Slurry Transport

Fundamentals, A Historical Overview &

The Delft Head Loss &

Limit Deposit Velocity Framework

By

Sape A. Miedema

Edited by

Robert C. Ramsdell

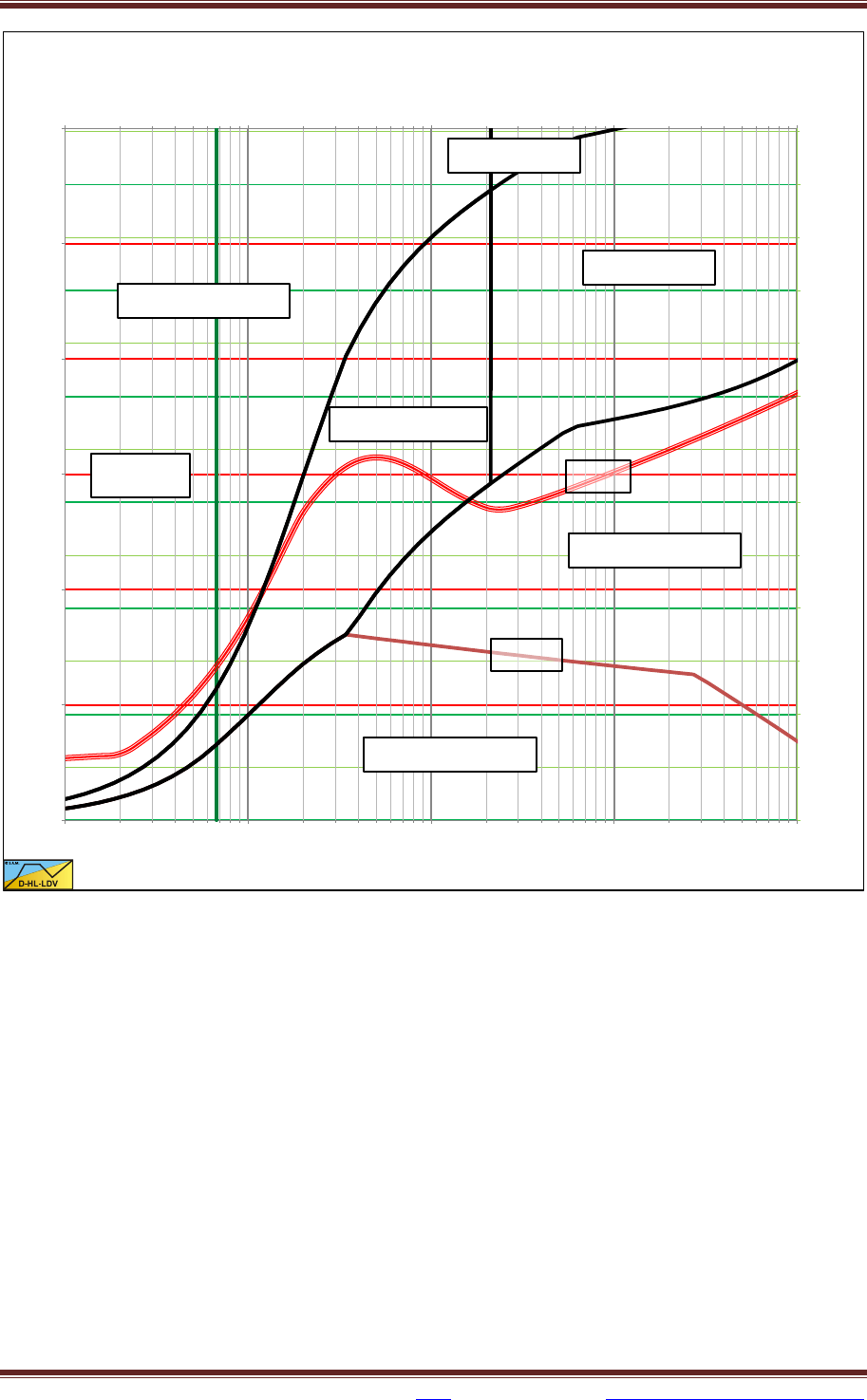

0.01 0.1 1 10 100

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

1.E-05 1.E-04 1.E-03 1.E-02 1.E-01

Particle diameter (mm)

Line speed (m/s)

Durand Froude number F

L

(-)

Particle diameter d (m)

DHLLDV Flow Regime Diagram

© S.A.M.

Dp=0.1524 m, Rsd=1.585, Cvs=0.175, μsf=0.416

Homogeneous (Ho)

Heterogeneous

(He)

Sliding Bed (SB)

Fixed/Stationary Bed (FB)

Viscous

Effects

Sliding Flow (SF)

LDV

FB-SB (LSDV)

Undefined

He-Ho

SB-He

SB-SF

FB-He

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page ii of xx TOC Copyright © Dr.ir. S.A. Miedema

Version: Wednesday, March 16, 2016

© 2013-2016 Dr.ir. S.A. Miedema

All rights reserved. No part of this book may be reproduced, translated, stored in a database or retrieval system, or

published in any form or in any way, electronically, mechanically, by print, photo print, microfilm or any other

means without prior written permission of the author, dr.ir. S.A. Miedema.

Disclaimer of warranty and exclusion of liabilities: In spite of careful checking text, equations and figures, neither

the Delft University of Technology nor the author:

Make any warranty or representation whatever, express or implied, (A) with respect of the use of any

information, apparatus, method, process or similar item disclosed in this book including merchantability and

fitness for practical purpose, or (B) that such use does not infringe or interfere with privately owned rights,

including intellectual property, or (C) that this book is suitable to any particular user’s circumstances; or

Assume responsibility for any damage or other liability whatever (including consequential damage)

resulting from the use of any information, apparatus, method, process or similar item disclosed in this book.

Design & Production: Dr.ir. S.A. Miedema

ISBN Book: 978-94-6186-293-8

ISBN EBook: 978-94-6186-294-5

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page iv of xx TOC Copyright © Dr.ir. S.A. Miedema

Preface

In dredging, trenching, (deep sea) mining, drilling, tunnel boring and many other applications, sand, clay or rock

has to be excavated. The productions (and thus the dimensions) of the excavating equipment range from mm

3

/sec

- cm

3

/sec to m

3

/sec. After the soil has been excavated it is usually transported hydraulically as a slurry over a short

(TSHD’s) or a long distance (CSD’s). Estimating the pressure losses and determining whether or not a bed will

occur in the pipeline is of great importance. Fundamental processes of sedimentation, initiation of motion and

erosion of the soil particles determine the transport process and the flow regimes. In all cases we have to deal with

soil and high density soil water mixtures and its fundamental behavior.

The book covers horizontal transport of settling slurries (Newtonian slurries). Pipelines under an angle with the

horizontal and non-settling (non-Newtonian) slurries are not covered.

Although some basic knowledge about the subject is required and expected, dimensionless numbers, the terminal

settling velocity (including hindered settling), the initiation of motion of particles, erosion and the flow of a liquid

through pipelines (Darcy Weisbach and the Moody diagram) are summarized. In the theory derived, the Zanke

(1977) equation for the settling velocity is used, the Richardson & Zaki (1954) approach for hindered settling is

applied and the Swamee Jain (1976) equation for the Darcy-Weisbach friction factor is used, Moody (1944). The

models developed are calibrated using these basic equations and experiments.

An overview is given of experiments and theories found in literature. The results of experiments are considered to

be the physical reality. Semi empirical theories based on these experiments are considered to be an attempt to

describe the physical reality in a mathematical way. These semi empirical theories in general match the

experiments on which they are based, but are also limited to the range of the different parameters as used for these

experiments. Some theories have a more fundamental character and may be more generic as long as the starting

points on which they are based apply. Observing the results of many experiments gives the reader the possibility

to form his/her own impression of the processes involved in slurry transport.

Flow regimes are identified and theoretical models are developed for each main flow regime based on constant

volumetric spatial concentration. The 5 main flow regimes are the fixed or stationary bed regime, the sliding bed

regime, the heterogeneous regime or the sliding flow regime and the homogeneous regime. It is the opinion of the

authors that the basic model should be derived for a situation where the amount of solids in the pipeline is known,

the constant volumetric spatial concentration situation.

A new model for the Limit Deposit Velocity is derived, consisting of 5 particle size regions and a lower limit.

Based on the Limit Deposit Velocity a (semi) fundamental relation is derived for the slip velocity. This slip velocity

is required to determine constant volumetric transport concentration relations based on the constant volumetric

spatial concentration relations. These relations also enable us to determine the bed height as a function of the line

speed.

The concentration distribution in the pipe is based on the advection diffusion equation with a diffusivity related to

the LDV.

Finally a method is given to determine relations for non-uniform sands based on the superposition principle.

The last chapter is a manual on how to reproduce the Delft Head Loss & Limit Deposit Velocity model.

The DHLLDV Framework is based on numerous experimental data from literature, considered to be the reality.

This book is supported by the website www.dhlldv.com containing many additional graphs and tables with

experimental data. The website also has spreadsheets and software implementing the model.

The name Delft in the title of the DHLLDV Framework is chosen because most of the modelling is carried out at

the Delft University of Technology.

Another book by the author is: The Delft Sand, Clay & Rock Cutting Model.

Published by IOS Press, www.iospress.nl, in Open Access.

Modeling is an attempt to approach nature without

having the presumption to be nature.

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page v of xx

About the Author

Dr.ir. Sape A. Miedema (November 8

th

1955) obtained his

M.Sc. degree in Mechanical Engineering with honours at the

Delft University of Technology (DUT) in 1983. He obtained

his Ph.D. degree on research into the basics of soil cutting in

relation with ship motions, in 1987. From 1987 to 1992 he was

Assistant Professor at the chair of Dredging Technology. In

1992 and 1993 he was a member of the management board of

Mechanical Engineering & Marine Technology of the DUT.

In 1992 he became Associate Professor at the DUT with the

chair of Dredging Technology. From 1996 to 2001 he was

appointeDelft Head of Studies of Mechanical Engineering and

Marine Technology at the DUT, but still remaining Associate

Professor of Dredging Engineering. In 2005 he was appointed

Head of Studies of the MSc program of Offshore & Dredging Engineering and he is also still Associate Professor

of Dredging Engineering. In 2013 he was also appointed as Head of Studies of the MSc program Marine

Technology of the DUT.

