Offline - Display and CommandARM

TM

Simulator

Help Guide

GS2 1800 Display

GS3 CommandCenter

TM

Display

GS3 2630 Display

Generation 4 CommandCenter

TM

Display

Last Updated: February 2017

Applies to Offline Simulator Version: 2.14

Offline Simulator Help Guide 2 | P a g e

Table of Contents

WHAT’S NEW IN RELEASE 2.14............................................................................................................................ 4

MINIMUM SYSTEM REQUIREMENTS ................................................................................................................ 4

OVERVIEW ................................................................................................................................................................ 5

INSTALLATION AND UPDATES ........................................................................................................................... 6

Installing the Display and CommandARM™ Simulator ............................................................................. 6

Un-installation ............................................................................................................................................ 6

REGISTRATION ........................................................................................................................................................ 7

Open the Simulator .................................................................................................................................... 7

Register the Simulator ............................................................................................................................... 7

Register the Simulator with (VPN) Proxy Server Internet Connection ...................................................... 8

LANGUAGES .............................................................................................................................................................. 9

Changing the Language on the Setup Page ........................................................................................... 10

Changing the Language on the GS2 1800 and GS3 CommandCenter™ Displays................................ 10

Changing the Language on the GS3 2630 Display ................................................................................. 10

Changing the Language on the Gen4 Command Center Display ........................................................... 10

GETTING STARTED ............................................................................................................................................... 10

Open the Simulator .................................................................................................................................. 10

Navigation ................................................................................................................................................ 11

1. Choose a Machine .......................................................................................................................... 11

2. Choose an Implement ..................................................................................................................... 11

3. Choose a Display ............................................................................................................................ 12

4. Select Options ................................................................................................................................. 12

Initial GPS coordinates ............................................................................................................................ 13

GENERAL SIMULATOR FUNCTIONS ............................................................................................................... 13

Turn Simulation ON / OFF ....................................................................................................................... 13

Help ......................................................................................................................................................... 13

Implement Functions ............................................................................................................................... 14

Sounds..................................................................................................................................................... 14

GPS Simulation ....................................................................................................................................... 14

INFORMATION ABOUT MACHINES.................................................................................................................. 14

Combine .................................................................................................................................................. 14

Cotton Harvesters .................................................................................................................................... 17

Sugarcane Harvesters ............................................................................................................................. 21

Tractors - 7R and 8R with Generation 4 CommandCenter™ ................................................................. 21

INFORMATION ABOUT IMPLEMENTS ............................................................................................................ 22

Baler ........................................................................................................................................................ 22

Planter ..................................................................................................................................................... 24

Offline Simulator Help Guide 3 | P a g e

GreenStar Rate Controller ....................................................................................................................... 25

INFORMATION ABOUT DISPLAYS .................................................................................................................... 26

GS2 1800 Display .................................................................................................................................... 26

GS3 2630 Display .................................................................................................................................... 26

Generation 4 CommandCenter™ Display ............................................................................................... 27

INFORMATION ABOUT OPTIONS ..................................................................................................................... 29

Machine Sync Shared Data ..................................................................................................................... 29

StarFire

TM

3000 ....................................................................................................................................... 32

AutoTrac Universal (ATU) ....................................................................................................................... 33

TROUBLESHOOTING ............................................................................................................................................ 34

Gen 4 CommandCenter™ Fails to Load ................................................................................................. 34

GS3 2630 Display Fails to Load .............................................................................................................. 34

Implement doesn’t load to Menu ............................................................................................................. 35

Communication error appears or Task fails to open ............................................................................... 35

Computer responds slowly ...................................................................................................................... 35

Cotton Picker ADU simulator buttons appear out of place ...................................................................... 35

Machine icon on map does not move ...................................................................................................... 36

Machine icon on map moves backwards ................................................................................................ 36

Machine icon on map looks skewed ........................................................................................................ 36

Reporting Issues ...................................................................................................................................... 36

Offline Simulator Help Guide 4 | P a g e

Offline-Display and CommandARM

TM

Simulator is an application that can be installed on a Microsoft

Windows® computer with multiple installation packages.

The purpose of this simulator is for supporting and learning to use John Deere displays and associated

equipment software. The simulator replicates the display software, equipment controller software and

connected sensors. There may be slight differences from the actual software.

What’s New in Release 2.14

Several miscellaneous improvements.

Known Issues in Offline Version:

GS3 2630 will not load on some Windows 8 and Windows 10 computers.

Gen 4 CommandCenter™ is no longer available to download for use with offline simulator. Due

to technical and usability considerations, it had not been updated from Software Update 2015-1

for offline use. Gen 4 CommandCenter™ simulation is now only available online.

