Owner's Manual

12 in. COMPOUND

MITER SAW

Double Insulated

Model No.

315.212120

Save this manual for

future reference.

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-557

9-98

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

NRT_C

• Table ofContents........................................................................................................................................... 2

• Warranty and Introduction........................................................... _.................................................................. 2

• Rules ForSafe Operation ........................................................................................................................... 3-6

• Glossary ......................................................................................................................................................... 6

• ProductSpecificationsand Unpacking.......................................................................................................... 7

• Labels............................................................................................................................................................. 8

• LoosePartsand Tools Needed...................................................................................................................... 9

• Features .................................................................................................................................................. 10-12

• Adjustments............................................................................................................................................. 13-19

• Operation................................................................................................................................................. 20-26

• Maintenance............................................................................................................................................ 27-28

• ExplodedView and Repair Parts List...................................................................................................... 30-35

• PartsOrdering/Service ............................................................................................................................... 36

FULL ONE YEAR WARRANTY

Ifthis productfails due to a defectin material or workmanshipwithinone year from the date of purchase,

Sears will repairitfree of charge.

Contact a Sears Service Center for repair.

Ifthis productis usedfor commercialor rentalpurposes,this warranty appliesonly for90 days from the date

of purchase.

Thiswarrantygives you specificlegal rights,and you may also have other rightswhich vary fromstate to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

II_li |',,[o]b]_l[O]lll[O]_i

Yoursew hasmanyfeatures for makingcutting

operationsmore pleasantand enjoyable.Safety,

performance and dependabilityhave been given top

priodtyin the designof this sew makingiteasy to

maintain and operate.

_k CAUTION: Carefullyread throughthis entire

owner'smanual beforeusingyour newsew. Pay

close attentionto the RulesFor Safe Operation,

and all Safety AlertSymbolsincludingDanger,

Warningand Caution. If you use your sew

propedyand onlyforwhat itis intended,you will

enjoyyears of safe, reliableservice.

_k Look for this symbol to point out important safety precautions. It means attention!l!

Your safety is involved.

_IL WARNING:

The operationof any power tool can result inforeignobjectsbeingthrown into your eyes,

whichcan resultin severe eye damage. Before beginningpower tool operation,always

wear safety gogglesor safetyglasseswith side shieldsand a full face shieldwhen needed.

We recommendW'_leVisionSafety Maskfor use over eyeglassesor standardsafety

glasses withside shields, availableat Sears Retail Stores.

2

ThepurposeofsafetysymbolsIs to attract your attention to poulbio dangers. The safety Symbols, and

the explanations with them, deserve your careful attention and uhderstanding. The safety warnings do

not by themselvse eliminate any.JFlanger.The Instructions or warnings they give are not 8ubetltutee for

proper accident prevention inseams.

SYMBOL

A

MEANING

SAFETY ALERT SYMBOL:

Indicatesdanger,warningor caution. May be used inconjunctionwithothersymbolsor picto-

graphs.

A

A

DANGER: Failure to obey a safetywarningwillresultinsedousinjuryto yourselforto others.

Alwaysfollowthesafety precautionsto reducethe riskof fire,electricshockand personalinjury.

WARNING: Failureto obeya safety warningcan resultin seriousinjurytoyourselfor toothers.

Alwaysfollowthesafety precautionsto reducethe riskoftire,electricshockand personalinjury.

A

CAUTION: Failure to obeya safetywarning may resultin properlydamage or personalinjuryto

yourselfor to others.Alwaysfollowthe safety precautionsto reducethe dsk of fire, electricshock

and personalinjury.

NOTE: Advisesyou of information or instructions vitalto the operationor maintenanceoftheequipment.

DOUBLE INSULATION

Doubleinsulationisa conceptin safety,inalectric

powertools,whicheliminatesthe need forthe usual

three-wiregroundedpowercord. Allexposedmetal

partsare isolatedfrom intemalmetalmotor

components withprotectinginsulation.Double

insulatedtoolsdo not needto be grounded.

A WARNING: Do not attempttooperatethis tool

untilyou have read thoroughlyand understand

completelyall instructions,safety rules, etc.

contained inthis manual. Failure to comply can

resultin accidentsinvolvingfire, electricshock,

or sedous personal injury.Save owner'smanual

and reviewfrequently for continuing safe

operation,and instructingotherswho may usa

this tool.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL Read the owner's

manual carefully.Learnthe saw's applications

and limitationsas well as the specificpotential

hazards relatedto this tool.

• GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH

GROUNDED SURFACES. Forexample; pipes,

radiators,ranges, refrigeratorenclosures.

• KEEP GUARDS IN PLACE and ingood working

order.

REMOVE ADJUSTING KEYS AND

WRENCHES. Get In the habit of checking to see

that hexkeys and adjusting wrenches are

removedfromtool before turningon saw.

IMPORTANT

Servicingrequiresextremecare and knowledgeofthe

systemand shouldbe performed onlyby a qualified

service technician.Forservice we suggestyou return

the toolto yournearestSears storefor repair.Always

useoriginalfactory replacementpartswhen servicing.

KEEP THE WORK AREA CLEAN. Clutteredwork

areas and work benchesinviteaccidents.DO

NOT leave tools or pieces of wood on the saw

whileit isin operation.

DO NOT USE IN DANGEROUS ENVIRON-

MENTS. Do not use power toolsnear gasolineor

otherflammable liquids,in damp or wet locations,

or expose them to rain. Keep the workarea wall

IlL

KEEP CHILDREN AND VISITORS AWAY. All

visitorsshouldwear safety glasses and be kept a

safe distancefrom work area. Do notlet visitors

contacttoolor extensioncord while operating.

• MAKE WORKSHOP CHILD-PROOF with pad-

locksand master switches,or by removing starter

keys.

• DO NOT FORCE THE TOOL It will do the job

betterand safer at the rate for which it was

designed.

• USE THE RIGHT TOOL Do notforce the toolor

attachment to do a job itwas not designedfor.

Don't use it for a purpose notintended.

RULES FOR SAFE OPERATION (Continued)

m

m

USE THE PROPER EXTENSION CORD. Make

sure yourextensioncordis ingood condition.

When usingan extensioncord, be sure touse

one heavy enoughto carrythe currentyour

productwilldraw.An undersizedcordwillcause

a drop in linevoltage resultingin lossof power

and overheating. A wiregage size (A.W.G.) of at

least 14 is recommended for an extensioncord

25 feet orless in length. If in doubt, use the next

heaviergage. The smallerthe gage number, the

heavierthe cord.

INSPECT EXTENSION CORDS PERIODI-

CALLY and replace ifdamaged.

DRESS PROPERLY. DOnotwear looseclothing,

gloves, neckties,rings,bracelets,or other

jewelry. They can get caughtand draw you into

movmgparts.Rubberglovesand nonslipfoot-

wear are recommendedwhen workingoutdoors.

Alsowear protectivehaircovering tocontain long

hair.

ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everydayeyeglasses have only

impact-resistantlenses; theyare NOT safety

glasses.

PROTECT YOUR LUNGS. Wear a face or dust

mask if the cuffingoperationis dusty.

PROTECT YOUR HEARING. Wear hearing

protectionduringextended periodsof operation.

SECURE WORK. Useclamps or a viseto hold

workwhen practical.It'ssafer than usingyour

handand it frees beth hands tooperate tool.

DO NOT OVERREACH. Keep properfootingand

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools

sharpand clean for betterand safer perfor-

mance. Followinstructionsfor lubricatingand

changingaccessories.

DISCONNECT ALL TOOLS. When not in use,

before servicing, or when changingattachments,

blades, bits,cutters,etc., all toolsshouldbe

disconnected.

M

m

AVOID ACCIDENTAL STARTING. Be sure

switchisoffwhen pluggingin.

USE RECOMMENDED ACCESSORIES. The

useof improperaccessoriesmay cause risk of

injury.

NEVER STAND ON TOOL Serious injurycould

occur ifthe toolis tippedor ifthe blade is unin-

tonflonally contacted.

CHECK DAMAGED PARTS. Beforefurther use

of thetool, a guardor other partthat is damaged

shouldbecarefullychecked todetermine that it

willoperate properlyand perform its intended

function.Check for alignmentof movingparts,

bindingof movingparts,breakage ofparts,

mountingand any other conditionsthatmay

affectitsoperation.A guardor other partthat is

damaged mustbe properlyrepairedor replaced

by a qualified servicetechnicianat a Sears store

to avoidriskof personalinjury.

NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tooluntilitcomesto a complete stop.

FIRMLY CLAMP OR BOLT yourmiter saw to a

workbenchor table at approximatelyhipheight.

USE ONLY CORRECT BLADES. Do not use

bladeswithincorrect size holes Never usa blade

washersor blade boltsthat are defectiveor

incorrect.The maximumblade capacity of your

saw is 12 in.

KEEP BLADES CLEAN, SHARP AND WITH

SUFFICIENT SET. Sharp blades minimize

stallingand kickback.

DO NOT REMOVE THE SAW'S BLADE

GUARDS. Never operatethe saw with anyguard

or cover removed. Make sure all guardsare

operatingproperlybeforeeach use.

KEEP HANDS AWAY FROM CUTnNG AREA.

Keep hands away from blades. Do not reach

underneathworkor aroundor underthe blade

whilebladeis rotating. Do notattempt to remove

cutmaterialwhen blade ismoving.

_i, WARNING: Bladecoasts afterturnoff.

DO NOT ABUSE CORD. Never yankcord to

disconnect it from receptacle. Keep cord from

heat, oil, and sharpedges.

INSPECT TOOL CORDS PERIODICALLY and if

damaged, have repaired bya qualified service

technicianat a Sears store. Stay constantly

aware of cord locationand keep itwell away

fromthe rotatingblade.

USE OUTDOOR EXTENSION CORDS, When

tool isused outdoors,useonlyextensioncords

withapprovedgroundconnectionthat are

intendedfor useoutdoorsand so marked.

DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Havedefective switches

replaced bya qualifiedservicetechnicianat a

Sears store.

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always usea clean cloth

whencleaning. Never use brake fluids,gasoline,

petroleum-basedproducts,or any solventsto

clean tool.

