DEPARTMENT OF THE AIR FORCE

OKLAHOMA CITY AIR LOGISTICS COMPLEX (AFMC)

TINKER AIR FORCE BASE OKLAHOMA

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01

21 MARCH 2022

REISSUED: 12 March 2024

MEMORANDUM FOR DISTRIBUTION C

MAJCOMs/FOAs/DRUs

FROM: OC-ALC/QA

3001 Staff Drive, Suite 2U77

Tinker AFB, OK 73145

SUBJECT: Air Force Guidance Memorandum to AFSCMAN21-102OC-ALCSUP, Depot

Maintenance Management

By Order of the Commander of the Oklahoma City Air Logistics Complex (OC-ALC),

this Air Force Guidance Memorandum immediately changes AFSCMAN21-102OC-ALCSUP.

Compliance with this Memorandum is mandatory. To the extent its directions are inconsistent

with other Air Force publications; the information herein prevails, in accordance with DAFI 33-

360, Publications and Forms Management.

This Memorandum becomes void after one year has elapsed from the date of this

Memorandum, or upon incorporation by interim change to, or rewrite of AFSCMAN21-

102_OC-ALCSUP, whichever is earlier.

BRIAN R. MOORE, Brigadier General

USAF Commander, OC-ALC

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Attachment

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01

Chapter 2

DEPOT MAINTENANCE WORK MEASUREMENT

2.2.2.2. (Added) Depot Maintenance Work Measurement Program (Labor standard Review).

2.1.1.1.1. (Added) This chapter provides guidance for the Depot Maintenance Work

Measurement Program. This program addresses use of direct labor methods, standards, and

work measurement. This chapter also outlines when labor standard reviews should be performed

and the OC-ALC approval process.

2.1.1.1.2. (Added) The Depot Maintenance Work Measurement Program is an annual review

of labor standards. In accordance with AFSCMAN 21-102 Chapter 2, labor standard reviews will

be accomplished budget lead-time away. Budget lead-time away for Engines and MISTR

workloads is defined as the period of 1 Oct thru 31 Jan for each fiscal year to support upcoming

pricing and budget cycles. No labor standard adjustments/changes will be allowed outside this

period, except for the following:

2.1.1.1.2.1. (Added) New workload

2.1.1.1.2.2. (Added) Tech Order changes

2.1.1.1.3. (Added) Aircraft will use the Aircraft Missile Requirements (AMR) process.

2.1.1.1.4. (Added) Review requirements: At minimum, production group planning

organizations should review PDN labor standards representing the top 20% of the overall group

production hour variance. Reports/logic used to determine top 20% drivers should represent at

least one year of data.

2.1.1.1.5. (Added) Approval limits: Labor standard adjustments exceeding +/- 10% standard

hours variance (by PDN) require OC-ALC/OBW chief approval.

2.1.1.1.6. (Added) Approval process: Final approval must be obtained before any

adjustments are made. All requests requiring OC-ALC/OBW approval will be sent via eSSS to

[email protected] in accordance with the below guidance.

2.1.1.1.6.1. (Added) Minimum coordination includes: squadron planning chief & group

MXDS chief or assigned alternate.

2.1.1.1.6.2. (Added) Include a brief summary/justification explaining the increase/decrease.

2.1.1.1.6.3. (Added) All labor standard review documentation, as attachment(s).

2.1.1.1.6.4. (Added) Logic: Include systems used and/or calculations to warrant

adjustment.

2.1.1.1.6.5. (Added) Timeline: Submitted not prior to 1 Oct and no later than 10 Jan.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

2.1.1.1.7. (Added) OC-ALC/OBW approval/disapproval will be returned within 15 business

days of submittal.

2.1.1.1.7.1. (Added) Approved: If approved, planner will send a copy of MM1 report

showing the 9999 history lines screen in E046B, which shows: old standard hours, new standard

hours, date of change, and the reason for the increase.

2.1.1.1.7.2. (Added) Disapproved: If disapproved, OC-ALC/OBW will send an email

response with rationale explaining disapproval.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 4

CAPITAL INVESTMENT PROGRAM (CIP)

4.1.2.22.2. (Changed) IT and/or communications projects will initially be coordinated with

72 ABW/SCXP. The SCXP will assist in getting the project loaded to the approved requirements

tracking system for review when necessary. Project discussions will start once an IT and/or

communications requirement is identified. During the planning stage, the IT investing

organization will provide IT investment information to the IT investment Portfolio Managers for

registration review. The IT investing organization will appoint primary and alternate program

managers to manage the IT investment and provide required information via the local Portfolio

Management (PfM) process. AF IT investments are registered and reported in the Information

Technology Investment Portfolio Suite (ITIPS). The organization will appoint primary and

alternate program managers to manage the IT investment via the local PfM process. Once an

investment is registered, the owner will be guided through compliance areas such as National

Defense Authorization Act (NDAA) and Clinger-Cohen Act (CCA) approval. Contact the AFSC

Tinker IT Portfolio Management Team via the Community site:

https://usaf.dps.mil/teams/22386/pfm/afsc-

tinker/SitePages/AFSC%20Tinker%20IT%20PfM%20Community%20Site.aspx. Use the PfM

Team e-mail address for contacting the first available team member. Additional AF IT

Investment PfM and ITIPS information and links are located on the PFM site. The NDAA

Defense Business System (DBS) Organizational Execution Plan (OEP) certification process can

take up to one year for final approval.

4.1.6.1.1. (Changed) The group CIP monitor and/or project engineer are responsible for

creating the Comprehensive Cost and Requirements (CCaR) record at the group level. Upon

identification of a requirement that meets CIP guidelines, a CCaR record will be created. At a

minimum, the record must contain known project information including the project name,

estimated cost, project engineer, and project point of contact (POC). Additional supporting

documentation, such as: vendor estimates, statement of work (SOW), statement of objectives,

etc., must be loaded to the project’s CCaR in the “Tools” section under “Attachments”.

4.1.7.7.1. (Changed) The ALC business office, in coordination with the group business

office and the group CIP monitor, must validate all workload projections prior to submitting data

for the EA and scoring the ALC analysis portion of the CCaR record.

4.1.7.14.2. (Changed) Hierarchy of controls determination is listed on the CCaR record

under DIFMS Project Information tab with a “YES” or “NO” drop-down response. If “YES” is

selected, the project requires PPE, and the CIP project engineer is required to attach to the CCaR

record, the hierarchy of controls statement form and supporting documentation stating the

methodology of how the determination was made. If “NO” is selected, the project must not

require any form of PPE and must also attach to the CCaR record a statement form that no PPE

is required. The PARTALC Analysis scores will not be approved if no selection is chosen and/or

no supporting documentation is provided.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

4.1.8.1.1. (Changed) The requirement’s POC/engineer will assess each requirement against

the ALC RLMT asset scoring matrix to calculate each requirement’s total score. The

requirement’s POC/engineer will also perform analysis on unquantifiable/intangible issues that

may impact the decision-making process. The POC/engineer will provide a written justification

to leadership outlining why their requirement should be considered for funding. The written

justification will address those unquantifiable/intangible issues, which may include but not

limited to, future workload, capacity, capabilities, additive manufacturing requirements,

technology insertions/reverse engineering, accreditation/authorizations, automated test stand

requirements, energy, customer demands, repatriation of workload, etc. Each requirement’s total

score and written justification will be reviewed by a Subject Matter Expert (SMEs) panel, group

leadership, the ALC technical director, and ALC leadership. A strategic decision will be made by

ALC/CC and group requirement POCs/engineers are notified of their requirements approval by

ALC leadership for submission. The POC/engineer will commence developing the

documentation required for the EA, create a CCaR record for the approved and back-up

requirements, and procurement package. Once the AFSC/LZDA data call is received for CIP

requirements the approved listing/supporting documentation will become the submittal for the

ALC. The budget submission shall be developed with a cost effective mindset. Historically, the

ALC would submit requirements in-line with the anticipated depreciation amount for each FY

applicable to the Task Management Tool (TMT); however, if the submittal is not within +/- 10%

of the deprecation amount, justification will be provided with the ALC submission.

4.1.9.3.1. (Changed) The ALC CIP managers will calculate and provide estimated

depreciation figures to AFSC/LZDA with the budget submission. The depreciation estimates

include projects listed on the fixed asset report currently depreciating, projects that have not

reached Full Operational Capability (FOC), but are expected to reach FOC during the budget

cycle submission plus two years, as well as, projects from the current execution year expected to

be completed in the budget cycle submission plus two years. The estimate should also take into

account any remaining depreciation for anticipated contributed assets.

4.1.9.4.1. (Changed) To facilitate standardization, the ALC implemented a gated process

that assists leadership in identifying potential risk areas that may result in contract award delays.

