Guidance Notes On

Data Integrity for Marine and Offshore

Operations

ABS CyberSafety

™

Volume 3

September 2016

GUIDANCE NOTES ON

DATA INTEGRITY FOR MARINE AND OFFSHORE

OPERATIONS

SEPTEMBER 2016

ABS CYBERSAFETY

™

VOLUME 3

American Bureau of Shipping

Incorporated by Act of Legislature of

the State of New York 1862

© 2016 American Bureau of Shipping. All rights reserved.

ABS Plaza

1701 City Plaza Drive

Spring, TX 77389 USA

Foreword

The marine and offshore industries are integrating connected sensors, communications, storage and

processing capabilities into vessels, offshore units and facilities as networking and computational power

penetrates all aspects of industry operations. The “Big Data” phenomenon has emerged as a direct result of

this growth, enabling development of tremendous new sources of data and information. But challenges

have also emerged. Sensors and data must be trustworthy in order to support the new analytic and decision

methods available for maritime industry use.

These Guidance Notes are intended to clarify the basic principles and concepts of Data Integrity for marine

and offshore assets. The document is intended to help the industry realize the new benefits from data

sources and data analytics systems via implementation of Data Integrity concepts. It also supports owners

who are increasingly required to provide data reporting to regulatory agencies. The intended users for these

Guidance Notes are cybersecurity specialists, data specialists, owners, shipyards, operators, designers,

suppliers, review engineers and Surveyors.

These Guidance Notes are Volume 3 of the ABS CyberSafety

TM

series, and are intended to be used in

conjunction with other volumes.

These Guidance Notes become effective on the first day of the month of publication.

Users are advised to check periodically on the ABS website www.eagle.org to verify that this version of

these Guidance Notes is the most current.

We welcome your feedback. Comments or suggestions can be sent electronically by email to

Terms of Use

The information presented herein is intended solely to assist the reader in the methodologies and/or

techniques discussed. These Guidance Notes do not and cannot replace the analysis and/or advice of a

qualified professional. It is the responsibility of the reader to perform their own assessment and obtain

professional advice. Information contained herein is considered to be pertinent at the time of publication,

but may be invalidated as a result of subsequent legislations, regulations, standards, methods, and/or more

updated information and the reader assumes full responsibility for compliance. This publication may not be

copied or redistributed in part or in whole without prior written consent from ABS.

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 ii

CONTENTS

SECTION 1 General..................................................................................................6

1 Purpose and Scope........................................................................ 6

3 Data Lifecycle Management........................................................... 7

5 Outline............................................................................................ 8

7 Definitions.......................................................................................9

9 Abbreviations and Acronyms........................................................ 10

11 References................................................................................... 12

11.1 ABS..................................................................................12

11.3 IEEE.................................................................................12

11.5 ISO...................................................................................12

11.7 Other................................................................................12

FIGURE 1 Data Source and Flow............................................................7

FIGURE 2 Data Lifecycle Management...................................................8

FIGURE 3 Guidance Notes Outline.........................................................9

SECTION 2 Data Sources...................................................................................... 13

1 General.........................................................................................13

3 Raw Data Input.............................................................................14

3.1 Data from Sensors (Raw/Unconditioned)........................ 14

5 Organized Data Sources (Information)......................................... 14

5.1 Data from Databases.......................................................14

5.3 Data Traces from Identified Equipment or Systems........ 14

5.5 Data from Industrial Internet-of-Things (IIoT).................. 15

7 Conditioned Data Sources (Knowledge).......................................16

7.1 Data Conditioned for Machine Interpretation/Use............16

7.3 Data Conditioned for Human Interpretation/Use..............16

9 Actionable Data Sources (Applied Knowledge)............................ 17

9.1 Manual Systems Control..................................................17

9.3 Mechanized System Control............................................17

GUIDANCE NOTES ON

DATA INTEGRITY FOR MARINE AND OFFSHORE

OPERATIONS

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 iii

9.5 Automated System Control..............................................17

9.7 Analysis........................................................................... 18

FIGURE 1 Data Source Model.............................................................. 13

FIGURE 2 Various Sensors................................................................... 14

FIGURE 3 Industrial Internet-of-Things (IIoT)........................................16

SECTION 3 Data Uses............................................................................................19

1 Monitoring for Situational Awareness........................................... 19

3 Monitoring for Intervention............................................................ 19

5 Monitoring by Regulatory Bodies..................................................19

7 Input to Control Systems.............................................................. 19

9 Input to Analysis and Patterning................................................... 20

11 Input for Maintenance...................................................................20

SECTION 4 Data Importance.................................................................................21

1 Data Integrity and Vessel Operations........................................... 21

3 Data Integrity and Business Strategy Development..................... 22

5 Data Integrity and Integrated System Support..............................22

7 Data Integrity and Compliance Reporting.....................................22

SECTION 5 Data Security...................................................................................... 23

1 Data Types/Protocols....................................................................23

1.1 Serial Data....................................................................... 23

1.3 Bus Data.......................................................................... 24

1.5 Streaming Data................................................................25

3 Data Classification (Protection Level)...........................................26

5 Data At-Rest (DAR)...................................................................... 29

7 Data In-Motion (DIM).................................................................... 29

9 Data In-Use (DIU)......................................................................... 30

9.1 Authorized Access Only...................................................30

9.3 Penetration Protection..................................................... 30

9.5 Handling Policies and Procedures...................................30

11 Security Measures and Controls...................................................30

TABLE 1 Data Types........................................................................... 23

TABLE 2 Data Classification............................................................... 27

FIGURE 1 Serial Data Illustration..........................................................24

FIGURE 2 Bus Data Illustration.............................................................25

FIGURE 3 Streaming Data Illustration...................................................26

FIGURE 4 Data Classification............................................................... 28

FIGURE 5 Three States of Data............................................................29

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 iv

SECTION 6 Data Integrity...................................................................................... 31

1 General.........................................................................................31

1.1 Definition..........................................................................31

1.3 Data Integrity and Data Security......................................32

3 Maintain Data Integrity from Traceable/Trustworthy Data

Source.......................................................................................... 32

3.1 Origin: Supplier and Sensor Accuracy.............................32

3.3 Organization: Data Schema Transformation Accuracy....33

3.5 Transmission: Transfer from Point of Use Accuracy

and Timing....................................................................... 35

5 Protect Data Integrity from Unintended and Intended

Modification...................................................................................37

5.1 Protection against Accidental Integrity Loss.................... 37

5.3 Best Practices for Intended (Beneficial) Integrity Loss.... 38

5.5 Preventive Actions Against Intended (Malicious)

Integrity Loss................................................................... 39

