1

HEAT AND MASS TRANSFER

LABORATORY MANUAL

UET

DEPARTMENT OF MECHANICAL

ENGINEERING (NEW CAMPUS)

UNIVERSITY OF ENGINEERING & SCIENCE TECHNOLOGY

LAHORE

ENGR. MUHAMMAD ADEEL MUNIR

(BSc. Mechanical Engineering UET, Lahore)

(MSc. Engineering Management UET, Lahore)

2

Submitted by:

Name =

Registration No =

Submitted to:

3

Preface

In most of the engineering institutions, the laboratory course forms an integral form of the basic

course in Heat and mass transfer at undergraduate level. The experiments to be performed in a

laboratory should ideally be designed in such a way as to reinforce the understanding of the

basic principles as well as help the students to visualize the various phenomenon

encountered in different applications.

The objective of this manual is to familiarize the students with practical skills, measurement

techniques and interpretation of results. It is intended to make this manual self-contained in all

respects, so that it can be used as a laboratory manual. In all the experiments, the relevant

theory and general guidelines for the procedure to be followed have been given. Tabular sheets

for entering the observations have also been provided in each experiment while graph sheets

have been included wherever necessary.

The students are advised to refer to the relevant text before interpreting the results and writing

a permanent discussion. The questions provided at the end of each experiment will reinforce

the students understanding of the subject and also help them to prepare for viva-voce exams.

4

General Instructions To Students

• The purpose of this laboratory is to reinforce and enhance your understanding of the

fundamentals of Heat and mass transfer. The experiments here are designed to demonstrate

the applications of the basic heat transfer principles and to provide a more intuitive and

physical understanding of the theory. The main objective is to introduce a variety of

classical experimental and diagnostic techniques, and the principles behind these

techniques. This laboratory exercise also provides practice in making engineering

judgments, estimates and assessing the reliability of your measurements, skills which are

very important in all engineering disciplines.

• Read the lab manual and any background material needed before you come to the lab. You

must be prepared for your experiments before coming to the lab.

• Actively participate in class and don’t hesitate to ask questions. Utilize the teaching

assistants. You should be well prepared before coming to the laboratory, unannounced

questions may be asked at any time during the lab.

• Carelessness in personal conduct or in handling equipment may result in serious injury to

the individual or the equipment. Do not run near moving machinery. Always be on the

alert for strange sounds. Guard against entangling clothes in moving parts of machinery.

• Students must follow the proper dress code inside the laboratory. To protect clothing from

dirt, wear a lab apron. Long hair should be tied back.

• Calculator, graph sheets and drawing accessories are mandatory.

• In performing the experiments, proceed carefully to minimize any water spills, especially

on the electric circuits and wire.

• Make your workplace clean before leaving the laboratory. Maintain silence, order and

discipline inside the lab.

• Cell phones are not allowed inside the laboratory.

• Any injury no matter how small must be reported to the instructor immediately.

• Wish you a nice experience in this lab

5

Table of Contents

Preface .................................................................................................................. 3

General Instructions To Students...................................................................... 4

Table of Contents ................................................................................................ 5

List of Equipment.............................................................................................. 15

List of Experiments ........................................................................................... 16

List of Figures .................................................................................................... 18

List of Tables ..................................................................................................... 19

List of Graphs .................................................................................................... 20

1. LAB SESSION 1 ......................................................................................... 21

1.1 Learning Objectives .................................................................................................. 21

1.2 Apparatus .................................................................................................................. 21

1.3 Main Parts of Linear Heat Transfer Unit .................................................................. 21

1.4 Useful Data ................................................................................................................ 21

1.5 Theory ....................................................................................................................... 22

1.5.1 Conduction Heat Transfer ............................................................................................. 22

1.5.2 Fourier’s law of heat conduction .................................................................................. 22

1.5.3 The Plane walls .............................................................................................................. 22

1.6 Experimental Procedure ............................................................................................ 22

1.7 Observations .............................................................................................................. 23

1.8 Calculated Data ......................................................................................................... 23

1.8.1 Objective:1 .................................................................................................................... 24

1.8.1.1 Specimen Calculations ............................................................................... 24

1.8.1.2 Graph: ......................................................................................................... 25

1.8.1.3 Statistical Analysis ..................................................................................... 25

1.8.1.4 Conclusion .................................................................................................. 25

1.8.2 Objective:2 .................................................................................................................... 26

1.8.2.1 Specimen Calculations ............................................................................... 26

1.8.2.2 Statistical Analysis ..................................................................................... 27

1.8.2.3 Conclusion .................................................................................................. 28

1.9 Questions ................................................................................................................... 28

6

1.10 Comments .............................................................................................................. 28

2. LAB SESSION 2 ......................................................................................... 29

2.1 Learning Objective .................................................................................................... 29

2.2 Apparatus .................................................................................................................. 29

2.3 Main Parts of Linear Heat Transfer Unit .................................................................. 29

2.4 Useful Data ................................................................................................................ 29

2.5 Theory ....................................................................................................................... 30

2.5.1 Conduction Heat Transfer ............................................................................................. 30

2.5.2 Fourier’s law of heat conduction .................................................................................. 30

2.5.3 The Composite wall ....................................................................................................... 30

2.6 Experimental Procedure ............................................................................................ 31

2.7 Observations .............................................................................................................. 32

2.7.1.1 Specimen Calculations ............................................................................... 33

2.7.1.2 Graph .......................................................................................................... 34

2.7.1.3 Statistical Analysis ..................................................................................... 35

2.7.1.4 Conclusion .................................................................................................. 35

2.8 Questions ................................................................................................................... 35

2.9 Comments.................................................................................................................. 35

3. LAB SESSION NO 03 ............................................................................... 36

3.1 Learning Objective .................................................................................................... 36

3.2 Apparatus .................................................................................................................. 36

3.3 Main Parts of Radial Heat transfer unit ..................................................................... 36

3.4 Useful Data ................................................................................................................ 36

3.4.1 Radial Heat Conduction ................................................................................................ 36

3.4.2 Heated disc:................................................................................................................... 36

3.5 Theory ....................................................................................................................... 36

3.5.1 Conduction Heat Transfer ............................................................................................. 36

3.5.2 Radial Systems .............................................................................................................. 36

3.5.2.1 Cylinders ..................................................................................................... 36

3.6 Procedure ................................................................................................................... 37

3.7 Observations .............................................................................................................. 38

3.8 Calculated Data ......................................................................................................... 38