RULES FOR SAFE OPERATION (Continued)

ALWAYS SUPPORT LONG WORKPIECES to

minimizedsk of blade I_nchingand kickback.

Saw may slip,walk, or slidewhilecuttinglongor

heavy beards.

BEFORE •AKING A CUT, BE SURE ALL

ADJUSTMENTS ARE SECURE.

GUARD AGAINST KICKBACK. Kickbackoccurs

when the blade stallsrapidlyand workpioceis

drivenback towardsthe operator. Itcan pullyour

hand intothe bladeresultingin sedouspersonal •

injury. Stay out of blade pathand turnswitchoff

immediatelyifblade bindsor stalls.

AVOID CUTTING NAILS. Inspectforand

remove all nailsfrom lumberbeforecuffing.

ALWAYS USE A CLAMP to secure the work-

piece when possible.

NEVER TOUCH BLADE or othermovingparts

during use.

NEVER START A TOOL WHEN THE BLADE IS

IN CONTACT WITH WORKPIECE. Allow motor

to come up tofullspeed before startingcut.

• AKE SURE THE MITER TABLE AND SAW

ARM (BEVEL FUNCtiON) ARE LOCKED IN

POSITION BEFORE OPERATING YOUR SAW.

Lockthe miter table bysecurelytighteningthe

miter lockhandle. Lockthe saw arm (bevel

funciton)by securelytighteningthe bevel lock

knob.

NEVER USE A LENGTH STOP ON THE FREE

SCRAP END OF A CLAMPED WORKPIECE.

NEVER hold ontoor bindthe free scrapend of

the workpiocein anyoperation. Ifa workclamp

and lengthstopare used together,they must

both be installedon the same side ofthe saw

table to preventthe saw from catchingthe loose

end and kickingup.

NEVER cut more than one piece at a time. DO

NOT STACK more than one workpieceon the

saw table at a time.

NEVER PERFORM ANY OPERATION "FREE-

HAND". Alwaysplace the workpieceto be cut on

the mitertable and position it firmlyagainstthe

fence as a backstop. Always usathe fence.

NEVER hand holda workpiecethat is too small

to be clamped. Keep hands clear ofthe no hands

zone.

NEVER reach behind,under, or withinthree

inches.ofthe bladeand itscuttingpath withyour

handsand fingersfor any reason.

NEVER reach to pickup a workpioce,a piece of

scrap,or anythingelse that is in or near the

cuffingpathofthe blade.

AVOID AWl(WARD OPERATIONS AND HAND

POSITIONS where a suddenslip couldcause

yourhandto move intothe blade. ALWAYS

make sure you havegood balance. NEVER

operateyourmiter sew on the flooror in a

crouchedposition.

NEVER standor have any partof your bodyin

linewiththe path of the saw blade.

ALWAYS release the powerswitchand allowthe

saw blade to stop rotatingbefore raisingitoutof

theworkpiece.

DO NOT TURN THE •OTOR SWITCH ON AND

OFF RAPIDLY. This could cause the saw blade

to loosenand couldcreatea hazard. Shouldthis

ever occur,standclear and allowthe sew blade

to cometoa complete stop. Disconnectyoursaw

fromthe power supplyand securelyretightenthe"

blade bolt.

REPLACEMENT PARTS. Allrepairs,whether

electricalor mechanical, should be made by

qualifiedservice technicianat a Sears store.

WARNING: When servicing use onlyidentical

Craftsmanreplacementparts. Useof any other

parts may create a hazard or cause product

damage.

NEVER USE IN AN EXPLOSIVE ATMO-

SPHERE. Normalsparkingof the motorcould

ignitefumes.

NEVER leave the miter saw unattendedwhile

connectedtoa power source.

POLARIZED PLUGS. To reducethe dskof

electricshock,thistoolhas a paladzed plug(one

bladeiswiderthan the other).This plugwillfitin

a polarized outletonlyone way. Ifthe plugdoes

not fitfullyin the outlet,reverse the plug. Ifit still

does notfit, contacta qualifiedelectricianto

installthe properoutlet. Do not changethe plug

in any way.

IF ANY PART OF THIS MITER SAW IS MISS-

ING or shouldbreak, band, or fail inany way, or

shouldany electricalcomponentfail to perform

properly,shutoffthe power switch,removethe

mitersaw plugfromthe power sourceand have

damaged, missing,or failed partsreplaced

beforeresumingoperation.

DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

5

RULES FOR SAFE OPERATION (Continued)

ALWAYS STAY ALERT! Do not allow familiarity

(gained from frequent use of your saw) to cause

a careless mistake. ALWAYS REMEMBER that

a careless fraction of a second is sufficient to

inflict severe injury.

STAY ALERT AND EXERCISE CONTROL

Watch what you ere doingand use common

sense. Do not operate tool when you are tired.

Do not rush.

MAKE SURE THE WORK AREA HAS AMPLE

UGHTING tosee the work and that noobstruc-

tionswillinterferewith safe operationBEFORE

performing any workusingyour saw.

ALWAYS TURN OFF SAW beforedisconnecting

it, to avoidaccidentalslarlJngwhen re-connect-

ingto powersupply.

SAVE THESE INSTRUClrlONS. Refer tothem

frequently and usa to instructother users. If you

loan someonethis tool,loan them these instruc-

tionsalso.

SAVE THESE INSTRUCTIONS

Arbor

The shafton whicha bladeor cuttingtool is mounted.

,Bevel Cut

Acuttingoperation made withthe bladeat any angle

otherthan 90° to the mitertable.

Cresacut

Acuttingor shapingoperationmade acrossthe grain

ofthe workplace.

Compound Miter Cut

Acompoundmitercut isa cut made usinga miter

angleand a bevel angle at the same time.

Freehand

Performinga cut withoutusinga fence, mitergage,

fixture,workclamp, or otherproperdevice to keepthe

workpiecefrom twis_ng or movingduringthe cut.

Gum

A sticky,sap based residuefrom wood products.

Mlter Cut

A cuttingoperation madewith the bladeat anyangle

otherthan 90" to the fence.

Resin

A sticky,sap bass substancethat has hardened.

Revolutions Per Minute (RPM)

The numberof toms completedby a spinningobject

inone minute.

Saw Blade Path

The area over, under, behind, or in frontof the blade.

As itappliesto the workplace,that area whichwillbe,

or has been, cut bythe blade.

Set

The distancethat the tip ofthe sawblade toothis bent

(or sat) outwardfrom the face of the blade,

Throw-Back

Throwing of a workplacein a manner similarto a

kickback.Usuallyassociatedwitha cause otherthan

the kerfclosing,suchas a workplacenot being

againstthe fence, beingdroppedintothe blade,or

being placedinadvertentlyincontact withthe blade.

Through Sawing

Any cuttingoperationwhere the blade extends

completely throughthe thickness ofthe workplace.

Workplace

The item on whichthe cuttingoperationis beingdone.

The surfacesof a workpieceare commonlyreferredto

as faces, ends, and edges.

Zero Clearance Throat Plate

A plasticthreat plate insertedinthe miter tablethat

allowsfor blade clearance. When you makeyour first

cutwithyourcompoundmitersaw, the saw blade cuts

a slotthrough the throat platethe exact width of the

blade. Thisprovidesfor a zero clearancekerfthat

minimizesworkplecetaar-out.

No Hands Zone

The area between the marked lineson the leftand

rightsideof the mitertable base. This zone is

identifiedby no handszone labelsplacedinsidethe

marked lineson the miter table base.

6

BladeDiameter 12in.

Blade Arbor 5/8 in.

No Load Speed 4000 RPM

Rating 120 Volts,60 Hz-AC Only

Input 15 Amperes

Nat Weight 41 Ibs.

CuttingCapacitywith Miterat 0°/Bevel 0°:

max widthx resultingheight 7-7/8 in. x 2-1/2 in.

MaximumCuttingCapacity with Miterat 45°/Bevel 0°:

max width x resultingheight 5-1/2 in. x 2-1/2 in.

MaximumCuttingCapacity with Miterat 0°/Bevel 450:

max widthx resultingheight 7-7/8 in. x 1-3/4 in.

YourCompoundMiterSaw hasbeen shipped

completelyassembledexceptforthe blade, miter lock

handle,and dust guide.

A WARNING: Ifany parts are missing,do not

operate this tool untilthe missing partsare

replaced. Failuretodo so could resultin possible

seriouspersonalinjury.

• Remove all loose partsfromthe carton. Separate

andcheckwiththe listof looseparts. See Figure2.

• Remove the packingmaterialsfromaround your

seW.

• Carefully liftsaw fromthe cartonand place it on a

level work surface.This saw is heavy. To avoid

back injury,get helpwhen needed.

• Do notdiscardthe packingmaterials untilyou

have carefullyinspectedthe sew, identifiedall

looseparts,and satisfactorilyoperated yournew

SeW.

• Your sew has been shipped withthe sew arm

lockedin the downposition.To release sew arm,

pushdownon top of sew arm and pullout the lock

pin. See Figure 4.

• Hand pressureshouldremainon thesaw arm to

preventsudden dse upon releaseof the lockpin.

• Examine all partsto make sure no breakage or

damage has occurredduringshipping.

Ifany partsare damagedor missing,do notattemptto

plug inthe power cordand turn the switchon untilthe

damaged or missingpartsare obtainedand are

installedcorrectly.

Thefollowinglabelsareonthemitersawwithloca-

tionsindicated,

Restorelowerbladeguard

andsecurelytightenscrew

beforeuse

DANGER: DO NOT REMOVE

ANY GUARD. USE OF SAW

WITHOUT THEIS GUARD WILL

RESULT IN SERIOUS INJURY.

tRNING/ ADVERTENI

• FOryoursafety,read owners manual beforeoparutln

• Wear eye protection,

• Keep bends Outut path of sawblade.

• DOnotoparath sawwithout guardsin place.

• O0 notperlorm anyoporutlonIreahad.

• Never roacharound the saw blade.

• Turnutf fool end waitfor saw blade to stopbefore moving

wad(piece or cbanoinOsethnos.

• Disconnectthe caw from the powersourcebalers changing

blade orservicing.

• Oo nutexposeto rain or use In dampplaces.