StarFire 6000 intermittently stops working in offline version.

Several CommandARM™ buttons are not yet functional.

Machine / implement simulations take about 10-30 seconds to fully load after display loads.

Button presses on simulator during this time may be slow to respond.

On rare occasions, the following GS3 2630 simulator issues may occur, particularly on computers

with limited CPU availability. Restart simulator to correct these issues:

1. Changing field names causes GS3 2630 to respond slowly and implement simulators to

fail.

2. Data and settings do not save intermittently.

3. Machine icon on map stops moving.

4. Machine icon on map moves in reverse.

Refer to Information sections of this document for known limitations, additional information, and operating

instructions for each machine.

Refer to Troubleshooting Section for computer specific items.

Minimum System Requirements

Operating System:

o Microsoft Windows® 7 (32 & 64-bit)

May work on some Microsoft Windows® XP, 8, and 10 computers

Requires Microsoft Redistributable packages

C++ 2005 Redistributable version 8.0.61001

C++ 2010 Redistributable version 10.0.40219

C++ 2013 Redistributable version 12.0.21005

Microsoft .NET Framework 4.0

NOTE: Microsoft ended support for Windows XP in 2014 and therefore simulator support for

Windows XP has ended also.

4 GB of RAM Recommended:

Offline Simulator Help Guide 5 | P a g e

o If running Generation 4 CommandCenter with only 2GB of RAM, you many need to

uncheck the option for Tractor (or Machine) Simulation for the simulator to perform

well.

o The simulator will generally work fine with 2 GB of RAM if not running many other

applications at the same time.

Dual core processor

Screen Resolution: The simulator is optimized for 1280 x 800, but will work with most

resolutions. Utilizing a HDMI or Display Port cable will provide better resolution for viewing on

projectors and TVs.

Internet Connection: The simulator requires an internet connection to register at least every 50

uses.

Overview

There are two ways that machines and implements are simulated:

Actual – The software from the product is used, so that it is as accurate as possible. Equipment

sensor signals are simulated.

Simulated – User interface is recreated. Expect pages to be fairly realistic, but there may be some

inconsistencies with the actual product.

Machines

Models

Model Year

Type

Tractor

None

---

Simulated

Tractor

1

7R, 8R

2014

Actual

Self-Propelled Sprayer

4730, 4830

2010

Actual

Combine

S-series

2012

Actual

Cotton Harvester

CP690, CS690

7660, 7760

2016

2012

Actual

Sugar Cane Harvester

CH330, 3520

CH570

2014

2015

Actual

SPFH

None

---

Simulated

Implements

Models

Type

Air Cart

1910

2014

Actual

Air Seeder

1990 CCS

2012

Simulated

Baler

469, 569 Premium

L330, L340

2015

2016

Actual

Planter

1720, 1770NT, 1790

1775NT

2012

2016

Simulated

Displays

Models

Type

GS2 1800

2013

Actual

GS3 2630

2016

Actual

GS3 CommandCenter™

2015

Actual

Technology Solutions

Models

Type

Active Implement Guidance

2016

Simulated

AutoTrac™ Controller – Raven®

2016

Simulated

AutoTrac RowSense™

---

Simulated

AutoTrac™ Universal

2010

Actual

Business Pack (Europe only)

---

Actual

GreenStar Rate Controller

2012

Actual

GreenStar Rate Controller Dry

2012

Actual

Harvest ID Cotton

2011

Simulated

Machine Sync Shared Data

---

Actual

Mobile Weather

2011

Simulated

Offline Simulator Help Guide 6 | P a g e

StarFire™ Receiver

3000

6000

2011

2016

Actual

Wireless Data Transfer

---

Actual

Notes:

1 – 7R and 8R tractors are only available with selection of Generation 4 CommandCenter™ display.

2 – Raven is a registered trademark of RAVEN Industries

Installation and Updates

Installing the Display and CommandARM™ Simulator

This installer includes all machines, implements, and displays except Gen 4 CommandCenter™.

NOTE: Register after installation to use more than 5 times.

1. Download the Display and CommandARM

TM

Simulator Installer from www.StellarSupport.com

(Training tab).

Run the installer DisplayAndCommandARMSimulator.exe and follow the prompts to

install.

Un-installation

Windows XP

1. Select Start -> Settings -> Control Panel -> Add or Remove Programs

2. Select Display and CommandARM Simulator and select Remove

3. Select Generation 4 Display Package and select Remove

Windows 7

1. Select Start -> Control Panel -> Programs and Features

2. Select Display and CommandARM Simulator and select Uninstall

3. Select Generation 4 Display Package and select Uninstall

Offline Simulator Help Guide 7 | P a g e

Registration

Registration is required to use the simulator more than 5 times. The simulator may be used up to 50

times without an internet connection after registering.

