I worked really hard

on this manual -

so please read it...

XOUIM1565S & XOUIM1565SP

XOUIM1565O & XOUIM1565OP

UNDERCOUNTER GOURMET ICE MAKER

2

UNDERCOUNTER

When buying any XO appliance

you can be confident you have chosen a

high quality, innovative and stylish product

from a company that cares about you!

If you require service or have questions,

Help is only a phone call away -

call: 973-403-8900

Talk to one of our undercounter experts.

CONGRATULATIONS

on purchasing your XO.

Before you proceed, take just

a moment to register your XO at:

Ensuring warranty coverage should you need service

Providing ownership verification for insurance purposes

Let’s XO notify you in the event of product changes or recalls.

www.xoappliance.com/register-your-product/

REGISTRATION HELPS YOU BY -

Before You Get Started

Safety Instructions

Electrical and Grounding Instructions

Care and Cleaning

Stainless Steel

Interior Washing

Cleaning

Sanitization

Maintenance Schedule

Winterizing

Trouble Shooting

Before You Call For Service

Warranty

4 - 7

Installation Instructions

S

Plumbing

With & Without Drain Pump

Reversing the Door

Door panel Installation

Outdoor Use

izes and Installation Dimensions

8 - 23

27 - 35

36 - 38

3

where things are

please read and follow

all safety instructions

It’s for your

own good...

Honest.

Installer Checklist

Find Your Model

Operating Instructions

24

- 26

Features & Specifications

Operating Instructions

4

heres’s ten steps for a quick & easy install

RISK OF CHILD ENTRAPMENT!

An empty refrigerator is a very dangerous attraction to children.

Remove door gaskets, latches, lids, lock and/or doors from unused or discarded appliances,

or take other actions to guarantee them harmless.

Always dispose of old appliances in accordance with local laws and regulations.

Inspect cabinet opening for water, drain and electrical connections.

The 1/4” O.D. water supply line must include isolation valve and should include an inline water

filter (consult manual). Do NOT use a self-piecing valve for the supply connection. Water

supply must have a minimum pressure of 20 psi and a maximum of 80 psi. Cold water

should be between 50 F and 90 F - NOTE: warmer water will slow ice production.

is strongly recommended.

Drain tubing will be 5/8” ID gravity fed or 3/8” ID for a pump model. All horizontal drain

runs must drop 1/4” per foot. The drain should include an air gap d

evice to prevent

siphoning and a sanitary trap. A restricted or inadequite drain can result in poor ice

production and possible flooding.

Electrical requirement is 15a dedicated, grounded circuit - outdoor installs must use a GFI.

Route water supply tubing to the water inlet located at the rear of the unit.

Connect the drain tubing to either the pump discharge or the barbed gravity fed elbow.

Be sure nothing is kinked, and excess slack is removed.

Be sure the electrical connection is secure into the wall outlet.

Slide the machine into location or cavity being careful not to allow for any kinks to occur

in the water inlet and drain tubing.

Adjust the Ice Maker to level using the leg levelers.

Add approximately 2-3 quarts of water to the bin and make certain it is draining properly

and check for leaks. If water does not drain, stop and verify tubing is not restricted.

Wash down the interior of the machine with a mild detergent solution (consult manual)

Turn the machine on and allow it to make ice for approximately 30-35 minutes to verify

ice is being produced and water is draining freely. Be sure to check the cube size, shape

and clarity. Discard the first batch of ice.

adjust if needed.

Always do one last check to be sure all water and drain connections are leak free.

1

2

3

4

5

6

7

8

9

10

o

o

5

GOURMET ICE MAKER

STAINLESS STEEL

XOUIM1565S & XOUIM1565SP

PANEL READY

XOUIM1565O & XOUIM156OP

2

these are the models

covered in this

book

take a minute to circle your model above

and record your serial number

here in case you need it later

INDOOR / OUTDOOR

Please read through completely before using your XO Unit

Periodic maintenance is essential for safe operation - the unit must be easily pulled out for full access.

The appliance must be positioned so that the plug and water shutoff are readily accessible.

Empty your XO unit before attempting to move the appliance. Moving while loaded may damage or

distort the frame.

The compressor will get HOT during operation / touching it may cause injury.

During installation follow all safety tips provided in this manual / appropriate safety equipment such as

safety glasses and work gloves should be worn.

Two people should move or lift your XO unit to prevent injury or damage.

Remov

e all interior and exterior packing materials prior to installation and dispose of properly.

Always use only approved cleaning and descaling products to maintain your XO Ice Maker.

For maximum efficiency, keep the door tightly shut unless removing ice.

Before installing, allow your XO unit to sit upright for 2 hours at the install site. This will allow the cooling

system to stabilize after transportation. Failure to follow this step may cause problems.

Location

Your XO unit should be located away from direct sunlight and heat sources (stove, heaters, etc.) which may

increase electrical consumption. High or low ambient temperature may cause units to work improperly.

Optimal operation occurs in the ambient temperatures of 50 - 68 F and water temperature below 50 .

The floor must be strong enough to support your XO unit fully loaded.

Your XO unit must not be installed in areas of where water or e

xcessive moisture are present.

Your XO unit’s final installation must observe the correct minimum air clearances around and behind the

unit to ensure adequate ventilation. In addition, all ventilation openings must be kept clear and free of

obstructions, failure to do so will result in damage to the unit.

WARNING

NEVER use external heat sources to accelerate defrosting

NEVER permit unauthorized service or modifications to your XO unit

NEVER tamper with the sealed refrigerant system - this unit uses R134a Refrigerant.

It should never be used in the vicinity of any flammable or explosive ignition sources.

ALWAYS FOLLOW THE ELECTRICAL SAFETY INSTRUCTIONS OUTLINED IN THIS MANUAL.

6

your safety matters

Never store bottles, cans or perishable food products such as meat or cheese in your XO Ice Maker.

Your XO unit must not be installed near

where flammable, corrosive or hazardous materials are present.

Failure To Follow All Electrical Safety Measures May Result in Serious Injury,

Fire Or Death

All electrical work should only be performed by an

experienced, licensed electrician.

All XO units MUST be grounded for safe operation and

come equipped with a

3 Prong molded cord/plug for that

purpose.

NEVER remove or disable the 3rd prong with an adapter.

NEVER use an extension cord to operate your XO unit.

Your XO unit is built to operate on 115V 60Hz and

should be plugged directly into a dedicated 15 amp

3 prong outlet. If you are uncertain as to the

vol

tage, amperage capacity or if the 3rd prong is

properly grounded - consult a licensed electrician.