• Pare se propiasepuridsd, lea el manual del usuorioautosde

userla €lerfa inplctadora.

12 inch Compound Miter Saw

WARNING:wa_,senwoNo, useONLYmemlc_.

MOOEL 315.212120 SER.NO.

MADE INTAIWAN

Sl_l_m _OL

. Customer Help Line 1-800-932-3188

Fig. 1

8

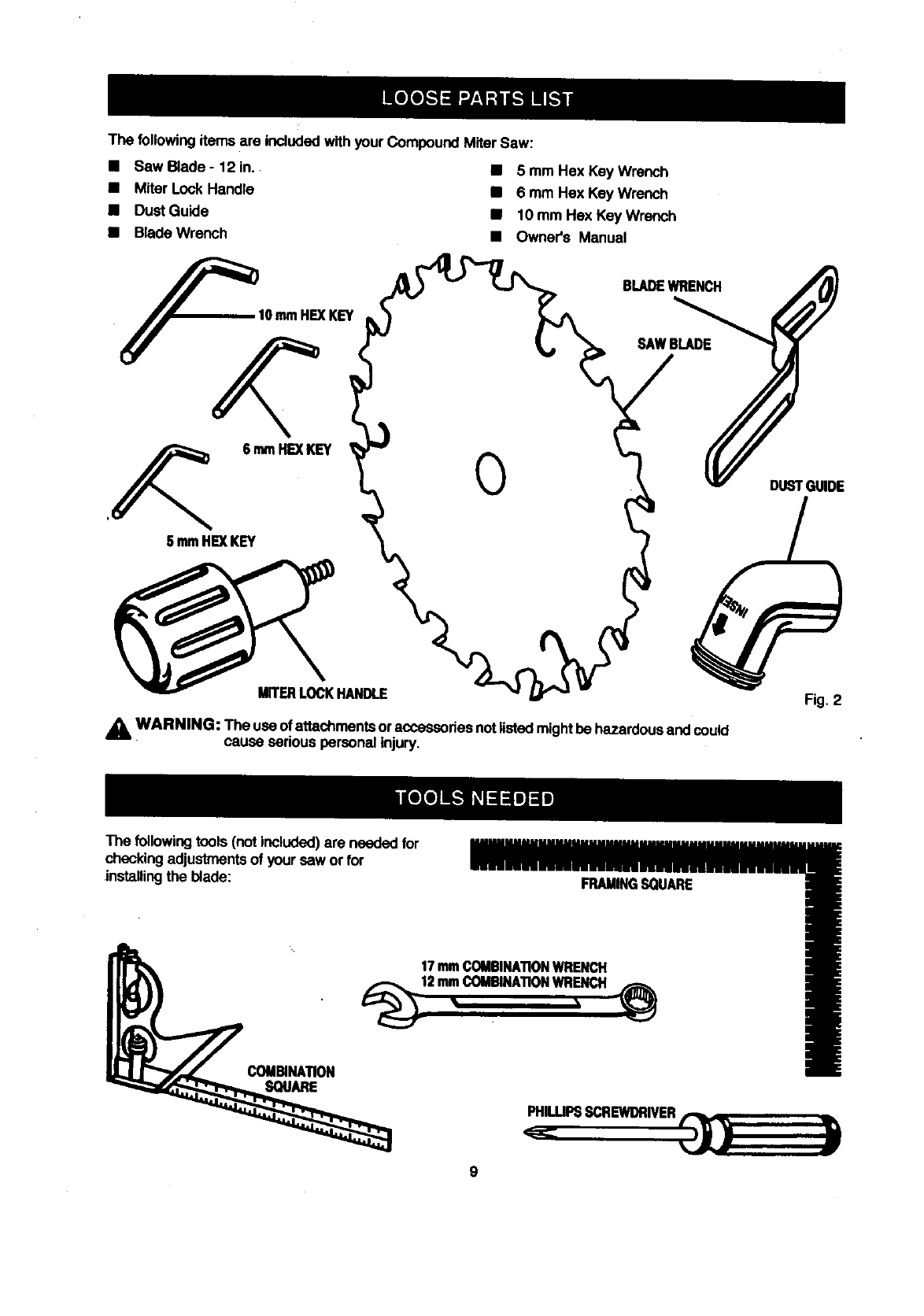

Thefollowingitemsare included with yourCompound Miter Saw:

• SawBlade- 12in.,

• Miter Lock Handle

• Dust Guide

• BladeWrench

• 5 mm Hex KeyWrench

• 6 mm Hex KeyWrench

• 10 mm Hex Key Wrench

• Owner's Manual

F IOtamHEXKEY

,_ 6mm HEXKEY

5 mmHEXKEY

MITERLOCKHANDLE

BLADEWRENCH

SAWBLADE

DUSTGUIDE

Fig. 2

A WARNING: The use o! attachmentsoraccessoriesnotlistedmightbe hazardousand coud

cause serious personalinjury.

The followingtools(notincluded)are neededfor

checking adjustmentsofyoursew or for

installingthe blade:

FRAMINGSQUARE

COMBINATION

SQUARE

17 mm COMBINATIONWRENCH

WR?H

9

PHIUJPSSCREWDRIVER

KNOW YOUR COMPOUND MITER

SAW

See Figure3.

Beforeattemptingto useyoursaw, familiarizeyourself

withall operatingfeatures and safety requirements.

_i WARNING: Do notallow familiaritywithyour

saw to make youcareless. Remember that a

careless fractionof a second is sufficientto inflict

severe injury.

15 AMP MOTOR

Your saw has a powerful15 amp motorwithsufficient

powerto handle toughcuttingjobs. It ismade withall

hellbearings, and has extemally accessiblebrushes

for ease of servicing.

12 in. BLADE

A 12 in. saw blade is includedwithyourcompound

miter saw. it willcut materialsupto 7-7/8 in.wide,

dependinguponthe thicknessofthe materialand the

'settingat whichthe cutisbeing made.

CUTTING CAPACITIES

When the miter angle (raRer table) Is set at 0° and

the bevel angle Is set at 0°:

Your saw win cut materials up to:

max widthx resultingheight 7-7/8 in. x 2-1/2 in.

When the miter angle (miter table) Is set at 45° and

the bevel angle Is eat at O°:

Yoursaw willcutmaterialsupto:

max widthx resultingheight 5-1/2 in. x 2-1/2 in.

When the miter angle (miter table) Is set at O° and

the bevel angle Is sat at 45°:

Yoursaw willcutmaterialsupto:

max widthx resultingheight 7-7/8 in. x 1-3/4 in.

SWITCH

LOCK-OFFLEVER

UPPER

BLADEGUARD

TRIGGER

6 mm DUSTGUIDE

HEXKEY

\

LOWER

BLADEGUARD

MITERTABLE

"NOHANDSZONE"

BOUNDARYMNE

NOHANDS

ZEROCLEARANCE

PLATE

' MRERSCALE

HEXKEY __

STORAGEAREA

MRER

TABLEFRAME

10

MmER

LOCKHANDLE

CONTROLARM

MITER

PosmvE STOP(S) LOCKPLATE

Fig. 3

CARRYING HANDLE

See Figure 4.

Forconveniencewhen carryingor transportingyour

miter saw from one place to another, a carrying

handle has been providedon top of the saw arm as

shownin figure 4. To transport,turnoffand unplug

your saw,then lowerthe saw armand lockit inthe

down position: Locksaw arm bydepressing the lock

pin.

SAW

ARM

\

LOCKPiN

CARRYING %%

HANDLE

SPINDLE LOCK BUTrON

See Figure5.

A spindlelockbuttonhas been providedfor locking

the spindlewhichkeeps the bladein yoursaw from

rotating.Depressand hold the lock button while

installing,changing,or removingbladeonly.

LOCK-OFF

SPINDLE

LOCKBUTrON

,SWITCH

TRIGGER

MITERLOCK

HANDLE

SAWARM

LOCKEDINDOWNPOSITION

Fig. 4

MITER LOCK HANDLE

See Figure 4.

The miterlockhandle securely locksyour saw at

desired miter angles.

LOCK-OFF LEVER

See Figure 5.

The switchtriggerisequippedwith a rock-offleverto

reducethe possibilityof accidentaletartJng.The lock-

off lever mustbe presseddownwiththe palm of your

handtoturn saw on. The spdngloaded lever will

springback intothe lock-offposition when the switch

triggeris released.

Fig. 5

TRIGGER LOCK

See Figure6.

To prevent unauthorizeduse ofyour compound miter

saw, we suggestthat youdisconnectit fromthe power

supplyand lockthe switchinthe offposition. To lock

the switch, installa padlockthrough thehole inthe

switchtrigger.A lock witha shackleup to 13/64 in.

diameter may be used. When the lockis installedand

locked,the switchisinoperable.Store the padlockkey

in anotherlocation.

SWITCH PADLOCK

TRIGGER

Fig. 6

11

POSITIVE STOPS ON MITER TABLE

Positivestops have been providedat 0°, 15°, 22-1/'Z',

31.62_,and 45° on beththe left and rightside of the

mitertable.

BEVEL LOCK KNOB

The bevel lockknobsecurelylocksyour compound

mitersaw at desired hovel angles. Positive stop

adjustmentscrewshave been providedon each side

ofthe saw arm. These adjustmentscrews are for

makingfine adjustmentsat 0° and 45°. Sea pages 18

and 19.

ELECTRIC BRAKE

An electricbrake has been providedto quicklystop

blade rotationafterthe switchisreleased.

FENCE

The fenceon yourcompound miter saw has been

providedto holdyour workpiecesecurelyagainst

when making all cuts.

SELF-RETRACTING LOWER BLADE

GUARD

The lower blade guard is made of shock-resistant,

see-throughplasticthat providesprotectionfrom each

side ofthe blade. It retractsover the upper blade

guardas the saw is lowered into the workpiece.

MOUNTING HOLES

See Figure 7.

Your compound mitersaw shouldbe permanently

mountedto a firm supportingsurface suchas work-

bench. Four 7/16 in,boltholeshave been providedin

the saw base forthis purpose.Each of the four

mountingholesshouldbe belted securelyusing7/16

in. machinebolts,lockwashers, and hex nuts(not

included).Beltsshouldbe of sufficientlengthto

accommodatethe saw base, lockwashers,hex nuts,

and the thicknessofthe workbench.