Open the Simulator

1. Select Display and CommandARM™ Simulator on the computer desktop. The simulator

may take 5 – 15 seconds to open.

NOTE: The following error, Unhandled exception (status 407), may appear if the internet

connection is through a proxy server the simulator has not been registered. Select and follow

the steps below for registering with an internet connection through a proxy server.

NOTE: The following error, Internet Proxy Configuration, may also appear if the internet

connection is through a proxy server or VPN server. Select Cancel and the simulator will work

like it is not connected to the internet.

Register the Simulator

1. Select Register

2. Enter your Name and if the Serial Number auto-populates, select Register.

Offline Simulator Help Guide 8 | P a g e

a. If the Serial Number does not auto-populate, open an internet browser and enter this

website http://jdlicensing.farreachinc.com/.

b. Select Generate Serial Number

c. Copy the Serial Number and paste it into the Registration window. Then select

Register.

3. The simulator will automatically complete registration.

NOTE: The simulator requires an internet connection at least every 50 uses to renew the license.

Simply connect your computer to the internet and start the simulator. The license will renew

automatically.

Register the Simulator with (VPN) Proxy Server Internet Connection

There are three options; if one does not work, try another:

Option 1:

1. Close all simulator windows

2. Open Internet Explorer and browse to an external website.

NOTE: This temporarily configures the proxy server settings used by the simulator.

3. Close Internet Explorer

4. Select Display and CommandARM Simulator on the computer desktop

Offline Simulator Help Guide 9 | P a g e

5. Follow the steps for Registering the Simulator

Option 2:

1. Close all simulator windows

2. Open Internet Explorer and browse to this website: http://jdlicensing.farreachinc.com

3. Select Generate Serial Number and Copy the Serial Number

4. Select Display and CommandARM™ Simulator on the computer desktop

5. Paste the serial number into the Registration window

6. Select Register.

Option 3:

1. Obtain internet access through an outside line that does not use a proxy or VPN server.

2. Complete the normal registration.

NOTE: With any of these options, the following error (Internet Proxy Configuration) will appear

when opening the simulator. Select Cancel and the simulator will work like it is not connected to

the internet. Options 1, 2, or 3 will need to be repeated to reset the usage count to 50.

Languages

The following languages are supported by the simulator.

Bulgarian

Estonian

Italian

Russian

Chinese

Finnish

Latvian

Serbian

Croatian

French

Lithuanian

Slovak

Czech

German

Norwegian

Slovenian

Danish

Greek

Polish

Spanish

Dutch

Hungarian

Portuguese

Swedish

English

Icelandic

Romanian

Turkish

Offline Simulator Help Guide 10 | P a g e

Changing the Language on the Setup Page

The simulator setup page language will be set automatically by the computer’s operating system.

1. Start menu on the computer

2. Control Panel

3. Region and Language

Changing the Language on the GS2 1800 and GS3 CommandCenter™ Displays

1. Menu

2. Display

3. Settings

4. Scroll to list box and select language

Changing the Language on the GS3 2630 Display

1. Menu

2. Display Settings

3. Global Settings

4. Regional tab

Changing the Language on the Gen4 Command Center Display

1. Menu

2. System

3. Language and Units

4. Select the language by selecting from the drop down for the option

Getting Started

Open the Simulator

Select Display and CommandARM™ Simulator on the computer desktop. The simulator may

take 5 – 15 seconds to open.

Offline Simulator Help Guide 11 | P a g e

Navigation

Next

Previous

Close

Minimize

Settings and Software Updates

Ignition Key

Help

Insert / Remove USB drive to display

(GS2 1800, GS3 CommandCenter™, and GS3 2630 displays only)

Screen Capture

1. Choose a Machine

2. Choose an Implement

If you chose Tractor as the machine, then you will be prompted to choose an implement.

Offline Simulator Help Guide 12 | P a g e

3. Choose a Display

The displays that are compatible with selected machine and implement will appear.

4. Select Options

The available options depend on the selected machine, implement, and display.

Offline Simulator Help Guide 13 | P a g e

Run StarFire

TM

3000: StarFire 3000 interface will populate on the display.

AutoTrac

TM

Integrated: Makes the simulator behave like it is connected to an AutoTrac Capable

machine.

Advanced AutoTrac Settings: Makes the simulator behave like it is connected to a machine

with a SSU capable of Advanced AutoTrac Settings.

AutoTrac Universal: Makes the simulator behave like it is connected to an ATU.

GreenStar

TM

Lightbar: Makes the simulator behave like it is connected to a GreenStar Lightbar

(i.e. the GreenStar Lightbar Settings will appear in Guidance Settings).