Dr.ir. S.A. Miedema teaches (or has taught) courses on soil mechanics and soil cutting, pumps and slurry transport,

hopper sedimentation and erosion, mechatronics, applied thermodynamics related to energy, drive system design

principles, mooring systems, hydromechanics and mathematics. He is (or has been) also teaching at Hohai

University, Changzhou, China, at Cantho University, Cantho Vietnam, at Petrovietnam University, Baria, Vietnam

and different dredging companies in the Netherlands and the USA.

His research focuses on the mathematical modeling of dredging systems like, cutter suction dredges, hopper

dredges, clamshell dredges, backhoe dredges and trenchers. The fundamental part of the research focuses on the

cutting processes of sand, clay and rock, sedimentation processes in Trailing Suction Hopper Dredges and the

associated erosion processes. Lately the research focuses on hyperbaric rock cutting in relation with deep sea

mining and on hydraulic transport of solids/liquid settling slurries.

About the Editor

Robert Ramsdell (23

rd

September 1964) obtained his BA

degree in Mathematics at the University of California at

Berkeley in 1985. Since 1989 he has worked for Great Lakes

Dredge & Dock Company. Robert started as Field Engineer,

eventually becoming a Project Engineer then Superintendent,

working with Trailing Suction, Cutter Suction and Mechanical

dredges on a variety of projects in the United States. From

1995 to 1996 Robert was the Project Engineer on the Øresund

Link project in DenmarK. In 1996 he joined the Great Lakes

Dredge & Dock Production Department as a Production

Engineer, becoming Production Engineering Manager in

2005. In the department Robert’s focus has been on

developing methods and software for estimating dredge

production, recruiting and training Engineers, and developing methods to analyse and improve dredge operations.

A particular focus has been in modeling slurry transport for dredging estimating and production optimization.

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page vi of xx TOC Copyright © Dr.ir. S.A. Miedema

Acknowledgements

The authors want to thank:

Ron Derammelaere, Edward Wasp and Ramesh Gandhi, Ausenco PSI, for reviewing the chapter about the Wasp

model.

Baha E. Abulnaga, director of Splitvane Engineers Inc., for reviewing the chapter about the Wilson 2 layer model,

the heterogeneous model and the Wilson & Sellgren 4 component model.

Pinchas Doron, CTO Aora Solar, for reviewing the chapter about the Doron & Barnea 2 and 3 layer models.

Randy Gillies, Pipe Flow Technology Centre SRC, for reviewing the chapter about the Saskachewan Research

Council (SRC) model.

Deo Raj Kaushal, Indian Institue of Technologu in Delhi, for reviewing the chapter about the Kaushal & Tomita

model.

Vaclav Matousek, Czech Technical University in Prague, for reviewing the chapter about the Matousek model.

Their contributions have been very valuable for having a correct reproduction of their models.

The authors also want to thank all the reviewers of our conference and journal papers for their effort. This has

improved the quality of our work.

A special thank to the 147

th

board of “Gezelschap Leeghwater” (the student association of Mechanical Engineering

of the Delft University of Technology) for letting us use their name for the Double Logarithmic Elephant

Leeghwater.

Recommendations

In this book, the author’s intention is to introduce the slurry transport in pipelines to the readers by describing the

relevant phenomena both physically and mathematically through underlying theories and governing equations. It

is a focused work presented by the author to the upcoming generation of researchers and practitioners, in particular.

The special feature of the book is that in a chapter, a specific phenomenon is presented starting with a physical

description followed by a derivation and ending with discussion and conclusions. All throughout the book,

coherence in presentation is maintained.

As a concluding remark, this book can effectively be used as a guide on slurry transport in pipelines.

Professor Subhasish Dey, Indian Institute of Technology Kharagpur, India

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page vii of xx

Table of Contents

Chapter 1: Introduction. 1

1.1 Introduction. 1

1.2 Flow Regimes Literature. 1

1.3 The Parable of Blind Men and an Elephant. 3

1.4 The Delft Head Loss & Limit Deposit Velocity Framework. 4

1.5 Approach of this book. 5

1.6 Nomenclature. 6

Chapter 2: Dimensionless Numbers & Other Parameters. 7

2.1 Dimensionless Numbers. 7

2.1.1 The Reynolds Number Re. 7

2.1.2 The Froude Number Fr. 7

2.1.3 The Archimedes Number Ar. 8

2.1.4 The Richarson Number Ri. 8

2.1.5 The Thủy Number Th or Collision Intensity Number. 8

2.1.6 The Cát Number Ct or Collision Impact Number. 9

2.1.7 The Lắng Number La or Sedimentation Capability Number. 9

2.1.8 The Shields Parameter θ. 9

2.1.9 The Bonneville Parameter D

*

. 9

2.1.10 The Rouse Number P. 10

2.1.11 The Stokes Number Stk. 10

2.1.12 The Bagnold Number Ba. 11

2.2 Applications of Dimensionless Numbers. 11

2.2.1 The Slurry Flow in the Pipe. 11

2.2.2 The Terminal Settling Velocity of a Particle. 12

2.3 Other Important Parameters. 12

2.3.1 The Slip Velocity and the Slip Ratio. 12

2.3.2 The Spatial and Delivered Volumetric Concentration. 13

2.3.3 Densities. 13

2.3.4 The Relative Submerged Density R

sd

. 14

2.3.5 Viscosities. 14

2.3.6 The Friction Velocity or Shear Velocity u

*

. 16

2.3.7 The Thickness of the Viscous Sub Layer δ

v

. 16

2.3.8 The Particle Size Distribution (PSD). 17

2.3.9 The Angle of Internal Friction. 19

2.3.10 The Angle of External Friction 20

2.4 Nomenclature. 21

Chapter 3: Pressure Losses with Homogeneous Liquid Flow. 23

3.1 Pipe Wall Shear Stress. 23

3.2 The Darcy-Weisbach Friction Factor. 24

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page viii of xx TOC Copyright © Dr.ir. S.A. Miedema

3.3 The Equivalent Liquid Model. 25

3.4 Approximation of the Darcy-Weisbach Friction Factor. 26

3.5 The Friction Velocity or Shear Velocity u

*

. 26

3.6 The Thickness of the Viscous Sub Layer δ

v

. 26

3.7 The Smallest Eddies. 26

3.8 The Relative or Apparent Viscosity. 28

3.9 Nomenclature. 32

Chapter 4: The Terminal Settling Velocity of Particles. 33

4.1 Introduction. 33

4.2 The Equilibrium of Forces. 33

4.3 The Drag Coefficient. 34

4.4 Terminal Settling Velocity Equations. 37

4.5 The Shape Factor 42

4.6 Hindered Settling. 43

4.7 Conclusions. 45

4.8 Nomenclature. 45

Chapter 5: Initiation of Motion and Sediment Transport. 47

5.1 Initiation of Motion of Particles. 47

5.1.1 Introduction. 47

5.1.1.1 Models on Sediment Threshold. 47

5.1.1.2 Hjulström (1935), Sundborg (1956) and Postma (1967). 50

5.1.1.3 Shortcomings of the existing models 52

5.1.1.4 Known’s and Unknowns. 53

5.1.2 Velocity Distributions. 55

5.1.2.1 Scientific Classification. 55

5.1.2.2 Engineering Classification. 55

5.1.2.3 Friction Velocity. 56

5.1.2.4 Turbulent Layer. 56

5.1.2.5 Bed roughness 57

5.1.2.6 Viscous Sub-Layer. 58

5.1.2.7 The Transition Laminar-Turbulent. 59

5.1.2.8 The Transition Smooth-Rough. 59

5.1.3 The Model for Initiation of Motion. 61

5.1.3.1 The Angle of Internal Friction/the Friction Coefficient. 61

5.1.3.2 The Pivot Angle/the Dilatation Angle. 61

5.1.3.3 The Lift Coefficient 62

5.1.3.4 Turbulence 63

5.1.3.5 Approach. 65

5.1.3.6 Drag and Lift Induced Sliding. 66

5.1.3.7 Drag and Lift Induced Rolling. 66

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page ix of xx

5.1.3.8 Lift Induced Lifting. 67

5.1.3.9 Resulting Graphs. 67

5.1.3.10 Natural Sands and Gravels. 68

5.1.3.11 The Shields-Parker Diagram. 68

5.1.3.12 Conclusions & Discussion. 71

5.1.4 Nomenclature Initiation of Motion of Particles. 72

5.2 Hydraulic Transport of Sand/Shell Mixtures in Relation with the LDV. 75

5.2.1 Introduction. 75

5.2.2 The Drag Coefficient. 76

5.2.3 Non-Uniform Particle Size Distributions. 77

5.2.4 Laminar Region. 77

5.2.5 Turbulent Region. 77

5.2.6 The Exposure Level. 78

5.2.7 The Angle of Repose & the Friction Coefficient. 78

5.2.8 The Equal Mobility Criterion. 78

5.2.9 Shells. 79

5.2.10 The Limit Deposit Velocity. 83

5.2.11 Conclusions and Discussion. 85

5.2.12 Nomenclature Hydraulic Transport of Sand/Shell Mixtures. 86

5.3 Erosion, Bed Load and Suspended Load. 87

5.3.1 Introduction. 87

5.3.2 Bed Load Transport in a Sheet Flow Layer. 87

5.3.3 Suspended Load Transport in Open Channel Flow. 89

5.3.3.1 Governing Equations. 89

5.3.3.2 A Physical Explanation. 90

5.3.3.3 Law of the Wall Approach (Rouse (1937)). 91

5.3.3.4 The Constant Diffusivity Approach. 93

5.3.3.5 The Linear Diffusivity Approach. 94

5.3.3.6 The Hunt (1954) Equation. 95

5.3.4 Conclusions & Discussion Open Channel Flow. 98

5.3.5 Suspended Load in Pipe Flow. 99

5.3.5.1 The Constant Diffusivity Approach, Low Concentrations. 99

5.3.5.2 The Constant Diffusivity Approach, High Concentrations. 100

5.3.5.3 The Constant Diffusivity Approach for a Graded Sand. 101

5.3.6 Conclusions & Discussion Pipe Flow. 104

5.3.7 Nomenclature Erosion, Bed Load and Suspended Load. 107

Chapter 6: Slurry Transport, a Historical Overview. 109

6.1 Introduction. 109

6.2 Early History. 111

6.2.1 Blatch (1906). 111

6.2.2 Howard (1938). 113

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page x of xx TOC Copyright © Dr.ir. S.A. Miedema