Tightenall four belts securely.

The hole pattern for an 20 in. x 30 in.workbenchis

shownin Figure7. Carefullycheckthe workbench

after mounting to make sure that no movement can

occurduring use. If anytipping,sliding,or walkingis

noted, secure the workbenchto the floorbefore

operating.

_k WARNING: Always make sureyour compound

miter saw is securelymountedto a workbenchor

an approvedworkstand.Failure todo so could

resultin an accident resultingin possibleserious

personal injury.

30in.

21-3/4in.

Fig. 7

Nextto the belt holes,four nail holeshave been

providedinthe saw basefor temporarilymounting

yourcompoundmiter saw. Use 4 nailsabout2-1/2 in.

longto secureyour saw temporarily.

Note: Make sure the surfacewhere you are mounting

yoursaw, isthick enoughto accommodatethe nails

being used.

ELECTRICAL CONNECTION

Your saw has a precisionbuiltelectric motor. It should

be connected to a power supply that Is 120 volts,

60 Hz, AC only (normal household current). Do not

operatethis toolon directcurrent(DC). A substantial

voltagedropwillcause a lossof power and the motor

willoverheat, ifyourtooldoes not operate when

pluggedintoan outlet,double-checkthe power

supply.

& WARNING: The operationofany saw can

resultin foreignobjectsbeing thrown intoyour

eyes, whichcan resultin severe eye damage.

Beforestartingpowertooloperation,always

wear safely gogglesor safety glasseswithside

shieldsand a fullface shieldwhen needed. We

recommendwide vision safety maskfor use over

eyeglassesor standardsafetyglasses withside

shields,

WARNING: Do net attemptto modifythis toolor

create accessories not recommendedfor use

with this tool. Any suchalteration or modification

is misuseand couldresultin a hazardous

condition leading to possible serious personal

injury.

12

_, WARNING: To preventaccidentalstartingthat

couldcause possibleseriouspersonalinjury,

assemble all partsto yoursaw beforeconnecting

itto powersupply.Saw shouldnever be

connectedtopower supplywhen you are

assemblingparts,makingadjustments,installing

or removingblades, or when not in use.

Asmentionedpreviouslyyoursew has been factory

assembled and adjusted.The miterlock handle, dust

guide,and blade are the onlypartsthat haveto be

installed.

MITER LOCK HANDLE

See Figure 8.

To installthe miter lockhandle, place the threaded

studon the end ofthe miterlockhandle intothe

threaded holeinthe controlarm. Tum clockwiseto

tighten.

TO

LOOSEN

CONTROL MITER

MITER ARM TABLE

LOCKHANDLE Fig. 8

DUST GUIDE

Sea Figure 9.

To installthe dust guide, place the end marked

INSERT over the exhaustport in the upper blade

guard.Tum the guide so that the open end is facing

downor towardthe rear ofthe saw.

TO INSTALL BLADE

See Figures 10, 11, and 12.

WARNING: A 12 in. blade is the maximum

blade capacity of yoursaw. Never use a blade

that istoothickto allowouterblade washerto

engage withthe flatson the spindle.Larger

bladeswillcome in contact with the blade

guards,whilethicker blades willpreventthe

blade screwfrom secudngthe blade onthe

spindle.Eitherof these situationscould resultin

a sedous accidentand can cause serious

personalinjury.

• Unplugyoursew.

& WARNING: Failuretounplugyoursaw could

resultinaccidentalstartingcausingpossible

sedouspersonal injury.

Push downon the sew arm and pullout the lock

[)into release saw arm. Raise sew arm to its full

raisedposition.Be cautious, sew arm is spring

loadedto raise.

• Loosenthe phillipsscrew on the blade bolt

cover untilbladeboltcover can be raised.

See Figure 10.

• Gently raisethe lowerblade guard bracketsothat

the lowerbladeguard and blade belt cover can be

rotatedup and backto expose the bladebelt. See

Figures10.

LOWER

BLADEGUARD

PHILUPS

SCREW

EXHAUST

PORT

BLADE

BOLT

DUSTGUIDE

ILADE

GUARDBRACKET Fig. 10

Fig. 9

13

LOWER

BLADEGUARD

ARROW

BLADE

BOLTCOVER

TO

(s)

ONSPINDLE

INNERBLADE

TO WASHERWITH

TIGHTEN DOUBLE'D"FLATS

BLADEBOLT BLADE

OUTERBLADEWASHER

wm.I DOUBLE"D"FLATS Fig. 11

• Depress the spindlelock buttonand rotatethe

blade belt untilthe spindlelooks.See Figure 12.

• Usingthe bladewrench provided,loosenand

remove the blade belt.

Note: The blade belt has left hand threads. Tum

blade belt clockwiseto loosen.

• Remove outer blade washer. Do not remove

inner blade washer.

SPINDLE

BuTroN

Fig. 12

• Wipe a dropof oil onto inner bladewasher and

outerblade washerwhere they contactthe blade.

& WARNING: If innerblade washer has been

removed, replace itbeforeplacing blade on

spindle. Failuretodo so couldcause an accident

since bladewillnot tightenproperly.

• Fit saw blade insidelower bladeguardand onto

spindle.The blade teeth pointdownwardat the

frontof saw as shown infigure 1I.

_k CAUTION: Always install the bladewith the

blade teethand the arrow printedon the sideof

the blade pointingdown at the frontof the saw.

The directionof blade rotationisalso stamped

withan arrowon the upperbladeguard.

• Replace outerblade washer.The double "D"fiats

on the bladewashers alignwiththe fiatson the

spindle.

• Depressspindlelockbuttonand replace blade

belt.

Note: The blade bolt has left hand threads.Turn

blade boltcounterclockwise to tighten.

• Tightenblade belt securely.

• Remove the blade wrenchand storeit in a safe

place for futureuse.

• Replace the lowerbladeguard and blade belt

cover.

• Retightenphillipsscrew securingblade boltcover.

Tightenscrewsecurely. See Figure 11.

_k WARNING: To preventdamage tothe spindle

lock,always allowmotorto come toa comPlete

stop before engagingspindlelock.Make sure the

spindlelockbuttonisnot engaged before

reconnectingsew intopowersource.

Your compoundmiter saw has been adjustedat the

factoryfor making veryaccurate cuts. However,some

of thecomponentsmighthave been jarred out of

alignmentduringshipping. Also,over a periodof time,

readjustmentwillprobablybecome necessarydue to

wear. After unpackingyour saw, check the following

adjustmentsbefore you beginusingsaw. Makeany

readjustmentsthat are necessaryand peflodically

checkthe parts alignmentto make sure thatyoursaw

is cuttingaccurately.

A WARNING: Your saw shouldnever be

connectedto powersupplywhen you are

assemblingparts,makingadjustments,installing

or removingblades, or when not inuse.

Disconnectingyour saw willpreventaccidental

startingthat could cause serious injury.

14

Note: Many of the illustrationsinthis manual show

onlyportionsofyourcompound mitersaw. Thisis

intentionalsothat we can clearlyshow points being

made in the illustrations.Never operate your saw

withoutall guards securelyin place and ingood

operatingcondition.

CUTTING A SLOT IN THE ZERO

CLEARANCE THROAT PLATE

In order to useyour compound miter saw, you must

cuta slotthrough the zero clearance throat plate to

allowfor bladeclearance. To cut the slot,set your

saw at 0 degrees miter, turn sew on and allowthe

bladeto roachfull speed, then carefullymake a

straightcut as far as itwillgo through thethroat plate.

Turn your saw offand allow the bladeto cometo a

complete stopbefore raisingthe saw arm.

Next, adjustthe bevel angle to45 degrees, turn your

sew on and allow the blade to reach full speed, then

carefully make another cutthroughthe zero clearance

throatplate.The throat plate willthan be wide enough

toallowthe bladeto passthrough it at any angle from

0 to 45 degrees.

SQUARING THE MITER TABLE

TO THE FENCE

See Figures 13 - 16.

• Unplugyoursaw.

_k WARNING: Failureto unplugyoursaw could

resultin accidentalstartingcausingpossible

seriouspersonal injury.

• Push downon the sew arm and pulloutthe lock

pin to release the sew arm.

• Raise saw arm to its full raised position.

• Loosen the miter lockhandle approximatelyone-

half turn.

• Depressthe miter lockplate and rotatethe miter

table until the pointer on the controlarm isposi-

tioned at 0°.

Release the miterlock plate and securelytighten

the miterlock handle.

Lay a framing squareflaton the mitertable. Place

one leg of the square againstthe fence. Place the

other leg ofthe squarebeside the zero clearance

throat plate in the mitertable. The edge of the

squareand the zero clearancethroat plate in

the mitertable shouldbe parallel as shown in

figure 13.

If the edge of the framing square and the zero

clearancethroat plate in the miter table are not

parallelas shown infigures 14 and 15, adjust-

mentsare needed.