Initial GPS coordinates

Enter the GPS coordinates of a field to locate the GPS simulation over it.

NOTE: Moving the GPS location far from the selected field’s reference point will make the machine icon

on the map look skewed. Create a new field name to solve this problem.

General Simulator Functions

Turn Simulation ON / OFF

The key switch turns on / off all selected machine, implement and display simulators. It may take

roughly 60 seconds for the display to load.

Help

The Help button opens the website where updated help information can be accessed.

Offline Simulator Help Guide 14 | P a g e

Implement Functions

Toggle through available alerts

Cancel alerts toggle. Note: this button will NOT clear alerts that are triggered by the machine /

implement software.

Air cart - triggers Front Tank Low error condition

Air cart – meter calibration switch

Sounds

Most beeps and other sounds are set to OFF. They can be turned ON/OFF by adjusting the volume in

Display Settings. Guidance alert sounds and tracking tones will still be ON. Tracking tones may be

turned OFF in Guidance Settings, as in an actual display.

GPS Simulation

Increase Speed

Information about Machines

Combine

Known issues and limitations:

Software shows all options at the same time on combine main page

Several buttons on CommandARM™ do not function

PDU Display not fully functional

Offline Simulator Help Guide 15 | P a g e

How to Begin Harvesting

1. Engage Separator

2. Engage Header

3. Set full throttle

4. Set gear

5. Select the middle of the Multi-Function Lever and move forward.

Yield map should now be recording.

RowSense™ on Combine

The RowSense option is checked by default in the options for the combine simulator.

Offline Simulator Help Guide 16 | P a g e

Operating RowSense:

1. Select the middle of the Multi-Function Lever and move forward.

2. Setup a guidance line on the display.

3. Enable RowSense

a. Menu

b. GS3

c. Guidance soft key

d. Change RowSense Settings

e. Guidance Settings

f. Enable System Status

g. Note that the Row Entry method can be set to Manual or GPS status.

Operating with Manual Row Entry method:

1. Drive combine into row

2. Press number 3 button to lower head

3. Press number 3 button a second time to engage guidance and row sensors.

Operating with GPS Row Entry method:

1. Drive combine into row

2. Press number 3 button to lower head and engage guidance

3. Press number 3 button second time to engage row sensors.

Offline Simulator Help Guide 17 | P a g e

Simulation RowSense States:

RowSense sensor is installed and enabled

Row Sensors Out of Crop – AutoTrac is

active and there is valid GPS data, but no data

from the crop feelers. NOTE: Simulator will set

crop yield input to 0 for out of crop simulation.

Differential Correction Lost – AutoTrac is

active and there is a valid data from crop

feelers but there is insufficient data from

StarFire™ GPS. NOTE: AutoTrac will run for

up to 3 minutes without GPS.

AutoTrac is active and there is a valid GPS and

sensor data from the crop feelers.

NOTE: Reference the AutoTrac RowSense operator manual for more detailed instructions.

Cotton Harvesters

Known issues and limitations for CP690 and CS690:

Wrap misfeed alert sometimes appears when bale is full size. Accept and press Auto button

wrap bale.

Offline Simulator Help Guide 18 | P a g e

GS3 2630 will sometimes lockup when selecting Menu > Message Center. Restart simulator to

recover.

Cotton Counter – Bale count does not increase automatically.

Known issues and limitations for ADU Display:

ADU Display requires user to have administrative rights and will not work on Windows 64bit and

Windows XP computers.

ADU Display is only operational with computer screen set to small text and icons; otherwise the

interface will appear like this image.

Changing Screen to Small Text and Icons

1. Start menu on the computer

2. Control Panel

3. Display

Offline Simulator Help Guide 19 | P a g e

4. Ensure selection is set to Smaller – 100%

NOTE: This setting will affect the size of text and icons on your desktop.

How to Begin Harvesting on CP690 and CS690

1. Engage Fan

2. Engage Units

3. Set full throttle

4. Turn off Park Brake

5. Select the middle of the Multi-Function Lever and move forward.

Offline Simulator Help Guide 20 | P a g e

6. Press Auto button when bale is full size. First accept wrap misfeed alert

if it appears.