6.2.3 Siegfried (Durepaire, 1939). 113

6.2.4 O’Brien & Folsom (1939). 113

6.2.5 Conclusions & Discussion Early History. 116

6.3 Empirical and Semi-Emperical Models. 121

6.4 The Durand & Condolios (1952) School. 127

6.4.1 Soleil & Ballade (1952). 127

6.4.2 Durand & Condolios (1952), (1956), Durand (1953) and Gibert (1960). 131

6.4.3 The Limit Deposit Velocity. 139

6.4.4 The Worster & Denny (1955) Model 145

6.4.5 The Zandi & Govatos (1967) Model. 149

6.4.6 Issues Regarding the Durand & Condolios (1952) and Gibert (1960) Model. 153

6.4.6.1 The Drag Coefficient of Durand & Condolios (1952) vs. the Real Drag Coefficient. 153

6.4.6.2 The Drag Coefficient as Applied by Worster & Denny (1955). 154

6.4.6.3 The Drag Coefficient of Gibert (1960). 154

6.4.6.4 The Relative Submerged Density as Part of the Equation. 154

6.4.6.5 The Graph of Zandi & Govatos (1967). 154

6.4.6.6 The F

L

Value as Published by Many Authors. 154

6.4.6.7 The Darcy-Weisbach Friction Coefficient λ

l

. 159

6.4.6.8 The Solids Effect Term in the Hydraulic Gradient Equation. 159

6.5 The Newitt et al. (1955) Model. 161

6.5.1 The Heterogeneous Regime. 161

6.5.2 The Sliding Bed Regime. 162

6.5.3 The Limit Deposit Velocity. 164

6.5.4 The Transition Heterogeneous vs. (Pseudo) Homogeneous Transport. 165

6.5.5 Regime Diagrams. 165

6.6 Silin, Kobernik & Asaulenko (1958) & (1962). 167

6.7 The Fuhrboter (1961) Model. 171

6.8 The Jufin & Lopatin (1966) Model. 177

6.8.1 Introduction. 177

6.8.2 Group A: Fines. 177

6.8.3 Group B: Sand. 177

6.8.4 The Limit Deposit Velocity. 180

6.8.5 Broad Graded Sands or Gravels. 180

6.8.6 Group C: Fine Gravel. 181

6.8.7 Group D: Coarse Gravel. 181

6.8.8 Conclusions & Discussion. 181

6.9 Charles (1970) and Babcock (1970). 183

6.9.1 Charles (1970). 183

6.9.2 Babcock (1970). 184

6.10 Graf et al. (1970) & Robinson (1971). 191

6.11 Yagi et al. (1972). 195

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page xi of xx

6.11.1 Introduction. 195

6.11.2 Pressure Losses. 195

6.11.2.1 Sand. 197

6.11.2.2 Gravel. 198

6.11.3 Limit Deposit Velocity. 200

6.11.4 The Slip Velocity. 201

6.12 A.D. Thomas (1976) & (1979). 203

6.12.1 Head Losses. 203

6.12.2 The Limit Deposit Velocity. 209

6.13 The Turian & Yuan (1977) Fit Model. 211

6.13.1 Introduction. 211

6.13.2 The Regime Equations. 212

6.13.3 Usage of the Equations. 214

6.13.4 Analysis of the Turian & Yuan (1977) Equations. 216

6.13.5 Transition Equations. 218

6.13.6 Conclusions & Discussion. 219

6.14 Kazanskij (1978). 221

6.15 The IHC-MTI (1998) Model for the Limit Deposit Velocity. 225

6.16 Conclusions & Discussion Empirical and Semi-Empirical Models. 227

6.16.1 Introduction. 227

6.16.2 The Darcy-Weisbach Friction Factor. 227

6.16.3 Heterogeneous Regime. 227

6.16.3.1 Durand & Condolios (1952). 228

6.16.3.2 Newitt et al. (1955). 228

6.16.3.3 Fuhrboter (1961). 228

6.16.3.4 Jufin & Lopatin (1966) Group B. 229

6.16.3.5 Wilson et al. (1992) Heterogeneous. 229

6.16.3.6 DHLLDV Graded, Miedema (2014). 230

6.16.3.7 Comparison. 230

6.16.4 Sliding Bed Regime. 233

6.16.5 Homogeneous Regime. 234

6.17 Nomenclature Early History & Empirical and Semi-Empirical Models. 237

6.18 Physical Models. 239

6.18.1 The Newitt et al. (1955) Model. 239

6.18.2 The Wasp et al. (1963) Model. 239

6.18.3 The Wilson-GIW (1979) Model. 239

6.18.4 The Doron et al. (1987) and Doron & Barnea (1993) Model. 240

6.18.5 The SRC Model. 240

6.18.6 The Kaushal & Tomita (2002B) Model. 240

6.18.7 The Matousek (2009) Model. 240

6.18.8 The Talmon (2011) & (2013) Homogeneous Regime Model. 240

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page xii of xx TOC Copyright © Dr.ir. S.A. Miedema

6.19 The Wasp et al. (1963) Model. 241

6.19.1 Introduction. 241

6.19.2 The WASP Method. 242

6.19.2.1 Step 1: Prediction Step. 242

6.19.2.2 Step 2: Correction Steps. 243

6.19.3 Different Versions of the WASP Model. 246

6.19.3.1 Abulnaga (2002). 246

6.19.3.2 Kaushal & Tomita (2002B). 247

6.19.3.3 Lahiri (2009) . 247

6.19.3.4 The DHLLDV Framework. 248

6.19.4 Discussion & Conclusions. 248

6.19.5 Nomenclature Wasp Model. 259

6.20 The Wilson-GIW (1979) Models. 261

6.20.1 The Wilson-GIW (1979) Model for Fully Stratified Flow. 261

6.20.1.1 Introduction. 261

6.20.1.2 The Basic Equations for Flow and Geometry. 261

6.20.1.3 The Shear Stresses Involved. 263

6.20.1.4 The Forces Involved. 264

6.20.1.5 Output with the Wilson et al. (1992) Hydrostatic Stress Approach. 266

6.20.1.6 The Fit Functions of Wilson et al. (1992). 271

6.20.1.7 The Fit Functions of Wilson et al. (1997). 275

6.20.1.8 The Stratification Ratio. 276

6.20.1.9 Suspension in the Upper Layer. 276

6.20.1.10 Conclusions & Discussion. 277

6.20.2 The Wilson-GIW (1992) Model for Heterogeneous Transport. 277

6.20.2.1 The Full Model. 277

6.20.2.2 The Simplified Wilson Model. 278

6.20.2.3 Generic Equation. 279

6.20.2.4 Conclusions & Discussion. 281

6.20.3 The 4 Component Model of Wilson & Sellgren (2001). 282

6.20.3.1 Introduction. 282

6.20.3.2 The Homogeneous or Equivalent Fluid Fraction. 282

6.20.3.3 The Pseudo Homogeneous Fraction. 283

6.20.3.4 The Heterogeneous Fraction. 283

6.20.3.5 The Fully Stratified Fraction. 284

6.20.3.6 The Resulting Equation. 284

6.20.3.7 Modified 4 Component Model. 284

6.20.3.8 Conclusions & Discussion. 288

6.20.4 Near Wall Lift. 289

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page xiii of xx

6.20.5 The Demi-McDonald of Wilson (1979). 293

6.20.6 Nomenclature Wilson-GIW Models. 294

6.21 The Doron et al. (1987) and Doron & Barnea (1993) Model. 297

6.21.1 The 2 Layer Model (2LM). 297

6.21.2 The 3 Layer Model (3LM). 302

6.21.3 Conclusions & Discussion. 306

6.21.4 Some Issues. 306

6.21.5 Modified Doron & Barnea Model. 310

6.21.6 Nomenclature Doron & Barnea Models. 315

6.22 The SRC Model. 317

6.22.1 Continuity Equations. 317

6.22.2 Concentrations. 317

6.22.3 The Mixture Densities. 318

6.22.4 Pressure Gradients & Shear Stresses. 319

6.22.5 The Sliding Friction. 319

6.22.6 The Bed Concentration. 322

6.22.7 Discussion & Conclusions Original Model. 323

6.22.8 Further Development of the Model. 327

6.22.9 Final Conclusions. 329

6.22.10 The Limit Deposit Velocity. 333

6.22.11 Nomenclature SRC Model. 335

6.23 The Kaushal & Tomita (2002B) Model. 337

6.23.1 Introduction. 337

6.23.2 The Hydraulic Gradient. 338

6.23.3 The Solids Concentration Distribution. 340

6.23.3.1 Closed Ducts. 342

6.23.3.2 Open Channel Flow. 342

6.23.4 Discussion & Conclusions. 342

6.23.5 Nomenclature Kaushal & Tomita Models. 343

6.24 The Matousek (2009) Model. 345

6.24.1 Introduction. 345

6.24.2 The Iteration Process. 346

6.24.3 Conclusions & Discussion. 353

6.24.4 Nomenclature Matousek Model. 354

6.25 Talmon (2011) & (2013) Homogeneous Regime. 357

6.25.1 Theory. 357

6.25.2 Nomenclature Talmon Model. 360

6.26 Conclusions & Discussion Physical Models. 361

6.26.1 The Newitt et al. (1955) Model. 361

6.26.2 The Wasp et al. (1963) Model. 361

6.26.3 The Wilson-GIW (1979) Model. 361

6.26.4 The Doron et al. (1987) and Doron & Barnea (1993) Model. 361

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page xiv of xx TOC Copyright © Dr.ir. S.A. Miedema