To maximize the depth of the installation recess -

your outlet should be mounted flush with the wall.

Your XO unit should not share the circuit with any other

electrical devices as this may cause overloading,

overheating, blown fuses or tripping circuit breakers.

In a worst case this can pose a fire hazard.

NEVER handle your XO unit in wet conditions as this

can pose a severe danger of electric shock.

Exercise care when moving your XO unit to avoid

damage to the electrical cord. If the electrical cord of

your XO unit becomes worn or damaged it must be

replaced immediately by a qualified technician.

NEVER unplug your unit by pulling on the cord.

Unplug by gripping the plug firmly and pull out

straight from the outlet.

FOR INDOOR OR OUTDOOR USE:

XO Ice Makers shown in this manual are rated for

Indoor and Outdoor use.

These units are designed to operate in ambient

temperatures between 50 and 90 F.

Avoid installing the unit where it may be exposed to

heat or direct sun, dusty or damp conditions or in a

location where it may be rained on or splashed by

water.

Never install the unit where flammable or corrosive

chemicals (such as pool chemicals) are present.

Installation in seaside environments where high

concentrations of salt are present will require more

frequent cleaning to avoid corrosion.

Use in any uncontrolled area or otherwise exposed

to the elements is hazardous and voids the warranty.

In regions where high humidity exists (greater than 70%)

condensation may appear on the door and/or door

gaskets. This is normal and will disappear as humidity

drops.

SERVICE 115V - 60 Hz -

1 phase

AMPS 15 Amp Circuit Breaker

Requires a Dedicated Outlet

GFI required for Outdoor Installations

All electrical work must be performed by

a licensed electrician

7

Serious injury, fire or death...

Okay -

o o

8

a perfect fit

install under counter

When installing, remember you need

to leave ready access to both the power

Cut access to an adjoining cabinet to

locate outlet and water there.

ALL XO UNDERCOUNTER

UNITS ARRIVE PRE-WIRED

WITH LOW PROFILE PLUGS

FOR EASY INSTALLATION

4"

(100mm)

7"

(178mm)

34” MINIMUM

(864mm)

15”

WHEN INSTALLING WITH

THE HINGE SIDE NEXT TO A WALL -

LEAVE ADEQUATE SPACE FOR

YOUR DOOR HANDLE

90°

Door Swing

WALL

Clearance

Gap

(381mm)

MINIMUM

9

a perfect fit

your xo is this big ( or small, as the case would be )

XOUIM1565G & XOUIM1565GP ICE MAKER

33-

HIGH

(857mm)

3/4”

W

H

height & width

depth

23-3/8”

(594mm)

D

THE OVERALL DEPTH SHOWN (22-5/8”) INCLUDES THE DOOR WITH 3/4” PANEL.

THE DEPTH OF THE ICE MAKER CABINET ONLY IS 21-3/16”

14-7/8” WIDE

(378mm)

TOP VIEW

105

º

10

before you install

check a few things

115V~60Hz

e

Is the installation location COOL, DRY, LEVEL and away from direct sun.

The water supply valve must provide positive shut off capability and be readily accessible.

Does the unit have a dedicated 115V three prong grounded outlet? (use GFI outdoors)

The Cold Water supply is 1/4” O.D. tube, it should be 50 to 90 F and be between 20 and 80 psi.

(NOTE: as the inlet water temperature increases - production efficiency goes down.)

YOU WILL NEED -

A few simple hand tools:

Pump pliers, adjustable wrench, #2 Phillips head screwdriver, level, razor knife

AND a few hardware items:

Teflon tape or Pipe dope

5/8” I.D. drain hose and hose clamps (if installing a gravity drain model)

1/4” O.D. water supply hose

Air Gap Device and/or Sanitary Trap (depending on your installation).

Water filter with isolation valve

Depending on your installation you will probably require additional site specific plumbing fittings

Water source valve

Water source tub

Drain hose

o o

11

All water contains some impurities and minerals.

Your XO Ice Maker is designed to produce crystal clear, gourmet ice. It does this by

reducing the mineral content in the water as the ice is forming.

PURER WATER YIELDS PURER ICE.

Cubes are formed by cold water spraying against a chilled mold. Pure water freezes faster

than water containing impurities. The spraying action causes the cubes to be built up in layers

as the pure water freezes more quickly and the water containing impurities is washed away by

the spray and falls into the water bin to be diluted and drained away.

When the ice maker senses the cubes are fully formed and ready, the ice cube molds are

heated slightly causing them to drop out of the mold and into the ice holding bin.

Periodic maintenance is required to ensure that your ice maker is performing at its best.

See the maintenance section of this book and the Maintenance Schedule.

FILTERS AND WATER TREAMENT

The correct filter is always recommended. It has the ability to remove odors as well as

particulate from water prior to reaching the ice maker.

(consult www.xoappliance.com for more information on which filter is right for you)

Water softeners exchange one mineral for another (salt) which can cause inferior ice quality

such as soft, mushy ice that clumps together. If you are using a water softener, you should

install a bypass to supply untreated water to the ice maker.

Water produced by Reverse Osmosis and deionized water are not recommended. It is more

corrosive than tap water and can cause harm to the equipment over time.

water quality

12

Plan the arrangement of the water supply pipes. You will need both a water supply line and

a drain (see section on installing a gravity drain unit or pump drain unit)

If the tap water has a high level of minerals, an inline filter will be required.

Attach the water supply line to the rear of the unit

with flexible tube to the fitting indicated here.

The tubing must be long enough to permit the

unit to be pulled out for service.

Water supply should be between 20psi and 80psi.

Attach the drain to the connection indicated here

If you are installing an XOUIM1565S unit with a

gravity drain, the line must be pitched down

1/4” per ft to ensure correct drainage.

If the drain is positioned at a higher elevation than

the connection on the rear of the unit, a pump

will be required. Use model XOUIM1565GP.

This unit comes with a pre-installed drain pump

capable on discharging to a drain up to 8’ above

the unit.

IMPORTANT: The keep drains as short and straight

as possible for optimal performance.

The electric power, water supply pipeline and drain pipeline must be in compliance with all

provisions under the local laws and building regulations.

IMPORTANT: The product is designed for use in a fixed condition but it may be required to

pull the product out for service. Therefore, do not install any material at the front, upper or

lower end of the product which may be an obstacle when pulling the product out.