FRAMING

SQUARE

FENCE

MITER TABLE r

ZEROCLEARANCE

THROATPLATE

MITER

MITER LOCKHANDLE

LOCKPLATE

VIEWOFMITERTABLESQUAREWITHFENCE

ANDCORRECTLYADJUSTED

Fig. 13

FENCE

MITERTABLE

FRAMING ZEROCLEARANCE

SOUARE THROATPLATE

VIEWOFMITERTABLENOTSQUAREWITH

FENCE,ADJUS1MENTEAREREQUIRED

Fig. 14

FENCE

MITERTABLE

FRAMING ZEROCLEARANCE

SQUARE THROATPLATE

VIEWOFMITERTABLENOTSQUAREWITH

FENCE,ADJUSTMENTSAREREQUIRED

Fig. 15

15

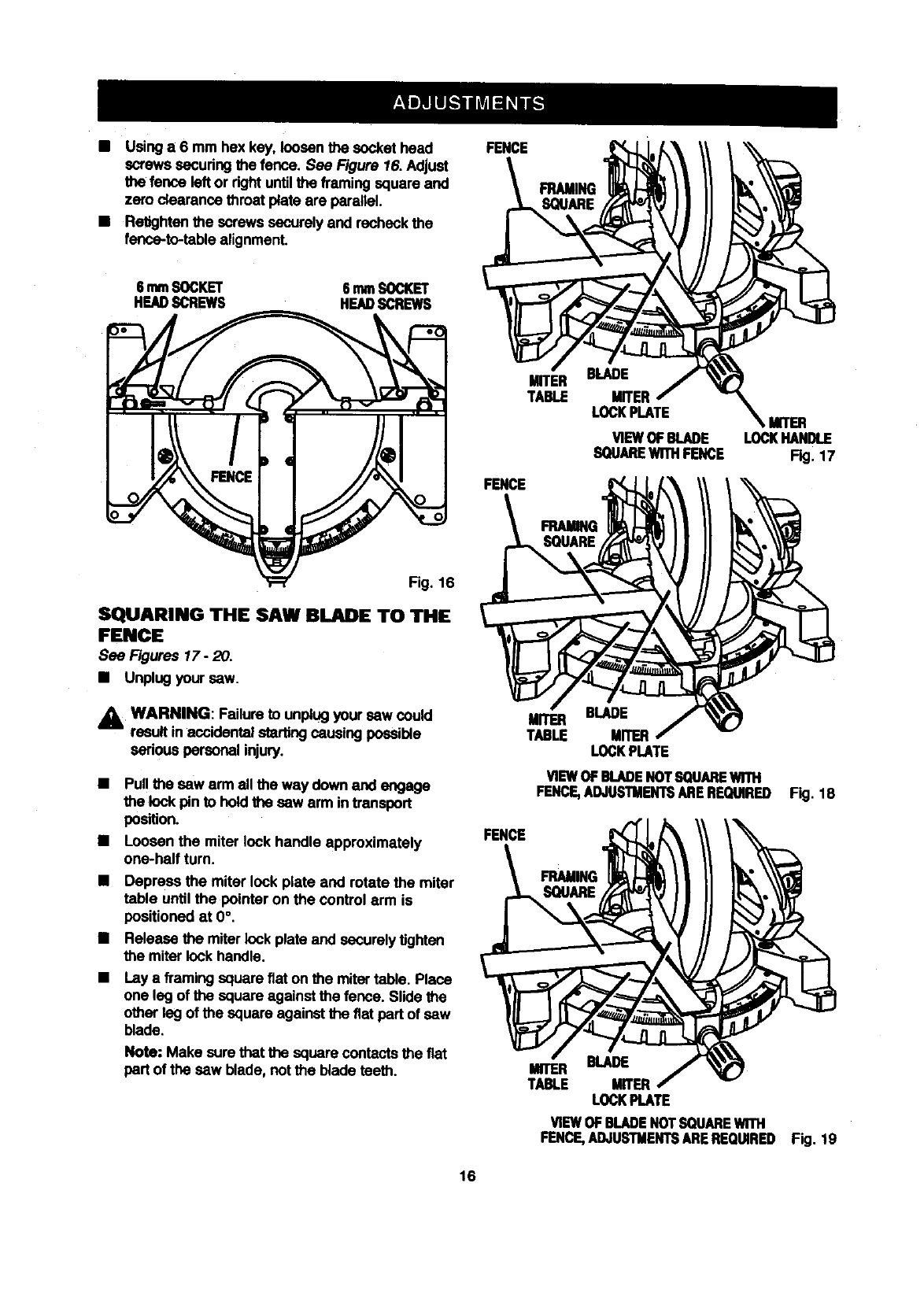

• Using a 6 mm hex key, loosenthe sockethead

screwssecudngthe fence. See Figure 16. Adjust

the fence leftor dghtuntilthe framingsquareand

zero clearance throat plate are parallel.

• Retightenthe screwssecurelyand recheckthe

fence-to-tablealignment.

6 mmSOCKET

HEADSCREWS

6 mmSOCKET

HEADSCREWS

Fig. 16

SQUARING THE SAW BLADE TO THE

FENCE

See Figures 17- 20.

• Unplugyoursew.

& WARNING: Failureto unplugyoursew could

result inaccidental startingcausingpossible

seriouspersonalinjury.

• Pullthe sew arm all the way down and engage

the lock pinto holdthe saw arm intransport

position;

Loosen the miter lock handle approximately

one-half turn.

Depress the miter lock plate and rotate the miter

table untilthe pointer on the controlarm is

positioned at 0°.

Release the miterlockplate and securelytighten

the miter lockhandle.

• Laya framing square fiat on the mitertable. Place

one leg of the square against the fence. Slide the

otherleg of the square againstthe fiat pert of sew

blade.

Note: Make surethat the square contactsthe fiat

part of the sew blade, not the blade teeth.

FENCE

FRAMING

SQUARE

MITER BLADE

TABLE MITER

LOCKPLATE

FENCE

MITER

VIEWOFBLADE LOCKHANDLE

SQUAREWITHFENCE Fig. 17

MITER BLADE

TABLE MITER

LOCKPLATE

VIEWOFBLADENOTSQUAREWITH

FENCE,ADJUSTMENTSAREREOUIRED Rg. 18

MITER BLADE

TABLE MITER

LOCKPLATE

VIEW OF BLADENOTSQUAREWITH

FENCE,ADJUSTMENTSARE REQUIRED

Fig. 19

16

• The edge of the square and the saw blade should

be parallelas shownin figure 17.

• Ifthe front or backedge of the saw bladeangles

away from the square as shown infigures 18 and

19, adjustmentsare needed.

• Usingthe 10 mm hex key provided,loosenthe

sockethead screwsthat secure the mounting

brackettothe mitertable. See Figure20.

Loosenbevel lockknoband set saw arm at 0°

bevel (bladeset 90° to mitertable). Tighten bevel

lockknob.

Place a combinationsquareagainst the miter

table and the flat part ofsaw blade.

Note= Make sure that the square contactsthe fiat

partofthe saw blade, notthe blade teeth.

• Rotate the blade byhand and checkthe blade-to-

table alignmentat several points.

• The edge ofthe square and the saw bladeshould

be pe.mllal as showninfigure 21.

FENCE

f0 mmSOCKET

10mln ._

HEXKEY"_"

M_NTING

B_CK_

/

MITER

TABLE

Fig. 20

• Rotate the mountingbracketleft or right untilthe

saw blade is parallelwiththe square.

• Retightenthe screwssecurelyand recheckthe

blade-to-fansaalignment.

SQUARING THE BLADE TO THE

MITER TABLE

See Figures 21.24.

• Unplugyoursaw.

,_k WARNING: Failure to unplugyour saw could

resultin accidentalstaffingcausingpossible

serious personalInjury.

Pullthe saw arm all the way down and engage

the lockpinto holdthe saw arm intransport

position.

Loosenthe miter lockhandle approximatelyone-

halfturn.

Depress the miterlock plate and rotatethe miter

table untilthe pointeron the controlarm Is posi-

tioned at 0°.

Release the miterlockplate end securelytighten

the miterlockhandle.

MITER

TABLE BLADE

MITER

LOCKPLATE MITER

LOCKHANDLE

CORRECTVIEWOFBLADE

SQUAREWITHMITERTABLE Fig. 21

• Ifthe top or bottomofthe saw bladeanglesaway

fromthe squareas shownin figures22 and 23,

adjustmentsare needed.

FENCE

MITER

TABLE BLADE

MITER MITER

LOCKPLATE LOCKHANDLE

VIEWOFBLADENOTSQUAREWITHMITER

TABLE,ADJUSTMENTSAREREQUIRED Fig, 22

17

FENCE

COMBINATION=

SQUARE

MITER

TABLE BLADE

VIEW OF BLADENOTSQUAREWITH MITER

TABLE, ADJUSTMENTSARE REQUIRED Fig. 23

• Usinga 10 mm wrench or adjustablewrench,

loosenthe locknut securingpositivestopadjust-

ment screw. Alsoloosen bevel lockknob.

• Adjustpositive stop adjustmentscrew to bring

saw blade into alignmentwith thesquare. See

Figure24.

BEVELLOCK

KNOB

POSITIVESTOP

ADJUSTMENT

45° ANGLES

LOCKNUT(S) Fig. 24

• Retightenbevel lookknob. Next, retightenlock nut

secudngthe positive stopadjustmentscrew.

Recheck blade-to-tablealignment.

Note: The above procedurecan be usedto check

blade squareness ofthe saw blade to the miter

table at both 0° and 45° angles.

Yoursaw hasthree scale indicators,twoon either

sideof the bevel scaleand one on the miterscale.

Aftersquaring adjustmentshave been made, it may

be necessaryto loosenthe indicatorsscrews and

resetthem tozero.

PIVOT ADJUSTMENTS

Note: These adjustmentswere made at the factory

and normallydo not requirereadjustment.

TRAVEL PIVOT ADJUSTMENT

• The saw arm should risecompletelyto the up

position by itself.

• Ifthe saw arm does not raise byitselfor ifthere is

play inthe pivotjoints,have saw repairedby a

qualified servicetechnicianat your nearest Sears

storetoavoid riskof personalinjury.

BEVEL PIVOT ADJUSTMENT

• Yourcompoundmitersaw should bevel easily by

looseningthe bevel lockknob and tiltingthe saw

armto the left.

• If movementistightor ifthere is play inthe pivot,

have saw repaired by a qualified servicetechni-

cian at yournearest Sears store to avoid dsk of

personalinjury.

DEPTH STOP

The depth stoplimitsthe blade'sdownwardtravel. It

allowsthe bladeto go below the mitertable enoughto

maintainfullcuttingcapacities.The depth stop posi-

tions the blade 114in. from the mitertable support.

Note: The mitertable supportis located insidemiter

table.

The depthstop isfactoryset to providemaximum

cuttingcapacityfor the 12 in. saw blade providedwith

yoursaw.Therefore, the saw blade providedshould

never need adjustments.

However, when the diameterof the blade has been

reduceddue to sharpening,it may be necessaryto

adjust the depth stop to provide maximumcuffing

capacity.Also, when a new blade isinstalled,it Is

necessarytocheckthe clearance ofthe blade to the

mitertable supportbefore starting the saw. Make

adjustmentsif needed.