6.26.5 The SRC Model. 362

6.26.6 The Kaushal & Tomita (2002B) Model. 362

6.26.7 The Matousek (2009) Model. 362

6.26.8 The Talmon (2011) & (2013) Homogeneous Regime Model. 362

6.27 The Limit Deposit Velocity (LDV). 363

6.27.1 Introduction. 363

6.27.2 Wilson (1942). 364

6.27.3 Durand & Condolios (1952). 364

6.27.4 Newitt et al. (1955). 364

6.27.5 Jufin & Lopatin (1966). 364

6.27.6 Zandi & Govatos (1967). 365

6.27.7 Charles (1970). 365

6.27.8 Graf et al. (1970) & Robinson (1971). 366

6.27.9 Wilson & Judge (1976). 366

6.27.10 Wasp et al. (1977). 366

6.27.11 Thomas (1979). 366

6.27.12 Oroskar & Turian (1980). 367

6.27.13 Parzonka et al. (1981). 368

6.27.14 Turian et al. (1987). 368

6.27.15 Davies (1987). 368

6.27.16 Schiller & Herbich (1991). 370

6.27.17 Gogus & Kokpinar (1993). 370

6.27.18 Gillies (1993). 371

6.27.19 Van den Berg (1998). 371

6.27.20 Kokpinar & Gogus (2001). 371

6.27.21 Shook et al. (2002). 372

6.27.22 Wasp & Slatter (2004). 372

6.27.23 Sanders et al. (2004). 372

6.27.24 Lahiri (2009). 373

6.27.25 Poloski et al. (2010). 373

6.27.26 Souza Pinto et al. (2014). 374

6.27.27 Conclusions & Discussion. 374

6.27.28 Nomenclature Limit Deposit Velocity. 378

6.28 Inclined Pipes. 379

6.29 Starting Points DHLLDV Framework. 381

6.29.1 The Liquid Properties. 381

6.29.2 Possible Flow Regimes. 381

6.29.3 Flow Regime Behavior. 382

6.29.4 The LSDV, LDV and MHGV. 383

6.29.5 The Slip Velocity or Slip Ratio. 383

6.29.6 The Concentration Distribution. 384

6.29.7 The Dimensionless Numbers used. 384

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page xv of xx

6.29.8 The Type of Graph used. 384

Chapter 7: The Delft Head Loss & Limit Deposit Velocity Framework. 385

7.1 Introduction. 385

7.1.1 Considerations. 385

7.1.2 Energy Dissipation. 388

7.1.3 Starting Points. 391

7.1.4 Approach. 393

7.1.5 Nomenclature Introduction. 396

7.2 Flow Regimes and Scenario’s. 397

7.2.1 Introduction. 397

7.2.2 Concentration Considerations. 398

7.2.3 The 8 Flow Regimes Identified. 400

7.2.4 The 6 Scenario’s Identified. 404

7.2.4.1 Scenarios L1 & R1. 404

7.2.4.2 Scenarios L2 & R2. 406

7.2.4.3 Scenarios L3 & R3. 408

7.2.4.4 Conclusions & Discussion. 409

7.2.5 Verification & Validation. 410

7.2.5.1 L1: Fixed Bed & Heterogeneous, Constant C

vs

. 411

7.2.5.2 R1: Heterogeneous, Constant C

vt

. 412

7.2.5.3 L2: Fixed & Sliding Bed & Heterogeneous, Constant C

vs

. 413

7.2.5.4 R2, R3: Sliding Bed & Sliding Flow, Constant C

vt

. 414

7.2.5.5 L1, R1, L2, R2:, Homogeneous. 415

7.2.5.6 L3, R3: Sliding Bed & Sliding Flow, Constant C

vs

. 416

7.2.6 Discussion & Conclusions. 417

7.2.7 Nomenclature Flow Regimes & Scenario’s. 418

7.3 A Head Loss Model for Fixed Bed Slurry Transport. 419

7.3.1 The Basic Equations for Flow and Geometry. 419

7.3.2 The Shear Stresses Involved. 420

7.3.3 The Forces Involved. 422

7.3.4 The Relative Roughness. 424

7.3.5 The Darcy-Weisbach friction factor first attempt. 429

7.3.6 Conclusion & Discussion 430

7.3.7 The Darcy Weisbach friction factor second attempt. 432

7.3.8 Conclusions & Discussion. 436

7.3.9 Nomenclature Fixed Bed Regime. 437

7.4 A Head Loss Model for Sliding Bed Slurry Transport. 439

7.4.1 The Friction Force on the Pipe Wall. 439

7.4.2 The Active/Passive Soil Failure Approach. 441

7.4.3 The Hydrostatic Normal Stress Distribution Approach. 445

7.4.4 The Normal Force Carrying The Weight Approach. 447

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page xvi of xx TOC Copyright © Dr.ir. S.A. Miedema

7.4.5 The Submerged Weight Approach. 450

7.4.6 Summary. 451

7.4.7 The 3 Layer Model. 457

7.4.8 Nomenclature Sliding Bed Regime. 465

7.5 A Head Loss Model for Heterogeneous Slurry Transport. 467

7.5.1 Introduction. 467

7.5.2 Physical Energy Considerations. 467

7.5.3 Estimating the Slip Velocity. 473

7.5.4 Simplified Models. 477

7.5.4.1 Simplified Model for Small Particles, d<0.3 mm. 478

7.5.4.2 Simplified Model for Medium Sized Particles, 0.3 mm≤d≤2 mm. 479

7.5.4.3 Simplified Model for Large Particles, d>2 mm. 480

7.5.4.4 Summary Approximations. 481

7.5.4.5 Comparison with Durand & Condolios (1952). 482

7.5.5 The Slip Velocity Applied to the Fuhrboter Equation. 483

7.5.5.1 Simplified Model for Small Particles, d<0.3 mm. 484

7.5.5.2 Simplified Model for Medium Sized Particles, 0.3 mm≤d≤2 mm. 485

7.5.5.3 Simplified Model for Large Particles, d>2 mm. 486

7.5.5.4 Summary Approximations. 487

7.5.6 The Concentration Eccentricity Coefficient. 489

7.5.7 Verification & Validation. 489

7.5.8 New Dimensionless Numbers. 491

7.5.9 Discussion & Conclusions. 492

7.5.10 Nomenclature Heterogeneous Regime. 494

7.6 A Head Loss Model for Homogeneous Slurry Transport. 495

7.6.1 Homogeneous Transport – The Equivalent Liquid Model (ELM). 495

7.6.2 Approach. 496

7.6.3 Method 1: The Talmon (2011) & (2013) Homogeneous Regime Equation. 497

7.6.4 Method 2: The Approach using the Nikuradse (1933) Mixing Length. 498

7.6.5 Method 3: Adding the von Driest (Schlichting, 1968) Damping to Method 2. 501

7.6.6 Method 4: The Law of the Wall Approach. 502

7.6.7 Comparison of the Models. 505

7.6.8 Method 5: Applying a Concentration Profile to Method 2. 507

7.6.9 Applicability of the Model. 509

7.6.10 Conclusions. 511

7.6.11 Nomenclature Homogeneous Regime. 512

7.7 The Sliding Flow Regime. 513

7.7.1 Literature & Theory. 513

7.7.2 Verification & Validation. 515

7.7.3 Nomenclature Sliding Flow Regime. 518

7.8 The Limit Deposit Velocity. 519

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page xvii of xx

7.8.1 Introduction. 519

7.8.2 Experimental Data. 520

7.8.3 Equations & Models. 522

7.8.4 Conclusions Literature. 523

7.8.5 Starting Points DHLLDV Framework. 524

7.8.6 The Transition Fixed Bed – Sliding Bed (LSDV). 524

7.8.7 The Transition Heterogeneous – Homogeneous (LDV Very Fine Particles).. 525

7.8.8 The Transition Sliding Bed – Heterogeneous (LDV Coarse Particles). 525

7.8.9 The Transition Sliding Bed – Homogeneous (LSBV). 526

7.8.10 The Limit Deposit Velocity (LDV All Particles).. 527

7.8.10.1 Introduction. 527

7.8.10.2 Very Small Particles, The Lower Limit. 529

7.8.10.3 Smooth Bed. 530

7.8.10.4 Rough Bed. 531

7.8.11 The Resulting Limit Deposit Velocity Curves. 535

7.8.12 Conclusions & Discussion. 540

7.8.13 Nomenclature Limit Deposit Velocity. 542

7.9 The Slip Velocity. 543

7.9.1 Introduction. 543

7.9.2 Slip Ratio in the Heterogeneous Regime. 544

7.9.3 Comparison with the Yagi et al. (1972) Data Step 1. 545

7.9.4 Derivation of the Slip Ratio at High A

b

/A

p

Ratios. 546

7.9.5 Comparison with the Yagi et al. (1972) Data Step 2. 548

7.9.6 The Region Around The Limit Deposit Velocity. 549

7.9.7 Comparison with the Yagi et al. (1972) Data Step 3. 551

7.9.8 Construction of the Slip Ratio Curve, Step 4. 551

7.9.9 Conclusions & Discussion. 551

7.9.10 The Slip Velocity, a Pragmatic Solution. 557

7.9.11 Nomenclature Slip Velocity. 559

7.10 The Concentration Distribution. 561

7.10.1 The Advection Diffusion Equation. 561

7.10.2 The Diffusivity Based on the LDV. 562

7.10.3 Simplification of the Equations. 563

7.10.4 Nomenclature Concentration Distribution. 570

7.11 The Transition Heterogeneous vs. Homogeneous in Detail. 571

7.11.1 The Transition Heterogeneous-Homogeneous. 571

7.11.2 The Lift Ratio. 571

7.11.3 Limit Deposit Velocity & Concentration Distribution. 573

7.11.4 Resulting Relative Excess Hydraulic Gradient Curves. 579

7.11.5 Conclusions & Discussion. 579

7.11.6 Nomenclature . 581

7.12 The Bed Height. 583

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page xviii of xx TOC Copyright © Dr.ir. S.A. Miedema

