larger diameter pipe, and when granular

bedding is used, mechanical pipe pullers may be required.

Several types of pipe pullers, or “come along” devices,

have been developed, but the basic force principles are

the same.

Large diameter pipe can be jointed by placing a “dead

man” block inside the installed pipe, several sections back

from the last installed section, which is connected by

means of a chain or cable to a strong back placed across

the end of the pipe section being installed. The pipe is

pulled home by lever action similar to the external

Concrete Pipe & Precast Installation

46

assembly. Mechanical details of the specific apparatus

used for pipe pullers, or come along devices, may vary, but

the basic lever action principle is used to develop the

necessary controlled pulling force.

Note: The excavating equipment must not be used to

push pipe sections together or to adjust pipe to the final

grade. The force applied by such equipment can damage

pipe joints.

References in Ontario Provincial Standards:

OPSS 410

Pipe Sewer Installation In Open Cut

OPSS 421

Pipe Culvert Installation In Open Cut

Concrete Pipe & Precast Installation

47

Jointing Procedures for Pre-lubricated Gasket

with Single Offset Joints

The unique design of the pre-lubricated pipe gasket

requires no field lubrication and no equalization after

installation.

Installation:

1. Ensure that concrete bell and spigot are free from

cracks, chips, or other defects.

2. Brush loose dirt, debris and foreign material from the

inside surface of the bell, the spigot and the gasket.

Concrete Pipe & Precast Installation

48

3. Stretch gasket around the spigot, with the “Nose”

against the step formed in the spigot, and the “Tube”

lying flat against the spigot.

4. Pre-lubricated gaskets do not typically require

equalization of the rubber gasket stretch. If

equalization is required, run a smooth round object

around the circumference several times.

5. Do not lubricate the gasket or joint as this could

adversely affect the performance of the gasket and

the joint.

6. Align the spigot with the bell, and thrust the spigot

home using suitable mechanical means. The homing

process will cause the lubricated tube to “roll” over

Concrete Pipe & Precast Installation

49

itself, above the compression section, allowing the

pipe to slide forward.

Once the pipe is fully homed,

The compression section seals the total annular space

The rolling tube comes to rest within the small

annular space – acting as a cushion against side loads

The serrations act to resist pipe pull-out.

Source: Hamilton Kent.

Concrete Pipe & Precast Installation

50

Jointing Procedures for O-Ring Gasket

Procedure Prevention

Clean all foreign material

from the jointing surface of

the bell end of the pipe.

Foreign material on the

jointing surface can prevent

proper homing of the pipe.

Carefully clean the spigot

end of the pipe, including

the gasket recess.

Spigot ends that are not

properly cleaned may

prevent proper sealing of

the gasket.

Concrete Pipe & Precast Installation

51

Procedure Prevention

Cover the entire jointing

surface using an approved

lubricant, using a brush,

cloth, sponge or gloves.

Bells and spigots which are

not properly lubricated can

cause gaskets to roll, or

possibly damage the joint.

Lubricate the spigot end of

pipe, especially the gasket

recess.

Concrete Pipe & Precast Installation

52

Procedure Prevention

Lubricate gasket before

inserting it on the spigot.

Excessive force will be

required to push the pipes

together if lubricant is

insufficient. This can cause

extensive damage.

When fitting the gasket,

equalize the gasket stretch

by running a smooth round

object around the

circumference several

times.

Unequal stretch can cause

bunching of the gasket and

can damage the bell or be

the source of leaks.

Concrete Pipe & Precast Installation

53

Procedure Prevention

When aligning the pipes,

before homing the joint,

check the gasket is in

contact with the entry

taper around the entire

circumference.

Improper alignment can

dislodge the gasket causing

leaks or possibly break the

bell.

Concrete Pipe & Precast Installation

54

How to Use Lift Anchors for Setting Pipe

The following procedures are published in Guidelines for

Handling Concrete Pipe and Utility Products by Dayton

Superior, and available from the OCPA.

Lift anchors in concrete pipe can be used to “home” or pull

the product into its final position with a three-legged chain

sling, as shown below.

1. The pipe is first transported to the installation site with the

symmetrical sling and lowered close to the already placed

pipe.

Concrete Pipe & Precast Installation

55

2. The long leg of the Pipe Laying Sling is attached to the

farthest anchor on the previously laid pipe. The free leg is

attached – out of the way – on the clevis link provided.

3. Locate the center of lift over the closest anchor of the

previously laid pipe. This will properly align the direction of

pull.

4. The pipe is pulled into position by slowly raising the boom

on the crane or backhoe without moving the boom forward

or backward.

5. When the pipe has been pulled into position, the load is

released and the Pipe Laying System is moved to the next

pipe, and the process is repeated.