The ALC CIP managers will establish internal timelines (Figure 4.5.) via the established gated

process outlining the milestone dates for verifying, validating, prioritizing, and approving the

ALC’s recommended investments in order to meet the annual CIP data call suspense. The

timelines included are associated with budget submission, package submission to contracting,

and Office of the Secretary of Defense (OSD) obligation goals. Additionally, all prioritized

projects must contain supporting documentation to justify the requirement being submitted for

AFSC/CA funding consideration.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

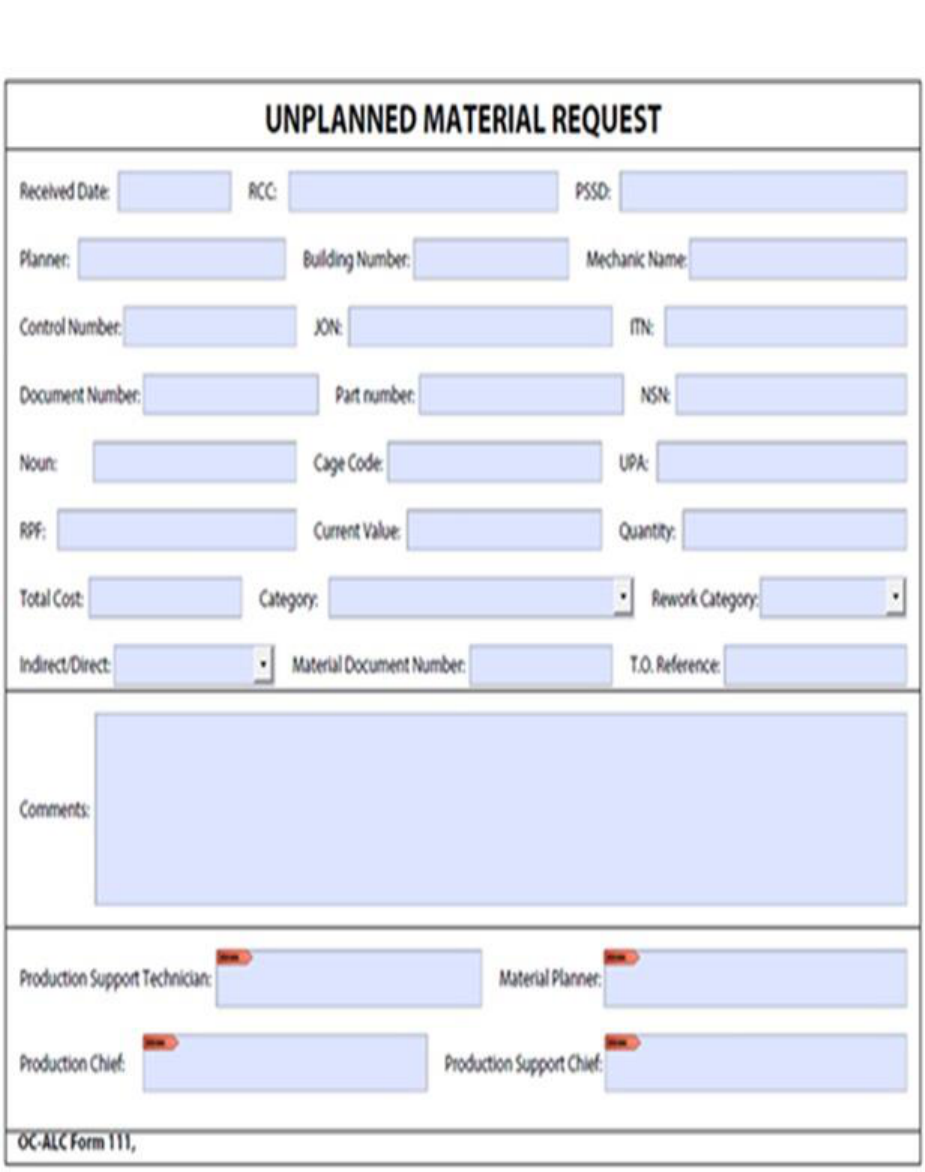

Figure 4.1. (Added) Example Gate Tracker Milestone Dates.

4.1.9.6.2.1. (Changed) When the CIP data call suspense is received from AFSC/LZ, the

ALC requirements prioritization process has already begun and will feed the ALC’s submission.

The process outlined in Paragraph 4.1.8.1.1 will be followed to prioritize and select

requirements; that process begins in January the year prior to the budget submittal date. The

AFSC/LZ data call will be sent to the group and staff office workflow boxes, as well as, the

group CIP monitors and will include detailed submission requirements, due dates, and required

templates. The submission will be for the budget year and two out years. The group CIP

monitors and/or assigned project engineer are expected to compile their package requirements to

include a CCaR record, EA, EIP or EEP, PIAP (if applicable), Hierarchy of Controls, and other

supporting documentation to substantiate the score in the ALC Analysis portion of the CCaR

record for each project in the budget year. The ALC CIP managers will review and compile the

submission to provide to AFSC/LZDA.

4.1.9.6.3.1. (Changed) AFSC/LZDA will work with the ALC CIP managers to resolve any

questions to ensure all projects are given equivalent consideration. The ALC CIP managers will

resolve any discrepancies with the group CIP monitors and group project engineer within three

business days of notification.

4.1.11.5.1. (Changed) The target load sheet will be submitted to 72 CPTS/FMAS and

AFSC/FZR for input to GAFS-BQ and DIFMS, respectively, at the project level within two

business days of approval in CCaR. Once the funds are loaded in the financial systems, the ALC

CIP managers will notify the group CIP monitors/project engineers that funding documents can

be released for coordination.

4.1.12.4. (Changed) The ALC Baseline Obligation Plan is created in coordination with

Contracting based on estimated contract award dates and considerations of Military

Interdepartmental Purchase Request (MIPR) acceptance dates for MIPR projects. The ALC CIP

manager will coordinate the proposed plan with group CIP monitors prior to providing the

baseline obligation plan to AFSC/LZDA.

AOP MILESTONE GOALS

27-Nov-18

14-Dec-18

14-Dec-18

04-Jan-19

21-Jan-19

26-Apr-19

17-May-19

17-May-19

17-May-19

29-Jun-19

01-Jul-19

15-Jul-19

01-Aug-19

25-Aug-19

27-Sep-19

11-Oct-19

31-Dec-19

IERB

ePART

Form &

9B

Full EA or

Waiver

Tech

Director

Review of

e-PARTS

Complex

Approval

Authority

to

Advertise

Letter

SOW or

SOO

Market

Research

Report

Tech Eval

Plan

Draft

PR/MIPR

Submit

completed

PR

package to-

PK

PK -

Approval

Legal

Review

Issue

Solicitation

Receive

Bid/Prop

Tech

Review-

Engineer

Legal

Review /

Contract

Award

Funds

Obligation

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

4.1.14.2.1. (Changed) Defense Federal Acquisition Regulation Supplement (DFARS) guidance

provides all 3400 federal supply stock class equipment will be purchased by the Defense

Logistics Agency (DLA). The AFSC/CC MIPR approval coordination process is managed by

purchase request (PR)/MIPR control 429 SCMS/GUMAB using their MIPR coordination

system.

4.1.16.1.2.1. (Changed) Reprogramming is handled by AFSC/LZDA on behalf of the ALC.

If an out-of-cycle requirement is identified or a cost increase is required and funding is not

available in the capability the requirement has been identified against, a reprogramming action

must occur. Once the ALC CIP managers are notified by the group CIP monitor of a pending

requirement, the ALC CIP manager will notify AFSC/LZDA of pending requirement and take

appropriate action.

4.1.19.1.1. (Changed) The approval consideration process for an out-of- cycle, emergency,

and back-up investment project are the same as the regular approval coordination process. These

processes include the creation of the CCaR record, EA, group CC approval, technical director

approval, and ALC CIP manager’s approval before the project will be submitted to AFSC/LZ for

consideration. The CIP managers will submit to AFSC/LZDA upon receipt of all required

documentation and signatory authorities.

4.1.22.8.1. (Changed) OC-ALC ensures projects FOC IAW the Engineering Execution Plan

(EEP)/Engineering Implementation Plan (EIP). Often projects have multiple deliverables

required to be in place prior to the project engineer declaring functional acceptability. In the

event a contract is not written to delineate required deliverables on separate Contract Line Item

Numbers (CLINs), the group CIP monitor, project engineer, or equipment custodian must

delineate the deliverables on the documentation required for FOC as determined by AFSC/FZR.

Once the equipment has reached FOC, it is the group CIP monitor, project engineer, and

equipment custodian’s (EC)’s responsibility to ensure the necessary documentation is completed

to get the equipment added to DIFMS and Defense Property Accountability System (DPAS).