7 Monitor, Verify, Validate and Measure Data Integrity.................... 39

7.1 Data Integrity Monitoring (Overall System of Systems)... 39

7.3 Verification and Validation of Data Integrity..................... 40

7.5 Measurement of Data Integrity........................................ 41

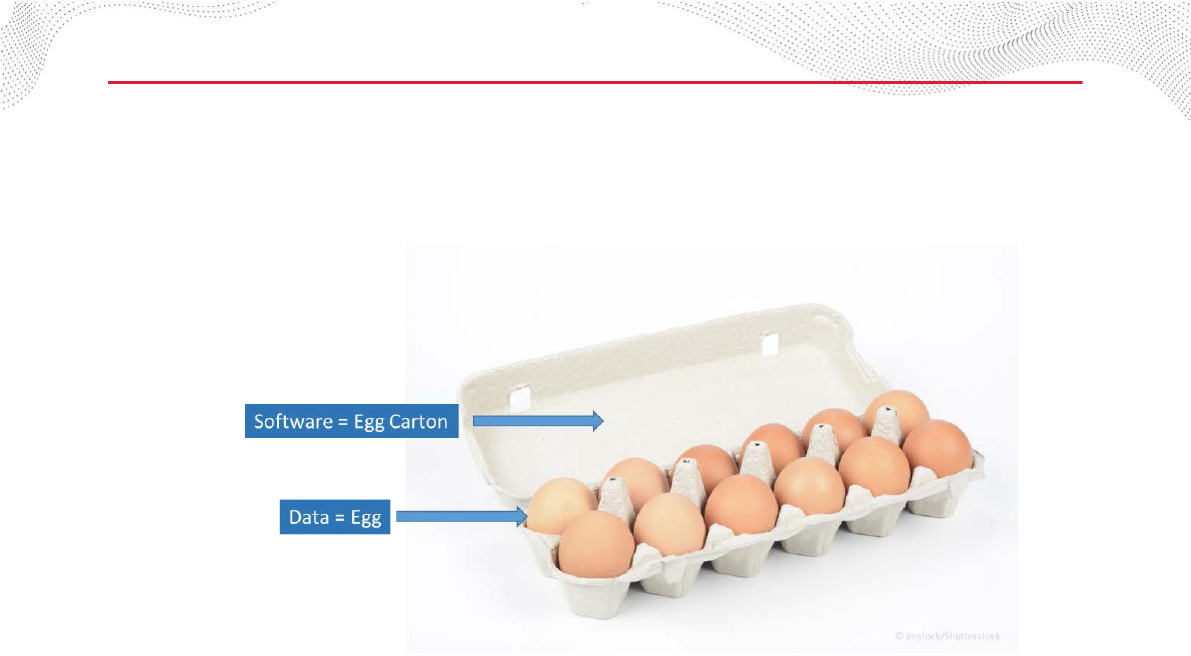

FIGURE 1 Data Schema....................................................................... 34

FIGURE 2 Data and Software Relationship...........................................35

FIGURE 3 Authentication, Authorization and Accounting......................37

FIGURE 4 Notional System of Systems Onboard Vessel......................40

FIGURE 5 Gauged System Value......................................................... 42

FIGURE 6 Gauged Incident Value and Corruption Vector Index........... 43

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 v

S E C T I O N 1

General

1 Purpose and Scope

The maritime industry is beginning to use data as an asset. Historically, marine and offshore owners’ and

operators’ major concerns were safety, asset integrity, and environmental protection. Increased presence

and use of cyber-enabled data systems introduces data as both an enabler to address safety risks and as

another area for concern. Vessels and their sensors generate large amounts of data from multiple sources.

Note:

The general term “vessel” used throughout these Guidance Notes denotes a ship, a barge, an offshore unit or facility, or any

other floating or fixed structure.

Section 1, Figure 1 illustrates nominal data sources and flows in marine and offshore operations. Three

typical data sources and paths include:

●

Data Generated and Communicated Locally. With the development of modern electronics and control

technologies, extensive data can be generated and captured. The data covers a wide range of on-

onboard systems and instruments, both from permanently-installed equipment and from cargo or

portable equipment.

●

Data Communicated between Vessels. The data communicated between vessels could be vessel status

such as position, speed, direction, etc., but it may also include performance data, cargo carriage data,

rig operational status data, or other raw or composite data sources.

●

Data Communicated between Shore and Vessel. Operational, performance, and commercial data may

come from shore-based systems as well as onboard systems. Data transferred from vessel to shore for

data processing such as fleet management and benchmarking and maintenance management.

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 6

FIGURE 1

Data Source and Flow

Data may be used for many functions beyond the traditional domains – for health and performance

monitoring, operation, accomplishment prediction, business decision support, and others. New technical

sources of data imply greater concern for data integrity and data security. Trustworthiness of data is vital to

decision processes and to decision support.

These Guidance Notes are intended to clarify the concept and principles of Data Integrity for Marine and

Offshore operations. The document will address data integrity as it relates to asset safety including human

safety, safety of the vessel and/or threat to the environment. The objective of these Guidance Notes is to

help the review engineers, surveyors, suppliers, shipyards, owners and operators to understand the

application of Data Integrity in marine and offshore operations. The practices described in these Guidance

Notes will improve the integrity of data.

3 Data Lifecycle Management

Data Lifecycle Management is illustrated in Section 1, Figure 2. The focus of this document is the security

and integrity of the data management lifecycle. These Guidance Notes do not encompass all phases of the

data lifecycle, but rather are directed at data source, data use, and data verification from the perspective of

data security and data integrity.

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 7

FIGURE 2

Data Lifecycle Management

5

Outline

The outline of these Guidance Notes is illustrated in Section 1, Figure 3. The outline indicates the

development plan for these Guidance Notes. It shows how to characterize data, how to secure data, and

how to maintain data integrity.

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 8

FIGURE 3

Guidance Notes Outline

Note:

V & V: Verification and Validation

7 Definitions

The following definitions are applied to the terms used in these Guidance Notes.

Access Control: Means to ensure that access to assets is authorized and restricted based on business and

security requirements. [ISO/IEC 27000: Information technology – Security techniques – Information

security management systems – Overview and vocabulary]

Bus Data: Data transmitted among multi-point networks.

CANbus: The data link layer of CAN; open transmitting of data between equipment, system controllers and

data analyzers.

Chain of Custody (CoC): Chronological documentation, showing the seizure, custody, control, transfer,

analysis, and disposition of physical or electronic evidence.

Data At-Rest (DAR): Data that resides in storage (a device or backup medium in any form) but excludes

any data frequently transferred in the network or residing in temporary memory.

Data In-Motion (DIM): Data in transit, traveling across a network or contained in a computer’s RAM

ready to be read, updated, or processed.

Data Integrity: Accuracy, consistency (validity), and completeness of data over its lifecycle.

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 9

Data In-Use (DIU): Data that is being processed by one or more applications.

Data Schema: Skeleton structure that represents the logical view of the entire database.

Data Security: Protecting data from the unwanted actions of unauthorized users.

Database: An organized collection of data.

Integrity Level: A number assigned by an Owner and/or Driller or Crew Organization (DCO) to a

computer-based function based upon the severity of the consequence of a failure of the function. Where 0

has little consequence to 3 where the consequence of a function failure is of significant concern. For

control systems refer to ABS Guide for Integrated Software Quality Management (ISQM Guide).

MODBUS: A common serial communications protocol for connecting industrial electronic devices such as

sensors and programmable logic controllers (PLCs).

Penetration Test: Testing that places an attack on a computer system looking for security weaknesses and

potentially gaining access to the computer’s features and data.

PROFIBUS: PROFIBUS (Process Field Bus) is a standard for fieldbus communication in automation

technology.