3.8.1 Objective ....................................................................................................................... 38

3.8.1.1 Specimen Calculations ............................................................................... 39

3.8.1.2 Conclusion .................................................................................................. 39

7

3.8.1.3 Graph .......................................................................................................... 40

3.9 Statistical Analysis .................................................................................................... 40

3.10 Questions ............................................................................................................... 40

3.11 Comments .............................................................................................................. 40

4. LAB SESSION 4 ......................................................................................... 41

4.1 Learning Objectives .................................................................................................. 41

4.2 Apparatus .................................................................................................................. 41

4.3 Main Parts ................................................................................................................. 41

4.4 Useful Data ................................................................................................................ 41

4.5 Theory ....................................................................................................................... 41

4.5.1 Radiation ....................................................................................................................... 41

4.5.2 Radiation Heat Transfer ................................................................................................ 41

4.5.3 Inverse square law ........................................................................................................ 42

4.5.4 Stefan–Boltzmann law .................................................................................................. 42

4.6 Procedure ................................................................................................................... 42

4.7 Observations: ............................................................................................................. 44

4.8 Calculated Data ......................................................................................................... 44

4.8.1 Objective:01 .................................................................................................................. 44

4.8.1.1 Graph .......................................................................................................... 45

4.8.1.2 Conclusion .................................................................................................. 45

4.8.2 Objective:02 .................................................................................................................. 45

4.8.2.1 Specimen Calculation ................................................................................. 45

4.8.2.2 Conclusion .................................................................................................. 46

4.9 Statistical Analysis .................................................................................................... 46

4.10 Questions ............................................................................................................... 46

4.11 Comments .............................................................................................................. 46

5. LAB SESSION 5 ......................................................................................... 47

5.1 Apparatus .................................................................................................................. 47

5.2 Main Parts ................................................................................................................. 47

5.3 Useful Data ................................................................................................................ 47

5.4 Theory ....................................................................................................................... 47

5.4.1 Radiation ....................................................................................................................... 47

5.4.2 Shape Factor ................................................................................................................. 47

5.5 Procedure ................................................................................................................... 48

5.6 Observations: ............................................................................................................. 49

8

5.6.1 Calculated Data ............................................................................................................. 50

5.6.1.1 Specimen Calculation ................................................................................. 50

5.6.1.2 Conclusion .................................................................................................. 51

5.7 Statistical Analysis .................................................................................................... 51

5.8 Questions ................................................................................................................... 51

5.9 Comments.................................................................................................................. 51

6. LAB SESSION 6 ......................................................................................... 52

6.1 Learning Objective .................................................................................................... 52

6.2 Apparatus .................................................................................................................. 52

6.3 Main Parts ................................................................................................................. 52

6.4 Useful Data ................................................................................................................ 52

6.5 Theory ....................................................................................................................... 53

6.6 Procedure ................................................................................................................... 53

6.7 Calculated Data ......................................................................................................... 55

6.7.1 Objective:01 .................................................................................................................. 55

6.7.1.1 Observations ............................................................................................... 55

6.7.1.2 Specimen Calculations ............................................................................... 55

6.7.1.3 Graph .......................................................................................................... 56

6.7.1.4 Conclusion .................................................................................................. 56

6.8 Statistical Analysis .................................................................................................... 57

6.9 Questions ................................................................................................................... 57

6.10 Comments .............................................................................................................. 57

7. LAB SESSION 7 ......................................................................................... 58

7.1 Learning Objective .................................................................................................... 58

7.2 Apparatus .................................................................................................................. 58

7.3 Main Parts ................................................................................................................. 58

7.4 Useful Data ................................................................................................................ 58

7.5 Theory ....................................................................................................................... 59

7.5.1 Forced convection ......................................................................................................... 59

7.6 Procedure ................................................................................................................... 59

7.6.1 Objective ....................................................................................................................... 61

7.6.1.1 Observations ............................................................................................... 61

7.6.1.2 Calculated Data ........................................................................................... 61

7.6.1.3 Specimen Calculations ............................................................................... 61

7.6.1.4 Graph: ......................................................................................................... 63

9

7.6.1.5 Conclusion .................................................................................................. 63

7.7 Statistical Analysis .................................................................................................... 63

7.8 Questions ................................................................................................................... 63

7.9 Comments.................................................................................................................. 63

8. LAB SESSION 8 ......................................................................................... 67

8.1 Learning Objective .................................................................................................... 67