DIFMS is the financial system used to maintain project depreciation records. DPAS is the system

used by the base equipment custodians to maintain equipment records. Additional instructions on

completing the necessary forms to add projects to DIFMS and DPAS can be found in AFSC SOP

– CIP Fixed Assets Capitalization and Modifications: Working Capital Fund - CIP Fixed Assets

Capitalization and Modifications.pdf - All Documents (dps.mil). Sample forms are located at the

following site: SOPs - Templates and Support Files - All Documents (dps.mil).

4.1.22.9. (Changed) Current and prior year project execution should be continually monitored

by the ALC CIP Manager to ensure any excess funds are returned to AFSC/LZDA in a timely

manner. Constant monitoring reduces the number of adjustments needed for the end of the year

close out. Execution activity is monitored by the CIP managers and documentation is

accomplished within FMSuite to ensure the tri-annual review (TAR) suspense is met.

Appropriate documentation uploaded to FMSuite will include at a minimum a justification for

why the obligation remains valid or what tasks are being accomplished to reduce outstanding

residuals.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

4.2.5.1.1.1. (Changed) The estimated depreciation included in the OC-ALC CIP budget

submission to AFSC/LZDA should include assets on the Fixed Asset Report with remaining

book value, assets on the FOC tracker or current year project list which are planned to be placed

in service within the budget period, as well as any anticipated contributed assets with remaining

book value.

4.2.5.2.1. (Changed) Documentation to support the value must be provided during the

transfer of equipment for addition to the equipment file and a copy provided to AFSC/FZR. The

depreciation cost value will be added to the DIFMS financial system by AFSC/FZR.

4.2.9.2.1. (Deleted) (Added) The project engineer must ensure all delivered equipment is

installed and achieves FOC IAW with EEP/EIP. If the asset will not achieve FOC by the

projected date, the project engineer must provide an action plan for achieving FOC to the group

CIP monitor and ALC CIP managers.

4.4.8.1.1. (Changed) Prior to the beginning of the FY, skeleton records will be built in

Departmental Cash Management System - Skeleton Records (DCMS DSK). Final accounting

addresses will not be available until the beginning of the new FY. During the year of execution,

if a new line of accounting needs to be established, the CIP manager will accomplish a 72 CPTS

address build template with the appropriate accounting elements and send to the 72 CPTS

workflow account requesting creation in General Accounting and Finance System (GAFS-BQ).

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 7

WORK CONTROL DOCUMENT (WCD) AND TECHNICAL DATA

7.2.2.3. (Added) WCD reviews do not require a PPT meeting and will be documented on an

AFSC Form 500-2 WCD Review Checklist. When a WCD review requires a PPT meeting, it

will be documented on an AFSC Form 500 Documentation of Production Planning Team (PPT)

Meeting Minutes. Ref. AFSCMAN 21-102, Para 7.2.9. through 7.2.9.1.

7.2.2.4. (Added) AFSC Form 500-2 WCD Review Checklist is not required when an

AFSC Form 957 is submitted for typographical error corrections or clerical change requests as

this would not trigger a WCD review.

7.2.19.6. (Added) The IET stamp is used to verify pen and ink changes to existing WCDs.

7.2.19.6.1. (Added) Pen and ink changes are administrative in nature (i.e., AFMC Form 202

number change, Technical data reference change, verbiage change, etc.). The IET will line

through the incorrect information and make the changes to the WCD then stamp/date as close as

possible to the change. All pen and ink changes need to be corrected in the effected systems for

WCDs ASAP.

7.3.4.1.4.1. (Added) Expeditors in the production maintenance groups are not issued

maintenance stamps for certification of work accomplished. Expeditors who receive and uncrate

incoming assets awaiting induction into production will legibly affix their printed name, job title,

legal signature, and date in the "Uncrate" task description block on the WCD as proof of

completion. Expeditors will only uncrate assets if the WCD certification block is coded "X" as

this code does not require any PAC certifications. If the WCD certification block for "Uncrate" is

coded "M", a PAC certified mechanic must accomplish the work and stamp the certification

block.

7.4.3.5. (Added) Stamp Management. All Groups MXDS will implement procedures to

maintain control of maintenance stamps to include, at a minimum, the following:

7.4.3.5.1. (Added) List the responsibilities of the Stamp Monitor.

7.4.3.5.2. (Added) Administrative procedures/criteria for request, issue, control,

accountability, revocation, and recall of stamps.

7.4.3.5.3. (Added) The requirements for documenting request, issue, receipt relocation, loss

and annual inventory of stamps.

7.4.6.10. (Added) The Aircraft Maintenance Group’s allotment of numbers further segregates

the stamps by use of an alpha letter—A for all Aircraft Squadron Production Flight stamps, and

X for 76 AMXG Expeditionary Depot Maintenance (EDMX) Flight stamps.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 8

QUALITY ASSURANCE PROGRAM QUALITY ASSURANCE (QA)

8.4.1.11.5.1. (Changed) Group LEAP site managers (known hereafter as group site

managers) serve as the primary focal point for LEAP within their group. Each organization is

authorized two group site managers, a primary and an alternate. Additional group site managers

may be requested by submitting a letter/e-mail to the Complex site manager. The duties of the

group site manager shall include, but not be limited to: [Note: 76th Software Engineering

Group (76 SWEG) and 76th Maintenance Support Group (76 MXSG) will belong under the OC-

ALC/QASC and is exempt from this requirement.]

8.4.1.11.5.6. (Changed) Submits in writing any e-mail issues, problems, recommendations

relating to LEAP software to the Complex Site Manager.

8.4.1.11.5.8. (Changed) Updates personnel profiles (evaluated persons) names, stamp

numbers, and organizations within the LEAP system.

8.4.1.11.5.9. (Deleted) Establishes a new assessment control number at the beginning of

each FY.

8.4.1.11.5.10. (Deleted) May establish and maintain customer feedback forms for

users/customers within their group.

8.4.3.5.1. (Changed) The following flow chart (Figure 8.1.) defines the process for tracking

Evaluator Proficiency Evaluation (EPE)s in TSS. EPEs will be documented in LEAP as EPE in

the quality assessment type block using “Quality Assurance” in the assessment category block

and “Evaluate the Evaluator” in the checklist block.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Figure 8.2. (Changed) PE/TSS Process for OC-ALC.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

8.4.4.1.6.1. (Deleted) Vehicle inspections will be input as MIs in LEAP and sent to the

owner of the vehicle, their supervisor for information or action, and the group QA office

workflow account. 76 AMXG organizations are required to fill in blocks in accordance with

IAW Table 8.6, and send the AFMC Form 343 to the respective squadron workflow account, as

well as the supervisor.

8.4.4.1.6.2. (Changed) Occupational Health and Environmental inspections accomplished

will be input as MIs in LEAP. Occupational Health and Environmental organizations are

required to fill in blocks IAW Table 8.6 and send the AFMC Form 343 to the respective

squadron workflow account, as well as the supervisor.

8.4.4.2.1.7. (Changed) No extensions will be granted for suspense dates. Issuing QA office

has two working days for acceptance or rejection of the AFMC Form 343 corrective/preventative

action(s). If a corrective/preventive action (CA/PA) is unacceptable/inadequate, the QAS will

notify the responsible person that a new CA/PA is required and document block 39 (Comments)

stating the QAS is working with the responsible person so an adequate CA/PA can be completed

in a timely matter.

8.4.4.2.1.10. (Changed) Failed follow-up inspections will be briefed to the supervisor or

designated work center official and the AFMC Form 343 documented as “failed follow-up” with

details of the failure in follow-up assessment block. A new AFMC form 343 will be opened and

a new finding will be completed referencing the original control number of the failed follow-up.

The date used on the new finding will be the date of the failed follow-up. The original finding

page will be closed. The shop supervisor or designated work center official will be notified and

will be required to input a new corrective action.

8.4.4.2.1.11. (Changed) Data generated from the submittal of subject forms shall be entered

and maintained in LEAP. LEAP provides approved users direct access for inputting, editing, and

viewing of data. Depot personnel may access LEAP for “View Only” purposes provided they

submit a Form DD2875, to their responsible group LEAP site manager.

8.4.5.3.4.3. (Changed) Minimum data fields contained in LEAP AFMC Form 343 will

include the following (Table 8.6.). MXSG and SWEG inspections are conducted by OC-

ALC/QASC. Items required for QASC, but not applicable to MXSG and SWEG will be

annotated on Table 8.6.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Table 8.6. (Changed) Populating AFMC Form 343 in LEAP.

Block

Name

Definition

Required?