Sensor: An electronic device that produces electrical, optical, or digital data derived from a physical

condition or event. [IEEE 1451: IEEE Standard for a Smart Transducer Interface for Sensors and

Actuators]

Serial Data: Data transmitted in serial communication.

Software Management of Change (SMOC): The process of how to manage software changes or software

evolution.

Streaming Data: Sequence of message-oriented data in-sequence used to transmit or receive information in

a real-time application among the networks.

System of Systems: Vessels with multiple existing standalone and networked systems.

9 Abbreviations and Acronyms

The following abbreviations and acronyms are applied to the terms used in these Guidance Notes.

AAA: Authentication, Authorization, and Accounting

ABS: American Bureau of Shipping

ACLs: Access Control Lists

ARQ: Automatic Repeat Request

BSEE: Bureau of Safety and Environmental Enforcement

CRCs: Cyclic Redundancy Checks

CPU: Central Processing Unit

DAR: Data At-Rest

DCO: Driller or Crew Organization

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 10

DCS: Distributed Control System

DIM: Data In-Motion (equivalent to Data In-Transit)

DIU: Data In-Use

DP and DPS: Dynamic Positioning (Systems)

ECC: Error-Correcting Code

ERP: Enterprise Resource Planning

FDD: Functional Description Document

FEC: Forward Error Correction

HMI: Human Machine Interface

ICS: Industrial Control System

IIoT: Industrial Internet of Things

IoT: Internet of Things

IP: Internet Protocol

NAC: Network Access Control

OEM: Original Equipment Manufacturer

PC: Personal Computer

PLC: Programmable Logic Controller

PMS: Power Management System

RAID: Redundant Array of Independent Disks

RTD: Resistance Temperature Detectors

SAN: Storage Area Network

SCADA: Supervisory Control and Data Acquisition

SIS: Safety Instrumented Systems

SMOC: Software Management of Change

SoS: System of Systems

USB: Universal Serial Bus

USCG: United States Coast Guard

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 11

11 References

11.1 ABS

ABS Guidance Notes on Application of Cybersecurity Principles to Marine and Offshore Operations –

ABS CyberSafety

TM

Volume 1

ABS Guide for Cybersecurity Implementation for the Marine and Offshore Operations – ABS

CyberSafety

TM

Volume 2

ABS Guide for Software Systems Verification – ABS CyberSafety

TM

Volume 4

ABS Guidance Notes on Software Provider Conformity Program – ABS CyberSafety

TM

Volume 5

ABS Guidance Notes on Equipment Condition Monitoring Techniques

ABS Guidance Notes on Failure Mode and Effects Analysis (FMEA) for Classification

ABS Guidance Notes on Risk Assessment Applications for the Marine and Offshore Industries

ABS Guide for Hull Condition Monitoring Systems

ABS Guide for Integrated Software Quality Management

ABS Guide for Surveys Using Risk-Based Inspection for the Offshore Industry

ABS Rules for Building and Classing Marine Vessels

11.3 IEEE

IEEE 1451: IEEE Standard for a Smart Transducer Interface for Sensors and Actuators

IEEE 1012 – 2004, IEEE Standard for Software Verification and Validation

11.5 ISO

ISO/IEC 27000: Information technology - Security techniques - Information security management systems

- Overview and vocabulary

ISO/IEC 27001: Information technology – Security techniques - Information security management systems

- Requirements

ISO/IEC 27002: Information technology – Security techniques - Code of practice for information security

controls

11.7 Other

National Institute for Science and Technology (NIST) Guide to Storage Encryption Technologies for End

User Devices

Section 1 General 1

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 12

S E C T I O N 2

Data Sources

1 General

For assets in the marine and offshore industries, data processing starts with the collection of data at the

sensor level. Examples of data include location, direction and speed, hull structural stresses encountered,

vessel motions, engine performance, equipment status, and environmental conditions. At this stage, both

structured and unstructured data is collected. Structured data is formatted for use in specific systems, such

as in transaction databases. Unstructured data may be data streams, messages, documents or other data

types or artifacts that may be stored by means other than in a transaction database.

Massive quantities of “random” data of sensed behavior are electronically transformed into organized data,

then into knowledge, and finally into purposeful actionable knowledge. Typically, an enterprise will

organize its data across many different systems and applications. Graphically, the data source model’s

fundamentals are shown in Section 2, Figure 1 below.

FIGURE 1

Data Source Model

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 13

3 Raw Data Input

3.1 Data from Sensors (Raw/Unconditioned)

Sensors are the eyes and ears of ship automation and condition and performance monitoring, and are

located in multiple locations and systems onboard the vessel. As the first stage of data sources, a sensor is

an electronic device that produces electrical, optical, or digital data derived from a physical condition or

event. Data produced from sensors is then electronically transformed into more organized output that can

later be correlated as system information.

Enormous amounts of measurement instrumentation have been incorporated in modern machinery control

systems, including temperature sensors, pressure sensors, flow sensors, vibration sensors, current sensors,

and many more. They come in the form of mechanical gauges, electrical meters, transducers,

thermocouples, resistance temperature detectors (RTD), etc. Section 2, Figure 2 below illustrates

representative samples of common sensors used onboard vessels.

FIGURE 2

Various Sensors

The information gained from the sensors is considered raw data without any conditioned process. At this

stage, the raw data is neither conditioned nor organized, which means the data cannot be directly used.

5 Organized Data Sources (Information)

5.1 Data from Databases

A database is a collection of data and information that is organized so that it can easily be accessed,

managed, and updated. It can be a collection of schemas, tables, queries, reports, views and other objects.

The data is typically organized to model the aspects of reality in a way that supports processes requiring

information. Databases are used to support internal operations of organizations, and to hold administrative

information and specialized data.

5.3 Data Traces from Identified Equipment or Systems

Sensor devices provide performance or status information to operators, and they are essential for

controlling equipment operation, providing alarms, or triggering equipment safety features, such as

automatic shutdowns, alerting a degradation on condition or performance for action by the maintenance

team. The engineering data onboard ship is used for machinery control decisions that may be performed by

'intelligent' devices or people.

The organized data is seeing a possible “tiered approach” to analytics. It can be from parameter level, to

equipment level, to system level, then to the holistic level overarching at vessel. An example is found in

shipboard engines. Leading engine manufacturers have transformed their operations through Engine

Section 2 Data Sources 2

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 14

Condition Monitoring. From approximately one hundred sensors on each engine, they receive real-time

performance data at central monitoring centers. Detailed information may be found in Norris, G. (2015,

October 28), Designing High-Tech Engines for Easier Maintenance, Aviation Week & Space Technology.

In an electrical propulsion system, data generated from sensors is required for monitoring and control use.

For example, bearing lube oil inlet pressure, voltage, frequency, current, stationary windings temperature,

field voltage and current are the data collected and traced from the sensors for the propulsion generator

system. Each of the data streams can be identified from certain equipment or system.

A Dynamic Positioning (DP) vessel has its own DP sensor network. It is a system comprising devices that

measure vessel heading (such as gyrocompasses or inertial navigation systems), vessel motions (such as

motion reference units), wind speed and direction, propulsion machinery system, and thruster system.