Warning: Anchors can become overloaded and fail if the

crane or backhoe continues to apply load after the

connection has been completed.

Concrete Pipe & Precast Installation

56

Service Connections

Service connections to the main pipe sewer should be

made using factory made tees or wyes, strap-on-saddles,

or other approved saddles. OPSS 410 requires factory

made tees or wyes for all service connections where the

diameter of the main pipe sewer is:

Less than 450 mm, or

Less than twice the diameter of the service

connection.

Holes in the main pipe sewer should be cut with approved

cutters and should be the minimum diameter required to

accept the service connection. If mortar-on saddles are

used, the inside of the pipe should be mortared at the

connection.

Where existing service connections are to be connected to

new pipe sewers or service connections, proper jointing

procedures must be used.

References in Ontario Provincial Standards:

OPSS 410

Pipe Sewer Installation In Open Cut

OPSD

708.010

Catch Basin Connection for Rigid Main Pipe Sewer

OPSD

1006.010

Sewer Service Connections for Rigid Main Pipe

Sewer

Changes in Alignment

Maintenance holes should be used when there is a need to

change alignment, grade or size of a pipeline. Alignment

Concrete Pipe & Precast Installation

57

changes in concrete pipe sewers can also be incorporated

into the line through the use of deflected straight pipe,

radius pipe, or bends. Since manufacturing and

installation feasibility are dependent on the particular

method used to negotiate a curve, it is important to

establish the method prior to excavating the trench.

For deflected straight pipe, the joint of each pipe

section is opened on one side while the other side

remains in the home position. The difference

between home and opened joint space is generally

designated as the pull. The maximum permissible pull

must be limited to that opening which will provide

satisfactory joint performance. This varies for

different joint configurations and is best obtained

from the pipe manufacturer.

When establishing alignment for radius pipe, the first

section of radius pipe should begin one half of a

radius pipe length before the beginning of curve, and

the last section of radius pipe should extend one half

of a radius pipe length beyond the end of curve.

When extremely sharp curves are required, deflected

straight pipe or radius pipe may not be suitable. In

such cases, bends or elbows may be used.

Since manufacturing processes and local standards vary,

local concrete pipe manufacturers should be consulted to

determine the geometric configurations available.

Concrete Pipe & Precast Installation

58

MH INSTALLATION

Structures must be installed on firm foundations at the

locations and elevations specified, and must be

constructed plumb and true to alignment.

Precast base slabs or monobases must be placed level

before subsequent sections complete with joint seal

systems be installed. Adjustment of the structure should

be carried out by lifting the affected sections free of the

excavation, re-leveling the base, if necessary, and re-

installing the sections. Damaged sections and gaskets

must be replaced.

When specified, the inside concrete bottom of the

structures should be benched and channeled to

accommodate the pipe. Concrete benching should have a

wood float finish and the channel should have steel trowel

finish. The channel must be smooth and flush with

adjacent pipe inverts.

Obtaining maintenance hole invert levels for the

preparation of as-built drawings, combined with visual

inspection of the sewer, provide an additional check that

settlement has not occurred.

References in Ontario Provincial Standards:

OPSS 407

Maintenance Hole, Catch Basin, Ditch Inlet, and

Valve Chamber Installation

OPSD

701.021

Maintenance Hole Benching and Pipe Opening

Alternatives

Concrete Pipe & Precast Installation

59

Prebenched MH Monobases

Having the precast MH base prebenched at the factory

offers advantages over benching in the field. Prebenching

is done under controlled conditions, resulting in a higher

quality product.

When used with flexible connectors, there is no need for

workers to enter the confined space created when the

maintenance hole is backfilled.

MH Connections

When the pipe connects to a rigid structure such as a

maintenance hole, it may shear or crack at the connection,

as a result of differential settlement. It is essential that

the bedding and foundation for the connecting pipe

section be highly compacted, to minimize differential

settlement.

Two methods are recommended by the precast concrete

pipe industry to maintain a watertight structure:

Flexible pipe-to-MH connectors. The flexible

connectors consist of a pre-formed rubber boot

inserted in the MH wall opening. The pipe is inserted

in the boot and the rubber connector is tightened to

create a positive connection.

Concrete grout. For many large diameter sewer

applications, contractors may connect directly to

MH’s using grout.

Concrete Pipe & Precast Installation

60

OPSS 407 requires that one of the following connections

be provided where a pipe connects to a structure:

A flexible pipe joint be provided within 300 mm of the

outside face of the structure for flexible and rigid

pipe.

A concrete cradle to the first joint for rigid pipe.

A resilient connector, i.e., a flexible, watertight

connector, in the structure opening for flexible and

rigid pipe.

A special approved structure designed for pipe

support.

Installation of pipe connectors must be according to the

manufacturer’s recommendations.