1

Quality

Assessment

Type

QVI – Quality Verification

Inspection

QVIQ-Quality Verification

Inspection Q-Stamps

RI – Routine Inspection

PE – Personnel Evaluation

SI – Special Inspection

MI – Management Inspection

DSV – Detected Safety Violation

TDV – Technical Data Violation

UCR – Unsatisfactory Condition

Report

EPE – Evaluator Proficiency

Evaluation

RII – Required Inspection Items

(FAA)

Yes; system requirement

2

Date Of

Evaluation

Date of assessment-select from

calendar.

Yes; system requirement

3

Assessment

Start Time

Four-digit designator in military

time format (numbers only).

Yes; system requirement

4

Total

Assessment

Time

Total time used to complete

inspection (numbers and decimal).

Yes; system requirement

5

Control

Number

System generated Evaluation

number.

Yes; auto-generated field

6

Assessment

Category

Category of the inspection type for

MIs and SIs (associated with block

8).

In-Process or End-Process for QVI,

QVIQ and RII.

Yes; OC-ALC required on

ALL EPE, MI, SI, QVI,

QVIQ and RII inspections.

EPE select Quality

Assurance.

7

Sub Category

Routine Inspection List

Yes; OC-ALC required on

ALL RILs.

8

Checklist

Name

HQ or Local checklist used

(associated with block 6)

Yes; OC-ALC required on

ALL EPE, RII, SI or MI. EPE

select Evaluate the Evaluator

9

Assessment

Rating

Quality rating assigned to each

assessment: QAR-1, QAR-3, or Not

Rated (Not Rated inspections must

be approved)

Yes; system requirement

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Block

Name

Definition

Required?

10

Misc

Free text field used at the discretion

of QA Groups.

OC-ALC required for all

EPEs (enter QAS name).

QASC required for in-process

QVIs (HIGH CRITICAL;

HIGH; MEDIUM; LOW),

QVIQs with planned WCDs

use Q, hand scribed

inspections use QVIQ.

MXSG/SWEG excluded.

11

Group

Assessed

Group Assessed during inspection

Yes; system requirement

12

Squadron

Assessed

Squadron assessed during inspection

As applicable. QASP

required.

12a

Flight

Assessed

Flight assessed during inspection

As applicable.

12b

Section

Assessed

Section assessed during inspection

As applicable. QASP

required for RCC codes.

QASC required for Unit

shops.

13

Person

Evaluated

Name of person responsible for

work/object being evaluated.

Yes; OC-ALC required on

ALL PE, RII, QVI, and QVIQ

inspections. Recommended

for all other inspections where

applicable.

14

Stamp Number

Stamp number of person responsible

for work/object being evaluated.

System generated block when

applicable.

Yes; OC-ALC required on

ALL PE, QVI and QVIQ

inspections. Recommended

for all other inspections where

applicable.

MXSG/SWEG excluded.

15

Product / Process / Task / Service Assessment Classifier

15a

NSN

National Stock Number (####-##-

###-######)

QASA – AIDR RCN when

applicable. QASC required

when available;

15b

P/N

Manufacturer part number

identifying an item, assembly, end

item, or equipment.

QASC & QASP required on

PE, QVI, & QVIQ, optional

otherwise.

MXSG/SWEG excluded

15c

S/N

Serial number. A unique number

that identifies an item, assembly,

end item or equipment.

QASA – Tool Box # when

applicable. QASC & QASP

required on product if

available, optional otherwise.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Block

Name

Definition

Required?

15d

Item

Description

A description of the product,

process, task, or service being

evaluated. If a product inspection,

the description should be consistent

with the Illustrated Parts

Breakdown.

Yes; OC-ALC required.

QASP-use WCD title or pre-

test/post-test engine

inspection

15e

JON

Job Order Number. A number that

identifies an accounting entity.

As applicable. QASC add

gate Complete/Incomplete

15f

MDS/TMS

List the Mission Design Series or

Type Model Series.

Yes; OC-ALC requirement on

all QVI, QVIQ and PE

inspections

MXSG/SWEG excluded

15g

WPN

Weapon System Code. Identifies a

weapon system type.

Yes; OC-ALC required on all

QVI, QVIQ and PE

inspections. QASP use

(PMXG). QASC use

(CMXG). MXSG/SWEG

excluded

15h

Tail Number

Tail number of aircraft being

inspected.

Required by QASA when

applicable, otherwise, if

available

15i

WUC

Work Unit Code

Required by QASA when

applicable, otherwise if

available. QASP to identify

ITN on PE and QVIs

15j

WCD Number

Work Control Document code

QASA - Task Inspection

Code, if applicable. WCD ID

number required for QASC &

QASP on ALL PE, QVI, &

QVIQ.

MXSG/SWEG excluded

15k

Operation

Number

Operation Number of a production

process

Yes; OC-ALC required for

ALL PE, QVI & QVIQ

inspections, except

MXSG/SWEG.

Recommended for all other

inspections when applicable.

15l

Control

Number

Control Number use determined by

each QA group and defined by local

directive.

QASA - Gate number/0

required. QASC required for

PE & QVI (if available),

QASC T-jobs put P/N,

optional otherwise. QASP

required Audit Code.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Block

Name

Definition

Required?

15m

PAC Task

Code

PAC/TSS Task Code for task being

evaluated

OC-ALC required TSS task

code on all PE, RII, QVI, and

QVIQ inspections.

MXSG/SWEG end process

excluded.

15n

Type

Maintenance

Type of maintenance performed:

Organic or Contractor

As applicable

15o

Product Area

Code that identifies shop/back shop,

file location, or ramp space.

Designates location where the

inspection was conducted.

Yes; system requirement

15p

Product

Location

Code that identifies exact building,

ramp space, etc., where inspection

occurred or group area.

Yes; system requirement

15q

Sample Size

Sample size of product or area

inspected.

Required for RI inspections

and when applicable on MI

inspections

15r

AQL

Used to indicate the acceptable

quality limit of the inspection

performed.

Yes; system requirement

15s

Other

Field reserved for use by each QA

group.

QASA requires Inspection ID

code number, QASC requires

ITN/LDMS number on PE

and QVIs, optional otherwise.

MXSG/SWEG excluded

15t

Defect

Category

Defect code category

Yes; system requirement

15u

Defect Code

Defect code description

Yes; system requirement

15v

Deficiency

Class

Rating value assigned to each

discrepancy: minor, major, or not

rated.

Yes; system requirement. ZD

inspections will use “Not

Rated”.

15w

Repeat

Finding/

Deficiency

Used to show the deficiency has

been reported before, within a

specified time frame.

Yes; system requirement

Yes if showing a continuous

problem. If used, yes would

indicate the same problem

within the RCC within six

months. If yes for QASA,

enter repeat AFMC IMT 343

control number in block 20.

16

Evaluator

Name

Name of person who performed the

assessment.

Yes; auto-generated field

17

Evaluator

Organization

Parent organization identifier of

person who performed the

assessment.

Yes; auto-generated field

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Block

Name

Definition

Required?

18

Finding /

Deficiency

Number

Each finding gets an auto-generated

Deficiency number associated with

the Evaluation number.

Yes; auto-generated field

19

Finding /

Deficiency

Describe the finding/deficiency

Yes, system requirement

20

Supporting/

Additional

Information

References to support noted

deficiency; comment to describe

task being performed and other

information that may be helpful.

Optional, but highly

recommended. QASP

required. Sub-op description

and any other pertinent

information. QASC

document what gate was

inspected.

MXSG/SWEG excluded

21

Reference AFI,

AFMCI, TO,

PO, Drawing

etc.

Regulation guidance, technical

order, process order, drawings, etc.

Used for the inspection or to identify

a discrepancy.

Yes; OC-ALC required on all

inspections, list primary tech

data

22

Reference

Chapter, Page,

and/or

Paragraph

Identifies the chapter, page, and/or

paragraph numbers (only) to the

reference used in block 21.

Yes; OC-ALC required on all

deficiencies. At a minimum,

must have paragraph number.

23

Finding/

Deficiency

Validator

Chief Evaluator or Site Manager

reviews 343 for accuracy and

validates that data, finding, and

deficiency code are correct.

OC-ALC required on all

QAR3 deficiencies

24

Responsible

Person

Name of person responsible for the

area where inspection was

conducted.

Yes; OC-ALC requirement

25

Responsible

Organization

Organization identifier of person

who is responsible for area.

Yes; OC-ALC requirement

26

Suspense Date

Suspense date for submittal of

corrective/preventative action by

responsible person (area

owner/organization).

Yes; auto-generated field

27

Corrective

Action

Action taken by the responsible

organization to correct the noted

deficiency.

Yes; OC-ALC requirement.

Input by the assessed

organization.

28

RCA Category

RCA category designator

Optional. May be requested

by QA

29

RCA Code

Three part code which categorizes

defects by root cause. Entered by

responsible person at time of

corrective/preventative input into

LEAP.