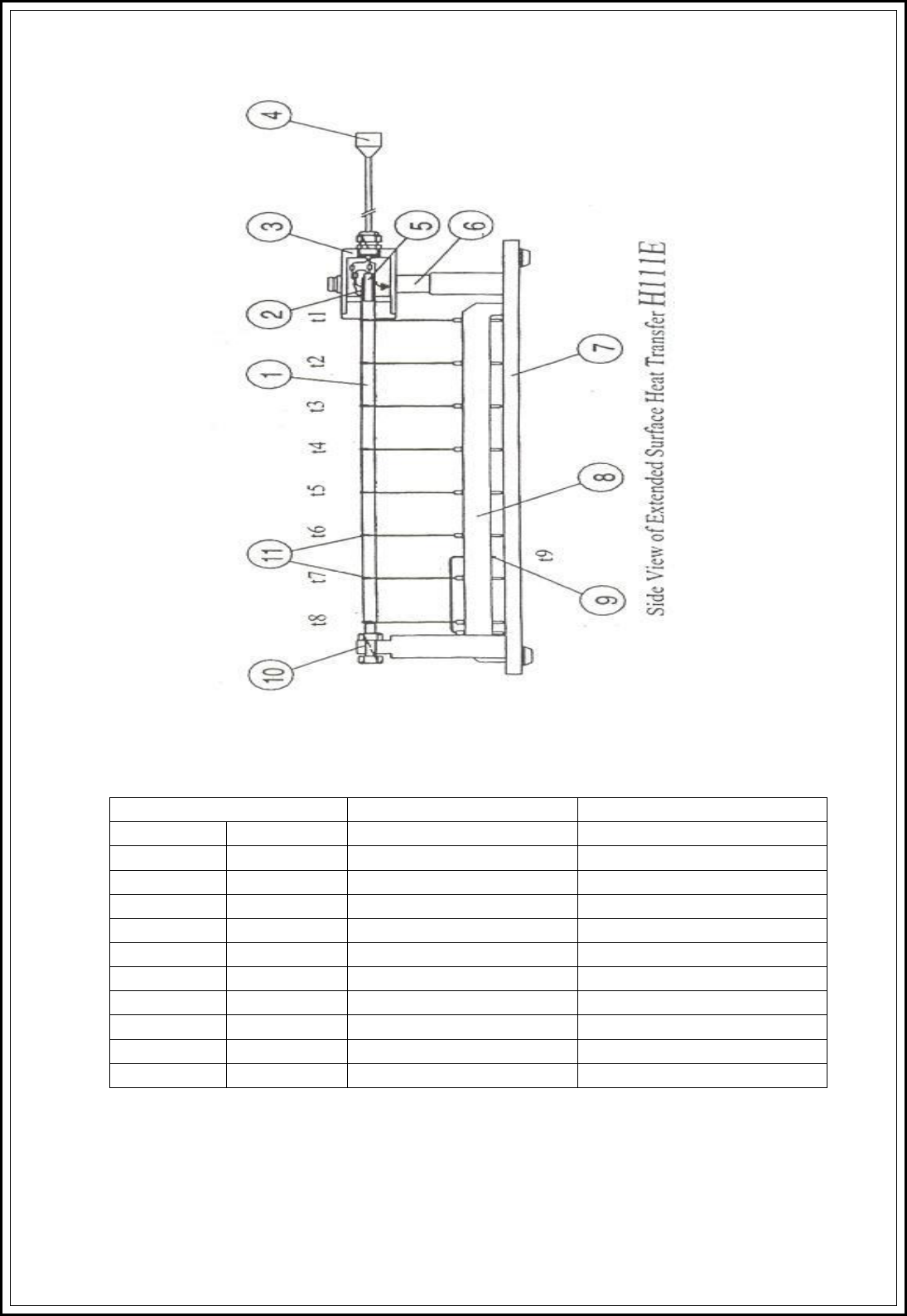

8.2 Apparatus .................................................................................................................. 67

8.3 Main Parts ................................................................................................................. 67

8.4 Useful Data ................................................................................................................ 67

8.5 Theory: ...................................................................................................................... 67

8.5.1 Fin (extended surface) .................................................................................................. 67

8.6 Procedure:.................................................................................................................. 68

8.7 Observations .............................................................................................................. 69

8.8 Calculated Data ......................................................................................................... 70

8.8.1 Specimen Calculation .................................................................................................... 70

8.8.2 Graph............................................................................................................................. 71

8.8.3 Conclusion ..................................................................................................................... 71

8.9 Questions ................................................................................................................... 71

8.10 Comments .............................................................................................................. 71

9. LAB SESSION 9 ......................................................................................... 72

9.1 Learning Objective .................................................................................................... 72

9.2 Apparatus .................................................................................................................. 72

9.3 Main Parts ................................................................................................................. 72

9.4 Theory ....................................................................................................................... 72

9.5 Procedure:.................................................................................................................. 73

9.6 Observations .............................................................................................................. 73

9.6.1 Objective ....................................................................................................................... 74

9.6.1.1 Graph .......................................................................................................... 75

9.6.1.2 Conclusion .................................................................................................. 75

9.7 Comments.................................................................................................................. 75

10. LAB SESSION 10 ................................................................................... 76

10.1 Learning Objective ................................................................................................ 76

10.2 Apparatus ............................................................................................................... 76

10.3 Main Parts .............................................................................................................. 76

10.4 Theory .................................................................................................................... 76

10

10.4.1 Transient Heat-Transfer ................................................................................................ 76

10.4.2 Lumped-Heat-Capacity System ..................................................................................... 76

10.4.3 Biot number (Bi) ............................................................................................................ 76

10.4.4 Fourier number (Fo) ...................................................................................................... 77

10.4.5 Heisler charts ................................................................................................................ 78

10.5 Procedure ............................................................................................................... 78

10.6 Observations .......................................................................................................... 80

10.7 Calculated Data ...................................................................................................... 81

10.7.1 Sample Calculations ...................................................................................................... 81

10.7.2 Graph............................................................................................................................. 83

10.7.3 Conclusion ..................................................................................................................... 83

10.8 Statistical Analysis ................................................................................................ 83

10.9 Questions ............................................................................................................... 83

10.10 Comments .............................................................................................................. 83

11. LAB SESSION 11 ................................................................................... 85

11.1 Learning Objective ................................................................................................ 85

11.2 Apparatus ............................................................................................................... 85

11.3 Main Parts .............................................................................................................. 85

11.4 Useful Data ............................................................................................................ 85

11.5 Theory .................................................................................................................... 86

11.5.1 Introduction of The Equipment .................................................................................... 86

11.5.2 Description of The Equipment ...................................................................................... 87

11.6 Objective: 1............................................................................................................ 87

11.6.1 Procedure ...................................................................................................................... 87

11.6.2 Observations ................................................................................................................. 88

11.6.3 Graph............................................................................................................................. 88

11.6.4 Conclusion ..................................................................................................................... 88

11.7 Objective: 2............................................................................................................ 88

11.7.1 Procedure ...................................................................................................................... 89

11.7.2 Observations: ................................................................................................................ 89

11.7.3 Graph............................................................................................................................. 89

11.7.4 Conclusion ..................................................................................................................... 89

11.8 Specimen Calculation ............................................................................................ 89

11.9 Statistical Analysis ................................................................................................ 89

11.10 Questions ............................................................................................................... 90

11

11.11 Comments .............................................................................................................. 90

12. LAB SESSION 12 ................................................................................... 91

12.1 Learning Objective ................................................................................................ 91

12.2 Apparatus ............................................................................................................... 91

12.3 Main Parts .............................................................................................................. 91

12.4 Useful Data ............................................................................................................ 92

12.4.1 Interior Tube ................................................................................................................. 92

12.4.2 Exterior Tube ................................................................................................................. 92

12.4.3 Base Unit ....................................................................................................................... 92

12.4.4 Heat Exchanger ............................................................................................................. 92

12.4.5 Physical Properties of The Hot And Cold Water ........................................................... 92

12.4.6 Mass Flow Rates ............................................................................................................ 92

12.5 Theory .................................................................................................................... 93

12.5.1 Heat transference in heat exchangers .......................................................................... 93

12.5.2 Overall Heat-Transfer Coefficient ................................................................................. 94

12.5.3 The Log Mean Temperature Difference (LMTD) ........................................................... 94

12.5.4 Effectiveness-Ntu Method ............................................................................................ 94

12.5.5 Capacity coefficient ....................................................................................................... 94

12.5.6 Reynolds number .......................................................................................................... 95