7.12.1 Concentration Transformation Equations. 583

7.12.2 Fixed Bed. 583

7.12.3 Sliding Bed. 585

7.12.4 Some Results. 587

7.12.5 Nomenclature Bed Height. 588

7.13 Influence of the Particle Size Distribution 589

7.13.1 Introduction. 589

7.13.2 The Particle Size Distributions. 592

7.13.3 Particle Diameter d

50

=0.2 mm. 594

7.13.4 Particle Diameter d

50

=0.5 mm. 596

7.13.5 Particle Diameter d

50

=1.0 mm. 598

7.13.6 Particle Diameter d

50

=3.0 mm. 600

7.13.7 Nomenclature PSD Influence. 602

7.14 Inclined Pipes. 603

7.14.1 Stationary Bed Regime. 603

7.14.2 Sliding Bed Regime. 603

7.14.3 Heterogeneous Regime. 604

7.14.4 Homogeneous Regime. 605

7.14.5 Sliding Flow Regime. 606

7.14.6 The Limit Deposit Velocity. 606

7.14.7 Conclusions & Discussion. 606

7.14.8 Nomenclature Inclined Pipes. 610

Chapter 8: Usage of the DHLLDV Framework. 611

8.1 Introduction. 611

8.2 Default Equations Used In This Book. 612

8.3 The Liquid Properties. 613

8.4 The Fixed or Stationary Bed Regime. 613

8.4.1 The Shear Stresses Involved. 615

8.4.2 The Forces Involved. 616

8.5 The Sliding Bed Regime. 618

8.6 The Heterogeneous Transport Regime. 619

8.7 The Homogeneous Transport Regime. 619

8.8 The Sliding Flow Regime. 621

8.9 The Resulting E

rhg

Constant Spatial Volumetric Concentration Curve. 621

8.10 The Transition Heterogeneous Regime - Homogeneous Regime. 623

8.10.1 Introduction. 623

8.10.2 The Lift Ratio. 623

8.10.3 The Heterogeneous Equation. 623

8.10.4 The Homogeneous Equation. 623

8.10.5 The Resulting Relative Excess Hydraulic Gradient. 624

8.11 Determining the Limit Deposit Velocity. 625

8.11.1 Introduction. 625

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Copyright © Dr.ir. S.A. Miedema TOC Page xix of xx

8.11.2 Very Small & Small Particles. 625

8.11.3 Large & Very Large Particles. 626

8.11.4 The Resulting Upper Limit Froude Number. 627

8.11.5 The Lower Limit. 627

8.11.6 The Resulting Froude Number. 628

8.12 Constructing the Transport Concentration Curves. 629

8.13 The Bed Height. 630

8.14 The Concentration Distribution. 630

8.15 Graded Sands & Gravels. 631

8.16 A Set of Resulting Graphs. 633

8.17 Conclusions & Discussion. 644

8.18 Nomenclature DHLLDV Framework. 645

Chapter 9: Comparison of the DHLLDV Framework with Other Models. 647

9.1 Introduction. 647

9.2 The Transition Velocity Heterogeneous-Homogeneous. 650

9.2.1 Considerations. 650

9.2.2 The DHLLDV Framework. 650

9.2.3 Durand & Condolios (1952) & Gibert (1960). 651

9.2.4 Newitt et al. (1955). 652

9.2.5 Fuhrboter (1961). 652

9.2.6 Jufin & Lopatin (1966). 653

9.2.7 Zandi & Govatos (1967). 654

9.2.8 Turian & Yuan (1977) 1: Saltation Regime. 654

9.2.9 Turian & Yuan (1977) 2: Heterogeneous Regime. 655

9.2.10 Wilson et al. (1992) (Power 1.0, Non-Uniform Particles). 655

9.2.11 Wilson et al. (1992) (Power 1.7, Uniform Particles). 656

9.2.12 Wilson & Sellgren (2012) Near Wall Lift Model. 656

9.2.13 The Saskachewan Research Council Model. 656

9.2.14 Examples Heterogeneous versus Homogeneous.. 657

9.2.14.1 The Influence of the Particle Diameter & Terminal Settling Velocity. 657

9.2.14.2 The Influence of the Pipe Diameter. 658

9.2.14.3 The Influence of the Concentration. 658

9.2.14.4 The Influence of the Sliding Friction Coefficient. 658

9.2.14.5 The Influence of the Relative Submerged Density. 658

9.2.14.6 The Influence of the Line Speed. 659

9.2.14.7 Summary. 659

9.2.14.8 A 0.0254 m Diameter Pipe (1 inch). 661

9.2.14.9 A 0.0508 m Diameter Pipe (2 inch). 662

9.2.14.10 A 0.1016 m Diameter Pipe (4 inch). 663

9.2.14.11 A 0.2032 m Diameter Pipe (8 inch). 664

9.2.14.12 A 0.4064 m Diameter Pipe (16 inch). 665

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page xx of xx TOC Copyright © Dr.ir. S.A. Miedema

9.2.14.13 A 0.762 m Diameter Pipe (30 inch). 666

9.2.14.14 A 1.2 m Diameter Pipe. 667

9.2.15 Conclusions & Discussion Heterogeneous-Homogeneous Transition. 668

9.3 The Limit Deposit Velocity. 669

9.3.1 Analysis. 669

9.3.2 Conclusions Limit Deposit Velocity. 671

9.3.3 Graphs. 672

9.4 Nomenclature Comparisons. 677

Chapter 10: Application of the Theory on a Cutter Suction Dredge. 679

10.1 Head Loss Equation. 679

10.2 The Limit Deposit Velocity. 681

10.3 The Resulting Head Loss versus Mixture Flow Graph. 681

10.4 The Relative Excess Hydraulic Gradient of Pump and Pipeline. 682

Chapter 11: Publications. 683

Chapter 12: Bibliography. 685

Chapter 13: List of Figures. 697

Chapter 14: List of Tables. 709

Chapter 15: Appendices. 711

15.1 Appendix A: List of Solids Densities. 711

15.2 Appendix B: List of Liquid Densities. 715

15.3 Appendix C: List of Mesh Sizes. 719

15.4 Appendix D: Flow Regime Diagrams. 721

Introduction.

Copyright © Dr.ir. S.A. Miedema TOC Page 1 of 738

Chapter 1: Introduction.

1.1 Introduction.

In dredging, the hydraulic transport of solids is one of the most important processes. Since the 50’s many

researchers have tried to create a physical mathematical model in order to predict the head losses in slurry transport.

One can think of the models of Durand & Condolios (1952) & Durand (1953), Worster & Denny (1955), Newitt

et al. (1955), Gibert (1960), Fuhrboter (1961), Jufin & Lopatin (1966), Zandi & Govatos (1967) & Zandi (1971),

Turian & Yuan (1977), Doron et al. (1987) & Doron & Barnea (1993), Wilson et al. (1992) and Matousek (1997).

Some models are based on phenomenological relations and thus result in semi empirical relations, other tried to

create models based on physics, like the two and three layer models. It is however the question whether slurry

transport can be modeled this way at all. Observations in our laboratory show a process which is often non-

stationary with respect to time and space. Different physics occur depending on the line speed, particle diameter,

concentration and pipe diameter. These physics are often named flow regimes; fixed bed, shearing bed, sliding

bed, heterogeneous transport and (pseudo) homogeneous transport. It is also possible that more regimes occur at

the same time, like, a fixed bed in the bottom layer with heterogeneous transport in the top layer. It is the

observation of the author that researchers often focus on a detail and sub-optimize their model, which results in a

model that can only be applied for the parameters used for their experiments.

1.2 Flow Regimes Literature.

Based on the specific gravity of particles with a magnitude of 2.65, Durand (1953) proposed to divide the flows of

non-settling slurries in horizontal pipes into four flow regimes based on average particle size as follows:

1. Homogeneous suspensions for particles smaller than 40 μm (mesh 325)

2. Suspensions maintained by turbulence for particle sizes from 40 μm (mesh 325) to 0.15 mm (mesh 100)

3. Suspension with saltation for particle sizes between 0.15 mm (mesh 100) and 1.5 mm (mesh 11)

4. Saltation for particles greater than 1.5 mm (mesh 11)

Due to the interrelation between particle sizes and terminal and deposition velocities, the original classification

proposed by Durand has been modified to four flow regimes based on the actual flow of particles and their size

(Abulnaga, 2002).

1. Flow with a stationary bed

2. Flow with a moving bed and saltation (with or without suspension)

3. Heterogeneous

Heterogeneous mixture with saltation and rolling

Heterogeneous mixture with all solids in suspension

4. Pseudo homogeneous and/or homogeneous mixtures with all solids in suspension

The four regimes of flow described can be represented by a plot of the hydraulic gradient versus the average speed

of the mixture as in Figure 1.2-1. The 4 transitional velocities are defined as:

• V

1

: velocity at or above which the bed in the lower half of the pipe is stationary. In the upper half of the pipe,

some solids may move by saltation or suspension. Below V

1

there are no particles above the bed.

• V

2

: velocity at or above which the mixture flows as an asymmetric mixture with the coarser particles forming

a moving/saltating bed.

• V

3

: velocity at or above which all particles move as an asymmetric suspension and below which the solids

start to settle and form a moving bed.

• V

4

: velocity at or above which all solids move as an almost symmetric suspension.

Wilson (1992) developed a model, which will be discussed in detail later, for the incipient motion of granular

solids at V

2

, the transition between a stationary bed and a sliding bed. He assumed a hydrostatic pressure exerted

by the solids on the wall. Wilson also developed a model for heterogeneous transport with a V

50

, where 50% of

the solids are in a (moving/saltating) bed and 50% in suspension. This percentage is named the stratification ratio.

The transitional velocity V

3

is extremely important because it is the speed at which the hydraulic gradient is at a

minimum. Although there is evidence that solids start to settle at lower line speeds in complex mixtures, operators

and engineers often refer to this transitional velocity as the speed of deposition or critical velocity. Figure 1.2-3

shows the 4 regimes and the velocity and concentration profiles. At very high line speeds the pressure drop will

reach an equivalent liquid curve asymptotically. Whether or not this occurs at practical line speeds depends on the

particle diameter, pipe diameter and the concentration. For large particle diameters and concentrations it may seem

like the pressure drop reaches the water curve asymptotically, but at higher line speeds the pressure drop will

increase again up to an equivalent liquid model. Whether or not this equivalent liquid model contains the mixture

density instead of the water density, or some value in between is still the question.

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page 2 of 738 TOC Copyright © Dr.ir. S.A. Miedema

Figure 1.2-1: The 4 regimes and transitional velocities (Abulnaga, 2002), D

p

=0.15 m, d

50

=2 mm, C

vt

=0.2.