Optional. May be requested

by QA

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Block

Name

Definition

Required?

30

Corrected By

Name of individual who performed

corrective action

Yes; OC-ALC requirement

31

Corrected By

Organization

Organization of person who

performed the corrective action

Yes; OC-ALC requirement

32

Action Date

Date corrective action performed

Yes; OC-ALC requirement.

Use calendar selection

33

Planned

Action To

Prevent

Recurrence

Action taken by the responsible

organization to prevent noted

deficiency recurrence.

Optional. May be requested

by QA

34

Performed By

Name of individual who is

responsible for implementing the

preventative action

Optional. May be requested

by QA

35

Organization

Organization of person who is

responsible for implementing the

preventative action

Optional. May be requested

by QA

36

Plan Date

Date responsible organization plans

to have preventative action in place

Optional. May be requested

by QA.

Use calendar selection

37

Accept / Reject

Indicated whether a

corrective/preventative action is

accepted or rejected (Quality

function)

Yes; OC-ALC requirement

38

Date

Date Quality accepts/rejects the

proposed corrective/preventative

action

Yes; OC-ALC requirement

Use calendar selection

39

Comments

Any relative comments relating to

the acceptance/rejection of the

AFMC IMT 343

OC-ALC requirement for all

rejections

40

QA Follow-Up

Assessment

Findings of follow-up assessment by

Quality, evaluating implementation

of corrective/preventative action

Yes; OC-ALC requirement

41

Follow-Up By

Name of person performing follow-

up assessment

Yes; OC-ALC requirement

42

Follow-Up By

Organization

Organization of person performing

follow-up assessment

Yes; OC-ALC requirement

43

Completion

Date

Date follow-up assessment

completed. This closes the form and

finding when date is entered and

saved.

Yes; OC-ALC requirement.

This action closes the

Evaluation and the Finding.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

8.6.1. (Changed) Current ISO/AS9110/ISO 9001 standard auditing. QAI is responsible for

planning and conducting internal current ISO/AS9110 standard program (non-weapon system

specific) audits within the OC-ALC to meet requirements contained in the current ISO/AS9110,

and ISO 9001 standard. OC-ALC organizations will be audited to current ISO/AS9110 standard.

8.6.3.1. (Changed) CATS will be used to record non-conformances identified as well as the

corrective actions IAW OCALCI90-420 and this supplement. An AFMC Form 343 may be used

when a finding is an isolated occurrence not directly related to or impacting the product or

service being provided and would not normally be identified as a current ISO AS9110/ISO9001

standard audit finding.

8.6.5.3. (Changed) Closure verification inspection performed on a CATS worksheet shall be

conducted by the issuing organization within 10 working days of request for closure. The

purpose of the verification audit is to verify successful implementation of the CAP and its

effective resolution of the problem. A 120 day follow-up inspection will be conducted after CAP

closure by the issuing organization to determine if the effectiveness of the CAP is being

maintained. Groups will be notified via e-mail when verification and/or follow-up activities are

unsuccessful. All verification and follow-ups will be documented as required by OCALCI90-

420.

8.6.7. (Deleted) Each group shall identify Level I and, as applicable, Level II CAP approval

authority for their organization as required by OCALCI90-420. A Level II approving authority

will be required for organizations performing internal audits within their groups. For all CARs,

the Level I approval is performed by a Level I authority within the assessed organization and the

CAR is forwarded to the assessing organization. For all CARs issued as a result of a Complex

level or external audit (registrar) the Level II approval authority is the Complex Quality office

and Level I approval authority is the OC-ALC/QA. The Level II approval authority for other

CARS will be the designated Level II approval authority within the organization that issued the

CAR. Level I and Level II approval authorities will document, process, review, approve and/or

disapprove CAR/CAP IAW the process and procedures contained in OCALCI90-420.

8.6.7.1. (Deleted) Level I and Level II approval authorities within the OC-ALC will review

and approve or disapprove the CAR, and CAP based on the requirements and using the process

contained in OCALCI90-420.

8.6.9. (Changed) The appointed OAA shall report CAR status every 30 days to the Lead

Auditor from date the CAP is approved throughout CAP implementation until the CAR is closed.

8.6.9.1. (Changed) An organization may revise or update the CAP after it has been approved.

When necessary, the group POC will be responsible for contacting the Lead Auditor to request

changes to the CAP. Upon approval, the revised CAP will be updated in CATS.

8.6.10. (Deleted) Within OC-ALC the "deferred" status in CATS may be used under the

following conditions with the approval of the organization that issued the CAR.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

8.6.10.1. (Deleted) When the CAP planned completion date is more than 60 days and the

same CAP is used to correct the non-conformances in two or more CARs. For this condition the

following process will be used. One CAR will be used for tracking the status of the

implementation of the CAP and will use processes IAW OCALCI90-420 and this supplement.

The CAR used for tracking the CAP implementation will include in both the CAP and notes

section of CATS, a statement that the CAP is also the corrective action for (insert CAR #) being

deferred. The CAR(s) deferred will include all the entries as required by OCALCI90-420 and

will include in the CAP and notes section of CATS, a statement that corrective action is being

tracked under (insert CAR#). The planned completion date of all CARs will be the same. Thirty

day status reporting is required on the CARs in "deferred" status. When requesting closure on the

CAR being used to track implementation, the assessed organization will request closure on those

associated CARs that were deferred.

8.6.10.2. (Deleted) When the CAP requires action from an authority outside of OC-ALC. The

CAR deferred will include all the entries as required by OCALCI90-420 and will include in the

CAP and notes section of CATS, a statement explaining the reason for the deferral. The planned

completion date of the CAR will be the same. Thirty day status reporting is required on a CAR in

"deferred" status.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 10

TOOL AND EQUIPMENT MANAGEMENT

10.3.2.4. (Changed) Monitor FEM for overdue loaned tools and tools awaiting pickup by the

groups.

10.5.2.4. (Deleted) Dispatchable tool kits (DTK). Tool kits specifically designed for checkout

from PSC will be taken to a job site with one individual responsible for the tool kit.

10.5.8.1. (Changed) A database has been added to Facilities and Equipment Maintenance

(FEM) to track annual inspections. Once the employee signs the TKCRL, they are accepting that

the documentation matches the physical inventory. The master TKCRL (original) will be

maintained at the MTIC. A second copy of the TKCRL will remain with the tool kit at all times

and will be suitably protected so that the list will remain legible. Both the signed TKCRL and

any updated version of the tool kit listing should be utilized for annual inspections as a resource

to ensure both listings match and any discrepancies are identified and communicated to the

MTIC. Every six months supervisor inspections will be conducted and maintained in FEM or

applicable database (applies to 76 CMXG only).

10.5.8.1.1. (Changed) Upon initial issue of a new kit, the supervisors or designee must enter

the issue date into FEM annual inspection database. Group Tool Manager (GTM) will enter issue

date upon notification from Main Tool Issue Center (MTIC) for six month (semi-annual)

supervisor inspection (applies to 76 CMXG only).

10.5.8.1.2. (Changed) Supervisors or designee must enter the date of annual inspection of all

tool kits under their control into FEM. Supervisors or designee must enter the date of six month

(semi-annual) supervisor inspection of all tool kits under their control into FEM (Applies to 76

CMXG only).

10.5.8.1.3. (Changed) The official record of the annual inspection will be maintained in

FEM.

10.5.8.1.4. (Added) Until FEM is operational, each respective GTM will maintain the

official record for annual inspections.

10.5.9.1. (Changed) Template changes will be requested using FEM tool request form.

10.5.10.1. (Changed) Turn-in-transfer request will be accomplished by using the FEM tool

request form.

10.5.13.2. (Added) When tools are added to an existing tool kit, it is acceptable for the tool kit

owner to inlay/shadow/silhouette the added tools.

10.5.22.1. (Changed) If supplied from a PSC, the PSC personnel must obtain supervisor

authorization prior to initial issue of items controlled on the supplemental list. Requests to add

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

supplemental tooling (tooling purchased around the MTIC that needs to be added to the TK) to

the Supplemental Listing shall be requested via email to MTIC workflow. Once request for

supplemental tool listing modification is received, the MTIC shall ensure proper documentation

of the supplemental listing items in the tool kit. The approved supplemental list for OC-ALC is

the OC-ALC Form 539 Supplemental Listing.

10.5.24.1. (Changed) MTIC managed tools that require etching or replacement shall be

documented via FEM Tool Delivery Receipt. The receipt shall be placed in the TK until the tool

has been issued/replaced.

10.8.3.3. (Added) MTIC will not etch/mark any grease guns, dispensing cans, spray bottles,

pump oilers, or similar containers due to potential flammability hazards that exist with such

containers.