Once the unit is in place, use the leveling legs to ensure the unit is level.

Each side should have at least 1/16" of space for projection of the screw head near the bottom.

the plumbing

REAR

VIEW

ELECTRICAL CORD

DRAIN

WATER

SUPPLY

1/4” O.D.

13

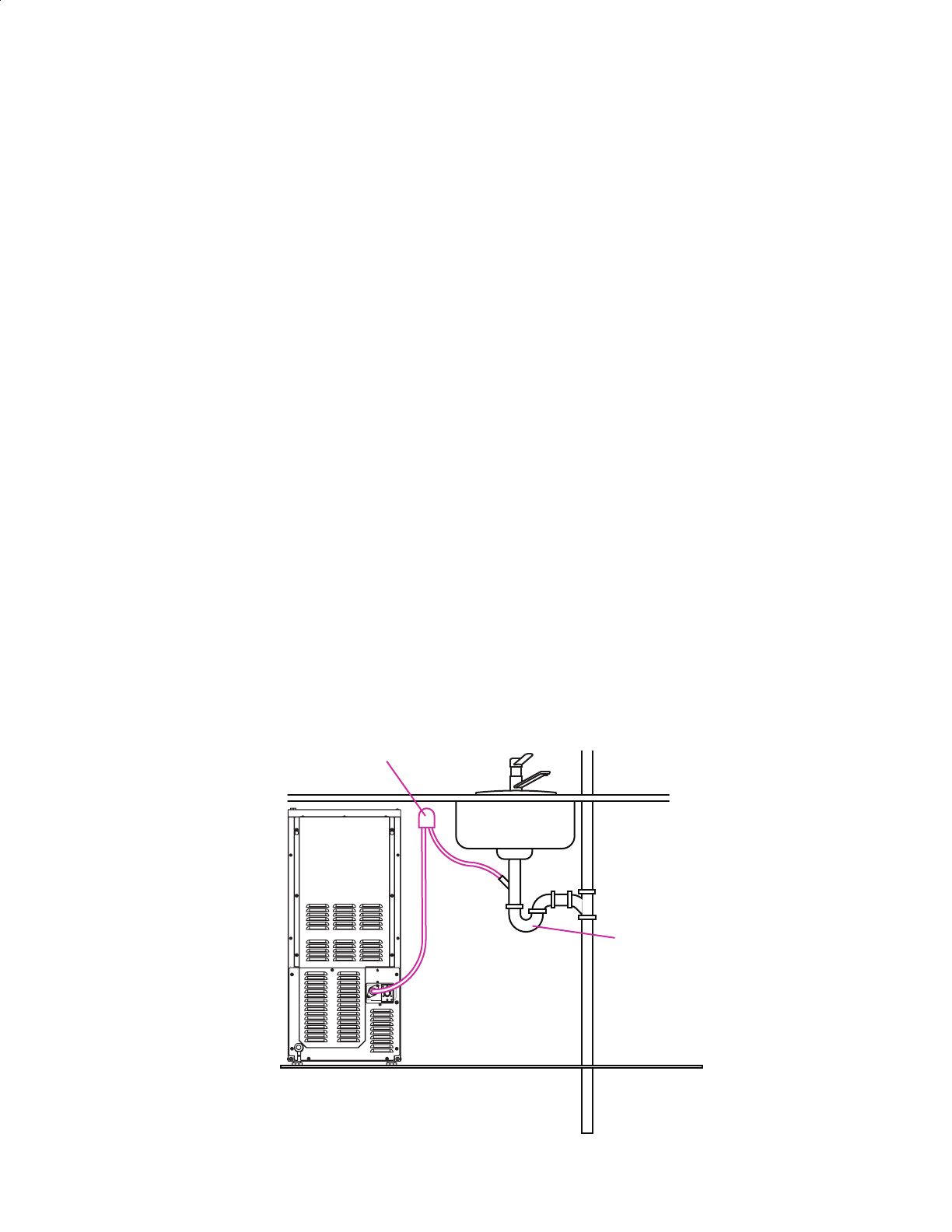

INSTALLING THE XOUIM1565S without a drain pump.

Position the ice maker in front of the opening. Level the unit using the leveling legs.

Wash and flush the water supply tube and connect the unit to the cold water isolation valve.

Prepare the drain. The drain must be pitched downward at a drop of 1/4” per foot to drain properly.

Horizontal runs of 5’ or more must be anchored to a wall for support to prevent sagging.

A sanitary trap and air gap must be installed in the line prior to entering the home’s drain system.

The trap prevents sewer gas from flowing back to the ice maker.

The air gap device prevents siphoning drain water back into the ice maker.

Cut the 5/8” ID drain hose (not supplied) to the required length. Immerse the hose in warm water to make

installation easie

hose to the drain using hose clamps.

r, then using a threaded hose barb connection sealed with teflon tape, connect the drain

Turn the water supply on and check to ensure there are no leaks.

If there are no leaks, plug the unit into the electrical outlet.

Press the switch to the “ICE” position. The compressor will run approximately 3 - 5 minutes.

Slide the unit back into it’s final position and recheck to ensure it is level.

REMEMBER to adhere to all local building codes and regulations

with gravity drain

DRAIN VENT

THE DRAIN POINT

MUST BE LOWER

THAN THE DRAIN

OUTLET OF THE

ICE MAKER

AI

DEVICE

R GAP

SANITARY TRAP

If you purchase a gravity drain unit

and find you need one with a pump

the XOUIM1565S can easily be

retrofitted with one in the field.

Simply order a XOUIMPUMP from

www.xoappliance.com

14

INSTALLING THE XOUIM1565SP with DRAIN PUMP.

Position the ice maker in front of the opening.

Level the unit using the leveling legs.

Wash and flush the water supply tube and connect the unit to the cold water isolation valve.

Cut the 3/8” diameter drain hose to the required length. Immerse the hose in warm water to make

installation easie

(9’ of 3/8” ID drain hose is included with pump models)

r, then connect the drain hose to the drain using hose clamps.

IMPORTANT: Check local codes to determine if an air gap is required between the drain and the pump.

Turn the water supply on and check to ensure there are no leaks.

If there are no leaks, plug the unit into the electrical outlet.

Fill the ice container with clean tap water approximately 3/4 full. The drain pump should turn on and pump

the water out. Check again for leakage.

Press the switch to the “ICE” position. The compressor will run approximately 3 - 5 minutes.

Fill the ice container to 3/4 full once more. Block the drain tube while the pump is running.