RowSense™ on CP690 and CS690

1. Before starting simulator, select GPS option.

2. Select AutoTrac RowSense™ option

3. Turn Key ON

4. Go to GS3 in Menu

5. Go to RowSense Settings in Guidance Settings

RowSense Settings

6. Enable RowSense

7. Select Steer ON in Guidance

Steer ON

8. Begin Harvesting

9. Engage RowSense

10. Press Resume for Manual RowSense

11. Press Resume again for Automatic RowSense

Offline Simulator Help Guide 21 | P a g e

Sugarcane Harvesters

Known issues and limitations:

CH570

o Several buttons on CommandARM™ do not function

o Harvest simulation

o Elevator Setup

3520 and CH330

o CommandARM™ and PDU display

o Harvest simulation

o Elevator Setup

o 6 trouble codes appear at startup

Tractors - 7R and 8R with Generation 4 CommandCenter™

Known issues and limitations:

CommandARM™, Navigation bar, and PDU display not available for the following configurations:

o 7R e23™

o 7R CommandQuad™

Gen 4 CommandCenter™ intermittently loses steering controller communication when running

Tractor (or Machine) Simulation.

If your computer has less than 3GB of RAM, uncheck Machine Controllers Simulation in Machine

Options for best performance. Refer to Resolution of RAM Usage Issues for more options.

NOTE: Unchecking this option will disable Tractor Settings applications in the Gen 4 CommandCenter™

Menu.

Known issues and limitations:

1. When Tractor (or Machine) Simulation is checked Gen 4 CommandCenter will start up more

slowly and DTC alerts may appear frequently. If many DTC alerts appear, try restarting the

simulator.

2. On Windows XP, the Tractor (or Machine) Simulation is disabled due to a compatibility issue

3. Help Center may not open from the shortcut bar. Open it from Menu > Applications instead.

Offline Simulator Help Guide 22 | P a g e

Information about Implements

Baler

Known issues and limitations for 469 and 569:

Twine tying is not supported.

Automation 1 and 2 is not fully supported.

Known issues and limitations for L330 and L340:

In Online Simulator, “Feeder forks plugged” stop alert appears during startup. Accept to continue.

469 and 569 Baler Calibration:

If you perform a Quick Calibration for Bale Diameter, then you must also perform a Precise Calibration.

Both Quick and Precise Calibration statuses must be green before other calibrations can be completed.

Enter 72 inches as bale diameter for Precise Calibration.

Offline Simulator Help Guide 23 | P a g e

469 and 569 Baler Operation:

1. Switch ON the PTO from the Baler window

2. Increase Speed from the Navigation window

3. Increase crop flow (Yield)

Crop flow (Yield) will automatically reset to None when bale size is reached for simulation purposes.

4. Open gate from the Baler window.

5. Close gate from the Baler window.

469 and 569 Baler Operation Example with B-Wrap:

1. Switch ON the PTO from the Baler window

2. Increase Speed from the Navigation window

3. Increase crop flow (Yield)

Offline Simulator Help Guide 24 | P a g e

Crop flow (Yield) will automatically reset to None when bale size is reached for simulation purposes.

4. After wrapping is complete, switch OFF the PTO from the Baler window.

5. Open gate from the Baler window.

6. Close gate from the Baler window.

NOTE: Use Reset button on Baler window if wrapping simulations fail or Actuator open load alert

appears frequently.

Planter

Known issues and limitations

1775NT Row Cleaner sensor simulation sometimes fails.

Offline Simulator Help Guide 25 | P a g e

1775NT seed meter vacuum not simulated.

1775NT Planter simulated seed rates are sometimes erratic and section control disappears

intermittently.

How to Begin Planting with 1775NT Planter

1. Select PTO ON in Navigation window.

Use PTO switch when CommandARM™ Simulation is

selected in Machine Options.

CommandARM™ Simulation

2. Select planter Power Generation ON in display.

3. Select Planter Down in Navigation window.

GreenStar Rate Controller

Rate controller option is available when air seeder, blockage, planter, sprayer, or rate controller are

selected. GreenStar Rate Controller has the following configuration groups, based on what machine and

implement it is running with.

Implement – planter, air seeder, or blockage

Liquid Fertilizer (default)

Pull-behind Sprayer

NH3

Implement – GreenStar Rate Controller

NH3 (default)

Pull-behind Sprayer

Planter

Machine – sprayer

Self-propelled Sprayer

Offline Simulator Help Guide 26 | P a g e

Information about Displays

GS2 1800 Display

NOTE: The GS2 1800 simulator screen will appear fuzzy, because it was scaled 75% to fit on a computer

screen.

