Operator’s Manual

Operator s Manual’

12 Speed

© 2017 PACCAR Inc. - All Rights Reserved

This

manual illustrates and describes the operation of features or equipment which may be either

standard or optional on this vehicle. This manual may also include a description of features and

equipment which are no longer available or were not ordered on this vehicle. Please disregard any

illustrations or descriptions relating to features or equipment which are not on this vehicle. PACCAR

reserves the right to discontinue, change specifications, or change the design of its vehicles at any

time without notice and without incurring any obligation. The information contained in this manual is

proprietary to PACCAR. Reproduction, in whole or in part, by any means is strictly prohibited without

prior written authorization from PACCAR Inc.

Contents

Chapter 1 | SAFETY

In this Chapter:

Using this Manual

..................................................................................................................................5

Safety Alerts..........................................................................................................................................5

Illustrations............................................................................................................................................6

General Safety Instructions...................................................................................................................7

Warnings and Cautions.........................................................................................................................9

A Special Word About Repairs..............................................................................................................9

SAFETY -

4 Y53-1272-1B1 (08/17)

1

Using this Manual

Please take the time to get acquainted with

your vehicle by reading this Operator’s

Manual. We recommend that you read and

understand this manual from beginning to

end before you operate this equipment.

This manual contains useful information for

the safe and efficient operation of this

equipment. It also provides service

information, with an outline for performing

safety checks and basic preventive

maintenance inspections. We have tried to

present the information you’ll need to learn

about functions, controls, and operation—

and to present it as clearly as possible. We

hope you’ll find this manual easy to use.

There will be times when you need to take

this manual out of the glovebox. When you

do, please be sure to return it when you

are finished using it. That way it will be

there when you need it the next time or

when you pass the vehicle on to the next

user.

NOTE

After you’ve read this manual, it should

be

stored in the cab for convenient ref-

erence and remain with this truck

when sold.

Your vehicle may not have all the features

or options mentioned in this manual.

Therefore, you should pay careful attention

to the instructions that pertain to just your

vehicle. In addition, if your vehicle is

equipped with special equipment or options

not discussed in this manual, consult your

dealer or the manufacturer of the

equipment.

There are several tools built into this

manual to help you find what you need

quickly and easily

. First is the Quick Table

of Contents. Located at the front of the

manual, this lists the main subjects

covered and gives section numbers where

you can find these subjects. Use the Quick

Table of Contents to find information on a

large subject like “Maintenance.” Cross-

referenced citations also help you get the

information you need. If some other part of

the manual contains further information on

the subject you are reading about, we’ll

indicate that in a cross-reference like this:

(See Safety Alerts on page 5

). You won’t

have to go searching for more information.

Finally you’ll find a helpful Subject Index.

It’s in the back of the manual and

alphabetically lists the subjects covered.

So if you want information on brakes, for

example, just look under Brake in the

Subject Index. You’ll find all the pages

listed where brakes or braking are

discussed.

All information contained in this manual is

based on the latest production information

available at the time of publication.

Kenworth Truck Company Peterbilt Motors

Company reserves the right to make

changes at any time without notice.

Safety Alerts

Please read and follow all of the safety

alerts contained in this manual. They are

there for your protection and information.

These alerts can help you avoid injury to

yourself, your passengers and help prevent

costly damage to the vehicle. Safety alerts

are highlighted by safety alert symbols and

signal words such as “WARNING”,

SAFETY - Using this Manual

Y53-1272-1B1 (08/17) 5

1

“CAUTION”, or “NOTE”. Please DO NOT

ignore any of these alerts.

W

arnings

The safety message following this symbol

and signal word provides a warning against

operating procedures which could cause

death or injury

. They could also cause

equipment or property damage. The alert

will identify the hazard, how to avoid it and

the probable consequence of not avoiding

the hazard.

WARNING

Hot engine oil can be dangerous. You

could

be burned. Let the engine oil

cool down before changing it. Failure

to comply may result in death, person-

al injury, equipment or property dam-

age.

Cautions

The safety message following this symbol

and signal word provides a caution against

operating procedures which could cause

equipment or property damage. The alert

will identify the hazard, how to avoid it, and

the probable consequence of not avoiding

the hazard.

CAUTION

Continuing to operate your vehicle with

insuf

ficient oil pressure will cause seri-

ous engine damage. Failure to comply

may result in equipment or property

damage.

Notes

The message following this symbol and

signal word provides important information

that is not safety related but should be

followed. The alert will highlight things that

may not be obvious and is useful to your

ef

ficient operation of the vehicle.

NOTE

Pumping the accelerator will not assist

in starting the engine.

Illustrations

Some of the illustrations throughout this

manual are generic and will NOT look

exactly like the engine or parts used in

your application. The illustrations can

contain symbols to indicate an action

required and\or an acceptable or NOT

acceptable condition.

The illustrations are intended to show

repair or replacement procedures. The

procedure will be the same for all

applications, although the illustration may

dif

fer.

SAFETY - Illustrations

6 Y53-1272-1B1 (08/17)

1

General Safety

Instructions

Important safety notices about operating

and servicing your engine.

WARNING

Improper practices, carelessness, or

ignoring

any warnings may cause

death, personal injury, equipment or

property damage.

Before performing any repair, read and

understand all of the safety precautions

and warnings. The following is a list of

general safety precautions that must be

followed to provide personal safety

. Failure

to follow these instructions may cause

death or injury. Special safety precautions

are included in the procedures when they

apply.

Keep in mind that even a well maintained

vehicle must be operated within the range

of its mechanical capabilities and the limits

of its load ratings. See the Weight Ratings

label on the driver's door edge.

Every new vehicle is designed to conform

to all Federal Motor Vehicle Safety

Standards applicable at the time of

manufacture. Even with these safety

features, continued safe and reliable

operation depends greatly upon regular

vehicle maintenance. Follow the

maintenance recommendations found in

Preventive Maintenance section. This will

help preserve your investment.

Make sure your vehicle is in top working

condition before heading out on the road, it

is the responsible driver's duty to do so.

Inspect the vehicle according to the

Driver's Check List.

•

Use the proper tool for manually

rotating the engine. DO NOT

attempt to rotate the crankshaft by

pulling or prying on the fan. This

practice can cause death, personal

injury, equipment damage, or

damage to the fan blades, causing

premature fan failure.

• Work areas should be dry, well lit,

well ventilated, free from clutter,

loose tools, parts, ignition sources

and hazardous substances.

• Wear protective glasses and

protective shoes when working.

• DO NOT wear loose-fitting or torn

clothing. Tie back and/or tuck in

long hair. Remove all jewelry when

working.

• Before beginning any repair,

disconnect the battery (negative [-]

cable) and discharge any

capacitors.

• Put a “DO NOT OPERATE” tag in

the operator's compartment or on

the controls.