The pump should continue to run.

Slide the unit back into it’s final position and re-check to ensure it is level.

REMEMBER to adhere to all local building codes and regulations

with drain pump

DRAIN VENT

THE DRAIN POINT

MAY BE HIGHER

THAN THE DRAIN

OUTLET OF THE

ICE MAKER

SANITARY TRAP

AIR GAP DEVICE

reversing the door

Your XO Ice Maker is shipped with the hinge on the right hand side but it can be easily reversed.

IMPORTANT NOTE: Stainless Steel door models and Panel Ready models use different hinges

and Panel Ready models require additional steps when reversing the door.

1. While supporting the door, remove the two (2) screws

(shown in RED) that hold the Top Hinge in place.

The Top Hinges are virtually the same for

Stainless Steel and Panel Ready models.

Remove the door by lifting it straight up.

2. Remove the two (2) screws that hold the Bottom Hinge in

place. Remove the two (2) corresponding screws on the left

hand side. Install the Bottom Hinge in the left hand position

and install the remaining two (2) screws into the holes on the

r

NOTE: The Panel Ready unit has an additional screw that

comes up from the bottom that must be also be removed.

In addition, you must reverse the DOOR STOP INSERT

shown in Step 2A before re-installing.

ight hand side.

.

TOP HINGE

RIGHT HAND

POSITION

LEFT HAND

POSITION

15

BOTTOM HINGE

RIGHT HAND

POSITION

LEFT HAND

POSITION

2A.

on the left side, you must reverse the DOOR STOP INSERT located

on the underside of the bottom hinge. Simply remove the hex head

bolt that doubles as the hinge pin (shown in BLUE) -

flip the stop over (shown in RED)

and re-install the hex head bolt.

Panel Ready Units Only: Before re-installing the bottom hinge

VIEWS OF

BOTTOM HINGE

SEEN FROM BELOW

BEFORE AND AFTER

REVERSING THE STOP

16

reversing the door cont.

3. At the rear of the unit, there are three (3) screws

along the top. Remove these screws.

On the top front of the unit, there is one (1) additional

screw on the left hand side, remove this screw.

The Top Cover plate will now lift off.

.

REAR OF UNIT

TOP COVER

4. Remove the Top Hinge Support which is held in

place by one (1) screw from the right hand side and

transfer it to the left hand side re-attaching it with the

screw.

Replace the Top Cover plate using the three (3)

screws along the rear of the unit. The screw removed

from the top front on the left hand side - must be screwed

i

Remove the plugs from the left hand side screw holes

on the top cover and door and move them to the right

hand side.

nto the corrosponding hole on the right hand side.

TOP HINGE

SUPPORT

Panel Ready Units Skip to Step 5A

5. Center the hole in the bottom left hand side of the door on the bottom hinge pin and slide the door

down into place. Install the top hinge using the two screws removed in Step 1.

5A. Panel Ready Units Only:

Turn the door so the bottom edge is facing up.

a Remove the DOOR STOP (shown in RED)

b Remove the ANGLE BRACKET (shown in Black)

c Flip the ANGLE BRACKET over and install

using one screw at the other side of the door.

d Replace the DOOR STOP with the mirror image

door stop supplied with the unit using the screws

removed earlier.

Pop the small plastic bushing out and replace it after

the panel is installed. SKIP TO STEP 2 ON PAGE 20

a

b

c

d

AFTER INSTALLTION UNDER COUNTER, OVERLAY DOOR MUST BE ABLE TO OPEN 90 .

o

overlay panel dimensions xouim1565o & xouim1565op

29 3/8”

MIN.

14 3/4"

FRONT

The panel has a minimum height of 29 3/8” - If making the panel 29 3/8” tall

no further adjustments are needed.

If the panel is taller than 29 3/8”

proceed to pages 18 and 19,

a notch or recess is required.

TOP

MAXIMUM PANEL THICKNESS 3/4”

PANEL MAXIMUM WEIGHT: 20 lbs.

17

3/4"

WATCH THE INSTALLATION

VIDEO ON OUR CHANNEL

https://www.youtube.com/channel/UCT-Ip-dM9hoPydpxZfrZzRA

www.xoappliance.com

AFTER INSTALLTION UNDER COUNTER, OVERLAY DOOR MUST BE ABLE TO OPEN 90 .

o

overlay panel dimensions xouim1565o & xouim1565op

14 3/4"

FRONT

3/4"

A

B

5/8"

NOTCH HEIGHT

30” DOOR

DETAIL A

30 1/8"

14 5/8"

3/4"

A

B

5/8"

9/16"

DETAIL A

SCALE 1 : 1

1"

DETAIL B

BACK

Door panels taller than 29 3/8” require a notch

as seen in Detail A & B on the hinge side.

If making the panel 29 3/8”, no notch (detail A,B)

is required.

The bottom of the notch should always be 29 3/8”

from the bottom of the panel.

To get the exact measurement subtract 29 3/8“

from the panel height.

EXAMPLES:

PANEL HEIGHT NOTCH HEIGHT

30” 5/8”

30 1/4” 7/8”

TOP

TOP

MAXIMUM PANEL THICKNESS 3/4”

PANEL MAXIMUM WEIGHT: 20 lbs.

18

DOORS

TALLER THAN

29 3/8”

5/8"

NOTCH HEIGHT

30 1/4” DOOR

30 1/8"

14 5/8"

3/4"

A

B

5/8"

9/16"

DETAIL A

SCALE 1 : 1

1"

5/8”

7/8”

MAXIMUM PANEL THICKNESS 3/4”

PANEL MAXIMUM WEIGHT: 20 lbs.

19

AFTER INSTALLTION UNDER COUNTER, OVERLAY DOOR MUST BE ABLE TO OPEN 90 .

o

overlay

handling handleless doors:

panel dimensions xouim1565o & xouim1565op

Handleless doors have a profile similar to that shown

Instead of a notch, if the design of the door will allow, a recess can be cut out with a router

to accommodate the hinge extension.

The bottom of the recess must be 29 1/4” up from the bottom of the door and 5/8” high -

the door, at the deepest point of the finger groove, must be at least 30” from the bottom

of the door.

5/8”

5/8”

1”

SIDE VIEW REAR VIEW

29 1/4”

TO BOTTOM

OF DOOR

installing the overlay panel

Installing the overlay panel is easy if you folllow these simple steps.

You will need the following tools:

A drill with 3/16” and 5/16” bits - and a #2 Phillipshead screwdriver

1.