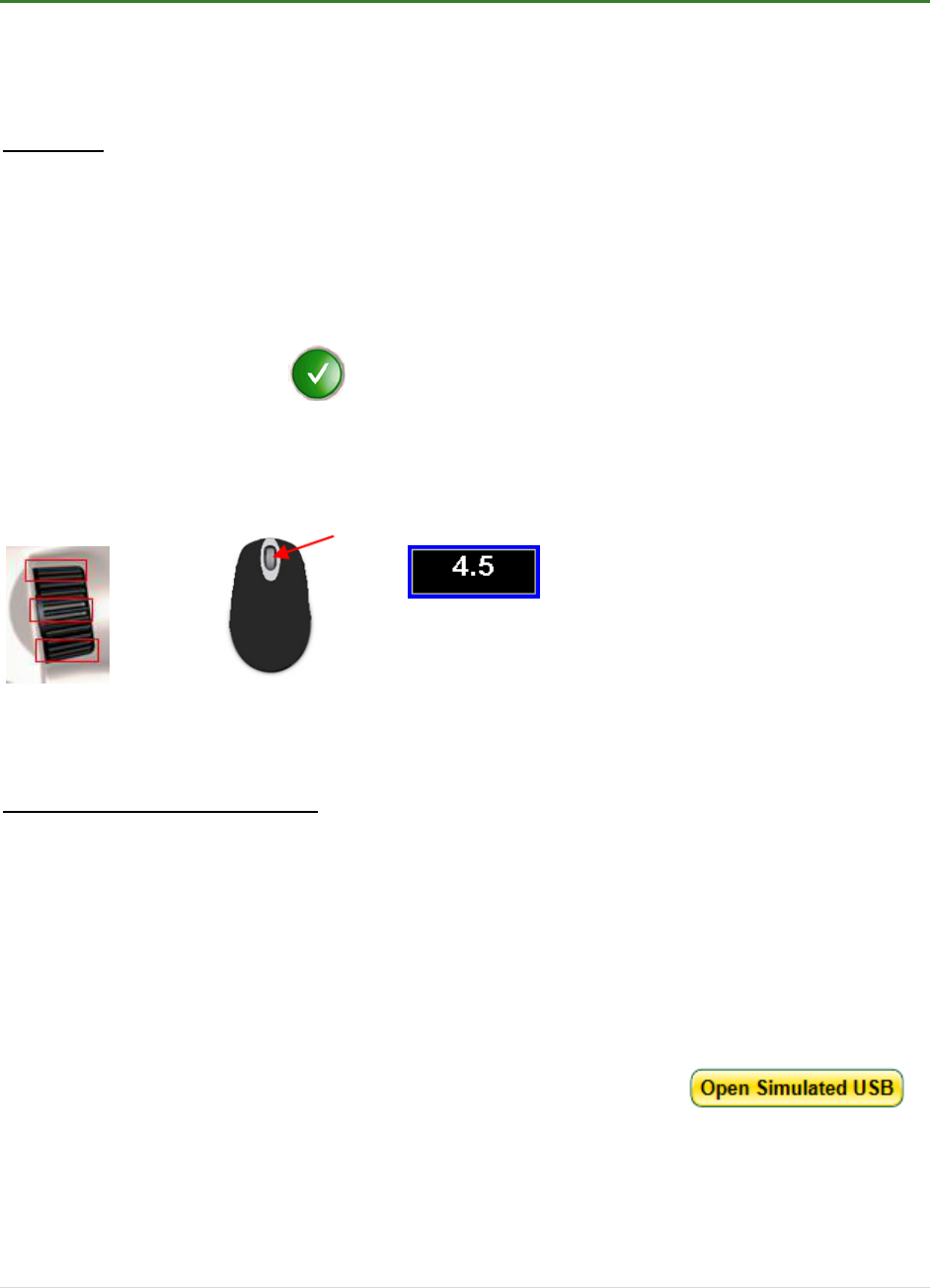

Navigation

There are 3 options for scrolling the thumbwheel in the simulator:

1. Left-click the mouse on the top or bottom of the thumbwheel.

2. Hover the mouse over the middle of the thumbwheel and turn the mouse wheel.

3. Use the up and down arrows on the keyboard.

There are 2 options for selecting a button in the simulator:

4. Press the check button.

5. Press down on the middle of the mouse (this option may be required for Live Edit Entries)

Thumbwheel Mouse wheel Live Edit Entry

GS3 2630 Display

NOTE: The GS3 2630 simulator is not currently capable of simulating Surface Water Pro Plus.

Import User Data to the Simulator

Import user data from a GS3 2630 display or Apex

TM

desktop software. This feature is meant for training

purposes only. The same software version rules apply for compatibility of importing data as with the real

display. As a rule of thumb, ensure the most recent updates are installed so that the data will import.

IMPORTANT: Simulator software updates will delete any data and settings stored in the simulator.

Export prior to updating simulator to save your data and settings.

1. Select Machine, Implement, and then GS3 2630 display.

2. Select Open Simulated USB in the Display Options. This will open

a folder on your computer that simulates a USB drive.

Open Simulated USB

Offline Simulator Help Guide 27 | P a g e

3. Open your actual USB drive and copy the “GS3_2630” folder to the

Simulated USB.