• Allow the engine to cool before

slowly loosening the coolant filler

cap to relieve the pressure from the

cooling system.

WARNING

Removing the fill cap on a hot engine

can

cause scalding coolant to spray

out and burn you badly. If the engine

has been in operation within the previ-

ous 30 minutes, be very careful in re-

moving the fill cap. Protect face,

hands, and arms against escaping flu-

id and steam by covering the cap with

a large, thick rag. DO NOT try to re-

move it until the surge tank cools down

or if you see any steam or coolant es-

caping. In any situation, remove the

cap very slowly and carefully. Be ready

to back off if any steam or coolant be-

gins to escape.

SAFETY - General Safety Instructions

Y53-1272-1B1 (08/17) 7

1

• Always use wheel chocks or proper

jack stands to support the vehicle

or vehicle components before

performing any service work. DO

NOT work on anything that is

supported only by lifting jacks or a

hoist. Before resting a vehicle on

jack stands, be sure the stands are

rated for the load you will be

placing on them.

•

Before removing or disconnecting

any lines, fittings, or related items,

relieve all pressure in the air, oil,

fuel, and cooling systems. Remain

alert for possible pressure when

disconnecting any device from a

system that contains pressure.

High pressure oil or fuel can cause

death or personal injury.

• Always wear protective clothing

when working on any refrigerant

lines and make sure that the

workplace is well ventilated.

Inhalation of fumes can cause

death or personal injury. To protect

the environment, liquid refrigerant

systems must be properly emptied

and filled using equipment that

prevents the release of refrigerant

gas. Federal law requires capturing

and recycling refrigerant.

• When moving or lifting any heavy

equipment or parts, make sure to

use proper techniques and

assistance. Ensure all lifting

devices such as chains, hooks, or

slings are in good condition and

are of the correct load capacity.

Make sure all lifting devices are

positioned correctly.

• Corrosion inhibitors and lubricating

oils may contain alkali. DO NOT

get the substance in eyes and

avoid prolonged or repeated

contact with skin. DO NOT

swallow. If ingested, seek

immediate medical attention. DO

NOT induce vomiting. In case of

contact, immediately wash skin

with soap and water. In case of

harmful contact, immediately

contact a physician. Always keep

any chemicals OUT OF REACH

OF CHILDREN.

• Naptha and Methyl Ethyl Ketone

(MEK) are flammable materials and

must be used with caution. Follow

the manufacturer's instructions to

ensure safety when using these

materials. Always keep any

chemicals OUT OF REACH OF

CHILDREN.

• When working on the vehicle, be

alert for hot parts on systems that

have just been turned off, exhaust

gas flow, and hot fluids in lines,

tubes, and compartments. Contact

with any hot surface may cause

burns.

• Always use tools that are in good

condition. Make sure you have the

proper understanding of how to use

the tools before performing any

service work. Use only genuine

replacement parts from PACCAR.

• Always use the same fastener part

number (or equivalent) when

replacing items. DO NOT use a

fastener of lesser quality if

replacements are necessary. (e.g.,

Do not replace a 10.9 grade with

8.8 grade fastener.)

• Always torque fasteners and fuel

connections to the required

specifications. Overtightening or

under-tightening can allow leakage.

• Close the manual fuel valves prior

to performing maintenance and

repairs, and when storing the

vehicle inside.

• DO NOT perform any repair when

impaired, tired, fatigued or after

SAFETY - General Safety Instructions

8 Y53-1272-1B1 (08/17)

1

consuming alcohol or drugs that

can impair your functioning.

•

Some state and federal agencies in

the United States of America have

determined that used engine oil

can be carcinogenic and can cause

reproductive toxicity. Avoid

inhalation of vapors, ingestion, and

prolonged contact with used engine

oil.

• DO NOT connect the jump starting

or battery charging cables to any

ignition or governor control wiring.

This can cause electrical damage

to the ignition or governor.

• Coolant is toxic. If not reused,

dispose of coolant in accordance

with local environmental

regulations.

CAUTION

Corrosive chemicals can damage the

engine. DO NOT use corrosive chemi-

cals on the engine. Failure to comply

may result in equipment, or property

damage.

California Proposition 65 Warning

•

Diesel engine exhaust and some of

its constituents are known to the

State of California to cause cancer,

birth defects, and other

reproductive harm.

• The catalyst substrate located in

the Diesel Particulate Filter (DPF)

contains vanadium pentoxide,

which has been determined by the

State of California to cause cancer.

Always wear protective clothing

and eye protection when handling

the catalyst assembly. Dispose of

the catalyst in accordance with

local regulations. If catalyst

material gets into the eyes,

immediately flood eyes with water

for a minimum of 15 minutes. Avoid

prolonged contact with skin. In

case of contact, immediately wash

skin with soap and water. In case

of harmful contact, immediately

contact a physician.

• Other chemicals in this vehicle are

also known to the State of

California to cause cancer, birth

defects or other reproductive harm.

• Battery posts, terminals, and

related accessories contain lead

and lead compounds, chemicals

known to the State of California to

cause cancer and reproductive

harm. W

ash hands after handling.

Warnings and Cautions

A Special Word About

Repairs

WARNING

Do not attempt repair work without suf-

ficient

training, service manuals, and

the proper tools. You could be killed or

injured, or you could make your vehi-

cle unsafe. Do only those tasks you

are fully qualified to do.

SAFETY - Warnings and Cautions

Y53-1272-1B1 (08/17) 9

1

WARNING

Modifying your vehicle can make it un-

safe.

Some modifications can affect

your vehicle's electrical system, stabili-

ty, or other important functions. Before

modifying your vehicle, check with

your dealer to make sure it can be

done safely. Improper modifications

can cause death or personal injury.

CAUTION

The installation of electronic devices to

the

On Board Diagnostics (OBD) con-

nector, the vehicle Controller Area Net-

work (CAN), or their associated wiring

is not permitted. Doing so can ad-

versely affect vehicle performance

and/or cause fault codes to be record-

ed. The OBD connector is provided for

temporary connection of service tools

and for diagnostic purposes only.

Your dealer’s service center is the best

place to have your vehicle repaired. Y

ou

can find dealers all over the country with

the equipment and trained personnel to get

you back on the road quickly—and keep

you there.

Y

our vehicle is a complex machine.

Anyone attempting repairs on it needs

good mechanical training and the proper

tools. If you are sure you have these

requirements, then you can probably

perform some repairs yourself. However,

all warranty repairs must be performed by

an authorized service facility. If you aren’t

an experienced mechanic, or don’t have

the right equipment, please leave all

repairs to an authorized service facility.

They are the ones equipped to do the job

safely and correctly.

Maintenance Manuals

If you do decide to do any complex repair

work, you’ll need the maintenance

manuals. Order them from your authorized

dealer. Please provide your Chassis Serial

Number when you order, to be sure you

get the correct manuals for your vehicle.