2. Place the door face down on a flat surface and

remove the door gasket from the groove (shown in RED)

gently starting at one corner. Lay it flat in a safe place,

you will be replacing it shortly.

In the four (4) corners of the groove, you will see four (4)

holes. These are for screws that will assist in securing the

panel.

3. Before proceeding, attach the handle (if used) to your overlay door panel in the desired position

remembering to countersink the screw heads so they do not prevent the overlay panel from laying

flat against the door.

4. Attach the BLACK support plate to the bottom of the door using the three (3) screws (shown on RED).

.

While supporting the door, remove the two (2) screws

(shown in RED) that hold the Top Hinge in place.

Then remove the door by lifting it straight up.

TOP HINGE

REMOVED

+ +

++ ++ ++

BOTTOM OF DOOR

20

+ +

++

+

++

+

++

+

BOTTOM OF DOOR

installing the overlay panel

5. Center the panel on the door and clamp it

in place to prevent shifting during attachment.

6. Using the HINGE ANGLE BRACKETS installed

on the door as a guide, drill two holes:

One 3/16” Hole down from the top into the door 1/2” deep.

Remove the plastic bushing from the lower angle bracket.

One 5/16“ Hole up from the bottom into the door 1/2” deep.

Replace the plastic bushing into the lower angle bracket.

This is to accommodate the hinge pins.

7. Taking care not to drill through the panel -

using the holes in the door, drill a 1/8” pilot hole

5/8” deep in each of the four screw holes located

in the corners of the gasket groove (ref: Step 2).

8. Using the four (4) self tapping screws provided

install one screw into each one of the four holes.

9. Drill a 1/8” pilot hole 3/4” deep in each of the three screw holes located in the BLACK support

plate mounted to the bottom of the door into the bottom edge of the panel. Using the three (3)

screws provided (shown in RED) secure the panel from the bottom to the support plate.

21

PANEL

DOOR

installing the overlay panel

10. Remove clamps and any debris that may remain from

drilling the pilot holes from the door gasket groove.

11. Beginning at one corner, replace the door gasket by

pressing it into the groove it was removed from in Step 2.

12. Replace the door by lowering it onto the lower hinge pin and replacing the top hinge removed

in Step 1.

22

23

When using your XO Ice Maker outdoors - follow these additional steps.

In outdoor installations care must be taken to protect the unit from excessive heat or direct

sun, dusty or damp conditions or in a location where it may be rained on or splashed by water.

The unit must be connected to a grounded circuit. If the installation is outdoor it must be

protected by a Ground Fault Interupter (GFI). If you are uncertain if the circuit is correctly

grounded and protected, consult a licensed electrician.

These units are designed to operate in ambient temperatures between 50 and 90 F.

As the ambient temperature approaches either extreme the production capacity of the ice

maker will be reduced. This is normal and expected.

Never install the unit where flammable or corrosive chemicals (such as pool chemicals)

are present.

Installation in seaside environments where high concentrations of salt, or in pool areas where

high concentrations of chlorine are present will require more frequent cleaning to avoid

corrosion.

Use in any uncontrolled area or otherwise exposed to the elements is hazardous and voids the

warranty.

In regions where high humidity exists condensation may appear on the door and/or gasket

seals.

CAUTION: Exposing the Ice Maker to freezing ambient temperatures can cause water

throughout the installation to freeze where it is not supposed to and may result in

damage to the unit.

Seasonally, once temperatures at the coldest part of the day begin to approach 40 F

you should take steps to winterize your ice maker following the steps in this manual.

for outdoor use

o

o

o

Dierent regions of the country can have radically dierent seasonal weather which can aect

performance and the influence your selection for the physical location of the unit.

24

2

features & specs

Produces up to 65lbs of crystal clear, gourmet ice

per day

Rectangular Bell Shaped Cubes -

designed to melt slowly and cool beverages

while minimizing dilution

Gravity drain and pump drain models available

Reversible Panel Ready steel door

Front venting - designed for under counter installation

Rated for Indoor or Outdoor use (50 - 90 )

Automatically pauses ice production when bin is full

MAXIMUM CAPACITY

CUBES per CYCLE

TIME per CYCLE

DIMENSIONS (WxDxH)*

NET WEIGHT

ELECTRICAL

POWER CONSUMPTION

REFRIGERANT

COOLING CAPACITY

INLET WATER TEMP.

INLET WATER PRESS.

AMBIENT TEMP.

* Overall Dimensions include 3/4” panel, hinges and legs

65 lbs per day

24

20-30 min

14 7/8” x 23 3/8” x 33 3/4”

104 lbs empty

115V - 60hz - 4.0 amps

340 Watts

R-134a

723 kcal/hr (2@ 45 F)

50 - 90 F

20 - 80 psi

50 - 100 F

o

o

o

o

o o

o

operating

Initial operation

Open the water supply valve connect ed with the ice maker.

Insert the plug of the ice maker into the electric outlet.

Open the door and turn the switch to the “ICE” position.”

Discard the first batch of ice.

Good-quality ice is produced 1-2 hour s later.

Using the ice maker

Use of the ice maker is very simple. Simply turn the switch at

the lower end of the product to the “ICE” position.

The product automatically starts ice production, which continues

until the ice container has been filled with ice. Remove the ice

using an ice scoop and insert the scoop into the holder on the

inside of the container (If you place the container in the ice,

it may be covered over by ice).

The ice maker produces 24 pieces of ice every 30 minutes.

Also, the produced ice drops down into the ice container;

water is supplied to the ice maker and the water is also drained.

Important Information : Do not put anything other than

ice in the ice container. Wine or beer bottles are unsanitary

and a detached label may block the drain pipe.

Ice

The ice has a rectangular bell shape (refer to the figure).

Newly produced ice is clear and transparent. The inside of the ice

is sometimes cracked; however, such cracks commonly occur in

the production process and disappear with time.

Ice stored in the container for a long time may gather frost on

the outside and look cloudy. This is normal ice and, once water

is poured on the ice, such frosting disappears.

Ice container

The product continues making ice until the level of ice reaches

the temperature sensing tube(right side). It then ceases operation.

The model with a drain pump drains away melted ice when the

ice maker is turned off. The pump works for only several seconds.

25

operating cont.

Operation time

It takes about 20-35 minutes to produce a set of 24 ice pieces. The length of one cycle

of the ice maker (ice production and ice removal) differs depending upon the cleanness

of the ice maker, the surrounding temperature, and the temperature of the water supplied

to the ice maker. It takes about 10-12 hours to fill the empty ice container with ice.