10.9.1.1.1.1. (Changed) Additional instruction for AFSC Form 309. Pages two and three of

AFSC Form 309 are available for documenting additional inspections performed where a high

completion of logical sequence of work exists (defined as a job, task, work step, etc.) and

movement to another area. Extra pages of 2 and 3 can be utilized, but they must be tracked to the

parent AFSC Form 309 on page one by usage date and kit number.

10.9.3.40. (Deleted) The 76 AMXG. Tools may be transferred from tool crib to tool crib if

they fall under the same RCC. This will be documented and managed by tool crib supervision;

the over eight-hour process will remain the same at each location.

10.10.1.8. (Changed) The 76 PMXG. All tool kits will be inspected by the supervisor, wage

leader or designee at 180 day intervals. This inspection will be documented in FEM and will be

the official record. (when re-established)

10.10.1.10. (Changed) Supervisors or designee must enter the date of annual inspection of all

tool kits under their control into FEM. (when re-established)

10.10.1.11. (Changed) The official record of the annual inspection will be maintained in

FEM. (when re-established)

10.10.1.14. (Changed) Random inspections will be conducted in the same manner as the

supervisory inspections and documented in FEM accordingly. (when re-established)

10.17.1.1. (Changed) Replacement of broken/worn tooling will be fulfilled via MTIC tool

delivery.

10.18.1.1.2.1. (Deleted) Quotes requested through FEMWeb will be available in FEMWeb

within 10 days.

10.18.8.1. (Changed) Overdue tools will be emailed to the GTM & Section Chief, for

immediate return to MTIC.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 13

FOREIGN OBJECT DAMAGE (FOD)/DROPPED OBJECT (DO) AWARENESS AND

PREVENTION PROGRAM

13.4.5.1.1 (Changed) FOD Reports: The MOC notify Complex primary/alternate

FOD/DOP by phone after being notified of FOD.

13.4.5.1.2. (Changed) FOD incidents: All FOD incidents will be reported with the exception

of minor sand nicks or scratches IAW OC-ALCI91-11.

https://wwwmil.tinker.af.mil/amocc/net20/incrpt_net20/Incidents.aspx. MIRS - Mishap &

Incident Reporting System. The initial FOD report will be completed by a supervisor on duty

within TWO HOURS of suspected or confirmed FOD incidents. The two-hour time constraint is

for FOD/DO reports only; this will allow for coordination through OC-ALC before the report is

released to HQ AFMC/A4M. The supervisor completing the FOD report will include all data in

Figure 13.1 of this supplement (found at the end of this chapter), OC-ALC and Aerospace

Maintenance and Regeneration Group (AMARG) only. Supervisors will use the FOD reporting

flowchart (Figure 13.2., found at the end of this chapter) to determine if damage is within limits

and should be reported as a general report (damage within limits, no maintenance action needed)

or out of limits, requiring maintenance action (i.e., blending, replace, repair etc.).

13.4.5.1.3. (Changed) DOP Incidents: All DOP incidents will be reported IAW OC-

ALCI91-11. IMMEDIATELY call the MOC when there is a known DO. The MOC will

IMMEDIATELY call the Airfield Management Operations (AM OPS) and base safety. Use the

Online MIRS - Mishap & Incident Reporting System. The DOP report will be completed by a

supervisor on duty within TWO HOURS. The two-hour time constraint is for FOD/DOP reports

only; this will allow for coordination through OC-ALC before the report is released to HQ

AFMC/A4M.

13.4.5.1.4. (Changed) DOP Reports: The MOC will notify Complex primary/alternate

FOD/DOP by phone after being notified of DOP.

13.4.9.5.2. (Changed) The following areas have been designated as FOD critical areas

within the OC-ALC: It is the responsibility of all maintenance personnel working in these areas

to be vigilant of FO and dispose of all FO at all times. All other areas not identified are

considered non-critical FOD areas. Non-critical FOD Areas that maintain, repair, and/or inspect

aircraft and propulsion parts/equipment will still comply with FOD prevention/control and

housekeeping procedures.

13.4.9.5.2.3.1. (Changed) Engine assembly/disassembly shops and quick engine change.

13.9.2.3. (Changed) Group and squadron FOD/DOP focal points will perform FOD spot

checks of their assigned areas of responsibility monthly. A minimum of 2 inspections per month

for each squadron will be conducted. The discrepancies found during the spot checks will be

entered in the Logistics Evaluation Assurance Program (LEAP). The group focal points will

forward their quarterly data from the spot checks to the Complex focal point by the 10

th

working

day following the quarter.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

13.10.4.1.1. (Changed) Every quarter, each group point of contact (POC) will submit a

nominee for their respective group (if applicable) to the Complex FOD POC and alternate, NLT

the seventh working day after the completion of the previous quarter. Nominee information will

include the name and location of the area being nominated, the supervisor’s name, and a

narrative of why this area deserves to win the Complex award. This information will be given to

OC-ALC senior management and submitted to the Tinker Take Off for publicity. Additionally,

this information will be 50 percent of the rating criteria. The winning team will receive a banner

for their work center, recognition in the Tinker Take Off and on the marquee.

13.12.2. (Changed) A Practical Problem Solving Method, also known as 8 step (or equivalent)

is required by the group for all preventable FOD incidents over $50K.

13.12.2.3. (Changed) Group POCs are required to send a copy of the Failure Analysis Service

Technology (FAST) to OC-ALC FOD monitor and alternate within 24 hours of receipt.

13.12.2.4. (Changed) The group POC will send a status to the OC-ALC FOD monitor and

alternate by the seventh working day of every month until closed. This status will be briefed in

the weekly Quality chief meetings.

13.12.2.5. (Deleted) Steps seven and eight will be followed up 90 days after step six has been

completed by the group POC.

13.12.2.6. (Deleted) Minimum attendees for 8-Step meetings: Group’s lead for the 8-Step,

group’s FOD POC, and any other knowledgeable candidates who would add value to the

process.

13.12.2.7. (Changed) All FOD 8-Steps (or equivalent) will be briefed to OC-ALC senior

management by the group’s lead of the 8-Step, during the quarterly FOD/DOP meetings.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Figure 13.1. (Changed) FOD Report.

FOD REPORT

1. PURPOSE: To gain Group approval to forward this report to HQ AFMC/A4M.

2.

BACKGROUND: FOD incidents will be reported to HQ AFMC/A4M within 24 hours of

occurrence. The following process was put in place to inform leadership before notification to

HQ AFMC/A4M:

a.

Incident is reported to 76 AMXG/MXDSO, Maintenance Control Center (MOC).

b.

MOC immediately notifies OC-ALC/SE and Complex FOD Manager by telephone.

c.

MOC drafts this e-mail. (Records name of OC-ALC/SE person notified and time of

notification below).

d.

MOC forwards to the appropriate Group Commander’s personal account with telephone

notification to recipient. (Subject line shows date/time due to HQ and is sent with high

importance).

e.

Appropriate Group Commander/CC/CL/DD/CD approves release of this report to

HQ AFMC/A4M by forwarding e-mail to 76 AMXG/MXDSO All [email protected]

followed with phone notification to 736-2500 (MOC).

f. (Changed) MOC forwards e-mail to OC-ALC using the appropriate group mailbox

(AMXG FOD/DOP Report Notification) reporting mailbox or (PMXG FOD/DOP PMXG

Report Notification) reporting mailbox located on the global address list.

3. DISCUSSION:

Summary of incident:

Date and time of incident:

Base, unit, and location of incident:

When discovered (preflight, postflight, in-coming, test cell, etc.) owning unit, Owning base:

Owning Command, engine type, make, series, modification (TMSM), serial number and

installed position (if applicable):

Description of damage:

Certifying official if impounded: name, grade/rank, unit, office symbol, DSN and commercial

number:

DISPOSITION of aircraft or engine:

OC-ALC/SE person notified:

Time of OC-ALC/SE notification:

This is preliminary data only. For follow-on investigation results, please contact the Complex

FOD Manager. For information during off-duty hours, please contact 76 AMXG/MXDSO,

MOC, at 736- 2500.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Figure 13.3. (Changed) DOP Report.

DOP REPORT

1. PURPOSE: To gain group approval to forward this report to HQ AFMC/A4M.

2.