Allow about four weeks for delivery. There

will be a charge for these manuals.

Final Chassis Bill of Material

A complete, non-illustrated computer

printout listing of the parts used to custom-

build your vehicle is available through the

dealer from whom you purchased your

vehicle.

SAFETY - A Special Word About Repairs

10 Y53-1272-1B1 (08/17)

1

SAFETY - A Special Word About Repairs

Y53-1272-1B1 (08/17) 11

1

Chapter 2 | DRIVING

In this Chapter:

Controls on the Right Hand of the Steering Column

...........................................................................13

Drive Neutral Reverse Selector...........................................................................................................13

Up or Down Shifting............................................................................................................................ 15

Engine Brake Operation for a Vehicle with Automated Transmission.................................................17

Using the Manual - Automatic Button..................................................................................................18

Start-Up and Power Down.................................................................................................................. 19

Transmission Power Take Off (PTO)...................................................................................................20

Snow/Ice Operation.............................................................................................................................21

Trailer Operation................................................................................................................................. 21

Features..............................................................................................................................................21

DRIVING -

12 Y53-1272-1B1 (08/17)

2

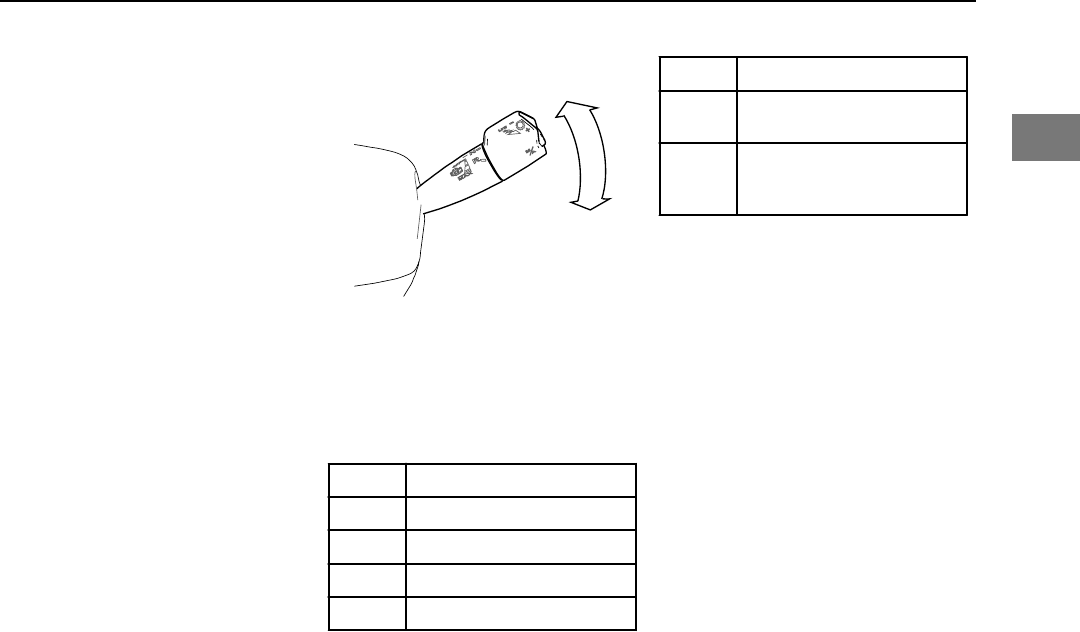

Controls on the Right

Hand of the Steering

Column

This vehicle may be equiped with the

PACCAR Transmission. The lever on the

right hand side of the steering column will

operate the transmission functions in

addition to operating the engine brake.

1 Transmission D - N

- R Function

2 Up (+) and Down (-) Shift and Low Mode

3 Engine Brake and Max Mode

4 Manual (M) / Automatic (A) Mode Button

Related concepts

Related tasks

Drive Neutral Reverse

Selector

Transmission mode is selected by rotating

the lever's outer knob. There is a detent for

Drive, Neutral, Reverse.

The instrument cluster will display the

corresponding mode.

For Kenworth Vehicles

For Peterbilt Vehicles

DRIVING - Controls on the Right Hand of the Steering Column

Y53-1272-1B1 (08/17) 13

2

NOTE

Selector (the transmission) must be in

N

(Neutral) to start the truck.

Neutral Mode

•

Selects Neutral.

• Initial Gear position after Start-Up.

WARNING

Apply parking brake and follow vehicle

manufacturer parking instructions. Fail-

ure to follow these instructions could

cause unintended vehicle movement re-

sulting in death, serious injury or dam-

age to property

.

NOTE

When attempting to start the engine and

the engine does not crank, confirm Neu-

tral is selected, vehicle parking brake is

applied and service brake is depressed.

Reverse Mode

•

Reverse mode selects the default

Reverse gear.

NOTE

If the driver attempts to select a non-

neutral mode without depressing the

service brakes the transmission will not

shift into gear and you will have to return

to Neutral and depress the service

brakes before selecting the desired

mode again.

• Each time Reverse is selected from

Neutral, the default Reverse gear is

engaged.

Drive Mode (Auto Mode)

•

Intelligent Start Gear Selection will

automatically select the start gear

depending on inputs such as, load,

grade, and axle/transmission ratio.

This start gear can be changed by

using the up/downshift request

procedure, as long as the selection

still falls into a gear that would

allow the vehicle to launch without

causing damage to the

transmission.

NOTE

If the driver attempts to select a non-

neutral mode without depressing the

service brakes the transmission will not

shift into gear

. The driver must re-select

Neutral and depress the service brakes

before selecting the desired mode

again.

• If the start gear is changed using

the up/downshift request

procedure, it will remain as the

default until the vehicle is powered

down or the selection is changed.

However

, conditions such as,

grade, may still override the default

start gear selection.

• A shift can be advanced by using

the up/downshift request procedure

when the transmission is near the

shift point.

DRIVING - Drive Neutral Reverse Selector

14 Y53-1272-1B1 (08/17)

2

NOTE

Multiple gear upshifts and downshifts

may be allowed when the up/downshift

request procedure is performed multiple

times (Each request equals one gear

change request).

• The transmission may also deny a

shift while ascending or

descending grades if the load of

the vehicle and grade of the terrain

in combination with the drivetrain

ratio and engine torque will fall

outside of the acceptable range to

perform a shift. If the shift is denied

it will sound a tone.

Up or Down Shifting

When in the Manual mode, the

transmission gears can be manually

selected by pushing or pulling on the lever

.

Pushing the lever forward will down shift.

Pushing and holding the lever forward will

engage the LOW gear range. Pulling the

lever towards the driver will upshift the

transmission.

Some vehicles may have a feature that

prompts the operator to shift for optimal

fuel economy.