Ice production

The ice production process largely consists of two cycles-ice production and ice removal.

24 pieces of ice are produced with each cycle of ice production and ice removal.

When water is sprayed on to the surface of the frozen ice forming mold, the ice production

cycle is started. When ice is removed and water is supplied to ice maker, the ice removal

cycle is started. The time taken for both cycles together is about 20-35 minutes.

Ice production cycle

Ice is produced on the surface of the ice -forming mold located at the top of the ice maker.

Water is sprayed against the chilled surface of the mold where it begins to freeze. Water

containing mineral impurities freezes more slowly and it falls back into the water container

where it will be diluted and drained off during the Ice Removal Cycle. This process of

spraying water allows ice to form in crystal clear layers.

As the ice-forming mold is filled with ice the temperature drops, the ice maker senses this

and the ice production cycle stops and ice removal is started automatically.

Ice removal cycle

The compressor works during the the ice removal cycle, but the pump motor and fan motor

are stopped. The hot gas valve and water supply valve are opened and the frozen surfaces

are heated, causing ice to drop into the container. The ice removal cycle is stopped and

the ice production cycle is started again automatically.

26

stainless steel

cleaning the exterior

Stainless Steel:

Stainless steel does not stain, corrode, or rust as easily as ordinary steel, but it is not stain or

corrosion proof. Stainless steels can discolor or corrode if not maintained properly.

Stainless steels differ from ordinary carbon steels by the amount metals such as chromium and

nickel used in the alloy. It is the chromium which provides an invisible protective film on the

surface called chromium oxide. If the protective chromium oxide film on the surface is damaged

or contaminated, it can result in discoloration, staining, or corrosion of the iron in the steel.

Care & Cleaning:

Routine cleaning of the stainless steel surfaces will serve to greatly extend the life of your

product by removing contaminants.

This is especially important in coastal areas which can expose the stainless to severe contaminants

such as halide salts, (sodium chloride) and also in pool areas where high concentrations of chlorine

are present.

.

It is strongly recommended to periodically inspect and thoroughly clean crevices, weld points,

under gaskets, rivets, bolt heads, and any locations where small amounts of moisture could collect,

become stagnant, and concentrate contaminates.

Additionally, any mounting hardware that is showing signs of corrosion should be replaced.

The frequency of cleaning depends upon the installation location, environmental factors, and use.

Cleaning Products:

Ultimately, the choice of a proper cleaning product belongs to the consumer, and there are many

products to choose from. Depending upon the type of cleaning and the degree of contamination,

some products are better than others.

Typically the most effective means of routine cleaning for most stainless steel products is to give

the surfaces a brisk rubbing with a soft cloth soaked in warm water with a gentle detergent, or mild

mixture of ammonia.

Rubbing should follow the polish lines of the steel, folllowed by a thorough rinsing after cleaning.

CAUTION: There are products on the market Called "stainless steel cleaners," which may contain

abrasives that could scratch the surface, (compromising the protective chromium oxide coating)

and other products which contain chlorine bleach which will dull, tarnish or discolor the surface if

not completely removed. Such cleaners should be avoided.

27

28

washing (interior)

Proper maintenance, cleaning and santizing is essential to ensure your

ice is safe, fresh and odor free.

Cleaning the nozzle / ice slide / water tank

1. Open the door and remove two front

injection bolts on the top cover.

2. Pull the top cover to remove it.

3. Slightly lift the ice slide to remove it.

4. Clean the slide with soft plastic brush

or sponge.

washing (interior) cont.

Proper maintenance, cleaning and santizing is essential to ensure your

ice is safe, fresh and odor free.

5. Clean the gap of the nozzle frame fixed

on the vessel sheet (water tank).

6. Lift the drain connection inside the vessel

sheet (water tank), clean it, and drain the water.

* The drain connection must be re-assembled

in the correct position after cleaning or it will

continue to drain and be unable to make ice.

CLEANING THE ICE TANK AND WATER TANK FILTERS

Empty the ice tank and prepare a cleaning solution by mixing

2 tablespoons of dishwashing detergent with 2 gallons of warm water

(95~115 F).

Soak a clean cloth in the solution

and clean the inside of the ice tank.

Pour an appropriate amount of the solution

into the drain pipe, and allow to air dry.

* Press the switch to set it to (WASH) when cleaning the product; this will

repeat the process of supplying water for about 2 minutes and operating

the circulation pump 3 times, enabling easier cleaning.

29

o

30

washing (interior) cont.

Proper maintenance, cleaning and santizing is essential to ensure your

ice is safe, fresh and odor free.

Cleaning the ice tank and water tank filters

WATER TANK ICE TANK

Always unplug the unit before performing maintenance.

Open the door of the Ice Maker and remove the filter screens from the bottom

of the water tank and ice tank (position indicated above).

Rinse them clean thoroughly with running water.

Replace the tank filters in the positions shown.

Failure to perform this simple maintenance can cause the water nozzles and drain

to become clogged and lead to reduced performance and/or damage to the unit.

BOTTOM FILTER SCREEN TOP FILTER SCREEN

31

the condenser

improve efficiency & performance

Cleaning the condenser

Remove dust and dirt from the surface of the condenser coils with a

vacuum cleaner

Remove two screws on the front panel

at the center of the inside

Vacuum the condenser coils

Reassemble the panel using the two

screws to after cleaning

cleaning/descaling

Ice makers must be thoroughly cleaned a minimum of 2-4 times each year, more frequently if circumstances require it.

All cleansers and sanitizing agents must comply with 40CFR 180.9403 as Food Contact Sanitizers.

The end user is responsible for maintaining this ice maker in accordance with the instructions in this manual. Failure to do so

may void warranties and cause an unsafe condition. Basic sanitization and maintenance will both increase reliability and

performance, as well as reduce the consumption of electricity and water.

Maintaining the ice maker according to these instructions will minimize unwanted repairs and extend the unit’s service life.

Maintenance activities must be performed either by the consumer or by an authorized service technician at required intervals.

If you are unfamiliar with sanitization procedures, contact your dealer or XO Customer Service at 973-403-8900 for service.

GENERAL:

Thoroughly clean the ice maker every three to six months for efficient operation.

If the ice maker needs to be cleaned and sanitized more frequently, consult a certified service company for water quality testing

and take appropriate action.