BACKGROUND: All DOP incidents will be reported to HQ AFMC/A4M within 24 hours

of occurrence. If it involves casualties, property damage, or if adverse publicity is likely, the

safety office should be notified immediately. The following process was put in place to inform

leadership before notification to HQ AFMC/A4M:

a. Incident is reported to 76 AMXG/MXDSO, Maintenance Control Center (MOC).

b.MOC immediately notifies OC-ALC/SE and Complex FOD Manager by telephone.

c. MOC drafts this e-mail (records name of OC-ALC/SE person notified and time of

notification below).

d. MOC forwards to the appropriate group commander’s personal account with telephone

notification to recipient. (Subject line shows date/time due to HQ and is sent with high

importance).

e. Appropriate group commander/CC/CL/DD/CD approves release of this report to HQ

AFMC/A4M by forwarding e-mail to 76 AMXG/MXDSO All [email protected] followed

with phone notification to (405) 736-2500 (MOC).

f. MOC forwards e-mail to OC-ALC using the appropriate group mailbox (AMXG FOD/DOP

Report Notification) reporting mailbox or (PMXG FOD/DOP PMXG Report Notification)

reporting mailbox located on the global address list.

3. DISCUSSION:

Summary of incident:

Date and time of incident:

Base, unit, and location of incident:

When discovered (preflight, postflight, in-coming, etc.): Owning unit, Owning base, Owning

Command:

MDS and tail number: Item, noun, description:

Certifying official if impounded: name, grade/rank, unit, office symbol, DSN and commercial

number.

OC-ALC/SE person notified: Time of OC-ALC/SE notification:

This is preliminary data only. For follow-on investigation results, please contact the Complex

FOD/DOP Manager. For information during off-duty hours, please contact 76 AMXG/MXDSO,

MOC, at 736- 2500.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Figure 13.4. (Changed) Areas of Responsibilities.

RED: 76 AMXG

BLUE: 552 ACW

GREEN: 507

ARW

YELLOW: SCW-1

PURPLE: RESPECTIVE AIRCRAFT ASSIGNED

ALL OTHER AREAS: 72 ABW RESPONSIBILITY

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 18

DEPOT MAINTENANCE MATERIEL CONTROL

18.2.5.2.3 (Changed) The 76 AMXG. If a component is installed and found to be defective,

the condition forms/tags for the defective component will be retrieved from designated ALS

and placed with the defective component for disposition in accordance with the applicable

directive. Exception: defective avionics equipment will be controlled.

18.14.3. (Changed) When an employee retrieves IPV material from open bin or auto crib, the

following must occur. Employee places individual NSN/Part Number in a separate bag and

clearly labels each bag with the BSL bin location and manufacturers part number or NSN of each

item taken. Material will not be co-mingled in bags.

18.14.3.2. (Added) Residual/excess material is NOT to be placed back into the

BSL/Autocribs by Air Force personnel. All residual material will be bagged and tagged

accordingly and placed in their appropriate color-coded tubs as explained in 18.14.3.1.

18.19.2.3. (Changed) Established forms, must be published within E-Publishing, and include

a checkpoint to indicate if material is indirect. When indirect material is required for

consumption on aircraft, engines and commodities, and not listed on the ABOM indirect table,

the PST will check the appropriate box on the material request form and send form to planner.

The planner will load material to the ABOM indirect table, coordinate, sign and return material

request form to PST. After validating the request form, the PST will use the automated bill of

material (ABOM). The 76 CMXG will use the Lean Depot Management system (LDMS) to

process material orders, and no issue request form is necessary.

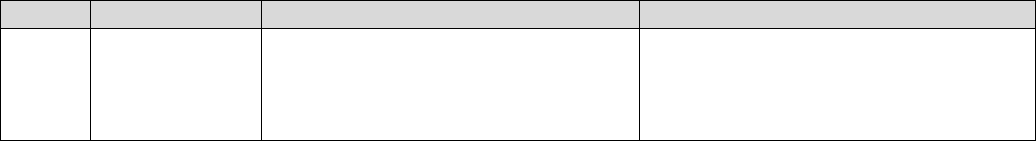

18.19.2.4.1 (Changed) OC-ALC Form 111 Unplanned Material Request (Figure 18.13)

may be used by 76 PMXG, 76 CMXG, 76 AMXG in lieu of forms listed in 18.19.2.4 for

unplanned material request.

18.19.2.8. (Changed) Part number request for non-stock listed (NSL) material will be

processed through the part number supply support request (PNSSR) system. If the Source

Maintenance Recoverability (SMR) code found in provisional T. O. shows this should be a

local manufactured item, select “JCL/JBD” in the SOS.

18.19.5.1.1.4. (Changed) If credit is expected, research must be accomplished prior to

input and the NSN must be in a buy status. The forced credit indicator must be used with

caution.

18.19.5.5.1.3.2. (Changed) Production/Mechanic will give tagged material to PST.

The PST will utilize the MN044P screen in NIMMS to process the turn-in to the Y- Store, the

input generates a stow document. Print Stowage Document and attach to material along with

DD Form 1574 if material is not in factory packaging. Verify the quantity has been added to

store detail via MN090P when turn-in is processed. Place material in the Outgoing area for

DLA- A SSC to pick up during daily run.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

18.19.5.9.1.2. (Changed) For serviceable part cost code “B” issued to maintenance, a turn-

in of the same part or an interchangeable and substitution (I&S) linked substitute must be used

to clear the DIFM. Turn-ins are reparable “F” condition or condemned “H” condition. The 76

AMXG is only authorized to turn-in cost code “B” material into “F” condition. The Wholesale

and Retail Receiving Shipping System (D035K) retail transaction history inquiry (RINA),

DIFM document number inquiry (RINE) and mass request for retail transaction history

(MRAG) screens are used to track DIFM/DOTM details. Exchange material transactions create

one of four details. These details are essential to identify and control the issue and turn-in of

exchange material.

18.40.3. (Changed) The AF PST or DIFM monitor will follow-up on D6 turn-ins. If the D6

has not crossed the daily DIFM/DOTM list within ten days, the AF PST should verify the status

of the turn-in. Initiate a DLA-OC/DL Form 14, D6 Turn-in Research Checklist (Figure 18.12),

and send to DLA Inventory Care of Supply and Storage (COSIS) team for research. Contact

information for the COSIS team is 739-3804 or Email [email protected]

18.43.1.7.1. (Changed) Additions to bench stock: When an NSN is identified to be added

to bench stock under the IPV contract, the following process will be completed. Any item with

a unit price greater than $250 ($750 for Avionics) and the unit of issue is “each” will require

coordination by the group business office prior to loading to bench stock.

18.43.1.9. (Changed) Once the AFSC Form 231 change recommendation/approval form

with appropriate coordination/approval is completed, the planner will forward to DLA Aviation

(DSCR) contracting officer representative (COR) office technical assistant for processing.

18.43.5.5. (Added) Movement of IPV Bench Stock Locations.

18.43.5.5.1. (Added) When a group identifies a need to move a Bench Stock Location

(BSL), coordination and notice must be given to OC-ALC/OBWC, DLA COR, and Lockheed

Martin.

18.43.5.5.2. (Added) When a movement of an IPV BSL is warranted, the following

procedures must be followed to relocate the BSL.

18.43.5.5.2.1. (Added) All groups will utilize the BSL Update Request Template to

request a BSL movement. Ensure all requested information is filled out accurately.

18.43.5.5.2.2. (Added) Once completed, the group must send the template to the specific

IPV Workflow box: [email protected], [email protected], and

18.43.5.5.2.3. (Added) DLA will process the request and forward the information to

Lockheed Martin to update their systems. Once LM has updated their system with the new

location, they will notify the DLA COR, who in turn, will inform OC-ALC/OB and groups

POC/shop as indicated on the request template.

18.43.5.5.2.4. (Added) Each organization is responsible for contacting the DLA COR in a

timely manner prior to any movement of a BSL. Failure to follow the proper procedures could

result in a delay in parts being delivered to their respective bins.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 20

MAINTENANCE TRAINING

20.3.13.2.2.1. (Added) The supervisor will assign the task(s) to the best qualified

journeyman technician, enter an OJT start date, and make a note in sec IV that the technician was

assigned to accomplish work for which he/she was not certified.

20.3.13.2.2.1.1. (Added) The supervisor will conduct a search via the TSS Supervisor

Dashboard function to identify personnel who were previously certified on task.

20.3.13.2.2.1.2. (Added) If there are individuals who are identified as being previously

certified on the task, the supervisor will reach out to the individual’s supervisor to ascertain the

possibility of the employee being available to conduct OJT with the identified journeyman

technician.

20.3.13.2.2.1.3. (Added) If there are no previously certified personnel available to conduct

training with the journeyman technician, then the task must be conducted by the technician, with

oversight by the Group Process Engineering Authority, until the Engineering Authority and the

technician feel confident that the employee can perform the task at the required proficiency level.

20.3.15.2.2. (Changed) Group Training and PAC Program Managers will conduct quarterly

face-to-face PAC and Training Compliance inspections. These inspections will be conducted at

the point of execution level of first-line supervisors. The number of inspections (sample size)

will be based on the number of first level supervisors, within the Group, who are assigned

maintenance technicians who stamp off WCDs. The quarterly inspection sample size will be

10% of the total number of first level supervisors and then 20% of the employees assigned to that

supervisor.