All pipes, except in valve chambers, must be flush with the

inside walls of the structure.

References in Ontario Provincial Standards:

OPSS 407

Maintenance Hole, Catch Basin, Ditch Inlet, and

Valve Chamber Installation

OPSS 410

Pipe Sewer Installation In Open Cut

OPSD

708.020

Support For Pipe at Catch Basin or Maintenance

Hole

Concrete Pipe & Precast Installation

61

Precast Concrete Adjustment Units

Precast concrete adjustment units can be used to set the

frame with grate or cover at the required position and

elevation. OPSS 408 requires a minimum of one

adjustment unit, but not more than three adjustment units

at each structure to a maximum height of 300mm.

The first adjustment unit should be laid in a full bed of

mortar and aligned with the opening in the structure.

Successive adjustment units are laid plumb to the first

adjustment unit and should be sealed between each unit.

Frames with Grates or Covers

When precast concrete adjustment units are used, frames

with grates or covers should be set in a full bed of mortar

on the adjustment units.

Ditch inlet grates should be installed as specified by the

precast manufacturer, or grate supplier.

Catchbasin grates which lie within the flow lines of a curb

and gutter system should be according to OPSS 353.

References in Ontario Provincial Standards:

OPSS 407

Maintenance Hole, Catch Basin, Ditch Inlet, and

Valve Chamber Installation

OPSS 408

Adjusting or Rebuilding MH, CB, Ditch Inlet and

Valve Chambers

OPSD

704.010

Precast Concrete Adjustment Units for

Maintenance Holes, Catch Basins, and Valve

Chambers

Concrete Pipe & Precast Installation

62

BOX UNIT INSTALLATION

Box units must be installed to the alignment and grade

specified in the contract documents. Installation of the

box units should start at the outlet end and proceed in the

upstream direction with the bell ends of the box units

facing upgrade.

OPSS 422 requires that the gap at box unit joints must not

exceed 20mm. Digging a small trench in the bedding at

each box joint with a round point shovel across the full

width of the box unit will ensure a proper alignment and

connection. This allows for the excess bedding material to

fall into the trench instead of getting trapped in the joint

as the next box unit is pulled into place.

For box units placed in parallel for multiple cell

installations, a 60mm ± 10mm gap filled with grout to

provide positive lateral bearing between adjacent cells.

For more information on precast concrete box, refer to the

OCPA Precast Box & Culvert Guideline.

Foundations

Precast box units should be constructed as specified in the

contract. The foundation must be firm in-situ soil, or

compacted backfill to provide uniform support for the full

length and width of each box unit. The foundation on

each side of the box unit, for a minimum distance equal to

the inside width of the box unit should be at least as stable

as the foundation directly below the box unit. Bedding

should not be placed on frozen earth.

Concrete Pipe & Precast Installation

63

Bedding

The maximum particle size for bedding should not exceed

25 mm in diameter, unless the bedding layer is at least 150

mm thick, in which case the maximum particle size should

not exceed 38 mm in diameter.

Bedding requiring compaction should be placed in layers

not exceeding 200 mm in thickness, loose measurement,

and each layer should be compacted before a subsequent

layer is placed.

The type of equipment used must be

suited to the material to be compacted, degree of

compaction required, and space available.

Levelling

The surface prepared to support the box units should have

a 75 mm minimum thickness top leveling course of

uncompacted Granular A or fine aggregates.

Backfill and Cover

Backfill and Cover should be placed in layers not exceeding

200mm in thickness, loose measurement, and each layer

should be compacted according to OPSS 501.

Backfilling on each side of the box units should be

completed simultaneously. The levels on each side must

not differ by more than 400mm.

Concrete Pipe & Precast Installation

64

Distribution Slab

Precast concrete box installed with a height of fill less than

0.60m typically requires a reinforced distribution slab

across the entire top of the box units, as detailed in OPSD

3920.110.

References in Ontario Provincial Standards:

OPSS 422

Precast Reinforced Concrete Box Culverts and Box

Sewers In Open Cut

OPSD

3920.100

Precast Reinforced Concrete Box Culvert with

Height of Fill ≥ 0.6m

OPSD

3920.110

Precast Reinforced Concrete Box Culvert with

Height of Fill < 0.6m

FIELD TESTING

The physical tests included in the material specifications,

under which the pipe is purchased, assure that pipe

delivered to the jobsite meets, or exceeds the

requirements established for a particular project. The

project specifications usually include acceptance test

requirements to assure that reasonable quality control of

workmanship and materials have been realized during the

construction phase of the project. Tests applicable to all

storm sewer, sanitary sewer and culvert projects are soil

density, line and grade and visual inspection, often by

video. For sanitary sewers, leakage limits are usually

established for infiltration or exfiltration.