12.6 Objective 01 ........................................................................................................... 95

12.6.1 Procedure: ..................................................................................................................... 95

12.6.2 Observations ................................................................................................................. 96

12.6.3 Calculated Data ............................................................................................................. 96

12.6.4 Specimen Calculations .................................................................................................. 97

12.6.4.1 Heat transferred by the hot water ............................................................... 97

12.6.4.2 Heat absorbed by the cold water ................................................................. 97

12.6.4.3 Heat Losses ................................................................................................. 97

12.6.4.4 Logarithmic temperatures mean difference between hot water and cold

water 97

12.6.4.5 Global heat transference coefficient= (U) .................................................. 97

12.7 Objective:02........................................................................................................... 97

12.7.1 Procedure ...................................................................................................................... 97

12.7.2 Observations ................................................................................................................. 98

12.7.3 Calculations ................................................................................................................... 99

12.7.4 Specimen Calculations .................................................................................................. 99

12

12.7.4.1 Heat transferred by the hot water ............................................................... 99

12.7.4.2 Logarithmic temperatures mean difference between hot water and cold

water 99

12.7.4.3 Number of transmission units ................................................................... 100

12.7.4.4 Capacity coefficient .................................................................................. 100

12.8 Graph ................................................................................................................... 100

12.9 Statistical Analysis .............................................................................................. 100

12.10 Conclusion ........................................................................................................... 100

12.11 Questions ............................................................................................................. 101

12.12 Comments ............................................................................................................ 101

13. LAB SESSION 13 ................................................................................. 102

13.1 Learning Objective .............................................................................................. 102

13.2 Apparatus ............................................................................................................. 102

13.3 Main Parts ............................................................................................................ 102

13.4 Useful Data .......................................................................................................... 103

13.4.1 Interior Tube ............................................................................................................... 103

13.4.2 Exterior Tube ............................................................................................................... 103

13.4.3 Base Unit ..................................................................................................................... 103

13.4.4 Heat Exchanger ........................................................................................................... 103

13.4.5 Physical Properties Of The Hot And Cold Water ......................................................... 103

13.4.6 Mass Flow Rates .......................................................................................................... 104

13.5 Theory .................................................................................................................. 105

13.5.1 Heat transference in heat exchangers ........................................................................ 105

13.5.2 Shell and tube heat exchanger.................................................................................... 105

13.5.3 Overall Heat-Transfer Coefficient ............................................................................... 105

13.5.4 The Log Mean Temperature Difference (LMTD) ......................................................... 106

13.5.5 Effectiveness-Ntu Method .......................................................................................... 106

13.5.6 Capacity coefficient ..................................................................................................... 106

13.5.7 Reynolds number ........................................................................................................ 106

13.6 Objective 1 ........................................................................................................... 107

13.6.1 Procedure: ................................................................................................................... 107

13.6.2 Observations ............................................................................................................... 107

13.6.3 Calculated Data ........................................................................................................... 108

13.6.4 Specimen Calculations ................................................................................................ 108

13.6.4.1 Heat transferred by hot water (q

h

) ............................................................ 108

13

13.6.4.2 Heat absorbed by the cold water (q

c

) ........................................................ 108

13.6.4.3 Heat losses (q

l

) .......................................................................................... 108

13.6.4.4 Logarithmic average temperatures difference between hot and cold water

(∆T

lm

) 108

13.6.4.5 Global heat transfer coefficient (U) .......................................................... 108

13.7 Objective 2 ........................................................................................................... 109

13.7.1 Procedure .................................................................................................................... 109

13.7.2 Observations ............................................................................................................... 109

13.7.3 Calculated Data ........................................................................................................... 110

13.7.4 Specimen Calculations ................................................................................................ 110

13.7.4.1 Experimental effectiveness (ϵ) ................................................................. 110

13.7.4.2 Logarithmic average temperatures difference between hot and cold water

(∆T

lm

) 110

13.7.4.3 Global heat transfer coefficient (U) .......................................................... 110

13.7.4.4 Number of transmission units ................................................................... 110

13.7.4.5 Capacity coefficient .................................................................................. 111

13.7.4.6 Temperatures at the exchanger outlet ....................................................... 111

13.8 Statistical Analysis .............................................................................................. 111

13.9 Conclusion ........................................................................................................... 111

13.10 Questions ............................................................................................................. 111

13.11 Comments ............................................................................................................ 111

14. LAB SESSION 14 ................................................................................. 112

14.1 Learning Objective .............................................................................................. 112

14.2 Apparatus ............................................................................................................. 112

14.3 Main Parts ............................................................................................................ 112

14.4 Useful Data .......................................................................................................... 112

14.4.1 BASE UNIT ................................................................................................................... 112

14.4.2 Heat Exchanger ........................................................................................................... 112

14.4.3 Physical Properties of The Hot and Cold Water .......................................................... 113

14.4.4 Mass Flow Rates .......................................................................................................... 113

14.5 Theory .................................................................................................................. 115

14.5.1 Heat transference in heat exchangers ........................................................................ 115

14.5.2 Plate heat exchanger .................................................................................................. 115

14.5.3 Overall Heat-Transfer Coefficient ............................................................................... 115

14.5.4 The Log Mean Temperature Difference (LMTD) ......................................................... 115

14.6 Objective .............................................................................................................. 116

14

14.6.1 Procedure .................................................................................................................... 116

14.6.2 Observations ............................................................................................................... 116

14.6.3 Calculated Data ........................................................................................................... 117

14.6.4 Specimen Calculations ................................................................................................ 117

14.6.4.1 Heat transferred by hot water (q

h

) ............................................................ 117

14.6.4.2 Heat absorbed by the cold water (q

c

) ........................................................ 117

14.6.4.3 Heat losses (q

l

) .......................................................................................... 117

14.6.4.4 Logarithmic average temperatures difference between hot and cold water

(∆T

lm

) 117

14.6.4.5 Global heat transfer coefficient (U) .......................................................... 117

14.7 Graph ................................................................................................................... 118

14.8 Statistical Analysis .............................................................................................. 118

14.9 Conclusion ........................................................................................................... 118

14.10 Questions ............................................................................................................. 118

14.11 Comments ............................................................................................................ 118

15

List of Equipment

1) Linear Heat Transfer Unit (H111A)

2) Radial Heat Transfer Unit (H111B)

3) Radiation Heat Transfer Unit (H111C)

4) Combined Convection & Radiation Heat Transfer Unit (H111D)

5) Extended Surface Heat Transfer Unit (H111E)

6) Radiation Errors in Temperature Measurements (H111F)

7) Heat Transfer Service Unit with Unsteady State Heat Transfer Unit (H111G)

8) Free and Forced Convection Heat Transfer Unit (TCLFC)

9) Turbulent Flow Heat Exchanger (TIFT)

10) Shell and Tube Heat Exchanger (TICT)

11) Plate Heat Exchanger (TIPL)

16

List of Experiments

Experiment No.