5.5 Data from Industrial Internet-of-Things (IIoT)

To date, the internet has primarily served as communication between humans, particularly in its application

in the World Wide Web, email, and social media etc. The Industrial Internet-of-Things (IIoT), simply refers

to Internet-enabled communication between non-human entities, such as devices and equipment, with data

storage, applications and computers. The idea is that items as diverse as temperature sensors and washing

machines can easily connect to Internet Protocol (IP) networks and communicate data about their own

condition or what they are measuring, and they may also respond to external requests for data and

actuation of certain commands.

The IIoT focuses strongly on intelligent cyber-physical systems. These systems comprise machines

connected to computers that interpret, analyze and make decisions almost instantly based on sensor data

from many widely distributed sources. IIoT-enabled devices activate when certain conditions arise and

send alerts and associated data about emerging conditions which may require a response. For example, one

situation might be that a thruster in a Dynamic Positioning System (DPS) may notice significantly different

excursions on a semi-submersible drilling platform compared to other thrusters. This anomaly would

initially be detected by communication and self-diagnostic analysis between the thrusters. When deviations

beyond certain acceptable tolerances are noticed, an alert can be issued to a central control center for

human oversight and intervention. Associated diagnostic data can also be provided for further analysis and

the root cause of the problem confirmed and/or resolved. In a DPS, like many others, a safe limit on how

much is controlled by computer must be carefully considered.

The advent of IIoT has spurred the creation of more and more intelligent machines that interact with other

machines, with their environments, with data centers and with humans. As illustrated in Section 2, Figure

3, the three main components of an IIoT system are:

●

Things: Device, sensors & actuators

●

Connections: Local network, Internet

●

Data: Information

Section 2 Data Sources 2

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 15

FIGURE 3

Industrial Internet-of-Things (IIoT)

It is important that connections, communications and access to IP-enabled sensors and systems that are

considered components of the Industrial Internet of Things (IIoT) are specifically addressed as part of the

Operational Technology (OT) security measures onboard any ship, asset or facility. Remote accessibility to

IIoT devices must be controlled carefully, as these devices are expected to be standalone, sealed, never-

updated network participants, meaning that they can become conduits into primary networks if left

exposed to unauthorized communications. These devices and similar systems are addressed in the

specification of Protect Operational Technology in Section 5, Capability (17) of the ABS Guide for

Cybersecurity Implementation for the Marine and Offshore Operations – ABS CyberSafety

TM

Volume 2

(Cybersecurity Guide).

7 Conditioned Data Sources (Knowledge)

Data conditioning is the processing of data in a way that prepares it for the next stage of processing. Many

applications involve environmental or structural measurement, such as temperature, pressure, level and

vibration, from sensors. These conditioned data sources contain knowledge and meaningful information

and feed for either machine interpretation or human interpretation.

By use of data management and optimization techniques, data conditioning will lead to intelligent routing,

optimization and protection of data for data transmission or storage in a computer system.

7.1 Data Conditioned for Machine Interpretation/Use

Normally, the data conditioning process intended for machine use includes amplification, filtering,

attenuation and isolation. For example, thermocouple signals have very small voltage levels that must be

amplified before they can be digitized. Other sensors, such as resistance temperature detectors (RTDs),

thermistors, strain gages, and accelerometers, require excitation to operate.

The machine uses the conditioned data to implement certain functions. For example, the air conditioning

system uses the thermo-sensors conditioned data (such as digitized signal) to automatically control the

room temperature.

7.3 Data Conditioned for Human Interpretation/Use

Algorithms, parameters, limits, stochastics, and statistics can be applied as applicable to aid operators in

assessing machinery conditions; such as satisfactory operation, impending degradation, and prognostics or

forecasting. Data conditioned for human use may include trend analysis visualizations, short-term

performance parameter alerting, and similar reporting that can accelerate human decision making by

reducing the steps required to interpret the aggregated data.

Section 2 Data Sources 2

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 16

9 Actionable Data Sources (Applied Knowledge)

The last stage on the peak of the data sources model is the actionable data sources which includes the

applied knowledge. The applied knowledge contained in the data is actually applied to the system to

control the outcomes and for health and performance monitoring where it may be provided by a 3

rd

party

vendor. At this stage, the data quantity has been significantly decreased compared to the previous process.

9.1 Manual Systems Control

Manual system control requires that a human operator be involved in all controlling activities in order to

perform system functions. In these systems, the operator alone senses control data, makes control

decisions, and implements the control actions without support by mechanical or computerized equipment.

On contemporary offshore assets, very few control systems are purely manual. The most common

application of actionable data is in automated control, discussed in 2/9.5 below.

Onboard the vessel, the operator can view the automated control systems from diesel engine control to

power management system, from alarm and monitoring system to DP control system. Programmable Logic

Controller (PLC), Distributed Control System (DCS) and Supervisory Control and Data Acquisition

(SCADA) systems are commonly used in automatic control systems. The actionable data sources play key

roles in these automated systems. For example, a DP control system aggregates multiple actionable data

sources to implement the automatic control required in dynamic positioning operations.

9.3 Mechanized System Control

Mechanized system control commonly requires the support of computerized data. A large number of

mechanized control systems are in place on contemporary offshore assets.

Mechanized control systems are simply systems that incorporate mechanical and digital machines to

augment human strength, intelligence, and judgment in order to control equipment. Systems that require

mechanized support to enable control commonly provide a combination of mechanical, electric, hydraulic,

pneumatic, or computerized controllers. No matter the type of control augmentation, the human operator is

an essential “component” of the control system. In contrast, manual systems and their control depend

solely on the strength, knowledge, and judgment of an operator without the benefit of the augmentation

described above. Fully automated systems can operate without the presence of a human operator.

Mechanized control system architectures that include computerized controllers, commonly rely on digital

data in order to function. The integrity of digital data supporting computer-augmented mechanized control

systems for critical functions is to be protected.

9.5 Automated System Control

Automated system control is increasingly present on contemporary offshore assets. A significant number

of sophisticated drilling control systems have been placed in drilling platforms.

The automated control system uses control theory for regulation of processes without direct human

intervention. Such systems require the least human operator involvement. Without human operator

presence, automated systems and their control depend on sensors, transducers, transmitters, controllers and

final control elements. In the simplest type of an automatic closed loop control, a controller compares a

measured value of a process with a desired set value, and processes the resulting error signal to change the

input to the process, in such a way that the process stays at its set point despite disturbances.

Automated control systems rely heavily on timely and accurate digital data in order to function. The

integrity of digital data supporting software based on automated control for critical functions must be

protected if the system is to operate reliably and correctly.

Some examples of automated control systems onboard vessels include diesel engine control, power

management systems, alarm and monitoring systems, and DP control systems.

Section 2 Data Sources 2

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 17

9.7 Analysis

Conditioned data may support data analysis applications in certain situations. Such systems come in many

forms, means of implementation, comprehensiveness, and off vessel communication capability. Such

applications may be as simple as a single machine Original Equipment Manufacturer (OEM)-provided

diagnostics package on an engine (a common example), or they may be implemented at the system or asset

level by a separate data analytics vendor who is tapping into a myriad of data streams coming from

automation systems (operational data) or condition or environmental monitoring sensors or devices. Such

data is then collected and analyzed at the asset level for diagnosis/prognosis of systems or vessel health

and performance states.