4. Turn ON the simulator

5. Select the USB button to simulate inserting the USB drive. Import

the Profile to the simulator just like you would on an actual display.

6. Select the USB button to simulate removing the USB drive.

Export User Data from the Simulator

1. Select the USB button to simulate inserting the USB drive. Export

data from the display just like you would on an actual display.

2. Turn OFF the simulator.

3. Select Machine, Implement, and then GS3 2630 display.

4. Select Open Simulated USB and use File Explorer to copy and

paste the Profile folder to a location of your choice.

Open Simulated USB

Generation 4 CommandCenter™ Display

The simulator has a minimum version check for Gen 4 CommandCenter™. When starting the simulator

with Gen 4 CommandCenter™, a message will appear if an update is required for compatibility. In that

case, download the latest Generation 4 display simulator package from the Stellar Support.

Import User Data to the Simulator

Import user data from a GS3 2630 display or Apex

TM

desktop software. This feature is meant for training

purposes only. The same software version rules apply for compatibility of importing data as with the real

display. As a rule of thumb, ensure the most recent updates are installed so that the data will import.

IMPORTANT: Simulator software updates will delete any data and settings stored in the simulator.

Export prior to updating simulator to save your data and settings.

Offline Simulator Help Guide 28 | P a g e

1. Put data on a USB drive as you would for

transferring to an actual Gen 4

CommandCenter™.

2. Insert the USB drive into your computer.

3. Open the simulator.

4. In Display Options, select the USB drive.

5. Turn ON the simulator

6. After the display loads the following message

should appear allowing you to Import Data to

the display.

If message does not appear refer to USB fails to connect in Troubleshooting section.

Export User Data from the Simulator

1. If Gen 4 CommandCenter™ simulator is not

already running, insert a USB drive into your

computer.

2. Open the simulator.

3. In Display Options, select the USB drive.

4. Turn ON the simulator

5. After the display loads the following message

should appear allowing you to Export Data to

the display.

Offline Simulator Help Guide 29 | P a g e

Information about Options

Machine Sync Shared Data

This feature simulates coverage data and guidance lines coming from and going to a second machine

(Machine 2). The coverage of Machine 2 drives at 4 mph (6.4 km/h) with an implement width of 60 feet

(18.3 meters) and turns around after 0.5 miles (0.8 km). The Machine 2 icon is not displayed and it is not

capable of section control.

Setup Sharing

Note: Network setup is saved between uses of the simulator.

1. Choose any Machine and Implement option with GS3 2630 display

2. Select Machine Sync Shared Data in Display Options page. The Machine Sync window

will appear after you turn the key to start the stimulator.

Offline Simulator Help Guide 30 | P a g e

3. Select the same Task in both the Machine Sync window and display. If you select a Task other

than Documentation Off in the GS3 2630, you will need to setup Documentation (Softkey I).

4. Setup Network in display

a. Go to Menu > GS3 > Equipment (H) > Network tab

b. Select Manage Networks

c. Select Add New

d. Enter any name for Network Name

e. Select Accept

f. Select Connect

g. Select Accept

h. Machine 2 will now show up on Network. Various signal qualities are simulated for

demonstration.

5. Go to Mapping (A) > Multi-Machine tab

a. Select Application from list: Machine Sync Shared Data

b. Check Share Coverage

Offline Simulator Help Guide 31 | P a g e

c. Select Communication Device from list: MCR

Join Coverage

Note: Machine 2 does not appear in Join Shared Data list, turn key to restart simulator.

1. Go to Menu > GS3 > Resources (G)

2. Select Join from Field list box

3. Select Join for Machine 2 in the window that appears. If Machine 2 is missing from the list,

restart the simulator.

Note: On some computers, a communication lost alert may appear. As long as the machine or

implement still appears in the Menu, the simulation is still working.

4. Go to Mapping (A)

5. Select Recording on the Machine Sync window. The second machine coverage will

display on the map to the right of the first machine. You may need to zoom out to see it.

Offline Simulator Help Guide 32 | P a g e

Share AB Line from Machine 1

1. Go to Menu > GS3 > Guidance (B)

2. Select Set Track 0

3. Select Share AB Line

4. Status on Machine Sync window will show: AB Line Received

Share AB Line from Machine 2

1. Select Send Guidance Line

2. AB Line Received message will appear on the GS3 2630. East Line_001 is the name of the

track.

Note: This AB line is created for the default GPS location of the simulator.

Reference the Machine Sync Operator Manual for more information.

StarFire

TM

3000

Calibrate TCM Alarm

The Calibrate TCM alarm will appear once every time the simulator is started with a different Machine,

Implement, or Display and the TCM has not been calibrated for that combination.