Description

Experiment No. 1

To apply Fourier Rate Equation for steady flow of heat through plane solid

materials.

Experiment No. 2

To apply Fourier Rate Equation for steady flow of heat through composite

plate

Experiment No. 3

To apply the Fourier Rate Equation for steady flow of heat through cylindrical

solid materials

Experiment No. 4

To verify laws of radiation by using shape factor

Experiment No. 5

To verify the role of shape factor involved in radiation heat transfer

Experiment No. 6

To calculate the total heat transfer of combined convection and radiation

heat transfer mechanism

Experiment No. 7

To calculate the total heat transfer of combined “forced convection” and

“radiation” heat transfer mechanism

Experiment No. 8

To experimentally verify the heat transfer from an extended surface from

combined modes of free conduction, free convection and radiation heat

transfer by comparing it with the theoretical analysis

Experiment No. 9

To Reduce radiation errors in measurement of temperature by using shield

between sensor and source of radiation

Experiment No. 10

To determine the Convective heat transfer coefficient of a solid cylinder

using analytical transient temperature/heat flow charts

Experiment No. 11

To measure the effect of different exchanger geometry on convection heat

transfer mechanism

Experiment No. 12

To Calculate logarithmic mean temperature difference (LMTD), global heat

transfer coefficient and effectiveness of turbulent flow heat exchanger

Experiment No. 13

To Calculate logarithmic mean temperature difference (LMTD), global heat

transfer coefficient and effectiveness of shell and tube heat exchanger

17

Experiment No. 14

To Calculate logarithmic mean temperature difference (LMTD) and global

heat transfer coefficient of plate heat exchanger

18

List of Figures

Figure 1.1: Temperature Profile in Fourier heat conduction ................................................... 22

Figure.1.2: Schematic diagram of experiment ........................................................................ 24

Figure.1.3: Schematic diagram of experiment ........................................................................ 25

Figure 1.4: Schematic diagram of experiment ........................................................................ 26

Figure 2.1: Temperature Profile in Fourier heat conduction ................................................... 30

Figure 2.2: Heat through composite wall ................................................................................. 31

Figure 2.3: Schematic diagram of experiment ........................................................................ 32

Figure 2.4: Schematic diagram of experiment ......................................................................... 34

Figure 3.1: Heat transfer through cylinder ............................................................................... 37

Figure 3.2: Temperature distribution in cylinder ..................................................................... 37

Figure 4.1: Schematic diagram of experiment ........................................................................ 43

Figure.5.1: Schematic diagram for shape factor ..................................................................... 47

Figure 5.2: Schematic diagram of experiment ........................................................................ 48

Figure 6.1: Schematic Diagram of Experiment ...................................................................... 54

Figure 7.1: Schematic Diagram of Experiment ...................................................................... 60

Figure 8.1: Schematic Diagram of Experiment ...................................................................... 69

Figure 8.1: Schematic Diagram of Experiment ...................................................................... 86

Figure 12.1: Schematic Diagram of Experiment ..................................................................... 93

Figure 13.1: Schematic Diagram of Experiment ................................................................... 104

Figure 13.2: Parallel and counter parallel flow ...................................................................... 105

Figure 13.3: Shell and tube heat exchanger ........................................................................... 105

Figure 14.1: Schematic Diagram of Experiment ................................................................... 114

Figure 14.2: Parallel and counter parallel flow ...................................................................... 115

19

List of Tables

Table 1.1: Temperatures observation at different points of specimen ..................................... 23

Table 1.2: Calculation of thermal conductivity ....................................................................... 24

Table 1.3: Distribution of temperature through uniform plane wall ........................................ 26

Table 2.1: Temperatures observation at different points of specimen ..................................... 32

Table 2.2: Calculation of overall heat transfer coefficient ...................................................... 33

Table 3.1: Distribution of temperature for different voltages .................................................. 38

Table 3.2: Thermal conductivity of given sample ................................................................... 39

Table 4.1: Measurement of temperatures from radiometer ..................................................... 44

Table 4.2: Calculation of intensity of radian ........................................................................... 45

Table 4.3: Calculation of shape factor ..................................................................................... 45

Table 5.1: Measurement of temperatures from radiometer ..................................................... 49

Table 5.2: Radiation incident on the detector .......................................................................... 50

Table 6.1: Table of Physical properties of Air at Atmospheric Pressure ................................. 52

Table 6.2: Measurement of temperature for free convection ................................................... 55

Table 6.3: Heat transfer due to free convection and radiation ................................................. 55

Table 7.1: Table of Physical properties of Air at Atmospheric Pressure ................................. 58

Table 7.2: Measurement of temperature due to forced convection ......................................... 61

Table 7.3: Heat transfer due to forced convection ................................................................... 61

Table 8.1: Temperatures measured at different distances from T1 ......................................... 69

Table 8.2: Heat transfer from extended surface ....................................................................... 70

Table 9.1: Temperatures at different points from radiant source ............................................. 74

Table 10.1: Specimen: 20mm diameter Brass Cylinder. ......................................................... 80

Table 10.2: Specimen: 20mm Stainless Steel Cylinder ........................................................... 80

Table 10.3: Properties of Specimen: 20mm diameter Brass Cylinder .................................... 81

Table 10.4: Properties of Specimen: 20mm diameter stainless steel Cylinder ....................... 81

Table 11.1: Temperatures in free convection .......................................................................... 88

Table 11.2: Temperatures in forced convection ...................................................................... 88

Table 11.3: Temperatures for different geometry of exchangers ............................................ 89

Table 12.1: Temperature at different points of turbulent flow heat exchanger ....................... 96

Table 12.2: Heat transfer calculation in turbulent flow heat exchanger .................................. 96

Table 12.3: Temperature for parallel and cross flow ............................................................... 98

Table 12.4: Effectiveness of turbulent flow exchanger ........................................................... 99

Table 13.1: Valve positions of shell and tube heat exchanger ............................................... 104

Table 13.2: Temperatures at shell and tube heat exchanger .................................................. 107

Table13.3: Heat transfer coefficient of shell and tube heat exchanger .................................. 108

Table 13.4: Temperatures for shell and tube heat exchanger ................................................ 109

Table 13.5: Effectiveness of shell and tube heat exchanger .................................................. 110

Table 14.1: Position of valves in plate heat exchanger .......................................................... 114

Table 14.2: Temperatures of Plate Heat Exchangers ............................................................. 116

Table14.3: Heat transfer in Plate heat exchanger .................................................................. 117

20

List of Graphs

Graph 7.1: Kinematic velocity of air at standard Pressure ...................................................... 64

Graph 7.2: Thermal conductivity of air at standard pressure ................................................... 65

Graph 7.3: Prandtl number of air at standard pressure ........................................................... 66

Graph 10.1: Heisler charts ....................................................... Error! Bookmark not defined.