One example in the marine and offshore world is the vessel hull and systems condition data that have been

continuously used as key performance analysis indicators. Hull monitoring systems continuously collect

the data used for motion, stress and voyage applications. Both unprocessed, collected data and summary

trend reporting are used for immediate interpretation of processed data and for subsequent longer-term

evaluation by vessels’ operating personnel. Conditioned, measured data can also be used for safety

assessment and analysis. Such data can lead to better drydock and survey planning. It can also provide

better understanding of damage accumulation and thus the prevalence of fatigue in certain prone locations,

which also feeds better survey and drydock planning.

In a propulsion system, for example, historical maintenance and failure records would be within the scope

of data to be included. Engine utilization and power settings, particularly just prior to the occurrence of

functional or performance issues or failures, would be useful information to understand how the failure

relate correlates to the Maximum Continuous Power Rating and operating times (i.e., operating profile).

Pump performance data (e.g., flow rates, temperatures, pressures), particularly issues just prior to the

occurrence of failures, would be useful in developing an improved operating profile.

On legacy assets, often those systems involved the addition of sensors, communication and wiring, and the

typing into a new data collection historian or similar device.

Section 2 Data Sources 2

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 18

S E C T I O N 3

Data Uses

This Section covers how collected data can be used and applied to improve asset performance.

1 Monitoring for Situational Awareness

Data monitoring can provide situational awareness. For example, all monitored real-time data is typically

transferred and displayed in the ship’s bridge so that the Master is aware of health measures on the vessels.

These data could contain weather, engine, power and vessel health and performance conditions.

3 Monitoring for Intervention

Data monitoring can be used for intervention or corrective actions. Monitored data and its reporting may

provide decision support and feedback for current operations. For example, a DP control system monitor

takes action to increase the speed or change the system thrust direction to optimize performance. A Power

Management System (PMS) control can reduce or increase power based on vessel demand.

In some cases, human intervention is required. The workflow for intervention is to be sensibly considered

and implemented within a system. For example, condition monitoring of equipment may indicate that a

failure is imminent, therefore requiring notification to maintenance personnel of the potential failure

modes and maintenance needs. Maintenance processes should be updated to incorporate this insight and

realize the benefits, which include more accurate troubleshooting and more efficient maintenance.

5 Monitoring by Regulatory Bodies

Data monitoring is often used by marine regulatory bodies, such as United States Coast Guard (USCG), or

the Bureau of Safety and Environmental Enforcement (BSEE). Critical data monitoring helps regulatory

bodies develop and enforce proper policies and requirements.

For example, BSEE has issued the final well control regulations. The regulations are BSEE, 30 CFR Part

250, Oil and Gas and Sulfur Operations in the Outer Continental Shelf-Blowout Preventer Systems and

Well Control. The final rule addresses the full range of systems and equipment related to well control

operations, with a focus on blowout preventer (BOP) requirements, well design, well control casing,

cementing, real-time monitoring, and subsea containment. Real-time data from well control equipment is

required to be transmitted to BSEE for monitoring.

7 Input to Control Systems

As described above, sensor data is used as inputs to control machines and equipment. An increasing

number of control system functions have been implemented onboard vessels and assets with some

examples listed below:

●

DP control

●

Propulsion remote control

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 19

●

Engine control

●

Power management system

●

Cargo control

As the industry moves towards autonomy and autonomous systems, data use becomes a vital part of

operations.

9 Input to Analysis and Patterning

For the marine and offshore industry, data analysis begins with the collection of data at the vessel level,

such as location, direction and speed, hull structure stresses encountered, vessel motions, and engine,

equipment, and environmental conditions. Then the data is transmitted securely by satellite to a response

center, which can offer basic services such as vessel tracking and structural integrity monitoring. This

process is still at the early adoption stages in the marine and offshore industries. It indicates that data

analysis will play a significant role the near future for improving the performance of individual systems or

vessels as a whole.

Significantly more value can be added by applying data analysis to the entire fleet or business unit, where

data monitoring objectives go beyond optimizing the performance of individual assets. It is at this level

that data from disparate, multidimensional sources may be analyzed to secure new macro-level insights.

Weather patterns and wider operating conditions, such as sea currents and temperatures, etc. could have an

effect on vessels operations, and data about those conditions may be gathered to provide insight on vessels

operations. Historical and transactional data trends can help identify risks and opportunities associated

with current data (e.g., gradually increasing vibrations of a certain frequency in a particular type of pump

may indicate imminent failure).

11 Input for Maintenance

As the demand for efficiency increases, maintenance plays a big role in improving asset operations. Data

can be used for maintenance to reduce unexpected or scheduled down time. Condition monitoring can

include both hull condition monitoring and equipment condition monitoring. Condition-monitoring tasks

are scheduled or continuous activities used to monitor machine condition and detect a potential failure in

advance so that action can be taken to prevent that failure. Condition Based Maintenance (CBM) is a

maintenance plan, which is based on the use of Condition Monitoring to trigger the relevant maintenance

task and corresponding part replacement or other corrective action. This process involves establishing a

baseline and operating parameters, then frequently monitoring the machine and comparing any changes in

operating conditions to the baseline. Maintenance tasks and overhauls are then carried out before the

machinery fails.

Further details regarding condition-based monitoring can be found in the following ABS publications:

●

ABS Guide for Hull Condition Monitoring Systems

●

ABS Guidance Notes on Equipment Condition Monitoring Techniques

Section 3 Data Uses 3

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 20

S E C T I O N 4

Data Importance

Most data collected and applied aboard marine and offshore vessels are important to vessel safety, security,

performance, and handling. Even so, data that support systems carrying out Integrity Level 2 (IL2) (details

provided in ISQM Guide and also for quick reference within Section 5, Table 2 below) and Integrity Level

3 (IL3) functions aboard a vessel are considered critical for protection of human life, the vessel, and

possibly the maritime environment. By contrast, systems and data supporting IL0 and IL1 functions are

important to onboard business and personnel comfort and convenience, but have minimal impact on safety

and security. This distinction leads to a need to determine the relative importance of data when making

decisions about applying limited resources to data integrity management. Data that supports essential

onboard functions deserve special integrity protections. This section provides a simple risk-based model

for decision making when applying resources to data integrity protection.

1 Data Integrity and Vessel Operations

While a number of functions aboard marine vessels operate independent of human intervention, others

require exceptional event monitoring and decision making by shipboard personnel and/or safety

instrumented systems (SIS). Sensors provide the data required for event monitoring and possible operator

intervention and resolution. The data-driven controls also provide the capability for operators to take

corrective action when failure or reduced-performance events occur. The data needed to guide actionable

knowledge for these corrective actions – especially when applied to IL2 or IL3 functions – merit

consideration as critical data within special integrity protection.

Additionally, most systems with control consoles and human-machine interface (HMI) situational

awareness dashboards support essential onboard functions. Simple examples are the navigation systems on

vessels and the consoles provided with driller’s chairs on drillships. Failure of these functions due to loss

of data integrity also represents a risk to vessel and crew safety. Therefore, these systems also merit

consideration for special data integrity protection.