Offline Simulator Help Guide 33 | P a g e

1. Menu

2. StarFire

3. Setup tab

4. CAL

5. Select Accept on the next 3 messages

AutoTrac Universal (ATU)

ATU Activation

The first time you run the ATU with a display you will need to activate it by entering 323. With the GS2

1800, turn the thumbwheel of the display using mouse wheel.

Offline Simulator Help Guide 34 | P a g e

Troubleshooting

Gen 4 CommandCenter™ Fails to Load

Common Symptoms:

“Not able to find Gen 4 CommandCenter window” alert appears.

Display appears with only a green screen.

Cause:

The Offline simulator requires a separate installer for the Gen 4 CommandCenter, which is no

longer available to download. Due to technical and usability considerations, it had not been

updated from Software Update 2015-1 for offline use.

The Offline Gen 4 CommandCenter has already been installed on your computer, but is no longer

functioning properly.

Common Fixes:

Gen 4 CommandCenter™ simulation is now only supported in the Online-Display

and CommandARM™ Simulator.

GS3 2630 Display Fails to Load

Common Symptoms:

Stays on green “Please Wait…” screen for longer than 20 seconds

Loads to blank yellow screen

Common Causes:

GS3 2630 will not load on some Windows 8 and Windows 10 computers.

Firewall, Administrative Rights, or antivirus software conflicts with simulator

Data files from previous versions were not cleaned up during uninstall

Common Fixes:

Use the Online-Display and CommandARM™ Simulator.

DO NOT turn off Firewall. When the firewall is off it can still block network communication that

the simulator requires for CAN communication. When the firewall is on it pops up a message

allowing you to give access to the simulator.

Reset all settings and data in GS2 and GS3 displays to defaults.

1. Settings

Offline Simulator Help Guide 35 | P a g e

2. Debug tab

3. Reset

Report issue to [email protected].

Implement doesn’t load to Menu

1. View table above in Machines and Implements section to determine whether the simulator

includes the ‘Display’ interface for the implement

2. If the simulator does include the interface but it does not appear:

a. First, wait 2 minutes, because they sometimes take time to load

b. Second, turn key to turn off Simulator and then turn key to turn it back on to reset

Communication error appears or Task fails to open

Common Causes:

Lack of available CPU or firewall settings.

Second, turn key to turn off Simulator and then turn key to turn it back on to reset

Exit back to the Setup page and then reopen the simulator. If this occurs frequently, contact help.

Common Fixes:

Close any other applications that are running

Turn key to turn off Simulator and then turn key to turn it back on to reset

Computer responds slowly

1. Determine CPU Usage

a. Press the Control, Alt, and Delete buttons at the same time

b. Select the Performance tab

2. If CPU Usage is over 60%, try closing any other applications that may be running.

Cotton Picker ADU simulator buttons appear out of place

Common Causes:

ADU Display is only operational with computer screen set to small text and icons.

Common Fixes:

See section on Information about Machines for instructions.

Offline Simulator Help Guide 36 | P a g e

Machine icon on map does not move

Common Causes:

Need to increase speed

1. Use Increase Speed button or

2. On CommandARM, put machine in gear and use multifunction hydrohandle

Lack of CPU availability during startup

Internal error in simulator

Common Fixes:

Turn key to restart simulator

Machine icon on map moves backwards

Common Causes:

Lack of CPU availability during startup

Common Fixes:

Turn key to restart simulator

Machine icon on map looks skewed

Common Causes:

GPS location is too far from reference point of selected field

Common Fixes:

On Simulator Setup page, select a GPS location over the selected field

Select a new name in the display

Reporting Issues

Report issues and submit feedback at www.JohnDeere.com/amscontact. Please state that it is

regarding the Offline-Display and CommandARM™ Simulator and include the exact text of errors you are

reporting.

The following information is helpful when reporting an issue to a John Deere technician.

Always send screenshots and a description of the issue.

If simulator does not open or crashes, sending an error log will be helpful. Error logs can be

found in in [C:\Program Files\John Deere\DisplayAndCommandARMSimulator]. Look at the

modified date to find that logs from the timeframe the issue occurred.

Issues resulting from firewall conflicts require advanced error logs. Enable advanced error

logging, run the simulator to reproduce the issue, and then send the log files. Advanced error

logging is OFF by default, so the simulator opens more quickly.

1. Open the simulator

Offline Simulator Help Guide 37 | P a g e

2. Open Settings

3. Select the Debug tab

4. Check Enable advanced error logging

5. Select Close and restart the simulator

Note: The advanced error logging will apply only to the next simulator run and not the current run in

which the option was enabled.