For Kenworth Vehicle with Shift Assist

For Peterbilt Vehicles with Shift Assist

If the prompt appears in the instrument

cluster

, use the manual gear selector lever

to change gears.

DRIVING - Up or Down Shifting

Y53-1272-1B1 (08/17) 15

2

The instument cluster will illuminate with

the corresponding gear

.

Gear Display

LOW Mode

LOW mode should be used any time you

want to maximize engine braking and

minimize the use of the brake pedal. For

example, when driving down long grades

or when coming to a stop.

•

Selects lowest available gear for

start gear. The starting gear cannot

be changed in LOW mode.

NOTE

If the driver attempts to select a non-

neutral mode without depressing the

service brakes the transmission will not

shift into gear

. The driver must re-select

Neutral and depress the service brakes

before selecting the desired mode

again.

• If LOW is selected while moving,

the transmission will not upshift

(except for the T

ransmission

Override conditions noted on the

previous page). The transmission

system will downshift at the earliest

opportunity to enable higher than

normal engine RPM to provide

maximum engine braking.

WARNING

On slippery surfaces minimize engine

braking in LOW mode. Excessive en-

gine braking at higher engine RPM

could cause a loss of traction and vehi-

cle control.

NOTE

The PACCAR Automated Transmission

initiates upshifts from MANUAL and

LOW for engine overspeed protection.

How to Deactivate MAX Mode

V

ehicles with automated transmissions will

have the engine brake function integrated

with the transmission controls. Follow

these steps to deactivate MAX engine

brake mode.

1. Accelerate with the throttle pedal.

2. Upshift, see Up or Down Shifting

on page 15.

3. Wait for the transmission coast

down gear to engage.

DRIVING - Up or Down Shifting

16 Y53-1272-1B1 (08/17)

2

4. Reduce engine brake level, see

Engine Brake Operation for a

V

ehicle with Automated

Transmission on page 17.

5. Re-initiate MAX mode, see Engine

Brake Operation for a Vehicle with

Automated Transmission on page

17.

6. Select Neutral N, see Drive Neutral

Reverse Selector on page 13.

7. Select LOW mode, see Engine

Brake Operation for a Vehicle with

Automated Transmission on page

17.

Engine Brake Operation

for a Vehicle with

Automated Transmission

Moving the lever clockwise will engage the

engine brake. Increase the amount of

engine brake by moving the lever further

clockwise. Each position has a

corresponding level of engine brake.

Position Amount of Engine Brake

Off 0 %

1 33%

2 66%

3 100%

Position Amount of Engine Brake

4* 100% AND will engage

transmission low gear

* This position is momentary

and will revert back to position

3 when the lever is released.

The corresponding engine brake level (or

MAX mode) will be illuminated in the

instrument cluster

.

DRIVING - Engine Brake Operation for a Vehicle with Automated Transmission

Y53-1272-1B1 (08/17) 17

2

Related tasks

Using the Manual -

Automatic Button

This button will put the transmission into

manual mode. Manual mode will allow the

operator to select the gear

. See Up or

Down Shifting on page 15.

To activate, put the gear selector in the D

(drive) mode and then depress the M/A

button. The instrument cluster will display

the corresponding selection.

For Peterbilt Vehicles

For Kenworth Vehicles

MANUAL Mode

MANUAL mode should be used whenever

the driver wants to select the shifts instead

of letting the transmission select them

automatically

.

• Driver manually selects the start

gear and uses the up/downshift

request to shift.

NOTE

Multiple gear upshifts and downshifts

may

be allowed when the up/downshift

request procedure is performed multi-

ple times (Each request equals one

gear change request).

• If the driver attempts to select a

non-neutral mode without

depressing the service brakes the

transmission will not shift into gear

.

The driver must re-select Neutral

and depress the service brakes

before selecting the desired mode

again.

• System holds current gear unless

otherwise prompted by using up/

downshift request, except for the

“Transmission Manual Override”

conditions noted below.

DRIVING - Using the Manual - Automatic Button

18 Y53-1272-1B1 (08/17)

2

NOTE

For optimal vehicle performance, it is

recommended

the vehicle be operated

in “D” Drive mode.

Transmission Manual Override

If the vehicle is being back-driven and the

engine is approaching a higher than

normal RPM level, the transmission system

will override the MANUAL position and

perform an upshift.

NOTE

The transmission initiates upshifts

from

MANUAL and LOW for engine

overspeed protection.

If the start gear is changed and it causes

the engine to lug at takeof

f, the

transmission system will override the

MANUAL position and select the best

available gear.

Start-Up and Power Down

Start-Up

1.

Ensure N, Neutral, is selected on

the Transmission Driver Interface

Device.

NOTE

The transmission will not allow the en-

gine

to crank if a mode other than

Neutral is selected, on Transmission

Driver Interface Device, when attempt-

ing to start the engine.

2. Turn the ignition key to “ON” and

allow the P

ACCAR Automated

Transmission to power-up.

NOTE

Engine cranking is delayed until the

transmission

power-up is complete

and the gear display shows a solid N.

If Neutral, N, is not shown in the gear

display, ensure that the vehicle air sys-

tem is at normal operating range be-

fore attempting to start the vehicle.

3. Start the engine.

4.

Allow vehicle air system pressure

to build to normal operating range.

5. Apply service brake.

NOTE

If the service brake is not applied while

selecting

a starting gear, the initial

start gear will not be engaged and the

driver will have to reselect Neutral and

press the brake while re-selecting the

desired mode.

6. Select the desired mode and

starting gear on the T

ransmission

Driver Interface Device.

NOTE

The transmission will override inappro-

priate

start gear selections to avoid

driveline damage.

7. Release the vehicle parking

brakes.

8.

Release service brake and Urge to

Move will allow the vehicle to

DRIVING - Start-Up and Power Down

Y53-1272-1B1 (08/17) 19

2

automatically launch and creep at

constant engine idle.

•

Upshifts and downshifts can be

made while at constant engine

idle by utilizing the up/downshift

request procedure. The

transmission may deny a shift

and sound a tone if the load of

the vehicle or grade of the

terrain falls outside the

acceptable range to perform a

shift.

Power Down

1. Select N Neutral on the

Transmission Driver Interface

Device.

• If gear display does not show

solidN , neutral has not yet

been obtained.

NOTE

Neutral should always be reached be-

fore

initiating power down, except in

cases of emergency.

2. Set the vehicle parking brakes.

WARNING

Apply parking brake and follow vehicle

manufacturer

parking instructions.

Failure to follow these instructions

could cause unintended vehicle move-

ment resulting in death, serious injury

or damage to property.

3. Turn ignition key to OFF and allow

the engine to shut down.

T

ransmission Power Take

Off (PTO)

The transmission may have a PTO

installed. Engaging the PTO differs if it is

operating in either a mobile or a stationary

application.