20.3.15.2.2.1. (Added) Prior to the Group Training and PAC Managers conducting their

quarterly inspections, notification will be sent, at least 2 days prior to inspections, to the

Complex PAC Program Manager identifying date, time, location, and list of supervisors to be

inspected.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

Chapter 22

CONTRACT SURVEILLANCE

22.2.1.1.9.5. (Changed) Identify additional contract surveillance requirements in the PP. PP

surveillance will be based on the minimum surveillance necessary to assess effective and

efficient contractor compliance to performance work statement requirements. Surveillance

methods shall be based on performance-based contract assessment methods and techniques.

22.2.1.1.9.11. (Changed) The scope of contract performance assessment or inspection

shall be based by the Quality Assurance Surveillance Plan (QASP), the Performance Work

Statement (PWS), and the Statement of Work (SOW).

22.2.1.1.12.1. (Changed) Surveillance scheduling. The COR will develop a monthly

schedule of surveillance activities based on PP requirements in the Procurement Integrated

Enterprise Environment (PIEE). The schedule must be completed no later than five duty days

prior to the beginning of the period it covers.

22.2.1.1.12.1.27. (Changed) COR organizations in coordination with the FSM and

PCO/ACO will accomplish annual contractor performance reporting for contracts awarded >= 1

million dollars for service contracts and >= 5 million dollars for commodity contracts using the

Contractor Performance Assessment Reporting System (CPARS) as identified in the May

CPARS Guide. For more information: https://www.cpars.gov

22.2.1.1.12.1.28. (Changed) Acceptance of services will be accomplished utilizing Form

DD250, Material Inspection and Receiving Report, or in the Wide Area Workflow Payment in

the Procurement Integrated Enterprise Environment (PIEE). It is the Primary and Alternate

COR’s responsibility to validate the accuracy of financial figures submitted by the contractor

prior to the government paying for services.

22.6.1.2.6. (Deleted) Review contractor proposals to new or revised DoD, AF, MAJCOM

and local directives.

22.6.1.3.13. (Deleted) Evaluate contractor proposals and provide comments and

recommendations to the FSM and ACO/PCO.

22.6.1.3.15. (Changed) Acceptance of services will be accomplished utilizing Form

DD250 or in Wide Area Workflow Payment in the Procurement Integrated Enterprise

Environment (PIEE).

22.6.1.4.6. (Changed) Perform surveillance according to the Performance Work Statement

(PWS), Quality Assurance Surveillance Plan (QASP) and the Performance Plan.

22.6.1.4.10. (Changed) Evaluate the effectiveness of the contractor's involvement in mishap

investigations, IAW DAFI 91-204, Safety Investigations and Reports.

AFSCMAN21-102_OC-ALCSUP_OC-ALCGM2022-01 21 MARCH 2022

22.6.11.1.2. (Changed) Contract specific training. Training must be completed for each

contract to which the Primary and Alternate COR is assigned. The FSM ensures the PCO/ACO

provides this training as required by Air Force Federal Acquisition Regulation System

(AFFARS) Mandatory Procedure 5346.103, The Quality Assurance Program.

22.6.11.1.6. (Changed) Federal Acquisition Regulation (FAR) Part 49, Termination of

Contracts. During the termination of a contract, the COR organization is responsible to ensure

the contractor meets all criteria outlined in the PWS, SOW, and/or contractor plans. The COR

will inform the FSM, PCO/ACO, and Chief COR of any work not accomplished prior to the

termination of the contract.

22.6.11.1.7. (Added) The COR will develop monthly surveillance schedules based on PP

and QASP requirements. The COR will submit via Surveillance and Performance Monitoring

(SPM) in Procurement Integrated Enterprise Environment (PIEE) to the Chief COR for review

and forward to the FSM for approval prior to CORs submittal to the PCO/ACO five duty days

prior to the beginning of the period it covers. The COR must provide a copy via SPM in PIEE

of the surveillance schedule to the ACO before the start of the surveillance period. Post

changes to the schedules observations as they occur and send copies to the ACO and FSM via

SPM in PIEE.

BY ORDER OF THE COMMANDER

OKLAHOMA CITY AIR LOGISTICS

COMPLEX

AIR FORCE SUSTAINMENT CENTER

MANUAL 21-102

OKLAHOMA CITY AIR LOGISTICS

COMPLEX

Supplement

3 JUNE 2021

Maintenance

DEPOT MAINTENANCE

MANAGEMENT

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available on the e-Publishing website at

www.e-Publishing.af.mil for downloading or ordering

RELEASABILITY: There are no releasability restrictions on this publication

OPR: OC-ALC/QA

Supersedes: AFSCMAN21-102_OC-ALCSUP,

2 August 2018

Certified by: OC-ALC/QA

(Mr. Daniel McCabe)

Pages: 152

This supplement implements and extends the guidance of the Air Force Sustainment Center

Manual (AFSCMAN) 21-102, Depot Maintenance Management and applies to Oklahoma City Air

Logistics Complex (OC-ALC). It contains depot maintenance management processes and

procedures previously found in the following publications: Air Force Instruction (AFI) 21-101_Air

Force Materiel Command Supplement (AFMCSUP) OC-ALCSUP, Aircraft and Equipment

Maintenance Management, Air Force Materiel Command Instruction (AFMCI) 21-105 OC-

ALCSUP1, Depot Maintenance Work Measurement, AFMCI21-130 OC-ALCSUP, Depot

Maintenance Material Control. This OC-ALCSUP may be supplemented at any level, but all

supplements must be routed to Office of Primary Responsibility (OPR) for coordination prior to

certification and approval. Refer recommended changes and questions about this publication to

the OPR using the Air Force (AF) Form 847, Recommendation for Change of Publication; route

AF Forms 847 from the field through appropriate functional chain of command. The authorities to

waive wing/unit level requirements in this publication are identified with a Tier (“T-0, T-1, T-2,

and T-3”) number following the compliance statement. See Department of the Air Force

(DAFI)33-360, Publications and Forms Management, for a description of the authorities

associated with the Tier numbers. Submit requests for waivers through the chain of command to

the appropriate Tier waiver approval authority, or alternately, to the publication OPR for non-

tiered compliance items. Ensure all records created as a result of processes prescribed in this

2 AFSCMAN21-102_OC-ALCSUP 3 JUNE 2021

publication are in accordance with DAFI33-360 and disposed of in accordance with Air Force

Records Information Management System (AFRIMS) Records Disposition Schedule (RDS). The

use of the name or mark of any specific manufacturer, commercial product, commodity, or service

in this publication does not imply endorsement by the AF.

SUMMARY OF CHANGES

This publication has been significantly revised and should be reviewed in its entirety. It

incorporates several updated depot maintenance management processes and procedures.

AFSCMAN21-102_OC-ALCSUP 3 JUNE 2021 3

Chapter 1

DEPOT MAINTENANCE MANAGEMENT PRINCIPLES

1.1.1. (Added) OC-ALC shall: provide Complex level policy, guidance, and staff coordination

for all activities required to operate depot maintenance activities for AF weapon systems and is

the OPR for this supplement.

1.1.1.1. (Added) All waiver packages pertaining to this supplement shall be fully coordinated

through OC-ALC/Quality Assurance (QA). See waiver template, Figure 1.1.

Figure 1.1. (Added) Waiver Request Template.

4 AFSCMAN21-102_OC-ALCSUP 3 JUNE 2021

1.14. (Added) OC-ALC/Commander (CC) shall:.

1.14.1. (Added) Ensure effective management of the Complex maintenance training program in

accordance with (IAW) AFI36-2651, Air Force Training Program, AFI36-2650, Maintenance

Training, AFI36-2650, AFMCSUP, Maintenance Training, and Chapter 21 of this supplement.

Provide aircraft, personnel, and equipment to support the maintenance training program.

1.14.2. (Added) Provide facilities and support (e.g., standard tools/equipment and Command

approved management information systems (MIS)s for organizations performing depot

maintenance or providing technical assistance at operating locations.

1.14.3. (Added) Ensure Air Force Smart Operations for the 21st Century (AFSO21) and

continuous process improvement activities are conducted in all depot maintenance organizations;

ensure improvement results are appropriately implemented and measured.

1.14.3.1. (Added) The foundation for investigating and solving problems within the Complex is

the practical problem solving method (PPSM) found in the AFSO21.

1.14.3.1.1. (Added) Group CC/directors, staff office directors or deputies will consider using an

AFSO21 8-Step event for the following events:

1.14.3.1.1.1. (Added) All impoundments.

1.14.3.1.1.2. (Added) Significant property damage (Class C or above).

1.14.3.1.1.3. (Added) Quality escapes.