21

1. LAB SESSION 1

To apply Fourier Rate Equation for steady flow of heat through plane solid materials.

1.1 Learning Objectives

[i] To identify a given sample by determining its thermal conductivity.

[ii] To measure temperature distribution through a uniform plane wall and analyse the

effect of a change in heat flow.

1.2 Apparatus

Linear Heat Transfer unit H111A (Serial no H111A/04417)

1.3 Main Parts of Linear Heat Transfer Unit

1) Hydraulic Bench

2) Specimen of different materials (Brass, Aluminium, Stainless Steel)

3) Main digital Control panel (H111)

4) Temperature Sensors

1.4 Useful Data

Heated Section:

Material: Brass 25 mm diameters, Thermocouples T1, T2, T3 at 15mm spacing. Thermal

Conductivity: Approximately 121 W/mK

Cooled Section:

Material: Brass 25 mm diameters, Thermocouples T6, T7, T8 at 15mm spacing. Thermal

Conductivity: Approximately 121 W/mK

Brass Intermediate Specimen:

Material: Brass 25 mm diameters * 30mm long. Thermocouples T4, T5 at 15mm spacing

centrally spaced along the length. Thermal Conductivity: Approximately 121 W/mK

Hot and Cold Face Temperature:

Due to the need to keep the spacing of the thermocouples constant at 15mm with, or

without the intermediate specimens in position the thermocouples are displaced 7.5 mm

back from the ends faces of the heated and cooled specimens and similarly located for the

Brass Intermediate Specimen.

T

hot face

= T

3

-

T

cold face

=

+

So that the equations are of the above form as the distance between T3 and the hot face

and T6 and the cold face are equal to half the distance between the adjacent pairs of

thermocouples.

22

1.5 Theory

1.5.1 Conduction Heat Transfer

When a temperature gradient exists in a body, there is an energy transfer from the high-

temperature region to the low-temperature region. The energy is transferred by conduction

and that the heat-transfer rate per unit area is proportional to the normal temperature gradient

1.5.2 Fourier’s law of heat conduction

Figure 1.1: Temperature Profile in Fourier heat conduction

q

x

=-KA

Equation I.1: Fourier law heat conduction equation

Where q

x

is the heat-transfer rate and ∂T/∂x is the temperature gradient in the direction of the

heat flow. The positive constant k is called the thermal conductivity of the material, and the

minus sign is inserted so that the second principle of thermodynamics will be satisfied; i.e.,

heat must flow downhill on the temperature scale as shown in figure 1.1. Equation 1.1 is called

Fourier’s law of heat conduction after the French mathematical physicist Joseph Fourier, who

made very significant contributions to the analytical treatment of conduction heat transfer.

(Equation 1.1) is the defining equation for the thermal conductivity and that k has the units of

watts per meter per Cels1ius degree in a typical system of units in which the heat flow is

expressed in watts

1.5.3 The Plane walls

First consider the plane wall where a direct application of Fourier’s law. Integration yields

q=-

(T

2

-T

1

) Equation 1.2: Integration of Fourier law

When the thermal conductivity is considered constant. The wall thickness is x, and T

1

and T

2

are the wall-face temperatures.

1.6 Experimental Procedure

1. Ensure that the main switch is in the off position (the digital displays should not be

illuminated). Ensure that the residual current circuit breaker on the rear panel is in the

ON position.

2. Turn the voltage controller anti-clockwise to set the AC voltage to minimum.

23

3. Ensure the cold-water supply and electrical supply is turned on at the source. Open the

water tap until the flow through the drain hose is approximately 1.5 litters/minute.

4. Release the toggle clamp tensioning screw and clamps. Ensure that the faces of the

exposed ends of the heated and cooled sections are clean.

5. Turn on the main switch and the digital displays should illuminate. Set the temperature

selector switch to T1 to indicate the temperature of the heated end of the bar.

6. Following the above procedure ensure cooling water is flowing and then set the heater

voltage V to approximately 150 volts. This will provide a reasonable temperature

gradient along the length of the bar. If however the local cooling water supply is at a

high temperature (25-35 or more) then it may be necessary to increase the voltage

supplied to the heater. This will increase the temperature difference between the hot

and cold ends of the bar.

7. Monitor temperatures T1, T2, T3, T4, T5, T6, T7, T8 until stable. When the

temperatures are stabilized record T1, T2, T3, T4, T5, T6, T7, T8, V, I

8. Increase the heater voltage by approximately 50 volts and repeat the above procedure

again recording the parameters T1, T2, T3, T4, T5, T6, T7, T8, V, I when temperature

have stabilized.

9. When the experimental procedure is completed, it is good practice to turn off the power

to the heater by reducing the voltage to zero and allow the system a short time to cool

before turning off the cooling water supply.

1.7 Observations

Sample

No.

T

1

T

2

T

3

T

4

T

5

T

6

T

7

T

8

V

I

Volts

Amps

1

2

3

4

Distance

from T1

0.000

0.015

0.030

0.045

0.060

0.075

0.090

0.105

Table 1.1: Temperatures observation at different points of specimen

1.8 Calculated Data

24

1.8.1 Objective:1

To identify a given sample by determining its thermal conductivity.

Figure.1.2: Schematic

diagram of experiment

Specimen cross sectional Area A=0.00049m

2

Specimen Length =0.030m

Sample

No.

Material

Name

1

2

3

4

Table 1.2: Calculation of thermal conductivity

1.8.1.1 Specimen Calculations

Intermediate Specimen and hot and cold section cross sectional Area;

Heat transfer rate from the heater;

Note that the thermocouples T3 and T6 do not record the hot face and cold face temperatures,

as are both displaced by 0.0075m from T3 and T6 as shown.