Stationary PTO Operation

The transmission countershaft PTO is used

in this application. To engage the PTO for

stationary operation, perform the following

steps:

1. Bring the vehicle to a complete

stop and apply the parking brake.

WARNING

Apply parking brake and follow vehicle

manufacturer parking instructions. Fail-

ure to follow these instructions could

cause unintended vehicle movement re-

sulting in death, serious injury or dam-

age to property

.

2. Select “N” on the Transmission

Driver Interface Device.

3.

Select the transmission PTO

switch.

4. Raise engine speed as required to

operate PTO.

NOTE

Use the transmission PTO switch to dis-

engage the PT

O.

Mobile PTO Operation

The transmission countershaft PT

O is used

in this application and provides limited

mobile operation in the start gears. To

engage the PTO for mobile operation,

perform the following steps:

DRIVING - Transmission Power Take Off (PTO)

20 Y53-1272-1B1 (08/17)

2

1. Bring the vehicle to a complete

stop and depress the service

brake.

2.

Select “N” on the Transmission

Driver Interface Device.

3. Select the transmission PTO

switch.

4. Select “Drive” or "Reverse" as

required for vehicle movement.

5. Release the service brake to

engage the clutch and the PTO.

6. Raise engine speed as required to

operate PTO.

NOTE

Use the transmission PTO switch to

disengage the PT

O.

Snow/Ice Operation

The P

ACCAR Automated Transmission is

designed to work in coordination with the

ATC system to ensure optimal operation.

However, if the driver observes low friction

road conditions (snow, rain, ice, etc.) and

does not want the transmission to shift,

risking wheel slippage, the driver should

select MANUAL mode. MANUAL mode

holds the current gear position under most

operating conditions- the transmission will

only shift when the driver uses the up/

downshift request. Once road conditions

improve, the driver should revert back to

Drive mode.

T

railer Operation

Trailer Connecting

• Prior to backing under the trailer,

ensure proper trailer height.

• Use Low mode (1st gear) for

forward direction and Reverse (R1)

for reverse direction.

Sliding Trailer Axle

• Ensure axle rails and locks are

properly maintained.

• Follow proper procedure for

unlocking and sliding the trailer

axles.

• Use Low mode (1st gear) for

forward direction and Reverse (R1)

for reverse direction.

• Avoid repeat attempts if the sliding

axle is not moving.

NOTE

If repeat attempts are made and the au-

tomated clutch starts to overheat, the

display will indicate “CA” along with a

warning tone.

Features

Hill Start Aid Operation (HSA)

Hill Start Aid defaults to the “On” position.

In P

ACCAR Automated Transmissions, it

can be turned “Off” by pressing and

releasing the Hill Start Aid switch, however,

it will turn back on after the first successful

launch. If the switch is turned off, the lamp

in the Hill Start switch will flash.

The grade at which Hill Start Aid is active is

defaulted to 1% but can be configured to

activate on a 2% or 3% grade.

Vehicle Facing Uphill – Forward

Mode

DRIVING - Snow/Ice Operation

Y53-1272-1B1 (08/17) 21

2

1. Vehicle must be on incline greater

than 1% and in a forward mode.

2.

Bring vehicle to a stop and depress

the service brakes then release the

service brakes to launch the

vehicle.

WARNING

Apply the vehicle service brakes or

launch the vehicle using the accelerator

pedal after Hill Start Aid releases. Fail-

ure to do so could result in unintended

vehicle movement resulting in death, se-

rious injury or damage to property

.

Vehicle Facing Downhill - Reverse

Mode

1. Vehicle must be on a decline

greater than 1% and in Reverse

mode.

2. Bring vehicle to a stop and depress

the service brakes then release the

service brakes to launch the

vehicle.

WARNING

Apply the vehicle service brakes or

launch the vehicle using the accelerator

pedal after Hill Start Aid releases. Fail-

ure to do so could result in unintended

vehicle movement resulting in death, se-

rious injury or damage to property

.

Clutch Abuse Protection

CAUTION

The PACCAR Automated Transmis-

sion

clutch can overheat and slip with

improper use.

• DO select the lowest possible start

gear for the application. If moving

slowly is required, select 1st or R1.

•

DO use the Service Brakes and let

Hill Start Aid assist you when

launching on an incline.

• Do NOT use the accelerator pedal

to hold the vehicle on an incline.

(Use Service Brakes).

• Do NOT use the accelerator pedal

to stop roll back on an incline after

Hill Start Aid disengages. (Use

Service Brakes and then relaunch).

•

If the PACCAR Automated

Transmission clutch does start to

overheat, the display will show

“CA” along with a warning tone. If

“CA” is active in the gear display,

immediately discontinue the

operation that is being performed

which is causing the clutch to

overheat.

• If the driver continues abusive

operation, the system will either

open the clutch if the

accelerator pedal is not applied

or close the clutch if the

accelerator pedal is applied.

• If the abuse continues, the

system will open the clutch and

take away accelerator pedal

control for a short period of time

to allow the clutch to cool down.

Urge to Move may be

inoperable when the clutch is

overheated.

Engine Overspeed Protection

• The transmission system will

upshift if necessary to prevent

DRIVING - Features

22 Y53-1272-1B1 (08/17)

2

engine overspeed in Drive,

MANUAL and LOW modes.

Shuttle Shifting

•

Shuttle shifting from Reverse to

any forward mode is only allowed if

the vehicle speed is approximately

zero.

Intelligent Start Gear Selection

• Intelligent Start Gear Selection will

automatically select the start gear

depending on inputs such as load,

grade and axle/transmission ratio.

• The start gear selection can be

changed using the up/downshift

request, however, if the selection

requested could cause damage or

engine lugging the request will be

denied and an audible tone will

sound.

Skip Shifting

• The Automated Transmission will

shift multiple gears at one time

(skip shift) with moderate to high

accelerator pedal input while in

Drive mode, up to 8th gear.

Auto Neutral

•

The transmission system will

automatically shift to neutral if the

vehicle is left in Drive and the

parking brakes are set.

• “AN” will appear in the gear display.

The driver must then select the

desired forward or reverse mode

with the service brake applied.

Load Based Shifting

• The transmission system will adapt

to the conditions of the vehicle to

change the shift points based on

the followings inputs:

• Vehicle grade

• Engine RPM

• Accelerator pedal position

• Vehicle load

• After changing loads or powering

up the transmission system needs

to relearn these inputs for the first

few shifts to make the proper

adjustments.

Coast Mode

• When coasting to a stop, in Drive

mode, on level terrain the

transmission system may not

downshift into lower gears. This

allows the transmission to coast to

a stop.

Cruise Control

•

This transmission system is

compatible with cruise control.

Neutral Coast Mode

Neutral Coast Mode allows the

transmission to disengage the driveline by

pulling out of gear on slight downhill

grades, where little to no engine power is

required, when the vehicle is in cruise

control and the transmission is in Drive

mode.