DEPTH STOP ADJUSTMENTS

See Figure25.

• Unplugyour saw.

WARNING: Failureto unplugyour saw could

resultin accidentalstartingcausing possible

seriouspersonalinjury.

To adjust the depth stop use a 17 mm wrenchor

adjustablewrenchand loosenthe hex nutat the

rear of the mitersaw arm.

Usethe 5 mm hex key wrench providedto adjust

the depthstop adjustmentscrew. The saw blade

is loweredby turningthe screwcounter-clockwiso

and raised by tuming the screw clockwise.

18

DEPTHSTOP

ADJUSTMENT

BEVEL

LOCKKNOB

MITER

PosmvE TABLE

STOPADJUSmENTLOCKNUT(S) Fig.25

• Lowerthebladeintothezeroclearancethroat

plataofthe miter table. Check blade clearance

and maximum cuttingdistance(distancefrom

fence where blade enters) to front of mitertable

sloL

• Readjustif necessary.

WARNING: Do not startyourcompoundmiter

saw withoutcheckingfor interferencebetween

the blade and the mitertable support.Damage

couldresulttothe bladeif itstrikesthe miter

table supportduringoperationofthe saw.

• Tightenthe hex nutwith a 17 mm wrench or

adjustablewrench.

• To prevent the depth stopadjustmentscrew from

tuming whiletighteningthehex nut,carefully held

itwiththe hex key whiletighteningthe hex nut.

APPLICATIONS

(Use only for the purposes limed below)

• Crosscuttingwood and plastic.

• Crosscuttingmiters,joints,etc. for pictureframes,

moldings, doorcasings, and fine joinery.

Note: The blade providedis fine for most wood

cuttingoperations,butforfine joinerycutsor cutting

plastic,usa one ofthe accessoryblades available

fromyour nearestSears store.

& WARNING: Beforestartinganycutting

operation,clamp,boltor nailyour compound

mitersaw to a workbench.Never operate your

miter saw on the flooror ina crouched position.

Failureto heed this waming can result insorious

personalinjury.

cu'n'ING WITH YOUR COMPOUND

MITER SAW

&

WARNING: When usinga workclamp or

C-clampto secure your workpiece,clamp

workpieceon one side ofthe blade only. The

workpiecemustremainfree on one side ofthe

blade topreventthe bladefrom bindingin

workpiece.The workpiecebindingthe blade will

cause motor stallingand kickback.This situation

couldcause an accidentresultingin possible

serious personal injury.

CROSSCUTTING

See Figure26.

A crosscutismade bycuttingacross the grainofthe

workpiece.A straightcrosscutismade withthe miter

table set at the zero degree position. Mitercrosscuts

are made with the mitertable set st some angle other

than zero.

TO CROSSCUT WITH YOUR MITER

SAW:

• Pulloutthe lock pinand liftsaw arm to itsfull

height.

• Loosenthe miterlock handle. Rotatethe miter

lockhandle approximately one-haftturntothe left

toloosen.

• Pressthe miter lockplate downwithyour thumb

and held.

• Rotate the control arm untilthe pointer alignswith

the desired angleon the miterscale.

• Release the miterlockplate.

Note: You can quicklylocate0°, 15°, 22-1/2°,

31.62°, and 45° leftor rightbyreleasingthe lock

plate as you rotate the controlarm. The lockplate

willseat itselfin one of the positive stopnotches,

locatedin the mitertable frame,

• Tightenthe miterlock handle securely.

,_ WARNING: To avoidseriouspersonal injury,

alwaystightenthe miter lockhandle securely

before makinga cut. Failureto do so could result

in movement ofthe controlarmor mitertable

whilemakinga cut.

19

STRAIGHT

CROSSCUT

C-CLAMP

• Slowlylowertheblade intoandthroughthe

workpiece.See Figure 26.

•• Release the switchtriggerand allow the sew

bladeto stoprotatingbeforeraisingthe bladeout

ofworkpiece.Wait untilthe electricbrake stops

bladefrom fuming before removingthe workpiece

from the mitertable.

BEVEL CUT

See Figures27 and 28.

A bevel outis made by cuttingacrossthe grain ofthe

workpiecewiththe bladeangled to the workpieca.A

straightbevelcut ismade withthe mitertable set at

the zero degreepositionand the blade set at an angle

between 0° and 45°,

LEFTSIDE RIGHTSIDE

LEFT

INDICATOR/ INDICATOR

POINT t POINT

Fig. 26

• Placethe workpiecefiat on the mitertable with

one edge securely against the fence. If the board

iswarped, place the convexside againstthe

fence. If theconcave edge of a board is placed

againstthe fence, the board couldcollapse on the

blade at the end of the cut,jammingthe blade.

See Figures 33 and 34.

• When cuttinglong piecesof lumberor molding,

supportthe oppositeend ofthe stockwith a roller

stand or witha work surfacelevel withthe sew

table.

Aligncuttinglineon the workpiecewith the edge

of sew blade.

Grasp the stockfirmlywith one handand secure

itagainstthe fence. Use the optionalwork clamp

or a C-clamp to secure the workpiecewhen

possible.See Figure 26.

_k WARNING: To avoid seriouspersonal injury,

keep yourhandsoutside theno handszone; at

least 3 in. from blade. Never performany cutting

operationfreehand (withoutholdingworkpiece

againstthe fence). The blade couldgrab the

workpieceif it slipsor twists.

SCALE

MOUNTINGBRACKET SCALE Fig. 27

• Beforeturningon the saw, performa dry run ofthe

cuttingoperationjust to make surethat no

problemswilloccurwhen thecut ismade.

• Grasp the saw handlefirmly,pressthe lock-offtab

down, then squeeze the switchtrigger.Allow

several secondsfor the blade to reach maximum

speed.

TO BEVEL CUT WITH YOUR MITER

SAW:

• Pulloutthe lock pinand liftsew arm to its full

height.

• Loosenthe miterlockhandle. Rotate the miter

lockhandle approximatelyone-half fum to the left

to loosen.

• Pressthe miterlock plate downwithyourthumb

and hold.

• Rotatethe control arm untilthe pointeralignswith

zero on the miter scale.

• Release the miter lockplate.

Note: You can quicklylocatezero byreleasing

the lockplate as you rotatethe controlarm. The

lockplate willseat itselfin one of the built-in

positivestop notches,locatedinthe mitertable

frame.

• Tightenthe miter lockhandle securely.

_k WARNING: To avoid seriouspersonalinjury,

always tightenthe miterlockhandle securely

beforemakinga cut. Failure to do so could result

in movementofthe controlarm or mitertable

while makinga cut.

20

\

Fig. 28

• Loosen the bevel look knoband movethe sew

arm to the lefttothe desiredbevel angle.

• Bevel angles can be set from 0° to45°.

• Foryourconveniencethere isa double scale

located on the mounting brackeL See F_jure 27. If

one side becomes difficultto read as you move

thesaw arm to the left, simplyrefer to the other

side.Alignthe indicatorpointforthe side you

choosewiththe desiredangle.

• Once the sew arm has been setat the desired

angle, securelytightenthe bevel lockknob.

• Place the workpiecefiat on the mitertable with

one edge securely against the fence. If the board

is warped, place the convexside against the

fence. If the concave edge of a boardis placed

againstthe fence, the beard couldcollapseon the

bladeat the end ofthe cut,jamming the blade.

See Figures 33 and 34.

• When cuttinglongpieces oflumberor molding,

supportthe oppositeend ofthe stockwitha roller

stand or witha worksurface level withthe sew

table.

Alignthe cuttingline on the workpisoewiththe

edge of saw blade.

Grasp the stockfirmlywithone handand secure it

against the fence. Use the optionalworkclamp or

a C-clamp to securethe workplecewhen pos-

sible. See Figure 28.

_1= WARNING: To avoid serious personal injury,

keep your handsoutsidethe no hands zone; at

least3 in. from blade. Never perform any cutting

operationfreehand (withoutholdingworkplece

againstthe fence). The blade could grab the

workpieceif itslipsor twists,

• Before tuming on the sew, perform a dry runof

the cuttingoperationjust to make sure that no

problemswilloccurwhenthe cut ismade.

• Grasp the sew handlefirmly,pressthe lock-offtab

down, then squeeze the switchtrigger.Allow

severalsecondsforthe bladeto reach maximum

speed.

• Slowlylowerthe blade intoand through the

workpiese.See Figure28.

• Release the switchtriggerand allow the saw

bladeto stoprotatingbefore raisingthe blade out

ofworkpiece.Wait untilthe electricbrake stops

bladefrom turningbefore removingthe workploce

from miter table.

COMPOUND MITER CUT

A compoundmitercut isa cut made usinga miter

angle and a bevel angle at the same time. This type of

cut is usedto make pictureframes, cutmolding,make

boxeswith slopingsides,and for certain roofframing

cuts.

To make thistype of cut the controlarm on the miter

table mustbe rotated tothe correct angle and the sew

arm must be tiltedto thecorrectbevel angle. Care

shouldalways be takenwhen makingcompoundmiter

setups due to the interactionofthe twoangle settings.

Adjustmentsof miterand bevel settings are interde-

pendent withone another. Eachtime you adjust the

miter setting you changethe effectof the bevel

setting. Also, each time you adjustthe bevel setting

you changethe effect ofthe miter setting.

It maytake several settings to obtain the desired cut.

The firstangle setting should be checked after setting

the secondangle, since adjustingthe secondangle

affects thefirst.

Once the two correct settings for a particularcut have

been obtained, alwaysmake a test cut in scrap

materialbefore makinga finish cut in goodmaterial.

21

TO MAKE A COMPOUND CUT WITH

YOUR MITER SAW:

• Pulloutthe lockpinand liftsaw arm to its full

height.

• Loosenthe miterlock handle.Rotatethe miterlock

handle approximatelyone-halftom tothe leftto

loosen.

• Pressthe miterlockplatedownwithyourthumb

and hold.

• Rotatethe controlarmuntilthe pointeralignswith

the desiredangle on themiterscale.

• Release the miterlock plate.

Note- You can quicklylocate0°, 15°, 22-1/2°,

31.52°, and 45° left or rightby releasingthe miter

lockplate as you rotatethe controlarm. The miter

lockplate willseat itselfinone ofthe positivestop

notches,locatedin mitertableframe.