Concrete Pipe & Precast Installation

65

Soil Density

To correlate in-place soil densities with the maximum

density of a particular soil, it is first necessary to determine

the Optimum Moisture Content for maximum compaction,

and then use this as a guide to determine the actual

compaction of the fill, or backfill. Several test procedures

have been developed for measuring in-place soil densities.

The maximum dry density can be determined by LS-706 or

LS-623 for granular and by LS-706, for earth. These tests

can be found in the MTO Laboratory Testing Manual:

• LS-623 - One Point Proctor Test (OPT)

• LS-706 - Moisture - Density Relationship of Soils Using

2.5 kg Rammer and 305 mm Drop

Field density and field moisture determinations can be

made in accordance with:

• ASTM D 2922 - Standard Test Methods for Density of

Soil and Soil-Aggregate in Place by Nuclear Methods

(Shallow Depth); and

• ASTM D 3017- Standard Test Method for Water

Content of Soil and Rock in Place by Nuclear Methods

(Shallow Depth)

A nuclear moisture and density gauge provides a rapid,

non-destructive technique for in-place determination of

density suitable for control and acceptance testing of soils.

It should be noted that the equipment utilizes radioactive

Concrete Pipe & Precast Installation

66

materials, which may be hazardous to the health of users,

unless proper precautions are taken.

References in Ontario Provincial Standards:

OPSS 501

Compacting

Visual/Video Inspection

Larger pipe sizes can be entered and examined, while

smaller sizes must be inspected by means of closed circuit

television cameras.

The following is a checklist for CCTV inspection of a pipe:

• debris and obstructions

• cracks exceeding the 0.3 mm wide design crack

for reinforced concrete pipe

• joints properly sealed

• invert smooth and free of sags or high points

• stubs properly grouted and plugged

• laterals, diversions, and connections properly

made

• catchbasins and inlets properly connected

• maintenance hole frames and grates properly

installed

• surface restoration, and all other items pertinent

to the construction, properly completed

References in Ontario Provincial Standards:

OPSS 409

Closed-Circuit Television Inspection Of Pipelines

Concrete Pipe & Precast Installation

67

Infiltration Testing

The infiltration of excessive ground water into a sanitary

sewer can overload the capacity of a sewer collection

system and treatment facilities. The infiltration test is

intended to demonstrate the integrity of the installed

materials and construction procedures as related to the

infiltration of ground water. Infiltration tests should be

conducted where the groundwater level at the time of

testing is 600 mm or more above the crown of the pipe for

the entire length of the test section. The test section is

normally between adjacent maintenance holes.

• Discontinue dewatering operations at least three days

before conducting the test and allow the

groundwater level to stabilize.

• A watertight bulkhead is constructed at the upstream

end of the test section.

• All service laterals, stubs, and fittings are plugged or

capped to prevent water entering at these locations.

• A V-notch weir or other suitable measuring device is

installed at the downstream end of the test section.

• Infiltrating water is allowed to build up behind the

weir until the flow through the V-notch has stabilized.

• The rate of flow is then measured.

In OPSS 410, the allowable infiltration is calculated as

0.075 litres/mm diameter/100 m of pipe sewer/hour.

References in Ontario Provincial Standards:

OPSS 410

Pipe Sewer Installation In Open Cut

Concrete Pipe & Precast Installation

68

Exfiltration Testing

Exfiltration tests should be conducted where the

groundwater level is lower than 600 mm above the crown

of the pipe or the highest point of the highest service

connection included in the test section.

The test section is normally between adjacent

maintenance holes. The test section of the pipe sewer

shall be isolated by temporarily plugging the downstream

end and all incoming pipes of the upstream maintenance

hole. All service laterals, stubs, and fittings are plugged or

capped to prevent water entering at these locations.

Since sanitary sewers are not designed, or expected to

operate as a pressure system, care must be exercised in

conducting the test and correlating the results with

allowable exfiltration limits.

References in Ontario Provincial Standards:

OPSS 410

Pipe Sewer Installation In Open Cut

Testing With Water

The test section is slowly filled with water making sure

that all air is removed from the line.

The test procedure outlined in OPSS 410 is as follows:

• A period of 24 hours for absorption or expansion may

be allowed before starting the test, except if

Concrete Pipe & Precast Installation

69

exfiltration requirements are met by a test carried

out during the absorption period.

• Water can be added to the pipeline prior to testing

until there is a head in the upstream maintenance

hole of 600 mm minimum over the crown of the pipe

or at least 600 mm above the existing groundwater

level, whichever is greater.

• The maximum limit of the net internal head on the

line is 8 m.

• In calculating net internal head, allowance for

groundwater head, if any, should be made.

• The distance from the maintenance hole frame to the

surface of the water should be measured.

• After allowing the water to stand for one hour, the