Based on the condition of the ice maker it may be necessary to disassemble parts of the unit for cleaning and disinfection.

Caution: Use only the certified ice-maker detergent and disinfectant. (The detergent can be purchased at your dealer).

Please read all labels printed on the container before use. Do not mix the detergent and the disinfectant.

Warning: Wear rubber gloves and goggles (or face cover) when using the detergent or the disinfectant.

PREPARATION:

Ice maker detergent is used to remove mineral deposits such as lime marks. It cannot be used to remove mold or adhesive mucus.

Mix Nickel Safe detergent and water in a plastic or stainless steel container following the manufacturer’s recommendations.

THE PROCESS:

Turn the switch to OFF - the machine will automatically complete making and separating ice, then stop.

Caution: Do not forcibly remove ice from the evapor

ator. It can damage the evaporator.

Remove all ice from inside of the tank.

Before proceeding, shut down the power to the icemaker at the breaker or by unplugging it.

Wash the ice scoop including the handle regularly with other food containers.

WARNINGS:

● The detergent may cause burns.

● If you accidentally drink the detergent, do not force yourself to vomit.

● Instead, drink large amount of water or milk and contact your doctor immediately.

● If the detergent gets on the skin, wash with water.

● Keep the detergent out of children’s reach.

32

cleaning cont.

If necessary, remove the top cover and disassemble the evaporator cover, water curtain, ice guide and nozzle frame.

Place all components into a basin to soak with approximately 3 quarts of the detergent water mixture for 5 to 20 minutes

depending on how much lime scale build up is present.

Disassemble the spray bar by removing the left and right silicon plugs, and separate the nozzles and inserts while soaking.

While the parts are soaking, clean the inside of the ice tank with a soft brush and rinse every corner of the inside door,

reservoirs, evaporator frame and evaporator upper pipe part with clean water.

Clean the parts which have been soaking with a soft nylon brush. You may have to use a toothpick to clear the nozzles.

After cleaning, rinse all the parts with clean water.

Re-assemble the unit with the newly cleaned parts.

Pour the remain quart of detergent mixture into the water tank.

Make sure the switch is in the “OFF” position and restore power by plugging the unit in or turning on the breaker.

AUTOMATIC CLEANING:

Start the automatic cleaning process by turning the switch to the “WASH” position.

The automatic cleaning cycle takes 21 minutes to complete. After it is finished set the switch in the “OFF” position.

RINSING:

If any cleaning solution remains in the water tank, remove the drain plug to empty the tank.

Re-install the drain plug, pour one quart of clean water into the water tank and run “WASH” again for 10 minutes.

If any bubbles or residue remains, repeat the rinse operation.

33

sanitizing

Ice makers must be sanitized monthly, more frequently if circumstances require it.

All cleansers and sanitizing agents must comply with 40CFR 180.9403 as Food Contact Sanitizers.

The end user is responsible for maintaining this ice maker in accordance with the instructions in this manual. Failure to do so

may void warranties and cause an unsafe condition. Basic sanitization and maintenance will both increase reliability and

performance, asa well as reduce the consumption of electricity and water.

Maintaining the ice maker according to these instructions will minimize unwanted repairs and extend the unit’s service life.

Maintenance activities must be performed either by the consumer or by an authorized service technician at required intervals.

If you are unfamiliar with sanitization procedures, contact your dealer or XO Customer Service at 973-403-8900 for service.

GENERAL:

Sanitize the ice maker every month for safe and efficient operation.

If the ice maker needs to be cleaned and sanitized more frequently, consult a certified service company for water quality testing

and take appropriate action.

Based on the condition of the ice maker it may be necessary to disassemble parts of the unit for cleaning and disinfection.

Caution: Use only the certified ice-maker detergent and disinfectant. (The detergent can be purchased your dealer.)

Please read all labels printed on the container before use. Do not mix the detergent and the disinfectant.

Warning: Wear rubber gloves and goggles (or face cover) when using the detergent or the disinfectant.

PREPARATION:

Prepare disinfectant (6.7 oz of 5.25% Sodium Hydroxide mixed in 5 liters of water).

THE PROCESS:

Turn the switch to OFF - the machine will automatically complete making and separating ice, then stop.

Caution: Do not forcibly remove ice from the evapor ator. It can damage the evaporator.

Remove all ice inside of the tank.

Before proceeding, shut down the power to the icemaker at the breaker or by unplugging it.

Wash the ice scoop including the handle regularly with other food containers.

Remove the top cover and disassemble the evaporator cover, water curtain, ice guide and nozzle frame.

Place all components into a basin to soak with approximately 2 quarts of the disinfectant water mixture for 10 minutes

While parts are soaking, scrub the inside of the ice tank with a soft brush and rinse every corner of the inside door,

reservoirs, evaporator frame and evaporator upper pipe part and rinse with clean tap water to avoid cross-contamination.

Rinse the parts which have been soaking with clean tap water to avoid cross contamination.

34

Re-assemble the unit with the newly cleaned parts.

Pour 3 quarts of disinfectant mixture into the water tank.

sanitizing cont.

Make sure the switch is in the “OFF” position and restore power by plugging the unit in or turning on the breaker.

AUTOMATIC SANITIZING:

Start the automatic sanitizing process by turning the switch to the “WASH” position. This will also sanitize the piping.

The automatic sanitizing cycle takes 21 minutes to complete. After it is finished set the switch in the “OFF” position.

RINSING:

If any disinfectant solution remains in the water tank, remove the drain plug to empty the tank.

Re-install the drain plug, pour one quart of clean water into the water tank and run “WASH” again for 10 minutes.

Do NOT wipe the interior dry.

Turn on the “ICE” function and the unit will resume making ice.

Discard the first batch of ice after sanitizing.

35

Proper maintenance assures better ice and longer product life.

Shown below is a recommended service schedule to maintain your ice maker at peak performance.

Failure to provide maintenance as prescibed in this manual may void warranty.

The intervals shown are based on average conditions, your unit may require more frequent

maintenance based on your particular installation, such as areas where hard water, dust or

salt air are present.

RECOMMENDED SCHEDULE:

IMPORTANT NOTE:

If your ice maker has been winterized, you must wash, sterilize and clean/descale it

thoroughly before returning it to service to ensure that any detergents or chemicals

have been completely flushed from the system.