• When Neutral Coast Mode is

active, the engine will drop to idle

speed and the transmission will

disengage.

• The gear display may flash a gear

number or indicate Neutral when

Neutral Coast Mode is active,

depending upon specific OEM

implementation.

• If a flashing number is indicated in

the gear display, this represents the

gear that the transmission will

DRIVING - Features

Y53-1272-1B1 (08/17) 23

2

select when it is necessary to

engage a gear

.

• The transmission will exit Neutral

Coast Mode and reengage an

appropriate gear under any of the

following conditions:

• Vehicle brakes are applied

• Driver depresses accelerator

pedal

• Cruise control is canceled

• A mode other than Drive is

selected

• Driver performs up/downshift

requests

• Cruise high or low set speeds

are exceeded

• Maximum vehicle grade is

exceeded

• Request by an adaptive cruise

system

• Various brand names may be used

for Neutral Coast systems.

Urge to Move

Urge to Move allows the vehicle to

automatically start moving when the

transmission is in gear and the driver

releases the service brake. After the

vehicle has launched the vehicle will creep

at a constant speed at engine idle without

the need to apply the accelerator pedal.

The configuration is useful for stop and go

applications allowing the vehicle to launch

and creep without applying the accelerator.

Creep Mode

Creep allows the vehicle to be driven at a

constant speed at engine idle without the

need to apply the accelerator pedal. The

configuration is useful for slow speed

applications where steady vehicle speed is

required. Upshifts and downshifts can be

requested to increase or decrease vehicle

speed.

DRIVING - Features

24 Y53-1272-1B1 (08/17)

2

DRIVING - Features

Y53-1272-1B1 (08/17) 25

2

Chapter 3 | MAINTENANCE

In this Chapter:

What is a Maintenance Program?

.......................................................................................................27

What is the Air System?......................................................................................................................29

Air Dryer Maintenance........................................................................................................................ 32

Proper Transmission Lubrication.........................................................................................................32

Vehicle Towing.................................................................................................................................... 33

How to Drain Fluid...............................................................................................................................33

How to Fill Fluid...................................................................................................................................34

Troubleshooting...................................................................................................................................34

MAINTENANCE -

26 Y53-1272-1B1 (08/17)

3

What is a Maintenance

Program?

Preventive maintenance program begins

with the daily checks. Routine vehicle

checks can help avoid many large,

expensive, and time consuming repairs.

The vehicle will operate better, be safer,

and last longer. Neglect of recommended

maintenance can void your vehicle’s

warranty. Some maintenance operations

demand skills and equipment you may not

have. For such situations, please take your

vehicle to an authorized Service Center.

WARNING

Always support the vehicle with appro-

priate safety stands if it is necessary to

work underneath the vehicle. A jack is

not adequate for this purpose. Failure

to comply may result in death, person-

al injury, equipment or property dam-

age.

WARNING

When working underneath the vehicle

without

appropriate safety stands but

with the wheels on the ground (not

supported), make sure that (1) the ve-

hicle is on hard level ground, (2) the

parking brake is applied, (3) all wheels

are blocked (front and rear) and (4) re-

move the ignition key so that the en-

gine cannot be started. Failure to com-

ply may result in death, personal in-

jury, equipment or property damage.

The following pages contain a table of

maintenance tasks with the related

intervals for each task on the right side of

the table. The top of the table displays a

guide to a maintenance interval and its

schedule. Some tasks are dependent on

the vehicle application. These tasks will be

shown as separate tasks and will have the

words “ON HIGHWAY”, “CITY DELIVERY”

or “OFF-HIGHW

AY” after the description.

These tasks are differentiated because

they are dependent on the vehicle’s

operating environment. On highway is

defined for applications where the vehicle

is NOT used off of a paved road during

normal operation. City Delivery is defined

for applications where frequent start and

stopping is required during normal

operation and the highway is used

infrequently and for short periods of time.

Off highway is defined for applications

where the vehicle may be driven off the

pavement on a regular basis, even if it is

an infrequent basis and/or for a brief time

period. Please contact an authorized

service dealership if there are questions

regarding which interval to follow. Consult

the supplier for specific recommendations

where discrepancies develop between

these recommendations in this table and

component supplier recommendations.

PACCAR Transmission

Maintenance Schedule

MAINTENANCE - What is a Maintenance Program?

Y53-1272-1B1 (08/17) 27

3

I A B C D E

At first 15,000 mi/

24,000 km or at first

PM

15,000 mi/24,000

km/Monthly

30,000 mi/48,000

km

60,000 mi/96,000

km/ 6 Months

120,000 mi/ 192,000

km/ Annually

240,000 mi/ 384,000

km

System Component Task I A B C D E

Air Air Compressor Governor Replace air strainer. •

Air Lines Check condition and routing to prevent

chafing.

•

System Lubricate; see What is the Air System?

on page

29.

•

Inline Filters Replace elements or clean with solvent. •

Air Dryer Perform the checks listed. •

Air Dryer (Oil-Coalescing Desiccant

Cartridge)

Replace Cartridge

Annually regardless of mileage

MAINTENANCE - What is a Maintenance Program?

28 Y53-1272-1B1 (08/17)

3

System Component Task I A B C D E

Main and

Auxiliary

T

ransmission

Main and Auxiliary Transmission and

Transfer Case

Inspect for visible damage, signs of

overheating, and leaks.

• •

Check the drain plugs for tightness. •

Mounting Brackets and Fasteners Check the condition of the fasteners and

their torque. Tighten to the specified

torque value as required.

•

Oil Cooler Clean the fins (air-to-oil type) and body.

Check the hose condition and for leaks:

replace as required.

•

Main and Auxiliary Transmission Check the oil level: refill as required. •

Main and Auxiliary Transmission (ON

HIGHWAY)

Drain lubricant while warm. Flush each

unit with clean flushing oil.

500,000 miles/ 800,000 km

Main and Auxiliary Transmission (OFF

HIGHWAY)

Drain lubricant while warm. Flush each

unit with clean flushing oil.

• •

Related concepts

Related reference

What is the Air System?

Important safety information about your

vehicle's air system.

The operation of the vehicle’s braking

system and many vehicle accessories

depends upon the storage and application

of a high-pressure air supply

.

MAINTENANCE - What is the Air System?

Y53-1272-1B1 (08/17) 29

3

WARNING

Do not attempt to modify, alter, repair

or disconnect any component of the air

system. Repairs or modifications to the

air

system, other than what is descri-

bed in this section, should only be per-

formed by an authorized dealer. Fail-

ure to comply may result in death or

personal injury.