Although the above concepts focus on exceptional event handling, all data that supports normal vessel

operation is important. The vessel’s data management system architect is responsible for defining and

documenting the risk hierarchy of managed data, and is to base data integrity protection decisions on that

hierarchy. The key concept is that software providers, asset owners, and asset operators are to base data

integrity protection decisions on a rigorous risk management process that is grounded in an assessment of

failure risks and consequences. The foundation of this risk management process is the realistic assignment

of integrity levels as provided in the ISQM Guide. More risk assessment guidelines can be found in the

following ABS publications,

●

ABS Guide for Surveys Using Risk-Based Inspection for the Offshore Industry

●

ABS Guide for Surveys Based on Machinery Reliability and Maintenance Techniques

●

ABS Guidance Notes on Risk Assessment Applications for the Marine and Offshore Industries

●

ABS Guidance Notes on Failure Mode and Effects Analysis (FMEA) for Classification

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 21

3 Data Integrity and Business Strategy Development

In the above section, data integrity is discussed in terms of operational performance and decisions –

decisions that support improved vessel and crew safety. Additionally, the same data is used in large part to

analyze patterns of vessel lifecycle characteristics that can be applied to strategic business decisions.

As discussed above, vessel data is used to improve design, vessel fleet maintenance and supplied services

decisions, staffing decisions, and supplier selection and supply chain management decisions. While these

decisions may not be accompanied by the immediacy of incident response actions, they can have equally

important long-term impact on the health and continuity of a marine enterprise. Data pulled from onboard

systems are used to both guide enterprise product and service development decisions, and drive

commitments to develop or implement emerging operational processes and technologies. Therefore, the

data used to build the knowledge needed to support these strategic decisions also merits consideration for

special data integrity protections.

5 Data Integrity and Integrated System Support

Marine systems are by nature highly integrated. As these systems become more functionally capable, they

also become more complex. These conditions combine to make the integrity of data transferred among

linked systems especially important. In standalone or discrete systems, a data integrity loss or timing

failure can cause a failure in that system. In highly integrated systems, similar issues can cause a cascading

failure that impacts numerous subsystems, some of which are likely to be linked to critical or essential

systems (e.g., IL2, IL3, and SIS subsystems). The data management system architect is responsible for

understanding the data integrity interdependencies and the risks to the major functions associated with an

integrity failure of data flows. Further, this understanding is to be made apparent in an asset’s functional

description documentation and the resulting data integrity protections.

7 Data Integrity and Compliance Reporting

Marine systems associated with condition or status monitoring for reporting to outside authorities should

also be considered as high-priority systems. Regulatory reporting may rely upon those systems monitoring

energy management, pollution emission control, oily discharge prevention, safety instrumented systems,

and others. Individual systems require security and measurable data integrity to represent their results,

monitoring or reports in ways that can be certified by the regulatory agency or compliance authority. These

systems may not have operational impacts on the safety, security, performance or handling of a ship or

offshore asset, but they may still be high integrity level systems due to their monitoring or reporting tasks.

Data verification also plays critical role in supporting owner compliance to regulations.

Section 4 Data Importance 4

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 22

S E C T I O N 5

Data Security

Data security is defined as protecting data from destructive forces and from the unwanted actions of

unauthorized users.

Data security risks can include unlawful control of device/machine, abusive insertion, update and deletion

of data, or negligent or inadvertent data losses that impact system functions.

Just as an organization would not leave a vessel unguarded, they must also protect their data from

unauthorized access. As hackers have gotten more sophisticated, so too have their traditional, data heavy

targets. As a result, hackers have been turning to targets such as those in the Marine and Offshore industry.

Even without hackers, uncontrolled data can easily be exposed. Confidential information is frequently

shared too broadly through internal reports distributed outside of their intended audience, emails forwarded

outside of an organization, or even in annual reports. Uncontrolled data is insecure data. For data security,

data is to be controlled while at rest, in motion (transit), and in use (processing).

This Section outlines the basic principles of how to identify and classify the data, and how the data may be

protected.

1 Data Types/Protocols

In these Guidance Notes, data types are defined according to the way data is transmitted during

communication. Serial Data, Bus Data and Streaming Data are the three types described in this document.

Section 5, Table 1 provides typical features of each data type.

TABLE 1

Data Types

Data Types Features

Serial Data

●

Point-to-Point

●

Physical Layer

Bus Data

●

Multi-point

●

Physical – Network – Physical Layer

Streaming Data

●

Sequence of messages continuously transmitted

●

Transport Layer

1.1

Serial Data

Serial Data refers to the data been transmitted in serial communication between point-to-point interfaces.

The data flow diagram between two nominal devices is shown in Section 5, Figure 1. Often, the receiving

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 23

end of one host is connected to sending end of the other and vice versa. Serial data is transmitted in the

physical layer and relatively easy to secure because the transmission medium is specified by standard, and

known by location.

FIGURE 1

Serial Data Illustration

Serial data transfer has the following advantages and benefits.

●

It requires only a limited number of wires to exchange data between devices, thereby simplifying

transmission path engineering. Signal strength can be augmented easily with repeaters and amplifiers.

●

Serial communications require low interface pin counts. Serial communications can be performed with

just one I/O pin, compared to eight or more for parallel communications. Many common embedded

system peripherals, such as analog-to-digital and digital-to-analog converters, LCDs, and temperature

sensors, support serial interfaces.

●

Serial buses can also provide inter-processor communication networks. This allows large tasks that

would normally require larger processors to be tackled with several inexpensive smaller processors.

Serial interfaces allow processors to communicate without the need for shared memory and

semaphores, and the problems they can create.

Perhaps the most successful serial data standard for native computer and telecommunications applications

is the RS-232. Similarly, the RS-485 and RS-422 are among the most successful standards for industrial

applications.

Typical marine implementations include RS232/485 serial data interfaces or fiber optic cables and hubs.

Each of the I/O modules is physically wired in a ring bus with unique IDs (detailed information available

in the ISQM Guide) to allow data transfer to/from each module. The wire protocol and messages utilized

are determined by the Original Equipment Manufacturer (OEM) of the control systems (automation,

control, and monitoring). There are multiple process protocols that exist which describe the messages

transmitted on the serial bus including MODBUS, CANbus, and PROFIBUS. A vessel’s serial bus thus

provides the data pathway between physical sensors and the hardware/software interfaces to enable

automated data collection.

Serial data is fairly easy to be secured since it transmits data in a physical layer (i.e. cables). There is

danger of electromagnetic interference (EMI) against serial data, but this risk can be reduced with cable

shielding, cable or interface armoring and grounding, or other physical solutions to reduce system noise.

1.3

Bus Data

Bus Data refers to the data transmitted among multi-point networks. Here multi-point networks can mean

bus, star, ring or mesh topology. An illustrated diagram of a multi-point ring network is shown in Section

5, Figure 2.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 24

FIGURE 2

Bus Data Illustration

Transmission Control Protocol (TCP)/Internet Protocol (IP) is the most common protocol set used on

modern bus transmission systems. Security measures and controls for these common systems may be

found in the Cybersecurity Guide.

1.5 Streaming Data

Streaming data is another type of data found in the marine and offshore industries. Streaming data refers to

a sequence of message-oriented data in-sequence transport used to transmit or receive information in a

real-time application among the networks. Three major types of streaming data are listed below:

●

Automatically-generated machine data streamed from connected devices. Such devices can be sensors

or Internet of Things (IoT)/Industrial Internet of Things (IIoT) devices. An example is streaming data

generated from a security network camera.