Always discard the first batch of ice made after restarting.

maintenance schedule

MAINTENANCE

CLEAN EXTERIOR

WASH INTERIOR

STERILIZE

CLEAN/DESCALE

VACUUM CONDENSER

CHECK ICE QUALITY

WEEKLY MONTHLY QUARTERLY ANNUALLY AT START-UP

CHANGE WATER FILTER

36

winterizing

Where seasonal installation ambient temperatures fall below 50 F

Clean and sanitize your system

Turn off the power

Empty the water container completely

Disconnect the pump hose - this requires the removal of the back panel

Close the water supply valve and disconnect the water supply line from the rear of the unit

Turn on the power and set the switch to the “WASH” position.

This will open the internal water supply valve allowing it to drain the inlet pipe

If your unit has a drain pump, pour 1/2 gallon of RV anti-freeze mixture (propylene glycol)

into the ice tank.

WARNING: Do NOT use anti-freeze intended for automobiles.

Turn the ice maker “OFF” and remove the plug from the outlet

When returning the ice maker to service - the unit must be thoroughly santized and cleaned

to ensure all chemicals and detergents are flushed from the system.

Discard the first batch of ice after returning to service.

IMPORTANT NOTE:

Should the ice maker require adjustment of the:

Evaporator temperature sensor,

Ice production cycle time delay - or -

Water supply timer

Call Customer Service, do not attempt yourself.

o

37

troubleshooting

PROBLEM

Unit does not operate

Cubes are too large

Cubes are too small

Ice is fragmented

Ice tank not filling

Ice cubes are white

Unit is running

but no ice is made

POSSIBLE CAUSE

Ice maker is unplugged

Breaker tripped

Switch turned to “OFF”

The ice tank is full

Low ambient temperature

Ice thickness control does not work

High ambient temperature

Too little water in the water tank

The water nozzle not spraying

Ice thickness control does not work

Nozzle partially blocked

Check the operation time

Check for water in the ice tank

Low water in water tank

Low water in water tank

Ice cubes are stuck on the mold

Water does not get cold

Water not spraying

Condenser coils dirty

Condenser not working

High ambient temperature

Hot gas leak

Needs refrigerant

CHECK THIS

Plug ice maker in

Reset breaker - if it happens again, call for service

Turn switch to “ICE”

Ice detection sensor is activated

Call Customer Service

Call Customer Service

Call Customer Service

Check the water supply

Check the water supply | nozzle may be clogged

Call Customer Service

Clean the ice maker

Requires approx 12 hrs to fill ice tank

Check and clean drain

Check water supply

Check for cracks or leaks

Check water supply

Check water supply | Check hot gas valve

Check water supply | Contact customer service

Low water in water tank | Check circulation pump

Vacuum condenser coils

Check condenser fan

Call Customer Service

Call Customer Service

Call Customer Service

Questions - Need Help...

You can always contact customer service at 973-403-8900

or visit www.xoappliance.com

YEAR

WARRANTY

To obtain ser vice:

38

we’ve got your back

1 5

YEAR

WARRANTY

PARTS + LABOR COMPRESSOR

Call 973-403-8900 |email [email protected] | or submit a request on our website

www.xoappliance.com

ONE-YEAR PARTS & LABOR LIMITED WARRANTY. XO warrants to the original purchaser of every new XO refrigerated unit, the

cabinet and all parts thereof, to be free from defects in material or workmanship under normal and proper use and maintenance as

specified by XO and upon proper installation and start-up in accordance with the instruction packet supplied with each XO unit. XO’s

obligation under this warranty is limited to a period of one (1) year from the date of original purchase.

FIVE-YEAR COMPRESSOR LIMITED WARRANTY. XO warrants its compressor to be free from defects in both material and workmanship

under normal and proper use and maintenance service for a period of five (5) years from the date of original purchase. If the compressor

fails during that time period due to a defect in material or workmanship, XO will supply a replacement compressor free of charge. The

consumer will be responsible for all related transporation and labor costs. Product must be registered with XO to qualify for this warranty.

TERMS APPLICABLE TO EACH WARRANTY. Any part covered under the above warranties that is determined by XO to have been

defective within the time frame is limited to the repair or replacement, including labor charges, of defective parts or assemblies. The

labor warranty shall include standard straight time labor charges only and reasonable travel time, as determined by XO.

WARRANTY CLAIMS. All claims for labor or parts must be made directly through XO. All claims should include: model number and

serial number of cabinet, proof of purchase, and date of installation. In case of warranted compressor, the compressor model tag must

be returned to XO along with the above listed information.

WHAT IS NOT COVERED BY THIS WARRANTY. XO’s sole obligation under this warranty is limited to either repair or replacement of

parts, subject to the additional limitations below. This warranty neither assumes nor authorizes any person to assume obligations other

than those expressly covered by this warrant

or obscured serial numbers and commercial applications are excluded from these warranties. Consumer shall be responsible for labor

and transportation costs where noted above.

y. Open box, factory seconds, scratch and dent, floor models, models with missing, altered

NO CONSEQUENTIAL DAMAGES. XO is not responsible for economic loss, profit loss; or special, indirect or consequential damages,

including without limitation, losses or damages arising from food or product spoilage claims whether or not on account or refrigeration failure.

WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original purchaser/user at the

original installation location. Any such assignment or transfer shall void the warranties herein made and shall void all warranties,

express or implied, including any warranty or merchantability or fitness for a particular purpose.

IMPROPER USAGE. XO assumes no liability for parts or labor coverage for component failure or other damages resulting from

improper usage or installation or failure to clean and/or maintain product as set forth in the warranty packet provided with the unit.

ALTERATION OR NEGLECT. XO is not responsible for the repair or replacement of any parts that XO determines have been subjected

after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit, improper installation, lack of scheduled

maintenance as outlined in this manual, fire, flood, or act of God.

SERVICE CONNECTIONS. XO is not responsible for the repair or replacement of failed or damaged components due to water supply, drain

or electrical power failure, high or low pressure, blocked drains, high or low voltage, use of extension cords, or improper grounding of the unit.

YOUR RIGHTS UNDER STATE LAW. This warranty gives you specific legal rights and you may have other rights that vary from state to

state. Some states do not allow the exclusion or limitation of consequential damages or a limitation on how long an implied warranty lasts,

so the above exclusion or limitation may not apply to you.

OUTSIDE U.S. This warranty does not apply to, and XO is not responsible for, any warranty claims made on products sold or used outside

the 48 continental United States.

notes:

SEE ALL THE LATEST XO PRODUCTS AND ACCESS PARTS AT:

WWW.XOAPPLIANCE.COM