Figure 1.2-1 gives the impression that the 4 flow regimes will always occur sequentially. Starting from a line speed

zero and increasing the line speed, first the fixed or stationary bed will occur without suspension, at a line speed

V

1

part of the bed starts to erode and particles will be in suspension, at a line speed V

2

the remaining bed will start

to slide while the erosion increases with the line speed, at a line speed V

3

the whole bed is eroded and the

heterogeneous regime starts and finally at a line speed V

4

the heterogeneous regime transits to the (pseudo)

homogeneous regime. In reality not all the regimes have to occur, depending on the particle size, the pipe diameter

and other governing parameters.

Figure 1.2-2: Flow regimes according to Newitt et al. (1955).

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0 1 2 3 4 5 6 7 8 9 10

Hydraulic gradient i

m

(m water/m pipe)

Line speed v

ls

(m/sec)

Hydraulic gradient i

m

versus Line speed v

ls

Water

Slurry

V1: Start Fixed Bed With Suspension

V2: Start Moving Bed/Saltating Bed

V3: Start Heterogeneous Transport

V4: Start (Pseudo) Homogeneous Transport

V1

V3

Moving

Bed/Saltating Bed

V1

V2

V4

Stationary Bed Without Suspension

Stationary Bed With Suspension

Heterogeneous Transport

Pseudo Homogeneous Transport

Homogeneous Transport

© S.A.M.

0.001

0.010

0.100

1.000

10.000

100.000

0 1 2 3 4 5 6 7 8 9 10

Particle Diameter d (mm)

Line Speed v

ls

(m/sec)

Flow Regimes according to Newitt et al. (1955) & Durand & Condolios (1952)

Limit of Stationary Bed

Dp=1 inch

Limit of Stationary Bed

Dp=6 inch

Limit of Moving Bed, All

Dp

Heterogeneous vs

Homogeneous Dp=1

inch

Heterogeneous vs

Homogeneous Dp=6

inch

© S.A.M.

Flow with a Stationary Bed

D

p

= 1 inch

D

p

= 6 inch

D

p

=1 inch

D

p

=6 inch

Flow with a

Moving Bed

Flow as a Homogeneous Suspension

Flow as a Heterogeneous

Suspension

Introduction.

Copyright © Dr.ir. S.A. Miedema TOC Page 3 of 738

Figure 1.2-2 shows the regimes according to Newitt et al. (1955). From this figure it is clear that not all regimes

have to occur and that the transition velocities depend on the particle and the pipe diameter. The influence of the

volumetric concentration is not present in this graph. Figure 1.2-3 shows the flow regimes as used by Matousek

(2004) also showing velocity and concentration distributions.

Figure 1.2-3: Different mixture transport regimes.

1.3 The Parable of Blind Men and an Elephant.

Wilson et al. (1992), (1997) and (2006) refer to the old parable of 6 blind men, who always wanted to know what

an elephant looks like. Each man could touch a different part of the elephant, but only one part. So one man touched

the tusk, others the legs, the belly, the tail, the ear and the trunk. The blind man who feels a leg says the elephant

is like a pillar; the one who feels the tail says the elephant is like a rope; the one who feels the trunk says the

elephant is like a tree branch; the one who feels the ear says the elephant is like a hand fan; the one who feels the

belly says the elephant is like a wall; and the one who feels the tusk says the elephant is like a solid pipe. They

then compare notes and learn they are in complete disagreement about what the elephant looks like. When a sighted

man walks by and sees the entire elephant all at once, they also learn they are blind. The sighted man explains to

them: All of you are right. The reason every one of you is telling a different story is because each one of you

touched a different part of the elephant. So actually the elephant has all the features you mentioned.

The story of the blind men and an elephant originated in the Indian subcontinent from where it has widely diffused.

It has been used to illustrate a range of truths and fallacies; broadly, the parable implies that one's subjective

experience can be true, but that such experience is inherently limited by its failure to account for other truths or a

totality of truth. At various times the parable has provided insight into the relativism, opaqueness or inexpressible

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page 4 of 738 TOC Copyright © Dr.ir. S.A. Miedema

nature of truth, the behavior of experts in fields where there is a deficit or inaccessibility of information, the need

for communication, and respect for different perspectives (source Wikipedia).

Figure 1.3-1: Flow regimes and the Double Logarithmic Elephant “Leeghwater”.

Figure 1.3-1 shows a comparison between the parable of the elephant and slurry flow. Slurry transport also has

many truths, points of view. Experiments can be carried out with small versus large pipes, small versus large

particles, low versus high concentrations, low versus high line speeds, low versus high particle diameter versus

pipe diameter ratios, laminar versus turbulent flow, Newtonian versus non Newtonian liquids, low versus high

solid densities, etc. Depending on the parameters used, experiments are carried out in different flow regimes, or

maybe at the interface between flow regimes, resulting in different conclusions.

Wilson et al. (1992), (1997) and (2006) show with this parable that the research of slurry flow often focusses on

different parts or aspects of the process, but not many times it will give an overview of the whole process. The

starting point is that every researcher tells the truth, based on his/her observations. Combining these truths gives

an impression of the aggregated truth, which is still not the whole truth. The 6 men for example cannot look inside

the elephant, only touch the outside. The internal structure of slurry flow may however be very important to

understand the slurry flow behavior. The 6 men cannot access the memory of the elephant, which is supposed to

be very good. In long pipelines the overall behavior of the slurry flow does depend on the history, so the memory

function is also important. The Double Logarithmic Elephant is named after the student association of Mechanical

Engineering of the Delft University of Technology, Leeghwater, using the elephant as their symbol. Leeghwater

stands for strength, precision and of course hydraulic transport through the proboscis.

1.4 The Delft Head Loss & Limit Deposit Velocity Framework.

In the following chapters the different models from literature will be analyzed, leading to a new integrated model

based on a new classification of the flow regimes. This new model is named the Dredging Head Loss & Limit

Deposit Velocity Framework (DHLLDV Framework). The Framework is integrated in a way that all flow regimes

are described in a consistent way showing the transition velocities. The model is validated by many experiments

from literature and experiments carried out in the Delft University Dredging Engineering Laboratory for particles

ranging from 0.05 to 45 mm, pipe diameters ranging from 0.0254 to 0.9 m and relative submerged densities ranging

from 0.24 to 4 ton/m

3

. The model does not just give hydraulic gradient relations, but also Limit Deposit Velocity

relations, slip ratio relations (the relation between the volumetric spatial concentration and the volumetric delivered

concentration), bed height relations and a concentration distribution model. The Framework also gives a tool to

determine the influence of the grading of the sand or gravel. The starting point of the model is a uniform sand or

gravel and a constant volumetric spatial concentration. Based on the hydraulic gradient and slip ratio relations, the

volumetric delivered concentration hydraulic gradient relations are derived. The latter is very important for

practical applications.

Introduction.

Copyright © Dr.ir. S.A. Miedema TOC Page 5 of 738

1.5 Approach of this book.

The book covers horizontal transport of settling slurries (Newtonian slurries). Pipelines under an angle with the

horizontal and non-settling (non-Newtonian) slurries are not covered.

The book has the following approach:

1. Chapter 1 explains the context of slurry flow, based on flow regimes as indentified in literature.

2. Chapter 2 gives definitions of the dimensionless numbers and other important parameters as used in the book.

Definitions are the language of engineers and scientists and are thus essential for the understanding.

3. Chapter 3 deals with homogeneous Newtonian liquid flow through horizontal circular pipes. Equations and

graphs are given to determine the Darcy Weisbach friction factor. The Swamee Jain (1976) equation for the

Darcy Weisbach (Moody (1944)) friction factor is used in this book. Also the influence of the concentration

of very fine particles on the liquid properties is discussed.

4. Chapter 4 explains the terminal settling velocity of particles, including hindered settling. In the theory derived,

the Zanke (1977) equation for the settling velocity is used and the Richardson & Zaki (1954) approach for

hindered settling is applied.

5. Chapter 5 shows the basics of the initiation of motion of particles and shells, which is important to understand

the behavior of the interface between a bed and the liquid flow above the bed, especially for the stationary and

sliding bed regimes. Initiation of motion is the start of sediment motion, but at higher flow velocities also

erosion and/or sediment transport will occur. The basics of sediment transport as bed load and suspended load

are discussed for open channel flow and pipe flow.

6. Chapter 6 gives an overview of the historical developments of models to predict head losses in slurry flow.

The overview starts with the early history, followed by empirical and semi empirical models. The models are

given, analysed and discussed and issues of the models are addressed. The models for the Limit Deposit

Velocity (LDV) are discussed, analysed and compared. Conclusions are drawn regarding the behavior of the

LDV related to the solids, liquid and flow parameters. A number of 2 layer models (2LM) and 3 layer models

(3LM) based on physics are given and analysed, as well as other physical models.

7. Chapter 7 describes the new Delft Head Loss & Limit Deposit Velocity (DHLLDV) Framework. The

DHLLDV Framework is based on uniform sands or gravels and constant spatial volumetric concentration.

This chapter starts with an overview of 8 flow regimes and 6 scenarios. The new models for the main flow

regimes, the stationary bed regime without sheet flow and with sheet flow, the sliding bed regime, the

heterogeneous regime, the homogeneous regime and the sliding flow regime, are derived and discussed. A

new model for the Limit Deposit Velocity is derived, consisting of 5 particle size regions and a lower limit.

Based on the LDV a method is shown to construct slip velocity or slip ratio curves from zero line speed to the

LDV and above. Based on the slip ratio, the constant delivered volumetric concentration curves can be

constructed. Knowing the slip ratio, the bed height for line speeds below the LDV can be determined. New

equations are derived for this. The transition from the heterogeneous regime to the homogeneous regime

requires special attention. First of all, this transition line speed gives a good indication of the operational line

speed and allows to compare the DHLLDV Framework with many models from literature. Secondly the

transition is not sharp, but depends on 3 velocities. The line speed where a particle still fits in the viscous sub

layer, the transition line speed heterogeneous-homogeneous and the line speed where the lift force on a particle

equals the submerged weight of the particle. Finally the grading of the Particle Size Distribution (PSD) is

discussed. A method is given to construct resulting head loss, slip velocity and bed height curves for graded

sands and gravels.