●

Human-generated data from social media, such as feeds originating from collaboration systems or

social media like Facebook and Twitter.

●

Automatically generated human data. For example, the streaming data generated due to actions while

performing online web browsing.

Conceptual streaming data is illustrated in Section 5, Figure 3 below.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 25

FIGURE 3

Streaming Data Illustration

In the marine and offshore industries, the most common streaming data is automatically generated machine

data. The major driving force for such data is the appearance of IoT/IIoT scenarios, such as real-time

remote management and monitoring. Some benefits of the streaming data include

●

Gain meaningful, time-sensitive insights into operational systems;

●

Perform real-time analytics for accelerated decision making; and

●

Achieve mission-critical reliability and scale with continuous system adjustments based on real-time/

near-real-time data reporting.

The IoT/IIoT connects bidirectional-communicating devices with one another in real time. With

computational systems becoming more ubiquitous as processors become cheaper and more capable, more

and more real-time data will be available among networked devices.

Streaming data has been designed for improved security. An example is a 4-way handshake to protect

against synchronized flooding attacks, and large “cookies” for association verification and authenticity.

Multi-homing and redundant paths increase resilience and reliability.

3 Data Classification (Protection Level)

Data Classification is the process of organizing data into categories for its most effective and efficient use.

Data Classification facilitates assignment of protection level based on its importance. As noted in Section

4, data has different criticality based on its supporting systems.

Once a data-classification scheme has been created, security requirements that specify appropriate

handling practices for each category and storage standards that define the data's lifecycle requirements are

to be defined.

In this document, data is classified in terms of criticality to the mission of the vessel. Four categories have

been defined as follows and shown in Section 5, Table 2. The data classification has immediate relevance

to Integrity Level (IL) (defined in the ISQM Guide and the Cybersecurity Guide). The relationship is also

represented in Section 5, Table 2:

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 26

●

Mission Critical: Data is critical to the vessel. For example, data in safety system/equipment for main

propulsion, power management data for the electric power generating system.

●

Mission Essential: Data that is essential to the vessel supporting IL2 functions systems. For example,

the vessel management system.

●

Non-Mission Essential: Data supporting IL1 functional systems is non-mission essential. Such data is

generally used for business essential purposes, including such examples as Enterprise Resource

Planning (ERP) data (orders, purchase orders, human resources data and employee payroll).

●

Non-Vessel: Data supporting IL0 functions systems is not for vessel operation. For example, personal

email and web data may be classified as IL0.

TABLE 2

Data Classification

Data Classification Integrity

Level (IL)*

Potential Consequences

Functional

Examples, not inclusive

Non-Vessel 0 Minor impact on operation. Might

affect supporting process system

but not main process system

Entertainment System, Administrative computer

systems, office network, Data Collection system

(non-Authority required)

Non-Mission

Essential

1 Might lead to maintenance

shutdown of non-critical system.

Main process continues to

operate.

Non-essential control of systems, BPCS, Non-

essential communication systems, Vessel

Management System. Enterprise Resource

Planning (ERP)

Mission Essential 2 Shutdown of main system,

excessive time for repair.

Drilling control system, BPCS, SIS systems

(minimum rating), PMS, essential systems, DP

control system, main engine control system,

safety systems, cargo control system, navigation

system, new or unproven essential technologies

minimum rating.

Mission Critical 3 Significant repair time or loss of

the marine or offshore asset.

Drilling Blowout Preventer control system, SIS

or safety control systems, boiler firing control

system, etc.

Note:

*Integrity Level for the control systems are defined in ISQM Guide. Please refer to ISQM Guide for the detailed procedures.

The four data classification relationships are shown in Section 5, Figure 4.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 27

FIGURE 4

Data Classification

●

Mission Critical data has the most criticality but the least quantity. Among all the data generated and

collected onboard, this data only occupies a very low percentage. This data is to receive the highest

protection to keep the data secure. The data protection method will be selected based on the data states

(explained in the following section).

●

Mission Essential data has the second highest level of criticality. These data are of a higher quantity

than Mission Critical data.

●

Non-Mission Essential data has the biggest quantity with fairly low criticality. These data are of the

highest quantity. Most of the data generated onboard are under this category.

●

Non-Vessel data has the lowest criticality and is trivial to the asset. The quantity of such data varies on

different assets.

As noted in the definitions in Section 1, three basic states of data characterize data: Data At-Rest (DAR),

Data In-Motion (DIM), and Data In-Use (DIU). Understanding the different data states can help to select

the methods of security measures and encryptions that appropriate for protecting the data. The three states

of data onboard a vessel are illustrated in Section 5, Figure 5.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 28

FIGURE 5

Three States of Data

5

Data At-Rest (DAR)

Data At-Rest refers to the data that resides in storage (a device or backup medium in any form) but

excludes any data frequently transferred in the network or residing in temporary memory. DAR is in an

inactive and stable state that is not currently being transmitted across a network or actively being read or

processed. It is not travelling within the system or network, and not being acted upon by any application or

the CPU.

Here are some examples of DAR:

●

Data in data shares or repositories

●

Data on endpoints (i.e., PC or laptop devices) that is not accessed or changed frequently

●

Archived data

●

File stored on hard drives or USB thumb drives

●

Files stored on backup tape and disks

●

Files stored off-site or on a storage area network (SAN)

7

Data In-Motion (DIM)

Data In-Motion (DIM) refers to the data currently in transit, traveling across a network or sitting in a

computer’s RAM ready to be read, updated, or processed. It is data in the process of moving through, or

crossing over networks from local to cloud storage or from a central server to a remote endpoint. In Marine

and Offshore operations, DIM includes the data traveling in vessel’s local communication paths, or

between vessel and vessel, or between vessel and shore (on shore, communicated between vendors, flags,

class etc.). The data moving could be through wire or wireless transmission.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 29

9 Data In-Use (DIU)

Data In-Use (DIU) refers to data that being processed by one or more applications. Such data is not under

storage status or during the transmission. DIU is in the process of being generated, updated, changed, or

deleted. It also includes data being viewed by users accessing it through various endpoints.

9.1 Authorized Access Only

The endpoints are the most vulnerable points for DIU since they are the place where users can access and

interact with the data. The data set can potentially have multiple users from multiple endpoints. Protecting

DIU starts from access control to the data.

First, the data is to be protected by authorized access only, which includes user authentication, identity

management, and profile permissions. This means only the individuals with the proper permission,

qualification and knowledge are able to access and manipulate the data.

Second, most employers have their employees sign legal agreements that they will not share data with

anyone that does not have permission to view it.

9.3 Penetration Protection

DIU is also to be protected from penetration by corruptive agents or incidents. Generally, the phrase

“penetration” describes an unauthorized or malicious intrusion into a computer system; however, an

unauthorized accidental intrusion is also a penetration that can have serious consequences. A successful

intrusion that is detected and characterized may reveal weaknesses in the system’s protective capabilities.

Intrusion characterization is also intended to reveal the actual and potentially corruptive nature of the

intrusion upon hardware, firmware, processing applications, networks, and data. For these reasons

penetration protection is to be implemented in the interest of protecting data integrity during data creation,

transport, processing, and storage.