• Tightenthe miterlockhandlesecurely.

A WARNING: To avoid sedous persor_| k_jury,

alwaystightenthe miterlockhandle securely

beforemakinga cut. Failureto do socouldresult

in movementofthe controlarm or mitertable

whilemaking a cut.

• Loosenthe bevel lockknoband movethe saw arm

tothe lefttothe desiredbevelangle.

• Bevelanglescan be setfrom 0° to 45".

• Foryour convenience there isa double scale

locatedon themountingbracket.See Figure27. ff

one side becomesdifficultto read as you move the

saw armto theleft, simplyrefertothe otherside.

Alignthe indicatorpointforthe side you choose

withthe desired angle.

• Oocethe saw arm has been set at the desired

angle, securelytighten the bevel lockknob.

• Recheck miteranglesetting.Make a testcut in

scrapmaterial.

• Placethe workplecefiat on themiter table with

one edge securelyagainstthe fence. Ifthe hoard

iswarped, place theconvex side againstthe

fence. Ifthe concaveedge of a boardcould

collapse on the hiade atthe end of thecut,

jammingthe blade. See Figures33 and 34.

• When cuttinglong piecesof lumberor molding,

supporttheoppositeend ofthe stockwith a roller

standor witha worksurfacelevel withthe sew

table.

• Alignthe cuttinglineon the workplecewiththe

edge of saw blue.

Grasp the stock firmly withone hand and secure it

againstthe fence. Use the optionalwork clampor

a C-clamp to secure the workpiecewhen possible.

See Figure29.

_1= WARNING: To avoidserious personalinjury,

a_wayskeep your hands outsidethe no hands

zone;at least3 in. from blade. Never performany

cuttingoperationfreehand (withoutholding

workpleceagainstthe fence), The blade could

grabthe workpieceifit slipsor twists.

COMPOUND

MITIERCUT

C-CLAMP Fig. 29

22

• Beforetuming onthe saw, performa dry runof the

cuttingoperationjusttomakesurethatno problems

willoccurwhenthe cutis made.

• Grasp the saw handlefirmly, press the lock-offtab

down, then squeeze the switchtrigger.Allow sev-

eralsecondsfor thebladetoreachmaximumspeed.

• Slowly lower the blade into and through the

workpiece.See Figures29 and 30.

• Release the switchtdggerand allow the saw blade

to stop rotating before raising the blade out of

workpiece.Wait untilthe electdcbrake stopsblade

from turning before removingthe workpiece from

mitertable.

SUPPORT LONG WORKPIECES

See Figure31.

Longworkpieces need extra supports.Supports

shouldbe placed along the workpieceso it does not

sag. The support shouldlet the workpiecelay flat on

the base ofthe saw and worktable duringthe cutting .

operation.Use the optionalworkclamp or a C-clamp

tosecure the workpiece.

_k WARNING: To avoid sadous personal injury,

always keep yourhandsoutsidethe no hands

zone; at least3 in. from blade. Never perform

any cuttingoperationfreehand (withoutholding

workpiece againstthe fence). The bladecould

grab the workpieceifitslipsor twists.

45° X 45° COMPOUNDMITERCUT

Fig. 30

LONGWORKPIECE

WORKPIECESUPPORTS

Fig. 31

23

CUTTING COMPOUND MITERS

To aid in making the correctsettings,the compound angle seffingchart belowhas been provided.Since com-

poundcutsare the mostdifficultto accuratelyobtain,trialcutsshouldbe made inscrap material, and much

thoughtand planningmade, priorto makingyourrequiredcut.

PITCH _U_BEROFSIDES

OFmDE 4 I 5 I 8 I 7 8 I 9 I 10

0O M- 45.00O M- 36.00 ° M- 30.00O M- 25.71° M- 22.50° M- 20.00O M- 18.00O

B- 0.00O B- 0.00° B- 0.00° B- 0.00 ° B- 0.00O B- 0.00O 13" 0.00°

5° M-44.89 ° M-35.90 ° M-29.91 ° M-25.63 ° M-22.42 ° M-19.93 ° M-17.94 °

13- 3.53 ° B- 2.94° B- 2.50 ° B- 2.17° 13- 1.91° B- 1.71° B- 1.54°

M-44.56 ° M-35.58 ° M-29.62O M-25.37O M-22;19 ° M-19.72O M-17.74 °

10°

B- 7.05° B- 5.86° B- 4.98° B- 4.32° B- 3.81° B- 3.40`> B- 3.08°

M-44.01 o M-35.06 o M-29.15 o M-24.95 o M-21.81 o M-19.37 o M-17.42 o

15°

B'10.55 ° B- 8.75° B- 7.44° B- 6.45° B- 5.68° B- 5.08° B- 4.59°

200 M-43.22O M-34.32O M-28.48 ° M-24.35 ° M-21o27° M-18.88 ° M-16.98 °

13-14.00° B-11.60 ° B- 9.85° B- 8.53° B- 7.52° B- 6.72° B- 6.07°

25o M-42.19 ° M-33.36 ° M-27.62O M-23.56 ° M-20.58 ° M-18.26 ° M-16.41 °

B- 17.39° B-14.38 + B- 12.20 ° B- 10.57° B- 9.31° B- 8.31° B- 7.50°

30o M"40.89° M'32.18 ° M'26.57 ° M'22.64 ° M'19.73 ° M'17.50 ° M-15.72O

B- 20.70`> 13-17.09° B- 14.48° B- 12.53° B- 11.03° B- 9.85° B- 8.89°

35° M"39.32o! M-30.76 ° M-25.31 ° M-21.53 ° M-18.74 ° M-16.60 ° M-14.90 °

B-23.93 ° B-19.70 ° 13-16.67° B-14.41 ° B-12.68 ° B-11.31 ° B-10.21 °

40° M-37.45 ° M-29.10O M-23.86 ° M-20.25 ° M-17.60 ° M-15.58 o M. 13.98o

B-27.03 ° B-22.20° B- 18.75 ° B-16.19 ° B- 14.24° B- 12.70° B- 11.46°

M'35.26 ° M-27.19 ° M-22.21 ° M-18.80O M-16.32 ° M-14.43 ° M-12.94 °

45°

13"30.00° 13-24.56° B-20.70 ° 13"17.87° B- 15.70° 13"14.00 ° B- 12.62°

M-32.73 ° M-25.03 ° M-20.36 ° M- 17.20° M- 14.91° M- 13.17° M- 11.80°

50° 13"32.80° 13-26.76° 13-22.52° B- 19.41° B- 17.05° B- 15.19° B- 13.69°

M-29.84 ° M-22.62 ° M-18.32O M-15.44 ° M-13.36 ° M-11.79 ° M-10.56 o

55o

13-35.40° B- 28.78° 13"24.18° B- 20.82° B- 18.27° 13-16.27 ° B- 14.66°

M"26.57° M"19,96° M'16.10 ° M'13.54 ° M-11.70 ° M'10.31 ° M- 9.23°

60°

B-37.76 ° 13"30.60° B-25.66 ° B-22.07 ° B- 19.35° B- 17.23° B-15.52 °

M'22.91 ° M'17.07 ° M'13.71 ° M'11.50 ° M- 9.93° M- 8.74° M- 7.82°

65° B-39.86 ° B-32.19 ° B-26.95 ° B-23.16 ° B-20.29 ° B- 18.06° B-16.26 °

M'18.88 ° M-13.95 ° M-11.17 ° M- 9.35 ° M- 8.06° M- 7.10° M" 6.34°

70°

B-41.64 ° B-33.53 ° B-28.02 ° B-24.06 ° j B-21.08 ° B- 18.75 ° B- 16.88°

75o M'14.51 ° M-10.65 ° M- 8.50° M- 7.10° M- 6.12° M- 5.38° M- 4.81°

B-43.08° 13"34.59° B- 28.88° B- 24.78° B- 21.69 ° B- 19.29° B- 17.37°

M- 9.85 ° M- 7.19° M- 5.73° M- 4.78° M- 4.11 ° M- 3.62 ° M- 3.23?

80o

B-44.14 ° B-35.37 ° B-29.50O B-25.30 ° B-22.14°! B-19.68 ° B-17.72 o

M- 4.98 ° M- 3.62° M- 2.88<' M- 2.40° M-2.07 ° M-1.82 ° M- 1.62°

85° B- 44.78° B-35.84 ° B-29.87 ° B-25.61° B-22.41° B- 19.92° B- 17.93°

90o M- 0.00O M- 0.00° M- 0.00° M- 0.00° M- 0.00° M- 0.00° M- 0,00°

B- 45.00° B- 36.00° B- 30.00O B- 25.71° B-22.50° B-20.00° B- 18.00°

Each B (Bevel) and M (Miter) Setting is Given to the Closest 0.005°.

COMPOUND-ANGLE SETTINGS FOR POPULAR STRUCTURES

24

cu'rI'ING CROWN MOLDING

Yourcompoundmitersew does an excellentjob of

cuttingcrown molding.In general,compoundmiter

sews do a betterjob of cuttingcrown moldingthan

anyothertoolmade.

In orderto fit properly,crown moldingmustbe com-

pound mitered with extreme accuracy.

The two contact surfaceson a piece ofcrownmolding

that fit fiat against the ceilingand the wall of a room

are at anglesthat, when added together, equal

exactly90°. Most crown moldinghas a top rear angle

(the sectionthat fits flat against the ceiling)of 52° and

a bottomrear angle(the sectionthat fits fiat against

the wall) of 38°.

52o CEILING

W

A

L

L FENCE

TOPEDGEAGAINSTFENCE:

• LEFTSIDE,iNSIDECORNER

• RIGHTSIDE,OUTSIOECORNER

MITERTABLE

O O

LAYING MOLDING FLAT ON THE

MITER TABLE

See Figure32.

To use this methodfor accuratelycutting crown

moldingfor a 90° insideor outsidecorner, laythe

molding withitsbroad backsurface fiaton the miter

table and againstthe fence.

When settingthe bevel and miteranglesfor Com-

poundmiters,rememberthat the seffings are interde-

pendent;changingone angle Changesthe otherangle

as well.