25

Figure.1.3: Schematic diagram of

experiment

If it is assumed that the temperature distribution is linear, then the actual temperature at the hot

face and cold face may be determined from the following equations.

T

hot face

= T

3

-

And

T

cold face

=

+

From the above parameters, the thermal conductivity of the aluminum intermediate section

may be calculated.

1.8.1.2 Graph:

Plot a graph b/w Temperature and Distance from T1 thermocouple. The thermal conductivity

of the intermediate sample may also be calculated from the data it is plotted on a graph. From

the graph the slope of the line is.

X

1.8.1.3 Statistical Analysis

For Thermal conductivity

% Error=

x

avg

=

S

x

=

1.8.1.4 Conclusion

26

1.8.2 Objective:2

To measure the temperature distribution through a uniform plane wall and demonstrate the effect of a

change in heat flow.

Figure 1.4: Schematic diagram of

experiment

Sample

No.

1-3

6-8

1-3

6-8

W

m

M

/m

/m

W/mK

W/mK

1

2

3

4

Table 1.3: Distribution of temperature through uniform plane wall

1.8.2.1 Specimen Calculations

Heat transfer rate from the heater;

Temperature difference in the heated section between T1 and T3;

Similarly the temperature difference in the cooled section between T6 and T8;

27

The distance between the temperatures measuring points, T1 and T3and T6 and T8, are

similar;

=

=

Hence the temperature gradient along the heated and cooled sections may be calculated from

If the constant rate of heat transfer is divided by the temperature gradients, the value obtained

will be similar if the equation is valid.

Hence, substituting the values obtained gives for the heated section and cooled sections

respectively for following values.

As may be seen from the above example and the tabulated data the function does result in a

constant value within the limits of the experimental data.

1.8.2.2 Statistical Analysis

For Constant “C”

% Error=

x

avg

=

S

x

=

28

1.8.2.3 Conclusion

1.9 Questions

1) What is conduction heat transfer?

2) What is Fourier law of heat conduction

3) What is meant by thermal resistance

1.10 Comments

29

2. LAB SESSION 2

To apply Fourier Rate Equation for steady flow of heat through composite plate

2.1 Learning Objective

I. To measure the temperature distribution through a composite plane wall and determine the

overall Heat Transfer Coefficient for the flow of heat through a combination of different

materials

2.2 Apparatus

Linear Heat Transfer unit H111A (Serial no H111A/04417)

2.3 Main Parts of Linear Heat Transfer Unit

5) Hydraulic Bench

6) Specimen of different materials (Brass, Aluminium, Stainless Steel)

7) Main digital Control panel (H111)

8) Temperature Sensors

2.4 Useful Data

Heated Section:

Material: Brass 25 mm diameters, Thermocouples T1, T2, T3 at 15mm spacing. Thermal

Conductivity: Approximately 121 W/mK

Cooled Section:

Material: Brass 25 mm diameters, Thermocouples T6, T7, T8 at 15mm spacing. Thermal

Conductivity: Approximately 121 W/mK

Brass Intermediate Specimen:

Material: Brass 25 mm diameters * 30mm long. Thermocouples T4, T5 at 15mm spacing

centrally spaced along the length. Thermal Conductivity: Approximately 121 W/mK

Stainless Steel Intermediate Specimen:

Material: Stainless Steel, 25 mm diameters * 30mm long. No Thermocouples fitted.

Thermal Conductivity: Approximately 25 W/mK

Aluminum Intermediate Specimen:

Material: Aluminum Alloy, 25 mm diameters * 30mm long. No Thermocouples fitted.

Thermal Conductivity: Approximately 180 W/mK

Hot and Cold Face Temperature:

Due to the need to keep the spacing of the thermocouples constant at 15mm with, or

without the intermediate specimens in position the thermocouples are displaced 7.5 mm

30

back from the ends faces of the heated and cooled specimens and similarly located for the

Brass Intermediate Specimen.

T

hot face

= T

3

-

T

cold face

=

+

So that the equations are of the above form as the distance between T3 and the hot face

and T6 and the cold face are equal to half the distance between the adjacent pairs of

thermocouples.

2.5 Theory

2.5.1 Conduction Heat Transfer

When a temperature gradient exists in a body, there is an energy transfer from the high-

temperature region to the low-temperature region. The energy is transferred by conduction

and that the heat-transfer rate per unit area is proportional to the normal temperature gradient

2.5.2 Fourier’s law of heat conduction

Figure 2.1: Temperature Profile in Fourier heat conduction

q

x

=-KA

Equation 2.1: Fourier law heat conduction equation

Where q

x

is the heat-transfer rate and ∂T/∂x is the temperature gradient in the direction of the

heat flow. The positive constant k is called the thermal conductivity of the material, and the

minus sign is inserted so that the second principle of thermodynamics will be satisfied; i.e.,

heat must flow downhill on the temperature scale as shown in figure 1.1. Equation 1.1 is called

Fourier’s law of heat conduction after the French mathematical physicist Joseph Fourier, who

made very significant contributions to the analytical treatment of conduction heat transfer.

(Equation 1.1) is the defining equation for the thermal conductivity and that k has the units of

watts per meter per Cels1ius degree in a typical system of units in which the heat flow is

expressed in watts

2.5.3 The Composite wall

If more than one material is present, as in the multilayer wall shown in Figure 2, the analysis

would proceed as follows: The temperature gradients in the three materials are shown, and

the heat flow may be written

31

q=−k

A

A

= −k

B

A

= −k

C

A

Equation 2.2: Heat through composite wall

Note that the heat flow must be the same through all sections

Figure 2.2: Heat through composite wall

Solving these three equations simultaneously, the heat flow is written

q=

Equation 2.3: Heat flow equation through composite wall

With composite systems, it is often convenient to work with an overall heat transfer

coefficient U, which is defined by an expression analogous to Newton’s law of cooling.

Accordingly

Q=UA∆T Equation 2.4: Overall heat transfer coefficient

Where ∆T is the overall temperature difference. Readers can read Further detail from book

“heat transfer by J.P Holman” in “chapter 2”

2.6 Experimental Procedure

1. Ensure that the main switch is in the off position (the digital displays should not be

illuminated). Turn the voltage controller anti-clockwise to set the AC voltage to

minimum.

2. Ensure the cold-water supply and electrical supply is turned on at the source. Open the

water tap until the flow through the drain hose is approximately 1.5 litters/minute.