Penetration testing is commonly used to attempt to penetrate a digital system environment in order to test

the capabilities of protective measures (system architecture, hardware, software, and procedures). A

penetration test is performed to determine sufficiency of protective measures. It is also performed to detect

and characterize weaknesses in protective measures. Based upon the outcomes of the test, protective

measures can be corrected and enhanced as necessary to prevent an attack or accidental data corruption

incident.

Routine penetration testing is recommended for systems that collect, process, store, and transport/transfer

protected data.

9.5 Handling Policies and Procedures

Detailed data handling policies and procedures are to be defined for secure management of protected data.

Data handling policies and procedures are provided in the Cybersecurity Guide, and are to minimally

include:

Documented data protection policies and procedures pertinent to each phase of the data management

lifecycle include:

i) Procedures documenting authorization process for accessing or handling protected data, including

read/write privileges, use locks, blocking devices, and strong login credentials;

ii) Procedures documenting process for updating or modifying protected data; and

iii) What type of operation can be run on the data

11 Security Measures and Controls

Security measures for DAR, DIM, and DIU are found in the Cybersecurity Guide.

Section 5 Data Security 5

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 30

S E C T I O N 6

Data Integrity

1 General

As more sophisticated automation systems become common in marine and offshore assets, growing

concerns regarding data integrity have been raised. The concerns cover various topics in data integrity,

such as basic concepts of data integrity in marine and offshore assets, how the data integrity is best

managed, and what are the measurement tools for data integrity. Traditional definitions and concepts may

not adequately support specialized data integrity applications in marine and offshore assets. This section

adopts a holistic view to define the data integrity concept, the systematic process of data integrity, and the

verification of data integrity.

1.1 Definition

As defined in ISO/IEC 27000 Information technology - Security techniques – Information security

management systems – Overview and vocabulary, Integrity means the “property of accuracy and

completeness”. Integrity can have a large number of meanings depending on the context. For example, it

can refer to accuracy, functionality, uncorrupted data, and absence of interference, restriction of access,

code structure, and calculation accuracy.

In these Guidance Notes, Data Integrity refers to the accuracy, consistency (validity), and completeness of

data over its lifecycle. Compromised data is almost no use to the marine and offshore asset, and could

cause a dangerous situation to human safety, safety of the vessel, and/or an environmental threat. For this

reason, maintaining data integrity is a core focus of marine and offshore asset cybersecurity. Maintaining

data integrity helps improve recoverability and searchability, traceability (to origin), and connectivity.

Data integrity may be compromised in various ways. Some representative failures that can affect data

integrity include:

●

Physical broken hardware devices (such as sensors or disk crash)

●

Human error, including unintentional actions and malicious intent

●

Transfer errors, including unintended alterations or change during the transfer process

●

Cyber threats, including viruses/malware, hacking

Data integrity is a fundamental component of information security. It can be used to describe a state, a

process or a function and is always used as a representation for data quality. The three descriptions are

listed as follows:

●

As a state: Data integrity defines a data set that is both valid and accurate and maintains fidelity.

●

As a process: Data integrity verifies that data has remained unchanged in transit from sending to

receiving.

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 31

●

As a function, related to security: Data integrity maintains information accuracy, is auditable, and

supports reliability.

1.3 Data Integrity and Data Security

Data security basic principles and criteria have been described in Section 5 of this document. Data integrity

and data security are closely related terms, and they both play important complementary roles.

Data integrity is the desired result of data security, mostly achieved by the act of data protection (securing

data). Efforts for data integrity focus on validity, accuracy, and completeness of data. Work in data security

focuses on the act of protecting data. Whether unintended modification or malicious intent, data security is

a critical part of maintaining data integrity.

For modern marine and offshore operations, data integrity plays an essential role in the accuracy and

efficiency of a vessel’s normal operation as well as business process.

As described in Section 4, the integrity level of data is to match the integrity level of the function it

supports.

Data integrity can be implemented in a variety of ways. The data is to remain unchanged while it is being

handled, transferred or replicated. These Guidance Notes will describe data integrity from the following

three areas:

●

Confirm data integrity from traceable and trustworthy data source

●

Protect data integrity from unintended and malicious modification

●

Monitor, verify, validate and measure data integrity

3 Maintain Data Integrity from Traceable/Trustworthy Data Source

3.1 Origin: Supplier and Sensor Accuracy

3.1.1 Pedigree Verification

In this context, the word “pedigree” describes the status of data origin. The definition provided by

the Oxford Dictionary for pedigree is “The record of descent of an animal, showing it to be

purebred”. The same meaning applied to origin of data source is that data has the record to

demonstrate it was born pure and accurate, plus it has the clear trace back to its root. The pedigree

of the data source is to be verified to maintain the data traceability. The supplier is to deliver a

system having an approved and accepted level of integrity which means the sources have been

selected appropriately and certified.

3.1.2 Chain of Custody Verification

The term Chain of Custody (CoC) has been commonly used in legal contexts which refers to the

chronological documentation or paper trail, showing the seizure, custody, control, transfer,

analysis, and disposition of physical or electronic evidence. We are adopting this term in data

integrity to explicitly demonstrate the properly documented CoC is an essential element of data

integrity. Correctly performed custody procedures allow that data to be validated.

Data generation, management, transmission, storage and processing must all trace through logs to

show a clear CoC. An example of the necessity for data tracking is ballast water treatment system

data. Due to the new regulatory requirements, ballast water data is required to be collected

periodically and reported to the regulatory agencies. Accuracy of reported data is crucial to

maintain correct reporting.

Data-generating systems must present data with a traceable pedigree and CoC traceability to

support both versioning and auditable record trail:

Section 6 Data Integrity 6

ABS GUIDANCE NOTES ON DATA INTEGRITY FOR MARINE AND OFFSHORE OPERATIONS • 2016 32

●

Versioning is to be an automated procedure to check data in and out to maintain the latest

version of the data.

●

Record trail is to be generated by the system instead of by users. System generated date and

time stamps and other related information such as location can be included in the record trail.

It will provide the log for both internal and external use.

3.1.3 Sensor Verification & Validation

As described in Section 2, the most common data source is from onboard reporting sensors.

Massive quantities of data may be generated and collected from hundreds, and perhaps thousands

of sensors installed on the vessel.

There are two potential reasons for non-trustworthy or erroneous sensor data: Unintentional errors

and intentional misbehavior.

●

Unintentional errors may be caused by hardware malfunctions (broken or obstructed sensors),

poor positioning of the node (unconnected or incorrectly attached node) or depleted batteries.

Loss of sensor may also include loss of a monitoring or aggregator system, excessive

electronic noise on the line, or transmission line breaks.

●

Intentional misbehavior may be caused by crew actions or external attackers, exploiting

security vulnerabilities for unexpected purposes. Standalone sensors and reporting nodes may

be at risk, given IoT or IIoT devices will be network-addressable, generally isolated in

unobtrusive areas, and infrequently updated. Most IoT or IIoT devices are expected to be

sealed appliances that will serve a purpose and be replaced before they will be maintained or

upgraded.

The best practices to resolve the above two issues include:

●

Testing of the sensor software/hardware to meet hardening standards applicable to the

industrial (marine or offshore) environment;

●