WARNING

Prior to the removal of any air system

component,

always block and hold the

vehicle by a secure means other than

the vehicle's own brakes. Depleting air

system pressure may cause the vehi-

cle to roll unexpectedly resulting in an

accident causing death or personal in-

juries. Keep hands away from cham-

ber push rods and slack adjusters,

they may apply as system pressure

drops.

WARNING

After completing any repairs to the air

system,

always test for air leaks, and

check the brakes for safe operation

before putting the vehicle in service.

Failure to comply may result in death,

personal injury, equipment or property

damage.

WARNING

Never connect or disconnect a hose or

line

containing air pressure. It may

whip as air escapes. Never remove a

component or pipe plug unless you are

certain all system pressure has been

depleted. Failure to comply may result

in death, personal injury, equipment or

property damage.

WARNING

Never exceed recommended air pres-

sure

and always wear safety glasses

when working with air pressure. Never

look into air jets or direct them at any-

one. Failure to comply may result in

death,

personal injury, equipment or

property damage.

WARNING

Never attempt to disassemble a com-

ponent

until you have read and under-

stood recommended procedures.

Some components contain powerful

springs and injury can result if not

properly disassembled. Use only prop-

er tools and observe all precautions

pertaining to use of those tools. Failure

to comply may result in death, person-

al injury, equipment or property dam-

age.

MAINTENANCE - What is the Air System?

30 Y53-1272-1B1 (08/17)

3

WARNING

Completely bypassing a Bendix®

ADIS

air dryer will bypass the system’s

pressure protection valves. This could

lead to loss of air pressure or damage

to the vehicle’s air system, which could

cause an accident involving death or

personal injury. Always adhere to the

manufacturer’s procedure if it is nec-

essary in an emergency to temporarily

bypass an ADIS series air dryer. Fail-

ure to comply may result in death, per-

sonal injury, equipment or property

damage.

WARNING

If a different air dryer brand or model is

installed

on the vehicle other than

what was originally installed, it could

cause the air system to not perform

correctly unless the full air system de-

sign is reviewed and modifications

made to comply with Federal Motor

Vehicle Safety Standards (FMVSS)

121 AirBrake Systems. Failure to

abide by this warning and maintain

compliance to FMVSS 121 could

cause

loss of vehicle control and may

lead to death or serious personal in-

jury.

WARNING

If the supply and service air tanks are

not

drained at the recommended fre-

quency, water could enter the air lines

and valves. This could cause corrosion

or blockage, which could compromise

the brake system safety and potential-

ly cause an accident. Failure to comply

may result in death, personal injury,

equipment or property damage.

Your vehicle’s compressor takes outside air

and compresses it, usually to 100-120 psi

(689-827 kPa). The compressed air then

goes to the reservoirs to be stored until

needed. When you operate your air

brakes, the stored compressed air flows

into the chambers where it is used to apply

your truck and trailer brakes. That is why

,

when you push down on your brake pedal,

you don’t feel the same amount of

pressure on the pedal that you do when

you apply the brakes on your car. All you

are doing on your truck is opening an air

valve to allow air to flow into the brake

chambers. Contamination of the air supply

system is the major cause of problems in

air-operated components such as brake

valves, and suspension height control

valves. T

o keep contaminants to the lowest

possible level, follow these maintenance

procedures.

Daily Checks

• Drain moisture from the supply and

service air tanks.

• Operate air devices to circulate

lubricants within the unit.

Periodically

• Clean filter screens ahead of the

valves by removing the screens

and soaking them in solvent. Blow

them dry with pressurized air

before reinstalling them.

Twice a Year

• Maintain the air compressor to

prevent excessive oil by-pass. See

your maintenance manual for

details.

• Replace worn seals in valves and

air motors as they are needed.

MAINTENANCE - What is the Air System?

Y53-1272-1B1 (08/17) 31

3

Air Dryer Maintenance

Vehicles equiped with a PACCAR

Transmission will have an air dryer fitted

with an oil-coalescing desiccant cartride.

This air dryer cartridge must be replaced

every 1 year regardless of mileage.

CAUTION

Replace oil-coalescing desiccant air

dryer

cartridge every 1 year regardless

of mileage. Only use oil-coalescing

desiccant replacement cartridge when

replacing. Failure to perform this main-

tenance task will void the PACCAR

Transmission warranty and may result

in expensive transmission damage.

Proper Transmission

Lubrication

Proper lubrication procedures are key to a

good all-around maintenance program. If

the lubricant is not doing its job or if the

lubricant level is ignored, all other

maintenance procedures are not going to

keep the transmission running or assure

long transmission life.

T

ransmission internal parts are amply

lubricated if these procedures are closely

followed:

1. Maintain lubricant level and inspect

regularly.

2. Follow maintenance intervals, see

Transmission Lubrication Change

Intervals on page 33.

3. Use the correct grade and type of

lubricant, see PACCAR

Transmission Lube Specification on

page 37.

4. Buy lubricant from an approved

dealer.

Mixing of Oil Types

CAUTION

Do not mix engine and gear oil in the

same transmission. Mixing engine and

gear oils could cause damage to the

transmission.

Engine oils and gear oils may not be

compatible; mixing can cause breakdown

of the lubricant and affect component

performance. When switching between

types of lubricants, all areas of each

af

fected component must be thoroughly

flushed.

NOTE

For a list of Approved Synthetic Lubri-

cants, see vehicle operator manual.

NOTE

Additives and friction modifiers must not

be introduced.

Proper Transmission Lubrication

Level

Make sure the transmission lubricant is

level with the bottom of the fill opening.

Being able to reach the lubricant with your

finger does not mean the lubricant is at the

proper level.

MAINTENANCE - Air Dryer Maintenance

32 Y53-1272-1B1 (08/17)

3

NOTE

Before checking the oil level, the en-

gine

must be idling and the transmis-

sion in neutral for at least 2 minutes.

Lubricant temperature must be be-

tween 60 °F and 120 °F (15.5 °C and

48.8 °C).

If the transmission operating angle is more

than 12° (or roughly a 21% grade),

improper lubrication will occur

. The

operating angle is the transmission

mounting angle in the chassis plus the

percent of upgrade (expressed in degrees).

T

ransmission Lubrication Change

Intervals

Lubricant changes should be based on a

combination of the intervals shown in

vehicle operator manual Lubrication

Specification Manual, and user judgment

based on the application and operating

environment. Extending drain intervals

beyond those shown in the tables is not

recommended and will put warranties at

risk.

Inspect the transmission exterior for leaks.

Look around the oil filter and exterior seals

for damage and replace as necessary.

On-Highway

Check fluid levels and inspect for leaks at

regular PM maintenance intervals, not to

exceed 12,000miles. Drain and replace

lubricant every 500,000 miles / 800,000

km.

Off-Highway

Check fluid levels and inspect for leaks

every week. Drain and replace lubricant

interval should not exceed 60,000 mi /

96,000 km / 6 Months.