8. Chapter 8 summarises the DHLLDV Framework. The essential equations are given, with reference to the

original equations, to reproduce the DHLLDV Framework, accompanied with flow charts.

9. In chapter 9 the DHLLDV Framework is compared with other models from literature.

10. Chapter 10 shows how to apply the DHLLDV Framework on the hydraulic transport of a cutter suction dredge.

11. Chapter 11 gives the journal and conference publications of the authors on which this book is based.

The DHLLDV Framework models have been verified and validated with numerous experimental data.

The results of experiments and calculations are shown in standard graphs showing Hydraulic Gradient versus

Line Speed i(v

ls

), the Relative Excess Hydraulic Gradient versus the Line Speed E

rhg

(v

ls

) and the Relative

Excess Hydraulic Gradient versus the Liquid Hydraulic Gradient (the clean water resistance) E

rhg

(i

l

). The

advantage of the E

rhg

(i

l

) graph is that this type of graph is almost independent of the values of the spatial

concentration C

vs

and relative submerged density R

sd

. The advantage of the i

m

(v

ls

) graph is that is clearly shows

head losses versus flow and thus gives an indication of the required power and specific energy, combined with

pump graphs. Most experimental data is shown in the Relative Excess Hydraulic Gradient versus the Liquid

Hydraulic Gradient graph, E

rhg

(i

l

).

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page 6 of 738 TOC Copyright © Dr.ir. S.A. Miedema

1.6 Nomenclature.

C

v

Volumetric concentration

-

C

vs

Volumetric spatial concentration

-

C

vt

Volumetric transport/delivered concentration

-

d

Particle/grain diameter

m

D

p

Pipe diameter

m

E

rhg

Relative Excess Hydraulic Gradient

-

i, i

l

, i

w

Hydraulic gradient liquid

m.w.c./m

i

m

Hydraulic gradient mixture

m.w.c./m

LSDV

Limit of Stationary Deposit Velocity

m/s

LDV

Limit Deposit Velocity

m/s

m.w.c.

Meters water column, pressure expressed in m.w.c.(10 m.w.c.=100 kPa=1 bar)

m

R

sd

Relative submerged density

-

v

Line speed

m/s

v

ls

Line speed

m/s

V

1

Transition fixed bed without suspension – fixed bed with suspension

m/s

V

2

Transition fixed bed with suspension – sliding bed with suspension

m/s

V

3

Transition sliding bed with suspension – heterogeneous transport

m/s

V

4

Transition heterogeneous transport – (pseudo) homogeneous transport

m/s

V

50

Velocity with 50% stratification according to Wilson

m/s

Publications.

Copyright © Dr.ir. S.A. Miedema TOC Page 683 of 738

Chapter 11: Publications.

This book is based on the following publications of the authors (green conference paper, blue journal paper):

1. Riet, E. van, Matousek, V. & Miedema, S.A., "A Reconstruction of and Sensitivity Analysis on the Wilson

Model for Hydraulic Particle Transport". Proc. 8th Int. Conf. on Transport and Sedimentation of Solid

Particles, 24-26 January 1995, Prague, Czech Republic.

2. Riet, E.J. van, Matousek, V. & Miedema, S.A., "A Theoretical Description and Numerical Sensitivity

Analysis on Wilson's Model for Hydraulic Transport in Pipelines". Journal of Hydrology &

Hydromechanics, Slovak Ac. of Science, Bratislava. Spring 1996.

3. Miedema, S.A., "Modeling and Simulation of the Dynamic Behavior of a Pump/Pipeline System". 17th

Annual Meeting & Technical Conference of the Western Dredging Association. New Orleans, June 1996.

4. Miedema, S.A., "A Numerical Method of Calculating the Dynamic Behaviour of Hydraulic Transport". 21st

Annual Meeting & Technical Conference of the Western Dredging Association, June 2001, Houston, USA

2001.

5. Miedema, S.A., & Riet, E.J. van, & Matousek, V., "Theoretical Description And Numerical Sensitivity

Analysis On Wilson Model For Hydraulic Transport Of Solids In Pipelines ". WEDA Journal of Dredging

Engineering, March 2002.

6. Ma, Y., Vlasblom, W.J., Miedema, S.A., Matousek, V., "Measurement of Density and Velocity in Hydraulic

Transport using Tomography". Dredging Days 2002, Dredging without boundaries, Casablanca, Morocco,

V64-V73, 22-24 October 2002.

7. Ma, Y., Miedema, S.A., Vlasblom, W.J., "Theoretical Simulation of the Measurements Process of Electrical

Impedance Tomography". Asian Simulation Conference/5th International Conference on System Simulation

and Scientific Computing, Shanghai, 3-6 November 2002, p. 261-265, ISBN 7-5062-5571-5/TP.75.

8. Ma, Y., Miedema, S.A., Matousek, V., Vlasblom, W.J., "Tomography as a Measurement Method for Density

and Velocity Distributions". 23rd WEDA Technical Conference & 35th TAMU Dredging Seminar, Chicago,

USA, June 2003.

9. Miedema, S.A., Lu, Z., Matousek, V., "Numerical Simulation of a Development of a Density Wave in a Long

Slurry Pipeline". 23rd WEDA Technical Conference & 35th TAMU Dredging Seminar, Chicago, USA, June

2003.

10. Miedema, S.A., Lu, Z., Matousek, V., "Numerical simulation of the development of density waves in a long

pipeline and the dynamic system behavior". Terra et Aqua, No. 93, p. 11-23.

11. Miedema, S.A., "An Analytical Method To Determine Scour". WEDA XXVIII & Texas A&M 39. St. Louis,

USA, June 8-11, 2008.

12. Ramsdell, R.C., Miedema, S.A., “Hydraulic transport of sand/shell mixtures”. WODCON XIX, Beijing China,

September 2010.

13. Miedema, S.A., “Constructing the Shields curve, a new theoretical approach and its applications”. WODCON

XIX, Beijing China, September 2010.

14. Miedema, S.A., “The effect of the bed rise velocity on the sedimentation process in hopper dredges”.

WODCON XIX, Beijing China, September 2010.

15. Miedema, S.A. & R.C. Ramsdell, "Hydraulic transport of sand/shell mixtures in relation with the critical

velocity". Terra et Aqua 122, March 2011, IADC, The Hague, The Netherlands.

16. Ramsdell, R.C. & Miedema, S.A., "Hydraulic transport of sand/shell mixtures". OMAE 2011 ASME, June

19-24, Rotterdam, The Netherlands.

17. Miedema, S.A., “Constructing the Shields curve”. OMAE 2011 ASME, June 19-24, Rotterdam, The

Netherlands.

18. Miedema, S.A., "Constructing the Shields Curve Part A: Fundamentals of the Sliding, Rolling and Lifting

Mechanisms for the Entrainment of Particles". Journal Of Dredging Engineering, Vol. 12, No. 1., 2012,

www.westerndredging.org.

19. Miedema, S.A., "Constructing the Shields Curve Part B: Sensitivity Analysis, Exposure and Protrusion Levels,

Settling Velocity, Shear Stress and Friction Velocity, Erosion Flux and Laminar Main Flow". Journal of

Dredging Engineering, Vol. 12, No. 1., 2012, www.westerndredging.org.

20. Ramsdell, R.C. & Miedema, S.A., “An Overview of Flow Regimes Describing Slurry Transport”. WODCON

XX, Brussels, Belgium, June 2013.

21. Miedema, S.A. & Ramsdell, R.C., “A Head Loss Model for Slurry Transport Based on Energy

Considerations”. WODCON XX, Brussels, Belgium, June 2013.

22. Miedema, S.A., “Constructing the Shields Curve, Part C: Cohesion by Silt”. WODCON XX, Brussels,

Belgium, June 2013.

23. Miedema S.A., “An Overview of Theories Describing Head Losses in Slurry Transport, A Tribute to Some of

the Early Researchers”. OMAE 2013, Nantes, France, June 2013.

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page 684 of 738 TOC Copyright © Dr.ir. S.A. Miedema

24. Miedema, S.A., “Constructing the Shields Curve, Part C: Cohesion by Silt, Hjulstrom, Sundborg”. OMAE

2013, Nantes, France, June 2013.

25. Miedema, S.A., “An Overview of Theories Describing Head Losses in Slurry Transport, A Tribute to Some

of the Early Researchers”. Journal of Dredging Engineering, Vol. 14, No. 1, 2014.

26. Miedema, S.A., “An Analysis of Slurry Transport at Low Line Speeds”. ASME-OMAE 2014, San Francisco,

USA, June 2014.

27. Miedema, S.A., Ramsdell, R.C., “An Analysis of the Hydrostatic Approach of Wilson for the Friction of a

Sliding Bed”. WEDA 34/TAMU 45, Toronto, Canada, June 2014.

28. Miedema, S.A. & Matousek V., “An explicit formulation for the Darcy-Weisbach friction factor of sheet

flow”. 15th International Freight Pipeline Society Symposium 2014. 24-26 June 2014, Prague, Czech

Republic.

29. Miedema, S.A., & Ramsdell, R.C., “The Delft Head Loss & Limit Deposit Velocity Model”. 19th International

Conference on HydroTransport. Denver, Colorado, USA, 24-26 September 2014.

30. Miedema, S.A., “Slurry Transport, an Analytical Approach to Explain the Fuhrboter Equation”. Maritime

Engineering Journal, Vol. 167, Issue 2, 2014, Special Dredging Issue.

31. Miedema, S.A., “A Head Loss Model for Homogeneous Slurry Transport”. Journal of Hydrology &

Hydromechanics, Vol. 63(1), 2015.

32. Miedema, S.A., ” Head Loss Model for Slurry Transport in the Heterogeneous Regime”. Journal of Ocean

Engineering Vol. 106, pp. 360-370, 2015.

33. Miedema, S.A. & Ramsdell, R.C., “The Limit Deposit Velocity, a New Approach”. Journal of Hydrology &

Hydromechanics, Vol. 63(4), 2015.

34. Miedema, S.A., “The Slip Ratio or Holdup Function in Slurry Transport". Dredging Summit & Expo,

Houston, USA, June 2015. WEDA/TAMU.