Keep in mindthatthe anglesfor crown moldings are

veryprecisea_nddifficultto set. Since it is very easy

for these anglestoshift,all settingsshouldfirstbe

tested on scrap molding.Also most wallsdo not have

anglesofexactly90°, therefore, youwill need to fine

tuneyour settings.

CORNER

OUTSIDE

FENCE CORNER

BoI"roMEDGEAGAINSTFENCE:

• RIGHTSIDE,INSIDECORNER

• LEFTSIDE,OUTSIDECORNER

MITERTABLE

O O

CROWNMOI.D_IGFLATONMITERTABLE

Fig. 32

25

Whencuttingcrownmoldingbythismethodthebevel

angleshouldbe set at 33.85 °. The miterangle should

be set at 31.62 ° either dghtor left,dependingonthe

desired cutfor the application.See the chartbelow for

correctangle settingsand correct positioningofcrown

moldingon mitertable.

The settings inthe chart below can be used forcutting

AllStandard (U.S.) crownmoldingwith52° and 38°

angles.The crown moldingis placed fiat onthe miter

table usingthe compound features of your miter saw.

%

Bevel

Angle Type of Cut

Setting

Left aide, inside comer

1.Top edge ofmoldingagainstfence

33'85° 2. Mitertable set dght31.62°

3. Save left end ofcut

Right side, Inside comer

1.Bottomedge ofmoldingagainstfence

33"85° 2. Mitertable sat left31.62°_

3. Save left end ofcut

Left side, outside comer

1.Bottomedge ofmolding againstfence

33"85° 2. Mitertable set left31.62°

3. Save dght end of cut

Right side, outside comer

1. Top edge of moldingagainstfence

33"85° 2. Mitertable set right31.62°

3. Save rightend of cut

Fig. 34

When cuttingwarped material, alwaysmake sure it is

positioned on the miter table withthe convex side

againstthe fenceas shown in figure33.

If thewarped matadal is positioned the wrongway as

shownin figure34, itwillpinchthe blade near the

completionof thecut.

WARNING: To avoid a kickbackand to avoid

sedouspersonalinjury,never positionthe

concave edge of bowedor warped matedal

againstthe fence,

CLAMPING WIDE WORKPIECES

See Figure 35.

CUTTING WARPED MATERIAL

See Figures 33 and 34.

RIGHT Fig. 33

WIDE

BOARD

Fig. 35

When cuttingwide workpiecessuch as a 2 in. x 6 in.,

boardsshouldbe clampedwitha C-clamp as shown in

figure 35.

26

_k WARNING: When servicing,useonlyidentical

Craftsmanreplacement ports. Useof anyother

part may create a hazard or cause product

damage.

GENERAL

Avoid usingsolventswhen cleaningplasticparts.

Most plasticsare susceptibleto damage fromvarious

typesof commercialsolvents and may be damaged

by their use. Use clean clothsto remove dirt,carbon

dust,etc.

_i_ WARNING: Do not at any time letbrake fluids,

gasoline, petroleum-basedproducts, penetrating

oils, etc. come incontact withplasticports. They

contain chemicalsthat candamage, weaken or

destroyplastic.

It hasbeen found that electrictoolsare subjectto

acceleratedwear end possiblepremature failure when

they are used on fiberglassbeats, sportscars,

wallboard,spacklingcompounds, or plaster.The

chipsand grindingsfrom these matedals are highly

abrasiveto electrictoolparts suchas bearings,

brushes,commutators, etc. Consequently,it isnot

recommendedthat this tool be usedfor extended

workon any fiberglassmaterial, wallboard,spackling

compounds, or p_estar.Dudngany use onthese

materialsit isextremely importantthat the toolis

cleanedfrequently by blowingwith anair jet.

LUBRICATION

Allofthe beadngs in this toolare lubricatedwith a

sufficientamountof highgrade lubricantfor the lifeof

the unitundernormal operatingconditions. Therefore,

no furtherlubricationisrequired.

EXTENSION CORDS

The useofany extensioncordwillcause some lossof

power.To keep the lossto a minimumand to prevent

tooloverheating,use an extensioncordthatis heavy

enoughto carrythe currentthe toolwilldraw.

A wiregage size (A.W.G.) of at least 14 isrecom-

mendedfor an extensioncord 25 feet or less in

length.When workingoutdoors,usean extension

cordthat is suitableforoutdooruse. The cord's jacket

willbe marked WA.

_ CAUTION: Keep extensioncordsaway fromthe

cuttingarea end positionthecord so that itwill

notget caughton lumber,tools,etc., dudng

cuffingoperation.

A WARNING: Check extensioncords before each

use. If damaged, replace immediately. Never use

toolwitha damaged cord sincetouching the

damaged area couldcause electricalshock

resultinginserious injury.

_1 WARNING: Alwayswear safety gogglesor

safety glasses withside shieldsduringpower

tooloperationor when blowingdust. Ifoperation

isdusty,alsowear a dust mask.

27

& WARNING: To ensuresafety and reliability,all

repairs -- with the exceptionofthe externally

accessiblebrushes-- shouldbe performedbya

qualifiedservicetechnicianat a Sears storeto

avoid riskof personal injury.

BRUSH REPLACEMENT

See Figure 36.

BRUSH

ASSEMBLYBRUSH

CAP

BRUSH

CAP BRUSH

ASSEMBLY Fig. 36

Yoursaw has externallyaccessible brushassemblies

that should be periodically checkedfor wear.

Proceed u follows when replacement Is required:

• Unplugyoursaw.

,_ WARNING: Failt_reto unplugyour saw could

resultin accidentatstartir_lcausingserious

injury.

• Remove brushcap witha screwdriver.Brush

assemblyis springtoadedandwiltpopout wben

you remove brushcap.

• Remove brushassembly,

• Check for wear. Replace bothbrusheswhen

either haslessthan 1/4 in. lengthof carbon

remaining.Do not replace one side without

replacingthe other.

• Reassembleusingnew brushassemblies. Make

sure curvatureof brushmatches curvatureof

motor and that brushmoves frse_yin brushtube.

• Make sure brushcap isorientedcorrectly

(straight)and replace.

• Tighten brushcapsecurely. Do not overtighten.

28

29

'----- CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 -'--

27

28

34

4

Figure A

30

CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 ---,

I The model numberwill be foundon a plate attached to the motorhousing.Always mentionthe model |

number in all correspondence regarding your COMPOUND MITER SAW or when ordering repair

!

parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

KEY PART

NO. NUMBER

1 976512-001

2 976578-001

3 980229-001

4 980230-001

5 980253-001

6 980232-001

7 360308-142

8 980117-001

9 980261-001

10 976568-001

11 976605-001

12 976570-001

13 980418-001

14 980243-001

15 980259-001

16 980244-001

17 980245-001

18 980234-001

19 976531-001

20 980239-001

21 980263-001

22 980256-001

23 980250-001

24 976507-001

25 980257o001

26 980251-001

27 980258-001

28 980233÷001

29 976242-001

30 980252o001

31 980264÷001

32 980260÷001

33 980231 o001

34 980240-001

35 977435-001

36 977434-001

PARTS LIST FOR FIGURE A

DESCRIPTION QUAN.

Flat Washer .......................................................................................... 2

Self-LockingNut ................................................................................... 1

SpringWasher ...................................................................................... 1

MiterTable Frame ................................................................................ 1

Table Spindle........................................................................................ 1

Fence .................................................................................................... 1

SpringWasher...................................................................................... 4

Belt (Hex Hd,) ....................................................................................... 4

Hex Key Holder..................................................................................... 1

BladeWrench ........................... :........................................................... 1

Hex Key (6 ram) .................................................................................... 1

Hex Key (5 ram) .................................................................................... 1

Hex Key (10 ram).................................................................................. 1

MiterTable .................................. _......................................................... 1

Hex Nut ................................................................................................. 2

Hex Belt ...................................................... :......................................... 2

Bevel PivotBracket............................................................................... 1

Bevel Scale ........................................................................................... 1

Rivet ...................................................................................................... 3

Belt (Hex Hd.) ....................................................................................... 2

SpringWasher ...................................................................................... 2

Screw (Pan Hd,) ................................................................................... 6

Screw (Pan Hd.) ............................................................................ _,..,..1

Flat Washer .......................................................................................... 1

Throat Plate .......................................................................................... 1

MiterScale indicator............................................................................. 1

Clamp Nut ............................................................................................. 1

MiterLockHandle ................................................................................. 1

FixedPlate............................................................................................ 1

Screw (Pan Hd.) ................................................................................... 2

LockPlate ............................................................................................. 1

Screw(Pan Hd.) ................................................................................... 2

Screw(Pan Hd,) ................................................................................... 3

MiterScale ............................................................................................ 1

LineWarning Label............................................................................... 2

HandWarning Label............................................................................. 2

31

r_

CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120

11m

8

21

FigureB

54

52

7

49

\

23

24

50

42

41

30

'\, 32

39

37

29

¢o

CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120

I The model number willbe found on a plate attachedto the motorhousing. Alwaysmention the modelnumber inallcorrespondence regarding your |

COMPOUND MITER SAW or when ordering repair parts.

J

KEY PART

NO. NUMBER

1 976512-001

2 980249-001

3 980255-001

4 980262-001

5 980238-001

6 980235-001

7 980247-001

8 976643-001

9 980254-001

10 980246-001

11 980237-001

12 976512-001

13 980236-001

14 976641-001

15 980266-001

16 980276-001

17 980275-001

18 980281-001

19 976526-001

20 980287-001

21 980248-001

22 976526-001

23 980265-001

24 979693-00!

25 976567-001

26 980293-001

27 976733-001

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST FOR FIGURE B

KEY PART

DESCRIPTION QUAN.

Flat Washer ............................................................. 1

Stop ......................................................................... 1

Screw(Pan Hd.) ...................................................... 1

ShoulderScrew ....................................................... 1

LinkAssembly......................................................... 1

Screw (Pan Hd.) ...................................................... 2

LinkHolder.............................................................. 1

Retaining'E' Ring.................................................... 1

Washer .................................................................... 1

PivotShaft............................................................... 1

Bevel LockKnob ..................................................... 1