Vehicle Towing

When towing the vehicle, the output shaft

of the transmission must not be allowed to

spin or turn. If the vehicle is towed with the

drive wheels still in contact with the road

surface, the vehicle axle shafts or driveline

must be removed or disconnected.

CAUTION

Always follow proper manufacturer

towing procedures. Failure to follow

proper towing procedures could result

in damage to the transmission.

How to Drain Fluid

1.

Use a drain pan under the

transmission drain plug to collect

oil from the bottom of the

transmission.

MAINTENANCE - Vehicle Towing

Y53-1272-1B1 (08/17) 33

3

2. Make sure the oil temperature is

cool.

3.

Clean around drain plug and

remove plug.

4. Allow transmission oil to drain out.

5. Clean drain plug and torque as

required.

How to Fill Fluid

1. Remove transmission oil fill plug.

2. Make sure drain plug is properly

installed.

3. Fill with approved oil until the oil

starts flowing out the fill hole.

4. Clean, install, and properly and

torque fill plug.

Troubleshooting

Diagnostics

In the event there is a problem with an

Automated Transmission, there are three

primary tasks the driver should perform:

1. Note the driving condition under

which the problem occurred.

2. Note the condition of the

transmission under which the

problem occurred (i.e. operation

mode (Drive, MANUAL, LOW),

current gear, engine speed, etc.).

3. Reset system.

Transmission Reset Procedure

In some cases, proper transmission

operation can be restored by “resetting” the

Transmission Control Module (TCM). Use

the following procedure to reset the TCM.

1. Continue to drive the vehicle to a

safe location before selecting “N”

NEUTRAL.

NOTE

Once “N” NEUTRAL is selected, a gear

engagement may not be allowed de-

pending on the nature of the problem.

2. Place the Transmission Driver

Interface Device in Neutral “N”.

3.

Set the vehicle parking brake.

WARNING

Apply parking brake and follow vehicle

manufacturer parking instructions. Fail-

ure to follow these instructions could

cause unintended vehicle movement re-

sulting in death, serious injury or dam-

age to property

.

4. Turn the vehicle ignition to the “off”

position.

5.

Wait at least 2 minutes.

6. Restart the engine.

7. If the problem continues, contact a

service facility to have the vehicle

and transmission system

evaluated.

Transmission Air Supply

For optimal performance, the PACCAR

Automated Transmission requires a

nominal air supply operating range

between 90 psi (5.9 bar) and 130 psi (9.0

bar).

MAINTENANCE - How to Fill Fluid

34 Y53-1272-1B1 (08/17)

3

WARNING

Maintain specified transmission air sys-

tem pressure range between 90 psi (5.9

bar) and 130 psi (9.0 bar). Failure to

maintain proper air system pressure

could result in degraded or complete

loss of transmission engagement and

shift capabilities resulting in death, seri-

ous injury or damage to property

.

Roadside Assistance

What to do in an emergency and roadside

assistance information.

Call toll-free to talk to someone at the

PACCAR Customer Center:

• Kenworth customers call: 1-800-

KW-Assist (1-800-592-7747) |

Peterbilt customers call:

1-800-4Peterbilt (800-473-8372)

• Open 24-7-365 days a year.

• They can help you get roadside

assistance.

• They have a custom mapping

system which locates authorized

PACCAR engine dealers and

Independent Service Providers

(ISPs) near you and lists types of

services of

fered, hours of operation

and contact information.

• They can assist with jump and pull

starts, tires, trailers, fines and

permits, chains, towing, hazardous

clean-up, out of fuel (roadside),

mechanical repairs and preventive

maintenance services.

• They have multilingual agents and

access to a translation service to

ensure quality assistance for

customers in any language.

• They can’t answer your warranty

questions, but can get you in

contact with an authorized dealer

who can.

• The PACCAR Customer Center

service is FREE.

MAINTENANCE - Troubleshooting

Y53-1272-1B1 (08/17) 35

3

Chapter 4 | INFORMATION

In this Chapter:

General Model Information

..................................................................................................................37

PACCAR Transmission Lubricant Capacities......................................................................................37

PACCAR Transmission Lube Specification.........................................................................................37

INFORMATION -

36 Y53-1272-1B1 (08/17)

4

General Model Information

Nomenclature

Following is a nomenclature tree that

describes the multiple configurations of the

transmission model numbers:

1 PACCAR Transmission

2 Overdrive

3 Torque Capacity (ft-lb) # x 100 +50

4 Design Level

5 Forward Speeds

6 Ratio Set

Transmission Identification

Nomenclature

The blank spaces provided below are for

recording transmission identification data

and part numbers of maintenance items.

All transmissions are identified by the

model and serial number

. This information

is stamped on the transmission

identification tag and affixed to the case.

NOTE

Do not remove or destroy the trans-

mission identification tag.

The blank spaces provided below are for

recording transmission identification data.

Have these reference numbers handy

when ordering replacement parts or

requesting service information:

Transmissio

n Model

Transmisiso

n Serial

Number

PACCAR Transmission

Lubricant Capacities

T

ransmissions equipped with Power Take

Off (PTO) or oil coolers are great than the

capacities listed here. These values are

approximate. Always use the fill hole as a

finale reference.

Pints (US) Liters

16 7.5

PACCAR Transmission

Lube Specification

PACCAR approves the PACCAR Genuine

PS-386 (Eaton approved) synthetic

transmission fluid to ensure the highest

performing lubricants for maximum

performance. All other approved

INFORMATION - General Model Information

Y53-1272-1B1 (08/17) 37

4

rebranders for PS-386 are also acceptable.

INFORMATION - PACCAR Transmission Lube Specification

38 Y53-1272-1B1 (08/17)

4

INFORMATION - PACCAR Transmission Lube Specification

Y53-1272-1B1 (08/17) 39

4

Index

A

Air Dryer Maintenance 32

C

Column Mounted Transmission Control 13, 15, 18

E

Engine Brake 13

Engine Brake Column Mounted Transmission Control 17

Engine Brake PACCAR Transmission 17

F

Fluid Level 32

G

Gear Display 16

General Safety Instructions 7

I

Illustrations 6

L

LOW Mode 16

Lube Interval

33

Lube Specification 37

M

Maintenance Schedule 27

Manual Mode 18

O

Override 19

P

PACCAR AMT 13

PACCAR AMT Shifting gears 15

PACCAR Transmission 27, 33

PACCAR Transmission Controls 13

PACCAR Transmission Lubrication Specification 37

PACCAR TransmissionAir Dryer 32

PACCAR TransmissionDrain Fluid 33

PACCAR TransmissionFill Fluid 34

Power Down 20

Index

x 1518

vue

A 98009

PACRI

P.O

. Bo

x 1518

Bellevue

, W

A 98009

Powertrain

Y53-1272-1B1