35. Ramsdell, R.C., & Miedema, S.A., “The Delft Head Loss & Limit Deposit Velocity Model”. Dredging 2015,

SavannaH, Georgia, USA. Pianc USA, Copri ASCE.

36. Miedema, S.A. “A Method to compare slurry transport models”. 17

th

International Conference: Transport &

Sedimentation of Solid Particles. September 22-25, 2015, Delft, The Netherlands.

37. Miedema, S.A. & Ramsdell, R.C., “The Delft Head Loss & Limit Deposit Velocity Framework”. Journal of

Dredging Engineering. Accepted October 2015.

38. Miedema, S.A. & Ramsdell, R.C., “A comparison of different slurry transport models”. WODCON XXI,

Miami, USA, June 2016.

39. Ramsdell, R.C. & Miedema, S.A., “DHLLDV – Open Source Software for Slurry Transport”. WODCON

XXI, Miami, USA, June 2016.

40. Miedema, S.A., “The Transition Heterogeneous-Homogeneous in Slurry Transport”. Journal of Ocean

Engineering. Submitted January 2016.

Bibliography.

Copyright © Dr.ir. S.A. Miedema TOC Page 685 of 738

Chapter 12: Bibliography.

Abulnaga, B. E. (2002). Slurry Systems Handbook. USA: McGraw Hill.

Azamathulla, H. M., & Ahmad, Z. (2013). Estimation of critical velocity for slurry transport through pipeline using

adaptive neuro-fuzzy interference system and gene-expression programming. Journal of Pipeline Systems

Engineering and Practice., 131-137.

Babcock, H. A. (1970). The sliding bed flow regime. Hydrotransport 1 (pp. H1-1 - H1-16). Bedford, England:

BHRA.

Bagnold, R. A. (1954). Experiments on a gravity free dispersion of large solid spheres in a Newtonian fluid under

shear. Proceedings Royal Society, Vol. A225., 49-63.

Bagnold, R. A. (1957). The flow of cohesionless grains in fluids. Phil. Trans. Royal Society, Vol. A249, 235-297.

Bain, A. G., & Bonnington, S. T. (1970). The hydraulic transport of solids by pipeline. Pergamon Press.

Berg, C. H. (1998). Pipelines as Transportation Systems. Kinderdijk, the Netherlands: European Mining Course

Proceedings, IHC-MTI.

Berg, C. v. (2013). IHC Merwede Handbook for Centrifugal Pumps & Slurry Transportation. Kinderdijk,

Netherlands: IHC Merwede.

Berman, V. P. (1994). Gidro i aerodinamiceskie osnovy rascota truboprovodnych sistem gidrokontejnernogo i

vysokonapornogo pnevmaticeskogo transporta. Lugansk: East Ukrainian State University.

Bisschop, F., Miedema, S. A., Rhee, C. v., & Visser, P. J. (2014). Erosion experiments on sand at high velocities.

To be submitted to the Journal of Hydraulic Engineering, 28.

Blatch, N. S. (1906). Discussion of Works for the purification of the water supply of Washington D.C.

Transactions ASCE 57., 400-409.

Blythe, C., & Czarnotta, Z. (1995). Determination of hydraulic gradient for sand slurries. 8th International Freight

Pipeline Society Symposium, (pp. 125-130). Pittsburg, USA.

Bonneville, R. (1963). essais de synthese des lois debut d'entrainment des sediment sous l'action d'un courant en

regime uniform. Chatou: Bulletin Du CREC, No. 5.

Bonnington, S. T. (1961). Estimation of Pipe Friction Involved in Pumping Solid Material. BHRA, TN 708

(December 1961).

Boothroyde, J., Jacobs, B. E., & Jenkins, P. (1979). Coarse particle hydraulic transport. Hydrotransport 6: 6th

International Conference on the Hydraulic Transport of Solids in Pipes. (p. Paper E1). BHRA.

Brauer, H. (1971). Grundlagen der einphasen- und mehrphasenstromungen. Verslag Sauerlander.

Brooks, F. A., & Berggren, W. (1944). Remarks on turbulent transfer across planes of zero momentum exchange.

Transactions of the American Geophysics Union, Pt. VI., 889-896.

Brownlie, W. (1981). Compilation of alluvial channel data: laboratory and field, Technical Report KH-R-43B.

Pasadena, California, USA: California Institute of Technology.

Buffington, J. M. (1999). The legend of A.F. Shields. Journal of Hydraulic Engineering, 125, 376–387.

Buffington, J. M., & Montgomery, D. R. (1997). A systematic analysis of eight decades of incipient motion studies,

with special reference to gravel-bedded rivers. Water Resources Research, 33, 1993-2029.

Camenen, B., & Larson, M. (2013). Accuracy of Equivalent Roughness Height Formulas in Practical Applications.

Journal of Hydraulic Engineering., 331-335.

Camenen, B., Bayram, A. M., & Larson, M. (2006). Equivalent roughness height for plane bed under steady flow.

Journal of Hydraulic Engineering, 1146-1158.

Charles, M. E. (1970). Transport of solids by pipeline. Hydrotransport 1. Cranfield: BHRA.

Chaskelberg, K., & Karlin. (1976). Rascot gidrotransporta pesanych materialov. Moskov: Gidromechanizacija.

Chepil, W. (1958). The use of evenly spaced hemispheres to evaluate aerodynamic force on a soil failure.

Transaction of the American Geophysics Union, Vol. 39(3), 397-404.

Chin, C. O., & Chiew, Y. M. (1993). Effect of bed surface structure on spherical particle stability. Journal of

Waterway, Port, Coastal and Ocean Engineering, 119(3), 231–242.

Clift, R., Wilson, K. C., Addie, G. R., & Carstens, M. R. (1982). A mechanistically based method for scaling

pipeline tests for settling slurries. Hydrotransport 8 (pp. 91-101). Cranfield, UK.: BHRA Fluid

Engineering.

Clift, R., Wilson, K., Addie, G., & Carstens, M. (1982). A mechanistically based method for scaling pipeline tests

for settling slurries. Hydrotransport 8 (pp. 91-101). Cranfield, UK.: BHRA.

Colebrook, C. F., & White, C. M. (1937). Experiments with Fluid Friction in Roughened Pipes. Proceedings of

the Royal Society of London. Series A, Mathematical and Physical Sciences 161 (906). (pp. 367-381).

London: Royal Society of London.

Coleman, N. L. (1967). A theoretical and experimental study of drag and lift forces acting on a sphere resting on

a hypothetical stream bed. International Association for Hydraulic Research,12th Congress, 3, pp. 185-

192.

Slurry Transport: Fundamentals, Historical Overview & DHLLDV.

Page 686 of 738 TOC Copyright © Dr.ir. S.A. Miedema

Condolios, E., & Chapus, E. E. (1963A). Transporting Solid Materials in Pipelines, Part I. Journal of Chemical

Engineering, Vol. 70(13)., 93-98.

Condolios, E., & Chapus, E. E. (1963B). Designing Solids Handling Pipelines Part II. Journal of Chemical

Engineering, Vol. 70(14)., 131-138.

Condolios, E., & Chapus, E. E. (1963C). Operating solids pipelines, Part III. Journal of Chemical Engineering,

Vol. 70(15)., 145-150.

Crowe, C. T. (2006). MultiPhase Flow Handbook. Boca Raton, Florida, USA: Taylor & Francis Group.

Davies, J. T. (1987). Calculation of critical velocities to maintain solids in suspension in horizontal pipes. Chemical

Engineering Science, Vol. 42(7)., 1667-1670.

Dey, S. (1999). Sediment threshold. Applied Mathematical Modelling, 399-417.

Dey, S. (2003). Incipient motion of bivalve shells on sand beds under flowing water. Journal of Hydraulic

Engineering, 232-240.

Dey, S. (2014). Fluvial Hydrodynamics. Kharagpur, India: Springer, GeoPlanet: Earth and Planetary Sciences.

DHL. (1972). Systematic Investigation of Two Dimensional and Three Dimensional Scour, Report M648/M863.

Delft, Netherlands: Delft Hydraulics Laboratory.

Di Filice, R. (1999). The sedimentation velocity of dilute suspensions of nearly monosized spheres. International

Journal of Multiphase Flows 25, 559-574.

Dittrich, A., Nestmann, F., & Ergenzinger, P. (1996). Ratio of lift and shear forces over rough surfaces. Coherent

flow structures in open channels., 126-146.

Doron, P., & Barnea, D. (1993). A three layer model for solid liquid flow in horizontal pipes. International Journal

of Multiphase Flow, Vol. 19, No.6., 1029-1043.

Doron, P., & Barnea, D. (1995). Pressure drop and limit deposit velocity for solid liquid flow in pipes. Chemical

Engineering Science, Vol. 50, No. 10., 1595-1604.

Doron, P., & Barnea, D. (1996). Flow pattern maps for solid liquid flow in pipes. International Journal of

Multiphase Flow, Vol. 22, No. 2., 273-283.

Doron, P., Granica, D., & Barnea, D. (1987). Slurry flow in horizontal pipes, experimental and modeling.

International Journal of Multiphase Flow, Vol. 13, No. 4., 535-547.

Doron, P., Simkhis, M., & Barnea, D. (1997). Flow of solid liquid mixtures in inclined pipes. International Journal

of Multiphase Flow, Vol. 23, No. 2., 313-323.

Duckworth, & Argyros. (1972). Influence of density ratio on the pressure gradient in pipes conveying suspensions

of solids in liquids. Hydrotransport 2. Coventry: BHRA.

Durand, R. (1953). Basic Relationships of the Transportation of Solids in Pipes - Experimental Research.

Proceedings of the International Association of Hydraulic Research. Minneapolis.

Durand, R., & Condolios, E. (1952). Etude experimentale du refoulement des materieaux en conduites en

particulier des produits de dragage et des schlamms. Deuxiemes Journees de l'Hydraulique., 27-55.

Durand, R., & Condolios, E. (1956). Donnees techniques sur le refoulement des mixture en conduites. Revue de

lÍndustriele Minerale, no. 22F, 460-481.

Durand, R., & Condolios, E. (1956). Technical data on hydraulic transport of solid materials in conduits. Revue

de L'Industrie Minerale, Numero Special 1F.