3. Release the toggle clamp tensioning screw and clamps. Ensure that the faces of the

exposed ends of the heated and cooled sections are clean. Similarly, check the faces of

the Intermediate specimen to be placed between the faces of the heated and cooled

section.

4. Turn on the main switch and the digital displays should illuminate. Set the temperature

selector switch to T1 to indicate the temperature of the heated end of the bar.

5. Following the above procedure ensure cooling water is flowing and then set the heater

voltage V to approximately 150 volts. This will provide a reasonable temperature

gradient along the length of the bar. If, however the local cooling water supply is at a

32

high temperature (25-35 or more) then it may be necessary to increase the voltage

supplied to the heater. This will increase the temperature difference between the hot

and cold ends of the bar.

6. Monitor temperatures T1, T2, T3, T4, T5, T6, T7, T8 until stable.

7. Increase the heater voltage by approximately 50 volts and repeat the above procedure

again recording the parameters T1, T2, T3, T4, T5, T6, T7, T8, V, I when temperature

have stabilized.

2.7 Observations

Sample

No.

T

1

T

2

T

3

T

4

T

5

T

6

T

7

T

8

V

I

Volts

Amps

1

2

3

4

Distance

from T1

0.000

0.015

0.030

0.045

0.060

0.075

0.090

0.105

Table 2.1: Temperatures observation at different points of specimen

To measure the temperature distribution through a composite plane wall and determine the overall Heat

Transfer Coefficient for the flow of heat through a combination of different materials in use.

Figure 2.3: Schematic diagram of experiment

33

Specimen cross sectional Area A = 0.00049m

2

Conductivity of Brass heated and cooled section =121

Conductivity of Stainless steel intermediate section =25

Sample

No.

Q

--

W

K

m

M

m

1

2

3

4

Table 2.2: Calculation of overall heat transfer coefficient

2.7.1.1 Specimen Calculations

Brass Intermediate Specimen and hot and cold section cross sectional Area;

The temperature difference across the bar from T1 to T8;

X

Note that

and

are the distances between the thermocouple T1 and the hot face and

the cold face and the thermocouple T8 respectively. Similarly

is the distance between the

hot face and cold face of the intermediate stainless steel section.

Sample No.

--

1

2

3

4

34

Figure 2.4: Schematic diagram of experiment

The distances between surfaces are therefore as follows.

0.0375m

0.030m

0.0375m

Heat transfer rate from the heater;

Hence

Similarly,

Note that the U value resulting from the test data differs from that resulting from assumed

thermal conductivity and material thickness. This is most likely due to un-accounted for heat

losses and thermal resistances between the hot face interface and cold face inter face with the

stainless steel intermediate section.

2.7.1.2 Graph

Plot a graph b/w Temperature and Distance from T

1

thermocouple. The temperature data may

be plotted against position along the bar and straight lines drawn through the temperature points

for the heated and cooled sections. Then a straight line may be drawn through the hot face and

35

cold face temperature to extrapolate the temperature distribution in the stainless steel

intermediate section.

2.7.1.3 Statistical Analysis

For Constant “U”

% Error=

x

avg

=

S

x

=

2.7.1.4 Conclusion

2.8 Questions

1) Define Overall heat transfer coefficient

2) Define thermal conductivity and explain its significance in heat transfer.

2.9 Comments

36

3. LAB SESSION NO 03

To apply the Fourier Rate Equation for steady flow of heat through cylindrical solid materials

3.1 Learning Objective

[i] To identify a given sample (disc material) by determining its thermal conductivity.

3.2 Apparatus

Radial Heat Transfer unit H111B

3.3 Main Parts of Radial Heat transfer unit

1) Hydraulic Bench

2) Specimen of different materials

3) Main digital Control panel (H111)

4) Temperature Sensors

3.4 Useful Data

3.4.1 Radial Heat Conduction

3.4.2 Heated disc:

Material: Outside Diameter: 0.110m

Diameter of Heated Sample Core: 0.014m

Thickness of Disc (x): 0.0032m

Radial Position of Thermocouples:

T1=0.007m

T2=0.010m

T3=0.020m

T4=0.030m

3.5 Theory

3.5.1 Conduction Heat Transfer

When a temperature gradient exists in a body, there is an energy transfer from the high-

temperature region to the low-temperature region. The energy is transferred by conduction and

that the heat-transfer rate per unit area is proportional to the normal temperature gradient.

3.5.2 Radial Systems

3.5.2.1 Cylinders

Consider a long cylinder of inside radius r

i

, outside radius r

o

, and length L, such as the one

shown in Figure 2.1.We expose this cylinder to a temperature differential T

i

−T

o

. For a cylinder

37

with length very large compared to diameter, it may be assumed that the heat flows only in a

radial direction, so that the only space coordinate needed to specify the system is r. Again,

Fourier’s law is used by inserting the proper area relation. The area for heat flow in the

cylindrical system is

A

r

=2πrL

So that Fourier’s law is written

q

r

= −kA

r

q

r

= −2πkrL

Equation 3.1: Fourier Law equation for cylinders

Figure 3.1: Heat transfer

through cylinder

Figure 3.2: Temperature distribution in cylinder

With the boundary conditions

T=T

i

at r=r

i

T=T

0

at r=r

0

The solution to Equation 3.1 is

q=

Equation 3.2: Fourier Law equation for cylinders

3.6 Procedure

1. Ensure that the main switch is in the off position (the digital displays should not be

illuminated).

38

2. Ensure the cold water supply and electrical supply is turned on at the source. Open the

water tap until the flow through the drain hose is approximately 1.5 liters/minute.

3. Turn on the main switch and the digital displays should illuminate. Set the temperature

selector switch to T1 to indicate the temperature of the heated centre of the disc.

4. Following the above procedure ensure cooling water is flowing and then set the heater

voltage V to approximately 50 volts.

5. Monitor temperatures T1, T2, T3, T4, T5, and T6 until stable. When the temperatures

are stabilized record: T1, T2, T3, T4, T5, T6, V, I

6. Reset heater voltage to 100 volts and repeat the above procedure again and Monitor

temperatures T1, T2, T3, T4, T5, and T6 until stable. When the temperatures are

stabilized record: T1, T2, T3, T4, T5, T6 V, I. Repeat procedure with the difference of

50 V voltage

3.7 Observations

Sample

No.

T

1

T

2

T

3

T

4

T

5

T

6

V

I

⁰C

⁰C

⁰C

⁰C

⁰C

⁰C

Volts

Amps